CAPABILITIES

Welding Service

If you need to create a joint on the Metal & alloy pieces for your project, the Welding process is the right choice!

- ISO-2768-c

- Lead time as fast as one day

- Aluminium, Steel, Stainless Steel and more

All uploads are secure and confidential.

Why Choose Our Welding Service

If you need to create a joint on the Metal & alloy pieces for your project, the Welding process is the right choice!Selecting the appropriate welding technique for your project can be difficult because it relies on the type of material, joint strength, end-product specifications, and many other factors. However, we will make it easy for you. Our experienced engineers will choose the best approach for your project.

Try Prolean Now!

Materials for welding

Aluminum Welding

Aluminum is a superior metal in terms of strength-to-weight ratio. It offers High Machinability, ductility, and thermal & electrical conductivity. Parts with aluminum also become highly resistant to corrosion.

Subtypes: 5052, 5083, 6061, 6082

Brass Welding

Golden shiny color, low friction, excellent Machinability, and high electrical & thermal conductivity. Brass can be easily machined and the best choice for low-friction applications.

Subtypes: C360, H59, H62

Copper Welding

It offers good strength, hardness, and excellent corrosion resistance with superior heat and thermal conductivity. It also has a very appealing aesthetic.

Subtypes: 101, C110

Steel Welding

High mechanical strength, toughness, resistance to wear and fatigue, and sturdiness. In addition to carbon, other alloying elements can be added depending on the needed mechanical and physical qualities.

Subtypes: 1018, SPCC

Stainless Steel Welding

High mechanical strength, Thermal, Wear, and Corrosion resistance. Stainless steel is low-cost and can be machined easily. Parts made from Stainless steel are durable and do not lose that strength over time.

Subtypes: 301, 304, 316

Finishing Options For Welding Part

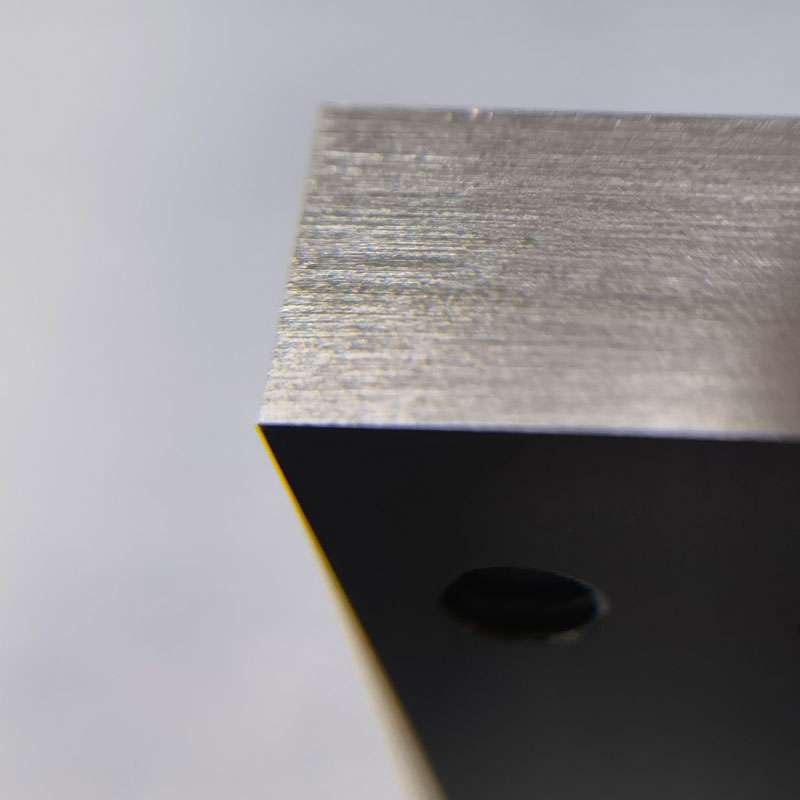

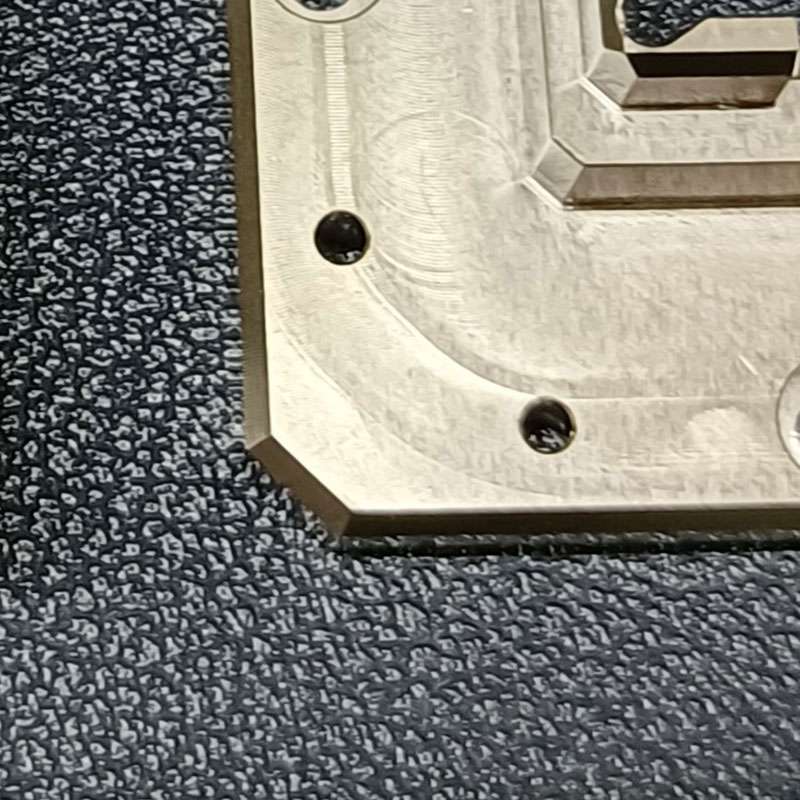

As the machined or deburring

The machined or deburring finish is the standard finish where unwanted attach chips are removed with deburring tools, and sharp edges are chamfered to smooth the surface (3.2 μm).

Bead Blasted

Bead blasting produces a matte texture, removing all the marks of machining tools. It applies to ABS, Aluminum, Brass, Stainless Steel, and Steel parts.

Anodizing

Anodizing involves adding an aluminum oxide coating to aluminum and its alloys. The layers, which come in various colors, increase strength and shield the surface from corrosion.

Powder coating

Powder coating is the electrostatically applying of dry powder to the surface. It produces a thin layer providing excellent resistance to wear, corrosion, and abrasion.

Polishing

Physical rubbing of a metal surface to create a shiny surface is called a polishing surface finish. It increases the reflectivity and does not affect the dimensional stability of parts.

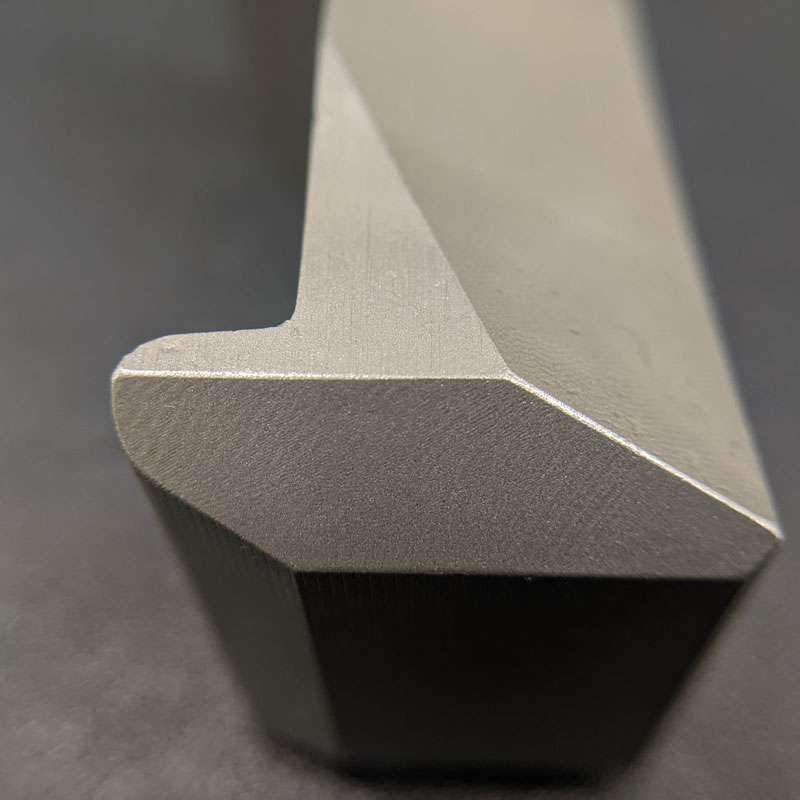

Brushing

Brushing is achieved by applying an abrasive brush to the metal surface, which produces a unidirectional satin finish. And it is not recommended for highly corrosive materials.

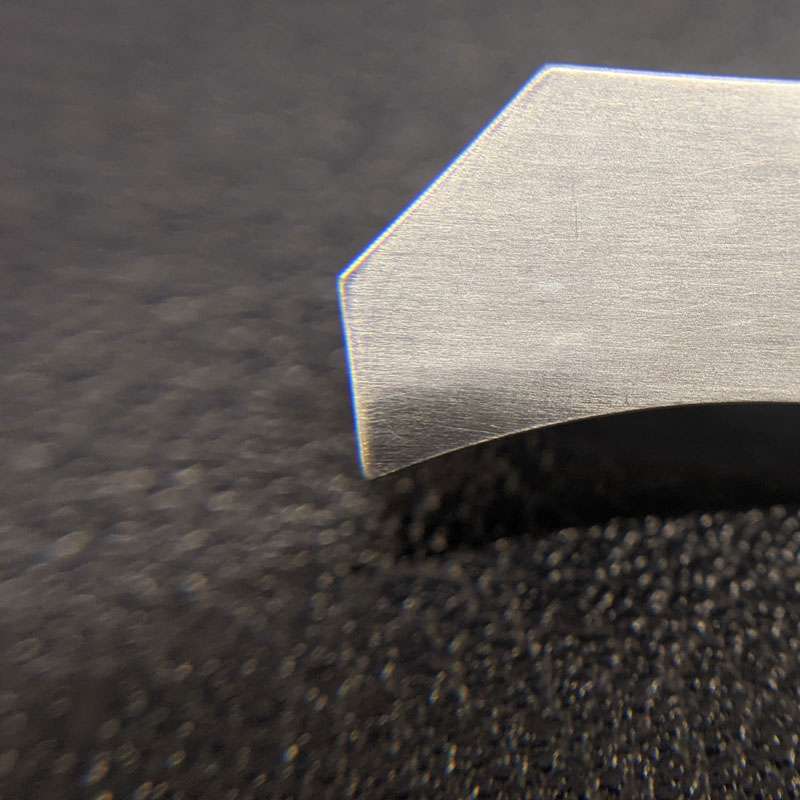

Smooth machining

Smooth machining is done by controlling the machining process, such as feed rate & cutting speed. It minimizes the tool marks and risk of corrosion.

Black-Oxide

Black oxide finish reduces surface reflectivity and offers mild corrosion protection. It involves adding a thin layer of magnetite to the surface.

Electro-less Nickel Plating

A thin layer of Nickel is created on the surface from a nickel-containing solution without electrolysis. Electro-less nickel plating provides a shiny appearance, excellent hardness, abrasive, wear, and corrosion-resistance to the substrate material.

Alodine

Provides excellent corrosion resistance property to the aluminum parts with greenish-gold color. It is the low-cost and quick surface finishing approach.

Electroplating

Electroplating increases the hardness of the steel &aluminum parts. It offers excellent corrosion, wears, and abrasion resistance.

Nickel plating

Make the parts super resistive to corrosion. It enhances mechanical strength, hardness, wear resistance, lubricity, and ductility. Nickel plating is applicable in different materials, including Steel, aluminum, copper, and brass.

Passivation

Enhance the appearance and functionality of the parts. After Passivation, parts of Steel and its alloys become super resistive from corrosion.

Yellow Chromate conversion coating

A shiny appearance with goldish color provides excellent corrosion resistance. It is applied on the surface of aluminum, magnesium, and their alloys. A layer of chromate also enhances the conductivity of parts

PTFE (Teflon) Coating

The Teflon layer on the parts offers excellent corrosion resistance, water resistance, and non-stickiness with a non-reactive surface.

Fine machining

The higher-precision machines produce delicate machining surfaces by utilizing sharper tools and regulating feed rate and cutting speed. Surface roughness up to Ra 0.8 μm can be maintained with smooth machining.

Laser Cladding

Provides excellent corrosion, wear, and abrasion resistance. Laser Cladding is also effective for treating minor surface imperfections such as cavities, tiny cracks, and rust damage.

Sanding

Provides a random, non-linear texture with a shiny, high gloss finish. However, it might be unable to create sharp corners and pockets

More

Provides a random, non-linear texture with a shiny, high gloss finish. However, it might be unable to create sharp corners and pockets

Welding Tolerances

Dimension detail | Tolerance(+/-) |

| Edge to edge, single surface | 0.005 inch |

| Edge to hole, single surface | 0.005 inch |

| Hole to hole, single surface | 0.002 inch |

| Bend to edge / hole, single surface | 0.010 inch |

| Edge to feature, multiple surface | 0.030 inch |

| Over formed part, multiple surface | 0.030 inch |

| Bend angle | 1° |

3 Ways to Ensure Perfection

Standards

Metals: ISO-2768 fH (fine)

Plastics: ISO-2768 mK (medium)

Metric threads tolerances: ISO 965-1 standard UN Threads Tolerances: ASME B1.1-2003 standard

Knurling: ISO13444:2012 standard.

Our factory is ISO 9001:2015 certificated

Inspection and Protection

Constant visual inspection conditions

Quantification of cosmetic surface quality

Process requirements

Part cleaning and Protection

Quality Inspection Report

Inspection Confirmation

Dimensional confirmation

Appearance confirmation

Quality documentation

Technology Overview

Introduction

If you need to create a joint on the Metal & alloy pieces for your project, the Welding process is the right choice!

Selecting the appropriate welding technique for your project can be difficult because it relies on the type of material, joint strength, end-product specifications, and many other factors. However, ProLean will make it easy for you. Our experienced engineers will choose the best approach for your project.

What is the Welding?

Welding is the joining process of metallic parts by using Intense Heat. Although, In some cases, pressure is also used for joining, heat is the most common. It is among the most straightforward techniques to join metal parts to form the desired shape.

Fusion and solid-phase welding are the two main types of welding processes. While solid-phase welding uses pressure and the material in the welding location is not melted, the fusion process uses heat to melt down the material.

Either electricity or gas generates the heat in the fusion welding. Heat unites the parts by developing a melt pool, which might involve adding other metals.

Advantages of welding in manufacturing

- Welding produces permanent and strong joints on a variety of material parts.

- It is economical, environmentally friendly, and not restricted in the factory environment.

- Joints created by welding are light in weight compared to other approaches such as Riveting.

- Highly corrosion resistive & less time consuming

- Capable of producing complex parts and can be used in a difficult position.

Types of Fusion Welding

There are several Fusion welding approaches for different types of materials and produce the joints according to the required specification and applications.

Shields Metal Arc Welding (SMAW) or stick welding use a welding rod to melt the weld position. Since SMAW is a straightforward and low-cost process, it is used in repair, construction, manufacturing & shipbuilding.In comparison, the MIG welding process uses the consumable solid wire electrode and produces a strong joint without risk of environmental contamination. That’s why it is best for outdoor applications and used in Automotive, Construction, and Industrial work.

The TIG welding process creates high-quality, smooth welds in the parts using a non-consumable electrode with a filler rod. It is mainly used in the aerospace and automotive industry. Laser beam welding is one of the most accurate welding, which uses a prolonged photon beam targeted at the welding location. Plasma arc welding welds the components by directing a high-velocity stream of ionized gas (plasma) at the welding spot.

Applications

Welding is the heart of the manufacturing process. It is applicable in the manufacturing of various components in several industries.

- Automotive

- Aerospace

- Defense

- Agriculture

- Jewelry

- Electrical & electronics

Welding FAQ

What are the Material Options for Welding at Prolean?

We have various material options for welding, Cast iron, Carbon Steel, Stainless Steel, Aluminum and its alloys, Copper, Magnesium alloy, Brass, Titanium, and more. Choose whatever you need.

Is the strength of the parts decreased after welding?

The joint strength may be less or more than the parent materials. Still, with the proper welding technique and a professional operator, it can be kept within the parent materials’ strength range. Be at ease; our engineers and operators are qualified to construct the joint, maintaining the strength not lower than the parent material.

What is the working temperature of the welding process?

It depends upon the melting point of the materials to be welded. The material needed to be melted down at the welding position, so the working temperature remained slightly more than the melting point.

Does welding cause heat damage to the workpiece?

Welding may affect the nearby heat zone since the material is melted at the welding position. Still, using our computer-controlled welding machines guarantees no thermal damage or change in the physical or mechanical properties.

What is the welding tolerance I can achieve from Prolean?

We are capable of maintaining a tolerance of ± 0.05 mm at the welding position.

Which sectors do you offer welding services to?

We provide welding services to various industries, including hardware, electrical, electronics, home appliances, automotive, aerospace, and defense. Contact ProleanHub with your specifications if you work in one of the sectors and need welding service to receive a free quote within 24 hours.

Related Blog

Aluminum 6061 vs 2024: Which Alloy Fits Your Project Best?

Choosing between aluminum 6061 vs 2024?

Iron Carbon Phase Diagram: Its Meaning And Relevance

The iron-carbon phase diagram shows how iron-carbon alloys behave by temperature and carbon levels—essential insight for engineers and manufacturers.

Impact Resistance Plastic | Types, Pros & Cons

Top 7 impact resistance plastics: ABS, PC, HDPE, Nylon types

Get Your Parts Made Today

All uploads are secure and confidential.