CAPABILITIES

Metal Stamping Service

Custom Metal Stamping service is a rapid process that generates parts with complex geometries at relatively lower costs.

- ISO-2768-m

- Lead time as fast as one day

- Aluminium, Steel, Stainless Steel and more

All uploads are secure and confidential.

Our Custom Metal Stamping Service

Custom metal stamping is the best approach to creating components with diverse shapes, including bends, curves, cutouts, and embossing. With Stamping, different shapes can be made out of sheet metal by pressing down on it inside the die. We are the best place to get the exact shape according to your stamping drawing. We use a fully automated and computer-controlled Stamping process to create quality parts.

Try Prolean Now!

Our Custom Metal Stamping Capabilities

Features | Info |

| Bend angle | 1° |

| Thickness | 0.1mm-10mm |

| Part size limit | 1000mm*500mm |

Advantage and Disadvantages of Metal Stamping

Before you choose metal stamping as your manufacturing process, it is crucial to understand what benefit you will get and what the pullback is.

Stamping is excellent for mass-producing complex parts. Its benefits include:

- Ability to create complex shapes and contours.

- Suitable for large-scale production, ranging from thousands to millions of parts per year.

- It uses techniques like fine blanking to work with thick metal sheets.

- Offers low costs per piece, making it economical.

Metal stamping, while efficient for large-scale production, does have certain drawbacks due to the necessity of producing dies first:

- Extended Lead Times: The initial production of parts can be delayed due to the time required to create the necessary dies.

- High Initial Costs: Upfront expenses are significant and driven by tooling, check fixtures, and engineering efforts to set up stamping production lines.

- Die Design Iterations: Suppliers may need to refine the die design multiple times before production starts to guarantee that products meet specifications reliably. This iterative process can further delay production.

Try Prolean Now!

Material Options for Stamping

Prolean offers the following materials for standard and custom metal stamping:

- Aluminum Alloys: 5052, 6061, and others like 5083 and 6082, depending on your project needs.

- Copper: Includes C110, a strong conductor that is easy to form, widely used in electrical products.

- Steel: Popular CRS steels include 1008, 1010, and 1018.

- Stainless Steel: Options include 301, 304, and 316/316L. 301 stainless steel offers excellent tensile strength, while 304 provides better performance and corrosion resistance at higher temperatures. 316/316L has the best corrosion resistance but is also more costly.

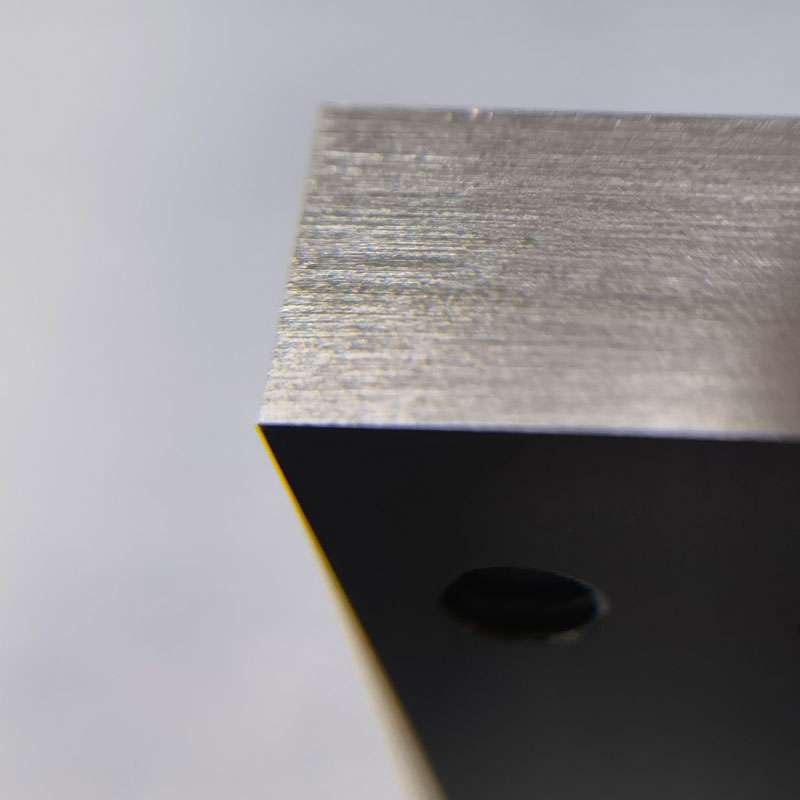

Aluminum Stamping Part

Aluminum is a superior metal in terms of strength-to-weight ratio. It offers High Machinability, ductility, and thermal & electrical conductivity. Parts with aluminum also become highly resistant to corrosion.

Subtypes: 5052, 5083, 6061, 6082

Brass Stamping Part

Golden shiny color, low friction, excellent Machinability, and high electrical & thermal conductivity. Brass can be easily machined and the best choice for low-friction applications.

Subtypes: C360, H59, H62

Copper Stamping Part

It offers good strength, hardness, and excellent corrosion resistance with superior heat and thermal conductivity. It also has a very appealing aesthetic.

Subtypes: 101, C110

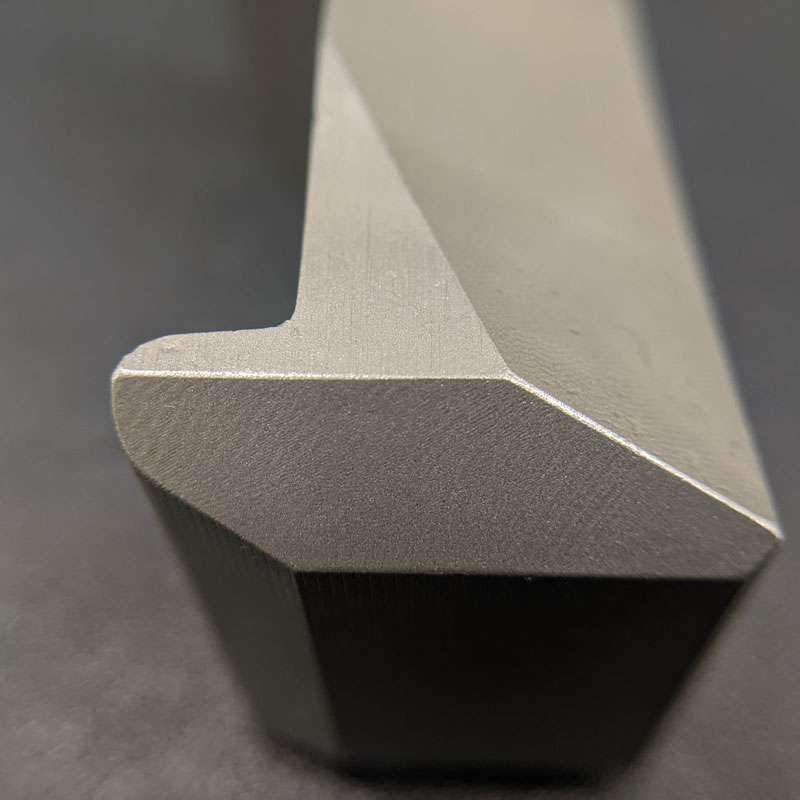

Steel Stamped Part

High mechanical strength, toughness, resistance to wear and fatigue, and sturdiness. In addition to carbon, other alloying elements can be added depending on the needed mechanical and physical qualities.

Subtypes: 1018, SPCC

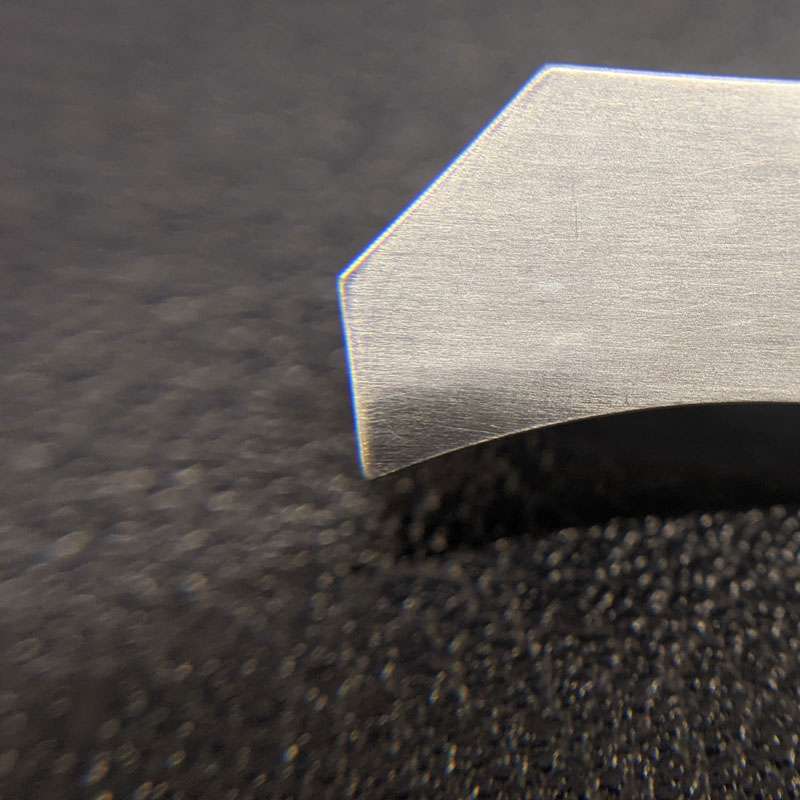

Stainless Steel Stamping Part

High mechanical strength, Thermal, Wear, and Corrosion resistance. Stainless steel is low-cost and can be machined easily. Parts made from Stainless steel are durable and do not lose that strength over time.

Subtypes: 301, 304, 316

Finishing Options For Stamping Part

We provide various surface finish options for your sheet metal project. If your required surface treatment is not listed below, feel free to contact us for more options.

Prolean’s post-processing treatments significantly enhance the functionality and appearance of your stamped parts, providing customized benefits for various applications:

- Bead Blasting cleans and smooths the surface and removes imperfections from stamped parts, making them ideal for high-quality finishes and coatings.

- Powder Coating adds a tough, protective layer that resists chipping, scratching, and fading. It is available in various colors.

- Chem Film: Particularly beneficial for aluminum stamped parts, this coating enhances corrosion resistance and ensures better adhesion for subsequent painting.

- Anodizing strengthens the surface of non-ferrous stamped parts, like aluminum.

- Plating: Gold, silver, and electroless nickel plating not only improves the visual appeal but also increases the corrosion resistance and electrical conductivity, making the stamped parts suitable for more demanding applications such as in electronic or automotive industries.

If you need a post-processing option not listed here, please contact us for more information.

As the machined or deburring

The machined or deburring finish is the standard finish where unwanted attach chips are removed with deburring tools, and sharp edges are chamfered to smooth the surface (3.2 μm).

Bead Blasted

Bead blasting produces a matte texture, removing all the marks of machining tools. It applies to ABS, Aluminum, Brass, Stainless Steel, and Steel parts.

Anodizing

Anodizing involves adding an aluminum oxide coating to aluminum and its alloys. The layers, which come in various colors, increase strength and shield the surface from corrosion.

Powder coating

Powder coating is the electrostatically applying of dry powder to the surface. It produces a thin layer providing excellent resistance to wear, corrosion, and abrasion.

Polishing

Physical rubbing of a metal surface to create a shiny surface is called a polishing surface finish. It increases the reflectivity and does not affect the dimensional stability of parts.

Brushing

Brushing is achieved by applying an abrasive brush to the metal surface, which produces a unidirectional satin finish. And it is not recommended for highly corrosive materials.

Smooth machining

Smooth machining is done by controlling the machining process, such as feed rate & cutting speed. It minimizes the tool marks and risk of corrosion.

Black-Oxide

Black oxide finish reduces surface reflectivity and offers mild corrosion protection. It involves adding a thin layer of magnetite to the surface.

Fine machining

The higher-precision machines produce delicate machining surfaces by utilizing sharper tools and regulating feed rate and cutting speed. Surface roughness up to Ra 0.8 μm can be maintained with smooth machining.

More

Provides a random, non-linear texture with a shiny, high gloss finish. However, it might be unable to create sharp corners and pockets

Stamping Tolerances

Dimension detail | Tolerance(+/-) |

| Edge to edge, single surface | 0.002 inch |

| Edge to hole, single surface | 0.002 inch |

| Hole to hole, single surface | 0.002 inch |

| Bend to edge / hole, single surface | 0.005 inch |

| Edge to feature, multiple surface | 0.015 inch |

| Over formed part, multiple surface | 0.015 inch |

3 Ways to Ensure Perfection

Standards

Metals: ISO-2768 fH (fine)

Plastics: ISO-2768 mK (medium)

Metric threads tolerances: ISO 965-1 standard UN Threads Tolerances: ASME B1.1-2003 standard

Knurling: ISO13444:2012 standard.

Our factory is ISO 9001:2015 certificated

Inspection and Protection

Constant visual inspection conditions

Quantification of cosmetic surface quality

Process requirements

Part cleaning and Protection

Quality Inspection Report

Inspection Confirmation

Dimensional confirmation

Appearance confirmation

Quality documentation

Technology Overview

Introduction

Metal stamping is a manufacturing process in which flat sheets or coils of material are shaped into specific forms. With Stamping, different shapes can be made out of the sheet metal by pressing down on it inside the die. According to your stamping drawing, Prolean is the best place to get the exact shape. We use a full-automated and computer-controlled Stamping process to create quality parts.

What is Stamping?

Stamping is a process in which sheet metal is converted into a pre-defined shape. The stamping die gives the shape of the sheet metal using pressure. So, the sheet metal is fed into the Die, and applied pressure will shape and shear the material into the desired final part, making it more affordable to manufacture several identical parts from sheet metal by stamping.

Types of Stamping

Progressive Stamping is performing numerous stamping operations sequentially using a sequence of workstations. Since diseases endure a long time with this procedure, identical parts can be made over an extended period. In addition, it also produces significantly less scrap. Transfer stamping is commonly used to manufacture large parts. After one operation is finished, the part is transferred to another workstation. With Fourslide, Four tools can be used simultaneously to shape the four slides of a workpiece. It allows for the formation of parts with complex geometries.

Deep-drawing stamping is perfect for manufacturing components with multiple diameters. It entails using a punch to pull a sheet into the Die and mold it there.

Advantages

Compared to other typical manufacturing processes, Stamping is more automated. It is also cost-effective to make high-quality identical items because the die can be used repeatedly. Additionally, it makes surface polishing or post-processing simpler.

Stamping Process

The first phase involves designing the Stamping dies according to the required operations, typically using CAD/CAM technology. For the stamping process to be accurate and for each stamp to retain the ideal component quality, a tight tolerance of dies is also essential

Specific Techniques for the Stamping Process

Under the stamping approach, numerous techniques include punching, blanking, flanging, embossing, bending, and more.

Punching and blanking are used to create the hole in the workpiece. Embossing refers to the raised or recessed design in the sheet metal while flagging is used to produce the flange structure. However, there is one thing common in all techniques: Die and pressure are involved, no matter whether they are associated with creating a hole, flange, recessed design, or bend.

Applications

Stamping is used in the manufacturing of various components in several industries.

- Automotive

- Home appliances

- Lighting Industry

- Electrical and Electronics

- Medical

- Defense

See why customers dig us

We are continuously working with Proleantech for three years now. They have been our trusted and reliable suppliers of battery contacts and enclosures.

-Brian Wright, Head of Prototyping Engineering at TechForm Industries

Our management team found ProleanTech stamping services and then we ordered a few equipment housing prototypes. After the delivery of the first batch, we immediately knew their capabilities. Thank you!

-Olivia Allen, AdvancedMold Solutions

Prolean is my first choice for sheet metal stamped parts. I am happy they help with design optimization and material selection with each design I send them. Kudos to their engineering team.

-Daniel Carter, Senior Die Designer

Working with Prolean has been fantastic. They provided competitive pricing and delivered high-quality stamped parts ahead of schedule. Also, thanks to their customer service staffs.

-Abigail Evans, Quality Control Engineer at PrecisionProto Works

From quote to delivery, Prolean made the entire process seamless. Their stamping service provides high-quality parts with exceptional precision. Highly recommend them for any stamping needs!

-Ryan Foster, MachiningEdge Labs

Stamping FAQ

What item can be produced using the stamping process?

We manufacture anything from essential items like metal clips, springs, weights, jars, washers, cups, cans, terminals, contacts, lead frames, springs, pins, and brackets to complex designs like engine parts. In addition, we provide Stamping services for various industries, including Automotive, electrical, Electronics, Home appliances manufacturers, defense, and many more.

What is the Stamping Tolerance that Prolean Offers?

Our computer-controlled Stamping machines are capable of maintaining the tolerance Hole diameter ± 0.005″, angle ±1 degree, Bend radii ±0.010″, outer dimension ±0.005″, and cut features to bend ±0.0010″.

What Types of Materials Can be used for Stamping?

Steel, aluminum, copper, nickel, and their alloys are most famous for Stamping. However, expensive materials such as gold and platinum are also applicable. These costly materials are primarily used in stamping to make electronic parts.

How Can I set up my part for Stamping?

With our computer-controlled automated stamping machines, you can get your parts by sending the CAD drawing to us. So, it would be perfect for making a 3D model and choosing the material options from your side. We accept PBX, DFX, DWG, STL, and wire Extension CAD files. However, our experienced engineers are also available to assist you with your design process.

Related Blog

Custom Manufacturing: Complete How-To Guide

Custom manufacturing creates tailored products

Delrin vs Nylon: Which Polymer Is Ideal for High-Wear Parts

Choosing between Delrin Vs Nylon?

Understanding Hard Chrome Plating and Decorative Chrome Plating

Explore chrome plating applications in the automotive and aerospace industries.

Get Your Parts Made Today

All uploads are secure and confidential.