CAPABILITIES

Sheet Metal Service

We provide sheet metal cutting and forming services from prototypes to on-demand production of sheet metal parts. Start a one-hour CNC quote from a real engineer, and get your parts made

- ISO 9001:2015 certificated

- Lead time as fast as one day

- Aluminium, Steel, Stainless Steel and more

- Laser & Waterjet Cutting, Stamping, Bending, Welding

All uploads are secure and confidential.

Our Amazing Clients

What is Sheet Metal?

Sheet metalworking creates strong, precise parts from thin metal sheets, ideal for chassis, enclosures, and brackets.

Prolean Tech offers sheet metal fabrication services, including welding, finishing, and insert installation on aluminum, copper, steel, and stainless steel. With domestic and overseas partners, we handle any volume, from prototypes to mass production.

Our sheet metal service features an efficient online quoting system and unlimited supply capacity to ensure fast delivery. We use advanced press brake punches and die tooling to shape metals to your specifications.

Try Prolean Now!

Our Sheet Metal Service Cards

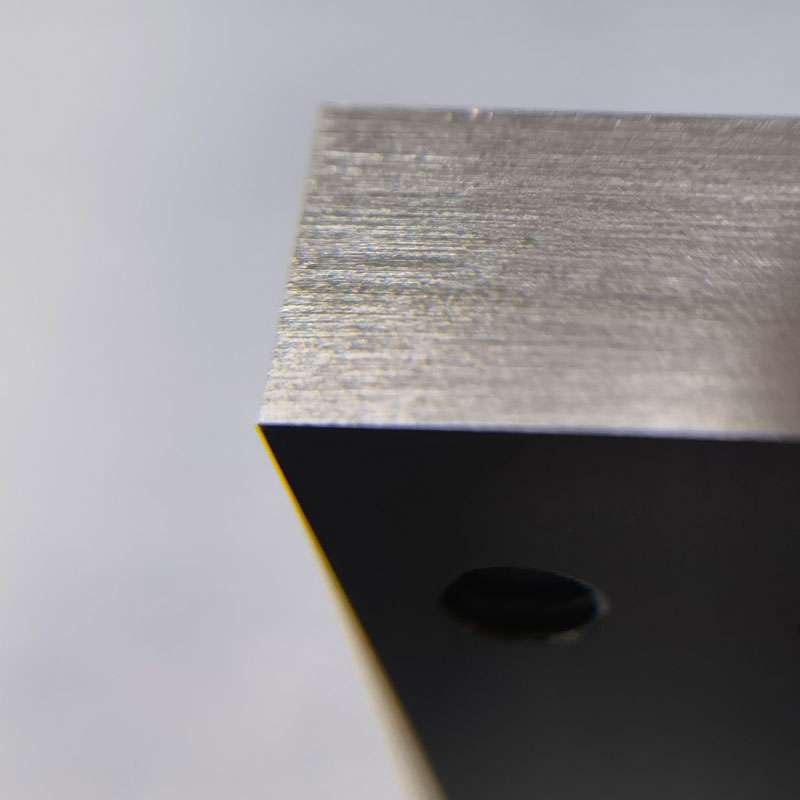

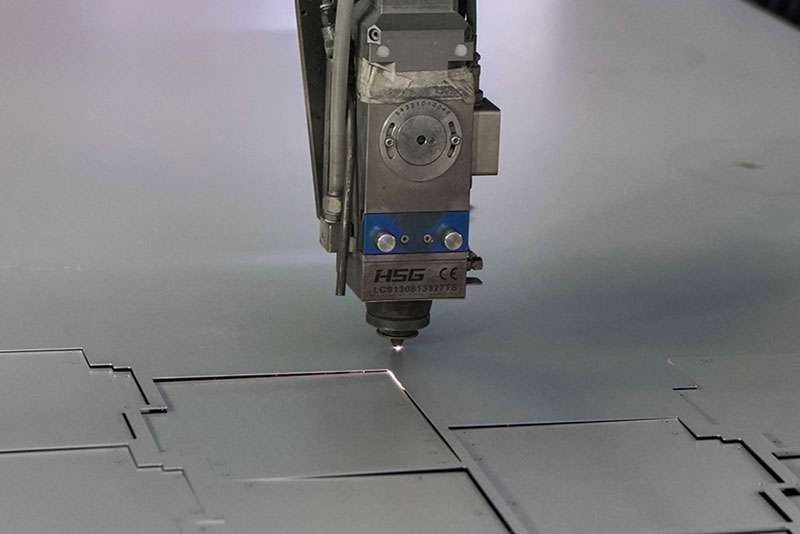

Laser Cutting Service

Our laser cutting service are able to deliver high-precision cutting and engraving on materials such as aluminum steel, coppe and more

Sheet Metal Bending

Deliver accurate angles with our bending services, achieving a final product that fits within tight tolerances

Stamping Service

Stamping service is a rapid process that generates parts with complex geometries at relatively lower costs.

Waterjet Cutting

High precision CNC waterjet cutting service cut through sheet metals without leaving burn marks

Welding Service

If you need to create a joint on the Metal & alloy pieces for your project, the Welding process is the right choice!

How does Sheet Metal work?

The below-mentioned steps are involved in the sheet metal fabrication process:

Design and CAD Modeling

The sheet metal fabrication process starts with creating a 3D CAD model, which outlines the product’s size, material, and specifications. This detailed CAD model is a blueprint, ensuring the final part meets all design requirements.

Material Selection

Material selection, such as aluminum, steel, or titanium, is crucial for enhancing product performance and durability based on the required strength, weight, and resistance. This ensures the part meets application demands effectively.

Machining Process

After selecting the material, the metal sheet is cut using a laser, water jet, or shearing to ensure accuracy and maintain material homogeneity. The sheet is then bent using press brakes to achieve the required angles and curves, ensuring the part’s geometry matches the CAD design.

Assembly

During assembly, welding may be used to combine all elements into the final product, ensuring efficient performance, structural strength, and overall system integrity.

Finishing Options

Polishing or painting enhances the part’s appearance and provides rust protection, preventing corrosion and improving surface quality. Finishing must meet design requirements and ensure functionality.

Our Sheet Metal Service Capabilities

Features | Description |

| Blank Size | 5′ x 10′ (1.52 m x 3.05 m), with the option for larger sizes upon request. |

| Standard Lead Time | 1 business days |

|

Sheet Thickness |

Typical thickness ranges from 0.024″ to 0.250″, with options for thicker or thinner gauges available. |

| Braking (Hydraulic) | Capable of handling lengths up to 14′. |

| Braking (Magnetic) | Provides 6 tons of magnetic pull with a 5/8″ minimum reverse bend. |

| Cutting Tolerance | Precision cutting with a tolerance of ± 0.00787″ (0.2 mm). |

| Bend Angle Tolerance | Bend angles are accurate to ± 1.0°. |

|

Bend to Edge Tolerance |

Bend to edge distance maintained within ± 0.010″ (0.254 mm). |

Try Prolean Now!

How to Order Parts?

Get a free quote from a real engineer; once we receive your design, our engineer will review it and send you a quote as fast as one hour.

Get A Quote Immediately

Upload your design or email our engineer directly and get your quotes as fast as one hour.

Start Production

Your parts will be made once your orders are confirmed. Besides, you will get real-time order updates of the production status from our order tracking system.

Receive Your Part

After all parts pass QC inspection, they will be well packed from transportation accidents. Then, your custom parts are delivered straight to your doorstep.

Types of Sheet Metal Operations

- Laser cutting Metal

Laser cutting is a highly accurate and effective technique for cutting metal sheets, and it is ideal for most operations. For thicker materials, plasma cutting is faster but less precise. Laser cutting is preferred for its superior quality.

- Mechanical Cutting

Shearing, or die cutting, is a process that cuts sheet metal without heat, similar to using scissors. It’s ideal for straight cuts and effective for parts that don’t require complex shapes.

- Bending

At Prolean Tech, we use bending processes with press brakes to shape metal into various parts, from brackets to enclosures. This precise technique is crucial in automotive, aerospace, and manufacturing industries.

- Punching

Punching cuts holes in sheet metal using a punch tool, ideal for high production volumes. It is cost-effective for creating multiple perforations or designs but can be expensive for small runs due to the need for various tools.

- Slotting

Slotting, or slitting, forms slots or notches in sheet metal using specialized machines. It’s crucial for applications requiring precise slots or unique fittings and connectors.

Sheet Metal Fabrication Materials

Titanium

We offer various grades, including Grade 2 and 6Al-4V, also known as Grade 5. These materials are highly valued for their excellent strength-to-weight ratio, corrosion resistance, and wear resistance.

Due to these properties, they are widely used in aerospace parts, medical implants, and high-performance components.

Aluminum

Prolean’s Aluminum Sheet Metal Fabrication Service is your gateway to precision-crafted, durable components. Marrying cutting-edge technology with seasoned craftsmanship, we transform raw aluminum sheets into masterpieces, ensuring reliability and aesthetic finesse in every creation.

Subtypes: 5052, 5083, 6061, 6082

Brass

Prolean offers Brass Sheet Metal Fabrication Services, focusing on precision and durability. Using quality brass sheets, we ensure reliable and long-lasting products for various applications.

Golden shiny color, low friction, excellent Machinability, and high electrical & thermal conductivity. Brass can be easily machined and is the best choice for low-friction applications.

Subtypes: C360, H59, H62

Copper

Our Copper Sheet Metal Fabrication Service transforms quality copper sheets into durable components. Trust us for dependable solutions tailored to diverse needs.

It offers good strength, hardness, and excellent corrosion resistance with superior heat and thermal conductivity. It also has a very appealing aesthetic.

Subtypes: 101, C110

Stainless Steel

Rely on Prolean’s Stainless Steel Sheet Metal Parts service for corrosion-resistant components that combine strength with a polished finish, which is ideal for both functionality and aesthetics.

High mechanical strength, Thermal, Wear, and Corrosion resistance. Stainless steel is low-cost and can be machined easily. Parts made from Stainless steel are durable and do not lose that strength over time.

Subtypes: 301, 304, 316

Steel

For robust and lasting results, Prolean’s Steel Sheet Metal Parts service crafts precision components from premium steel sheets, ensuring strength and quality in every piece.

High mechanical strength, toughness, resistance to wear and fatigue, and sturdiness. In addition to carbon, other alloying elements can be added depending on the needed mechanical and physical qualities.

Subtypes: 1018, SPCC

Try Prolean Now!

Finishing Options For Sheet Metal Part

As the machined or deburring

The machined or deburring finish is the standard finish where unwanted attach chips are removed with deburring tools, and sharp edges are chamfered to smooth the surface (3.2 μm).

Bead Blasted

Bead blasting produces a matte texture, removing all the marks of machining tools. It applies to ABS, Aluminum, Brass, Stainless Steel, and Steel parts.

Anodizing

Anodizing involves adding an aluminum oxide coating to aluminum and its alloys. The layers, which come in various colors, increase strength and shield the surface from corrosion.

Powder coating

Powder coating is the electrostatically applying of dry powder to the surface. It produces a thin layer providing excellent resistance to wear, corrosion, and abrasion.

Black-Oxide

Black oxide finish reduces surface reflectivity and offers mild corrosion protection. It involves adding a thin layer of magnetite to the surface.

Sheet Metal Applications

To help you understand the diverse applications of sheet metal and determine if it’s right for your project, Prolean Tech offers insights into its various uses:

Automotive

Rapid sheet metal prototyping is commonly used in the automotive industry because of its flexibility and strength. It is widely employed in making parts like doors, hoods, and roofs. Sheet metal can be easily bent, shaped, and welded to make it suitable for producing strong auto parts.

Construction

In the construction industry, sheet metal is an important aspect of construction and framing of structures. It is employed in roofing, cladding, and structural members and offers the necessary shield against various natural factors and increases the life span of structures.

Electrical Enclosures

Sheet metal plays a critical role in the electronics industry, particularly in the fabrication of enclosures and for shielding purposes. It safeguards delicate electronic devices and apparatus from potential interference and damage, thus enhancing their performance and safety.

Jewelry Crafting

Sheet metal is one of the most popular materials used in jewelry making. It allows designers to create special designs, and that is why jewelry prefers it when making functional and ornamental products.

Sheet Metal Service FAQ’s

Technical FAQ’s

What is sheet metal forming?

Sheet metalworking involves the use of metal sheets to form several structures by using various techniques like bending, pressing, and rolling. The process uses carefully directed pressure to change the form of the material without having to cut it in any way.

What are the benefits of sheet metal fabrication?

Sheet metal fabrication is economical and gives high-strength, lightweight, sturdy, and tough parts in less time. It is general and can be used in the electronics industry, automotive industry, construction, energy, and many other prototype-demanding sectors.

Can you assist me with the prototype design?

Our experienced engineers will work closely with you to optimize the functionality of your parts and provide comprehensive assistance throughout the entire manufacturing process. They will ensure that each step aligns with your specific requirements and desired outcomes for the final product.

What is the difference between metal stamping and metal fabrication?

Metal stamping is a method of using punch press tools with a die to cut large quantities of high-precision parts in the shortest time possible. Metal fabrication involves, forming, shaping, and joining metals as required for a given application which provides more design freedom and is better for small runs.

General FAQ’s

What products can you create?

Prolean Tech specializes in fabricating ductwork, electrical enclosures, HVAC cabinets, and more. We also craft custom items like tables, chairs, workbenches, and vehicle chassis. To get more, fill out our sheet metal instant quote form, and get advice from our engineers for your sheet metal project.

What is Custom Metal Fabrication?

Custom metal fabrication is a process of creating metal parts that have been designed according to the needs of a particular project. This process involves the use of metal sheets, angle iron, and tubing to come up with unique products, such as special, non-regular parts, which are needed to fulfill specific functional requirements.

What materials do you offer for sheet metal manufacturing?

We provide a range of materials for sheet metal fabrication, including aluminum, stainless steel, mild steel, copper, and zinc. If you have specific material requirements, just let us know!

Are the sheet metal prototypes the only objects that you make?

Prolean Tech offers sheet metal prototyping、high-volume and low-volume production services to its clients. From one prototype to hundreds of identical parts, such as ductwork and enclosures, we can deliver them all with accuracy.

3 Ways to Ensure Perfection

Standards

Metals: ISO-2768 fH (fine)

Plastics: ISO-2768 mK (medium)

Metric threads tolerances: ISO 965-1 standard UN Threads Tolerances: ASME B1.1-2003 standard

Knurling: ISO13444:2012 standard.

Our factory is ISO 9001:2015 certificated

Inspection and Protection

Constant visual inspection conditions

Quantification of cosmetic surface quality

Process requirements

Part cleaning and Protection

Quality Inspection Report

Inspection Confirmation

Dimensional confirmation

Appearance confirmation

Quality documentation

Technology Overview

Introduction

Are you looking to create actual parts and products from your 2D or 3D design? Then, sheet metal fabrication might be the best approach for you.

Sheet metal fabrication refers to the creation of the desired shape from steps of the manufacturing process. It involves various alternatives for each step, such as cutting, bending, joining, and surface finish. But, choosing the right type of process helps optimize the fabrication’s functionality and cost. ProLean makes it easy for you. We decide the best steps for your project based on your requirements.

What is Sheet Metal Fabrication?

Sheet metal fabrication is converting the metal sheet into the desired shape. The process involves more than one step while manipulating the sheet metal to form the body, such as cutting, bending, welding, surface treatment, and many more, depending upon the complexity of the required shape.

The fabrication of sheet metal begins with drawings (2D& 3D). However, before starting the actual fabrication, manufacturers develop a 3D such as a CAD file. The 3D of desire shape provides guidance on what actions should be made, which strategy is the most appropriate and practical, which manufacturing steps are needed, and many other things.

Advantages

• Sheet metal fabrication is the low-cost and effective approach for prototype development and large-scale production.

• The finished part or product made of sheet metal has a high strength-to-weight ratio.

• Sheet metal fabrication offers a wide range of material options to create the desired shape.

Fabrication Steps

The steps of sheet metal fabrication begin with preparing a complete blueprint of required parts. For example, it might be the paper drawing or CAD-3D containing all dimensions. Then, it requires identifying the manufacturing steps such as cutting, bending, welding, assembly, & surface treatment.

Cutting the sheet metal is the step where the actual fabrication starts. Cutting the sheet metal into pieces as the dimension in the drawing can be achieved with various approaches such as CNC cutting, Laser cutting, and Water-jet cutting. After the Cutting operations, the cutting pieces need to be joined to form the shape with Riveting & welding. Other processes, such as bending and turning, are involved if angular or complex shapes are required. If holes are present in the shape, punching or drilling operations are used to create them.

Assembly of components is done to produce the desired shape according to the design of parts or products. Last but not least, surface finishing procedures, including plating, deburring, powder coating, or painting, must be carried out.

Applications

Several industries use sheet metal fabrication processes to create parts and the final product.

- Automotive

- Aerospace

- Defense

- Agriculture

- Medical

- Home appliances

- Construction

- Electrical & electronics

See why customers dig us

Fully impressed with the precision of the laser cutting on our stainless steel panels. The team delivered the parts with consistent quality across the batch. I can ensure Prolean will not disappoint in your custom metal projects.

-Kimberly Gray

We sent the design pf aluminum brackets with complex bends, and prolean’s engineers were spot-on. The delivered product exceeded our expectations in both durability and fit.

-Matthew Brooks, Director of Product Engineering at CustomForm Innovations

Top-notch sheet metal service! The CNC punching was accurate, and the final anodized aluminum parts arrived on time. We'll reorder the subsequent batches in future.

-Lauren Sanders, Prototyping Specialist at TechProto Works

I ordered copper busbars for an electrical research project. They were cut and bent with precision. Excellent service and communication throughout the process.

-Brandon Ward, Senior Casting Engineer at CastTech Innovations

The powder-coated steel enclosures we received were flawless. Thank you for attention to detail in th e fabrication process, it makes our assembly process seamless.

-Samantha Park, R&D Engineering Manager at ProtoEdge Manufacturing

I was looking for mild steel shredder flails for a project, and Prolean delivered within 5 days. There was no compromise on quality and specified requirements. Highly professional and accommodating service!

-Tyler Hughes, DieCastPro Solutions

Related Blog

Punching vs Laser Cutting: Which One is Right?

Punching suits high-volume, laser cutting delivers high precision

What You Should Know About HVAC Sheet Metal Fabrication

Get the insights on HVAC sheet metal fabrication

MIG VS TIG Welding: A Comprehensive Technical Comparison

Key differences between MIG and TIG welding

Get Your Parts Made Today

All uploads are secure and confidential.