Heat sink

Heat sinks play a vital role in various electronics and high-performance technological devices. Different electronic components & mechanism generates heats heat that can damage the device if not appropriately dissipated. A heat sink is designed to draw heat away from the device and dissipate it into the surrounding environment, usually using a combination of conduction, convection, and radiation.

Electronics & machinery would be more prone to overheating, and failure without heat sinks, resulting in lower performance, a limited life span, and higher maintenance expenses. This article will discuss the heat sink design process in depth, including design considerations, material selection, working principle, and performance metrics.

How to Design a Heat Sink?

The effectiveness of a heat sink design depends on its ability to conduct heat away from the component, so you should grasp the fundamentals of heat flow before proceeding with the design.

Understanding heat transfer

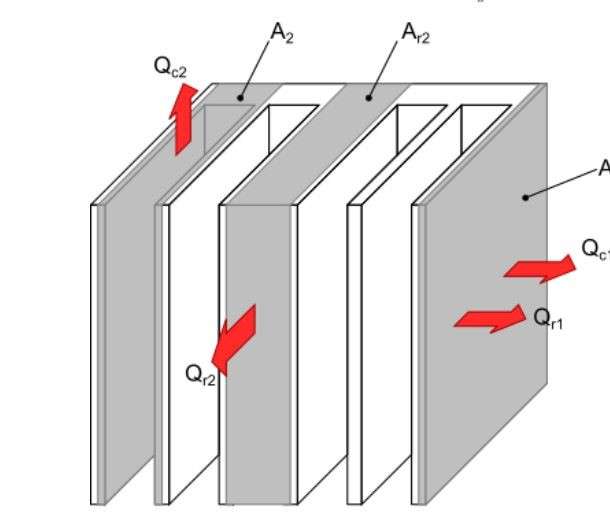

Heat can be transferred in three ways: conduction, convection, and radiation.

Conduction is transferring heat through a substance from a higher to a lower temperature zone. When an electronic component creates heat, it is drawn away from the component via a solid substance, such as a metal heat sink. The heat transmission rate via conduction is determined by the material’s thermal conductivity, which measures how easily heat flows through the material.

The transfer of heat through a fluid or gas is known as convection. When air flows over a heat sink, convection carries heat away from the heat sink to the atmosphere. The rate of convection depends on fluid velocity, temperature difference, and surface area.

Radiation transmits heat through electromagnetic waves, such as infrared radiation. The principle behind radiation is straightforward when an object is hotter than its surroundings and radiates heat energy through electromagnetic waves. Cooler things, including heat sinks, can absorb this heat energy.

Choosing the right material for heat sink design

Choosing the right material for heat sink design is crucial because it affects the heat transfer efficiency, weight, and cost of the heat sink. You should consider thermal conductivity, specific heat capacity, density, and other properties according to the needs and specifications of the intended application.

The following are the common heat sink materials;

| Aluminum | Aluminum is a popular heat sink material because of its low cost, high thermal conductivity, and lightweight characteristics. |

| Copper | Copper offers excellent thermal conductivity, making it an ideal material for high-performance heat sinks. |

| Graphite | Graphite is known for its lightweight and thermal conductivity. It could be an ideal material where weight is an issue. |

| Ceramics | Ceramics are suitable for high-temperature applications as they can withstand high temperatures without losing properties. |

There are several other considerations (based on the intended application) to take while choosing a material for a heat sink, such as required size & weight, cost, manufacturing process, and operating condition.

Calculating the required heat sink size and fin design

Sizing of the heat sink

The size and fin design of your heat sink heavily depends on the heat generated by the device, available space, and airflow around the component.

Several formulas and software programs are available to calculate the heat sink’s required size and fin design. Factors to consider include the heat sink’s thermal resistance, the fins’ surface area, and the airflow velocity and direction.

Related resource: Heat Sink Size Calculator

Design considerations for heat sink manufacturing

To minimize material waste and enhance efficiency, the heat sink design should be optimized for manufacturing. You can ensure that by considering material thickness, machining tolerances, and the number and size of fins to ensure that the heat sink can be produced efficiently and cost-effectively.

Here are some of the key heat sink design considerations to ensure that it can be manufactured efficiently and effectively.

- Material for the heat sink: The material you choose for your heat sink will affect its thermal conductivity, corrosion resistance, and ease of manufacture.

- Fin configuration: The shape and placement of your heat sink’s fins will influence its thermal performance. The surface area available for heat dissipation can be affected by different fin shapes, such as straight fins or pin fins.

- Fin size & shape: The size and form of the fins influence the heat transfer capability and overall dimension. For example, too big or too small fins may not dissipate heat compared to the correct size and form.

- Surface finish: Consider the manufacturing method and desired surface finish early in the design process. So you can optimize the efficient heat transfer and corrosion resistance.

- Attachment mechanism: Design the attachment mechanism to reduce thermal resistance while making assembly easier.

- Tolerances: It is essential to balance the need for precise dimensions with the practical considerations of the manufacturing process.

Cases of Heat Sink Design

To understand the heat sink design concept in-depth, let’s discuss two cases in different applications.

Case I: Aluminum Heat Sink Design for Power Electronics

Designing an aluminum heat sink for power electronics starts with calculating the heat generated by the electronic components. The calculation provides the information to determine the size & shape of the designed aluminum heat sink needed to dissipate the heat effectively.

In addition, the size and shape offer enough surface area for heat dissipation while fitting within the power electronics’ physical limits.

Finally, determine how the heat sink will be attached to the device. Through-hole mounting and surface mounting are the most frequent attachment methods.

- Through-hole mounting entails drilling holes in the heat sink and device and attaching them with screws or bolts.

- Surface mounting entails attaching the heat sink to the device’s surface with a thermal adhesive or clip.

Case II: Custom heat sink design for high-performance applications

In high-performance applications, such as advanced computing systems, speed vehicles, or aerospace equipment, custom heat sink designs need to address the unique thermal requirements of the device. Therefore, custom heat sink designs can be complicated, demanding advanced engineering techniques and software applications.

The first step involves understanding thermal requirements, such as the heat generated by the high-performance device, the required operating temperature range, and the size & shape of the heat sink.

After determining the thermal requirements, a heat sink design can be designed utilizing advanced software tools such as finite element analysis (FEA) software. FEA software allows engineers to simulate the heat transfer and thermal performance of aluminum heat sink design and optimize it for the device’s needs. Overall, the best part of the custom heat sink design is that it can address the unique heating problems of electronics and machinery.

Good and bad heat sink design examples

A good heat sink design effectively drains heat from electronic components, ensuring the device’s function is reliable and efficient. Let’s discuss the characteristics of good and bad heat sink design examples.

A good heat sink design should have the following elements:

- Enough surface area for heat dissipation

- Appropriate fin design for a specific application

- Excellent thermal contact with electrical components

- Effective device attachment method

- Appropriate material use, such as aluminum or copper

A bad heat sink design fails to adequately dissipate heat, resulting in device failure or lower performance, which may include the following characteristics:

- Inadequate heat dissipation surface area

- Incorrect fin design for the application

- Limited thermal contact with electrical components

- Use of low thermal conductivity materials, such as plastic or wood.

How Heat Sinks Work

Heat sinks improve convective cooling and offer a large surface area for heat transmission. Three forms of heat transfer occur throughout the heat sink mechanism.

- Conduction heat transfer occurs, and heat flows from electronic components to the attached heat sink because of temperature difference.

- Fans or other attachments on the device increase the heat transfer rate (from the heat sink to the surrounding) via natural or forced convection. Often, heat sink designs for power electronics use a fan or additional cooling system for forced convection.

- Heat is also transferred to the environment in the form of electromagnetic waves.

Heat sink operation principles

The operation of a heat sink can be explained using heat transfer principles, and these principles are the basics to start a heat sink design project. It states, “When there is a temperature difference between two things, heat transfer occurs when energy moves from the object with the higher temperature to the object with the lower temperature.”

The heat flows from electronic components to the heat sink because of the temperature difference between heated components and heat sink material. Then, the heat sink transfers the heat to the surroundings, fans, or another mechanism is often used to pace the heat transfer from the heat sink to the components.

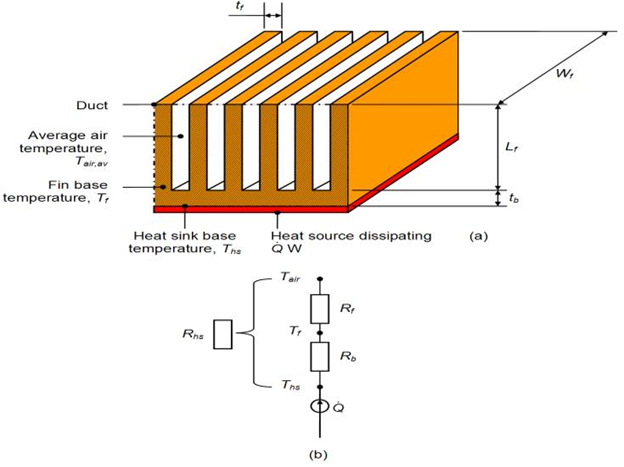

Understanding Thermal Resistance and Thermal Conductivity

Thermal resistance diagram

Thermal resistance refers to a material’s ability to resist heat flow. Heat transformation through a material becomes more difficult as thermal resistance increases. In contrast, thermal conductivity measures the material’s ability to conduct heat. That means the greater the thermal conductivity, the better heat flow through the material.

It is critical in heat sink design to select materials with high thermal conductivity and low thermal resistance. This allows heat to quickly travel from the electronic component to the heat sink and from the heat sink to the surrounding air.

Heat sink performance metrics

Performance metrics are essential to maximize heat dissipation and minimize the temperature increase in the electronic component. In heat sink design, three primary metrics are used: thermal resistance, impedance, and capacity metrics.

- Thermal resistance metrics: Thermal resistance measures the material’s ability to transfer heat through it. It is typically measured in degrees Celsius per watt (°C/W) and indicates how much the temperature of the heat sink will increase for every watt of power dissipated.

- Thermal impedance metrics: Thermal impedance refers to a measure of the heat flow resistance between two objects. This metric is essential in heat sink design since it determines how much the temperature of the electronic component will rise for every watt of power dissipated.

- Thermal capacity metric: The designer can calculate how much heat a heat sink can absorb before reaching a specific temperature. It is commonly expressed in joules per degree Celsius (J/°C) and reflects how much energy the heat sink can store before becoming saturated.

Overall, the performance metrics are crucial for heat sink design. They help designers select the most suitable heat sink for a specific application, optimize its performance, and ensure electronic devices’ reliable and optimal performance.

How to Make a Heat Sink?

Heat sink from CNC machining

Heat sink designs can be converted into physical forms with various manufacturing techniques, such as CNC machining, Wire cut EDM, stamping, heat sink extrusion, and casting. Using the right manufacturing approach depends on the required accuracy, heat sink material, design complexity, and many more factors.

Let’s discuss some of the heat sink manufacturing approaches in brief.

CNC machining is the finest way to create heat sinks with complex designs. The designers get a great deal of flexibility with this approach. An entire metal block can be used to create the sink where the required fins are cut with the CNC machines and bent from the base of the block. However, cnc heatsink could be expensive and time-consuming.

Wire-cut EDM is another method to manufacture heat sinks. The first step in wire cutting is to create a 2D drawing of the heat sink design. Next, mount the workpiece on a wire cut machine, and it cuts the heat sink into the desired shape and size through digital instructions.

Heat sink manufacturing with extrusion involves pressing billets of malleable material into a high-strength steel die to form plate fins. They are utilized in most cooling applications, including aluminum heat sinks. Of course, aluminum is the most commonly used material in manufacturing heat sinks.

Surface finishing for heat sinks.

Surface quality has a substantial impact on heat sink performance. A heat sink’s surface has to be smooth and free of flaws or roughness, as these can limit heat transfer. A rough surface can create air pockets and restrict the contact area between the heat sink and the component, resulting in poor heat transfer and higher temperatures.

Therefore, it is critical to apply the correct surface finishing to prevent corrosion and optimize the surface quality of the heat sink. You can consider the following common surface finishing practices for heat sinks during heat sink designing.

However, the surface finishing option for a particular heat sink depends on the material type, operating conditions, complexity of the heat sink, and other considerations.

Related to: Anodized Aluminum Heatsinks: Cooling Solutions for Modern Electronics

Conclusion

Proper heat sink design is crucial for maintaining the safe operating temperature of electronic components, increasing their lifespan and reliability, and ensuring optimal performance. Only a well-designed heat sink can efficiently dissipate the heat generated by the element, providing sufficient surface area.

Therefore, heat sink design requires consideration of material choice and intended application. This helps control the component’s temperature, preventing thermal runaway and potential system failure. Additionally, a properly designed heat sink reduces the size and weight of devices while maintaining efficient heat dissipation.

ProleanTech offers manufacturing services for your heat sink design with CNC machining, extrusion, and wire EDM. Our experienced engineers and advanced manufacturing setup will provide the best heat sink manufacturing service with a design consultation. So, please send us your heat sink design for a quote to start the project.

FAQ

What are some common mistakes to avoid in heat sink design?

Some common mistakes to avoid in heat sink design includes insufficient size, use of poorly conductive material, impractical attachment system, airflow blocking, and insufficient surface area.

Can different materials be used for heat sink design?

YES, various materials can be used in heat sink design, but the choice depends on the individual application requirements. For example, aluminum and copper are used in heat sinks for high-performance electronics.

How do I choose the right heat sink for my application?

Choosing the right heat sink for your application can be influenced by several factors, such as the amount of heat generation, the available space, and the required airflow.

Can heat sinks be used in combination with other cooling technologies?

Absolutely, heat sinks can be combined with other cooling technologies to increase heat transfer rate and efficiency. Examples of cooling systems combined with heat sinks are fans, liquid cooling, and thermoelectric cooling.

What is the difference between natural convection and forced convection heat sinks?

Natural convection heat sinks rely on the natural movement of air to transfer heat away from the heat source. In contrast, forced convection heat sinks use an external source of airflow, such as a fan, to increase the heat transfer rate.

Such a nicely composed article on heat sink design process! Loved it

Thanks Zoe!