CAPABILITIES

Waterjet Cutting

High-precision CNC waterjet cutting service cut through sheet metals without leaving burn marks

- ISO-2768-c

- Lead time as fast as one day

- Aluminium, Steel, Stainless Steel and more

All uploads are secure and confidential.

Why Choose Our CNC Waterjet Cutting Service

Are you working on projects that need cuts without any thermal damage? Then, the water-jet cutting process is fully capable of fulfilling your requirement. Abrasive media, Water-jet Pressure, and many parameters need to maintain according to material and required specification, so it is a bit of a complicated process. But we make it easy for you. We are committed to ensuring that our customers are satisfied. Our water jet cutting machines, with CNC guidance and Experienced engineers, are ready to meet your needs.

| Precision | Waterjet cutting offers high levels of accuracy and precision, producing parts with consistent dimensions and tolerance. |

| Versatility | Waterjet cutting can be used to cut a wide range of materials, including metals, plastics, composites, and ceramics. |

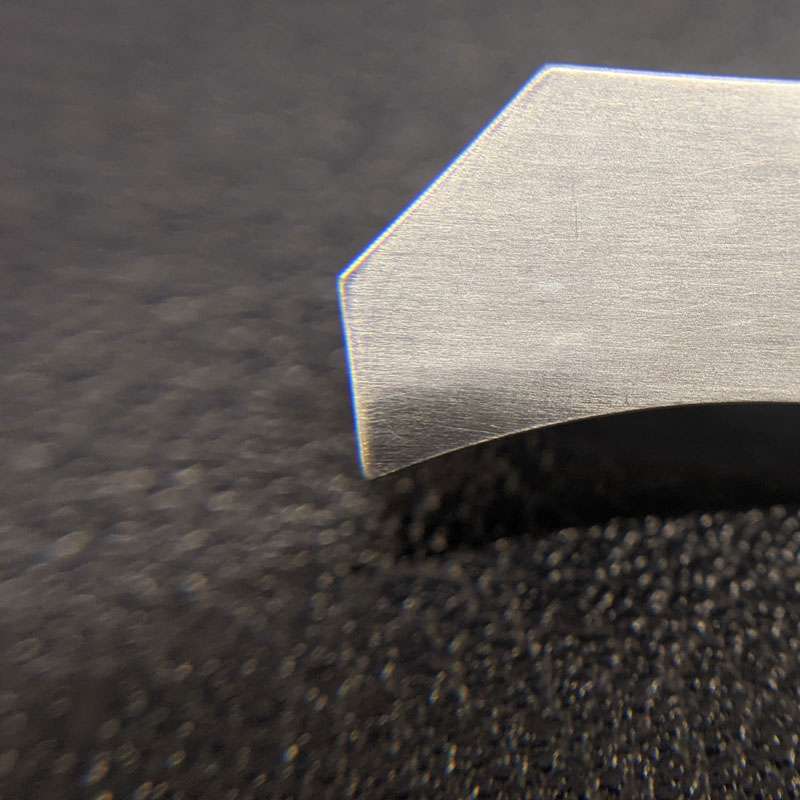

| No Heat-Affected Zone | Waterjet cutting does not generate heat, meaning that there is no heat-affected zone or warping, making it ideal for sensitive materials. |

| No Mechanical Stresses: | Waterjet cutting does not apply mechanical stress to the material, making it ideal for delicate or brittle materials. |

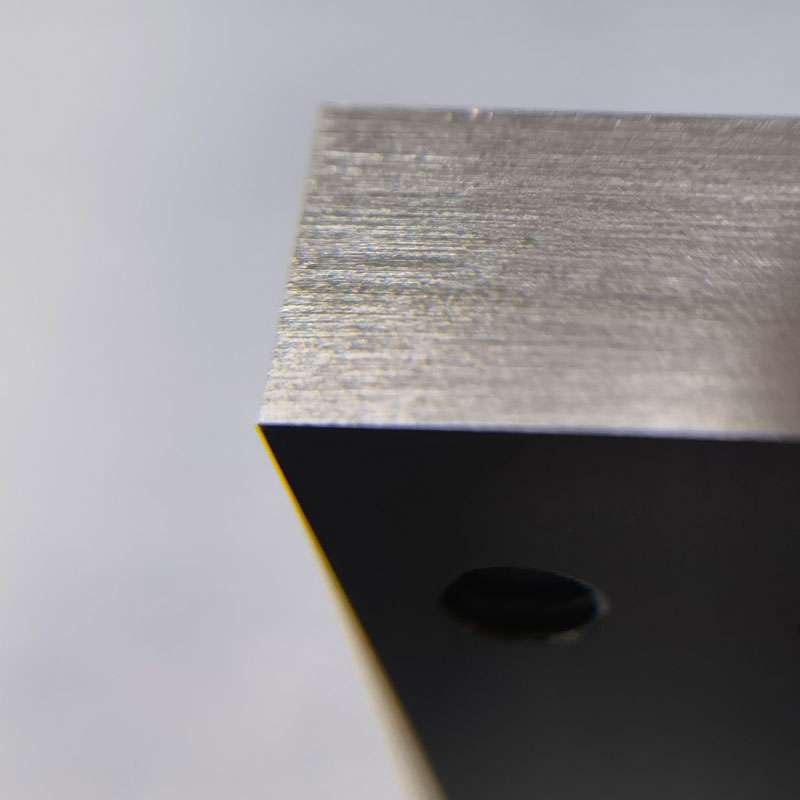

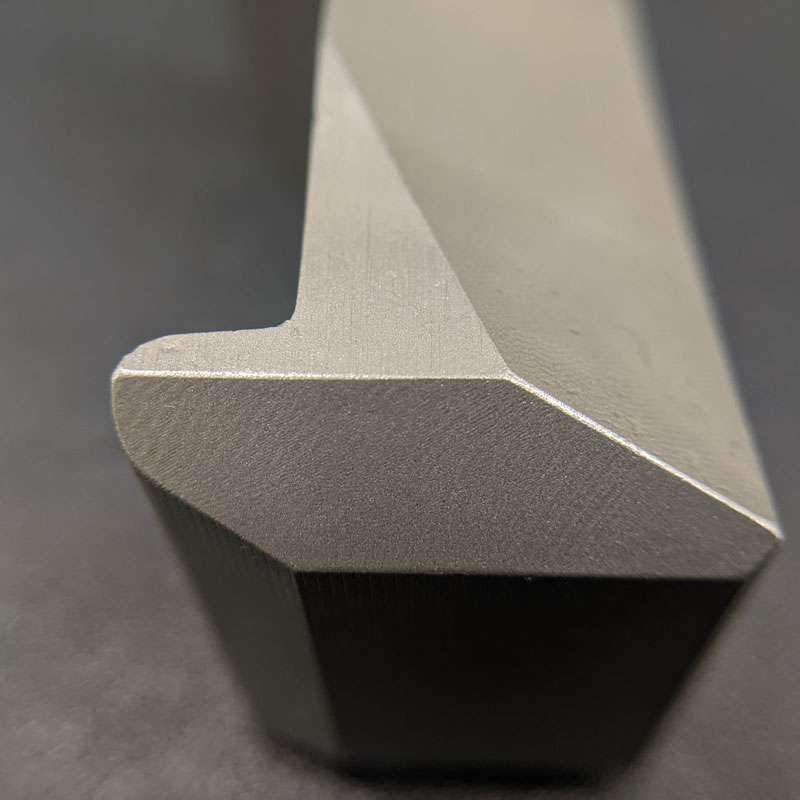

| High-Quality Surface Finish | Waterjet cutting produces a high-quality surface finish, reducing the need for secondary operations and improving overall part quality. |

| Efficient Production | Waterjet cutting is a fast and efficient process, reducing lead time and increasing productivity. |

| Experienced Team | Our team is highly experienced in waterjet cutting, ensuring that your parts will be produced to the highest standards. |

Materials for Waterjet Cutting

Aluminum Water-jet Cutting

Aluminum is a superior metal in terms of strength-to-weight ratio. It offers High Machinability, ductility, and thermal & electrical conductivity. Parts with aluminum also become highly resistant to corrosion.

Subtypes: 5052, 5083, 6061, 6082

Brass

Golden shiny color, low friction, excellent Machinability, and high electrical & thermal conductivity. Brass can be easily machined and the best choice for low-friction applications.

Subtypes: C360, H59, H62

Copper Water-Jet Cutting

It offers good strength, hardness, and excellent corrosion resistance with superior heat and thermal conductivity. It also has a very appealing aesthetic.

Subtypes: 101, C110

Steel Water-Jet Cutting

High mechanical strength, toughness, resistance to wear and fatigue, and sturdiness. In addition to carbon, other alloying elements can be added depending on the needed mechanical and physical qualities.

Subtypes: 1018, SPCC

Stainless Steel Waterjet Cutting

High mechanical strength, Thermal, Wear, and Corrosion resistance. Stainless steel is low-cost and can be machined easily. Parts made from Stainless steel are durable and do not lose that strength over time.

Subtypes: 301, 304, 316

Finishing Options For Waterjet Cutting

We provide various surface finish options for your sheet metal project. If your required surface treatment is not listed below, feel free to contact us for more options.

As the machined or deburring

The machined or deburring finish is the standard finish where unwanted attach chips are removed with deburring tools, and sharp edges are chamfered to smooth the surface (3.2 μm).

Bead Blasted

Bead blasting produces a matte texture, removing all the marks of machining tools. It applies to ABS, Aluminum, Brass, Stainless Steel, and Steel parts.

Anodizing

Anodizing involves adding an aluminum oxide coating to aluminum and its alloys. The layers, which come in various colors, increase strength and shield the surface from corrosion.

Powder coating

Powder coating is the electrostatically applying of dry powder to the surface. It produces a thin layer providing excellent resistance to wear, corrosion, and abrasion.

Polishing

Physical rubbing of a metal surface to create a shiny surface is called a polishing surface finish. It increases the reflectivity and does not affect the dimensional stability of parts.

Brushing

Brushing is achieved by applying an abrasive brush to the metal surface, which produces a unidirectional satin finish. And it is not recommended for highly corrosive materials.

Smooth machining

Smooth machining is done by controlling the machining process, such as feed rate & cutting speed. It minimizes the tool marks and risk of corrosion.

Black-Oxide

Black oxide finish reduces surface reflectivity and offers mild corrosion protection. It involves adding a thin layer of magnetite to the surface.

Fine machining

The higher-precision machines produce delicate machining surfaces by utilizing sharper tools and regulating feed rate and cutting speed. Surface roughness up to Ra 0.8 μm can be maintained with smooth machining.

More

Provides a random, non-linear texture with a shiny, high gloss finish. However, it might be unable to create sharp corners and pockets

Waterjet Cutting Capability & Tolerances

Dimension detail | Tolerance(+/-) |

| Thickness | 5mm-20mm |

| Part size limit | 6000mm*4000mm |

Water cutting is usually used when precision tolerances are not required

3 Ways to Ensure Perfection

Standards

Metals: ISO-2768 fH (fine)

Plastics: ISO-2768 mK (medium)

Metric threads tolerances: ISO 965-1 standard UN Threads Tolerances: ASME B1.1-2003 standard

Knurling: ISO13444:2012 standard.

Our factory is ISO 9001:2015 certificated

Inspection and Protection

Constant visual inspection conditions

Quantification of cosmetic surface quality

Process requirements

Part cleaning and Protection

Quality Inspection Report

Inspection Confirmation

Dimensional confirmation

Appearance confirmation

Quality documentation

Technology Overview

Introduction

Are you working on projects that need precise cuts without any thermal damage? Then, the water-jet cutting process is fully capable of fulfilling your requirement.

Abrasive media, Water-jet Pressure, and many parameters need to maintain according to material and required specification, so It is a bit of a complicated process. But Prolean makes it easy for you. We are committed to ensuring that our customers are satisfied. Our water jet cutting machines, with CNC guidance and Experienced engineers, are ready to meet your needs.

What is the Water-jet Cutting?

Water-jet cutting is the process of narrow line cutting to raw material using a high-pressure water jet. The water jet erodes the specific position to separate the workpiece into two parts. It is a straightforward cold-cutting process, and the cutting temperature only dwells between 40 to 60 0 C.It is based on the principle of water erosion. When a high-velocity jet of Water strikes the surface, material removal occurs.

A pure water jet is applicable for the softer materials, but to cut the more rigid materials, some abrasive particles are mixed with the Water for machining. The function of abrasive particles is to enhance the cutting ability of the water jet.

Advantages

- The water-jet cutting is capable of producing complex & Intricate cuts in material. In addition, It has greater precision in the machining.

- The machining area is kept completely clean and free of burrs and dust during this operation. Furthermore, it offers exceptional edge quality.

- Because it is the cold-cutting process, the thermal damage to the workpiece is negligible.

- It gives flexibility in cutting position as any location can be targeted with the jet.

- There is no need to change tools, so it operates highly efficiently.

Types of Water-jet Cutting

Pure Water and abrasive water jet cutting are the two forms of water jet cutting. The main distinction between them is whether or not the abrasive particles mixed with the Water. Abrasive water jet cutting is capable of cutting hard materials that cannot be eroded by Water alone. In contrast, pure water jet cutting is used to cut softer materials, including paper, fabric, rubber, foam, and felt. Another distinction is that a pure water jet cutter lacks a mixing chamber.

Diamond, ruby, lead beads, garnet, or sands are used as abrasive materials, mixed with Water in the mixing chamber, and a high-pressure jet targets the cutting location. The abrasive particles eat away & erode the material to complete the cutting.

Applications

Since the Water-jet is a precise, effective, and environmentally friendly approach to cutting both soft & hard materials, several industries use this technology.

- Manufacturing

- Automotive

- Aerospace

- Food

- Agriculture

- Electrical & Electronics

- Hardware

- Jewelry

Contact ProLean with your specifications if you work in one of the sectors mentioned above and require water jet cutting to receive a free quote within 24 hours.

Water-jet Cutting FAQ

What are the Material Options for Water-jet cutting at Prolean?

What is the range of tolerance I can achieve with Water-jet cutting?

How much thickness can be cut with a water jet?

What benefits do water-jet cuts have over laser cuts?

How may water-jet cutting be customized to meet unique requirements?

What is the working pressure of water jet cutting?

Related Blog

Punching vs Laser Cutting: Which One is Right?

Punching suits high-volume, laser cutting delivers high precision

What You Should Know About HVAC Sheet Metal Fabrication

Get the insights on HVAC sheet metal fabrication

MIG VS TIG Welding: A Comprehensive Technical Comparison

Key differences between MIG and TIG welding

Get Your Parts Made Today

All uploads are secure and confidential.