“It is possible to perform machining and shape various materials, including metal, alloys, plastics, composites, fibers, and wood. CNC machine can work with almost every material as long as it doesn’t damage the CNC machining cutting tool.

One of the most significant advantages of CNC machining is that it is compatible with a wide range of materials. However, the selection of materials for CNC machining is very critical. It directly affects the final product’s functionality, durability, and cost-efficiency. This article will discuss the common metal, their alloys, plastics, and composites used in CNC machining projects.

Common Metals and Alloys for CNC Machining

Metal and alloys are used in CNC machining for various applications, from simple machining tools to advanced aircraft and defense parts. They offer mechanical strength, hardness, electrical & heat conductivity, wear & tear resistance, and many more. Metals have high melting and boiling points and are flexible with the operating temperature.

Metals can operate at a wide range of temperatures because they have high melting and boiling points. Metal and alloys can be machined using CNC technology if their hardness does not damage the tool. Let’s look closer at the common metals and alloys used in CNC machining.

Let’s overview the common metals and alloys used in CNC machining, one by one.

Stainless steel

Stainless steel is a steel alloy, where carbon and chromium are the primary alloying materials. However, other elements are also present in specific grades, such as molybdenum and sulfur. Stainless steel offers High tensile strength, corrosion, and thermal resistance.

Stainless Steel

It has extensive applications in the construction, automotive, aerospace, defense, heavy machinery, surgical equipment, kitchen appliances, hardware, and tool sectors, among many others. It is used in various applications requiring a high degree of mechanical strength and reliability.

Popular grades of stainless steel for CNC machining are 304, 316, 416, and 17-4 PH.

| Grade | Properties | Applications |

| 303 | The addition of Sulphur in stainless steel improves machinability. Still, it remains tough and austenitic. | Aircraft parts, architectural parts, pumps, valves, nuts, bolts, and many more. |

| 304 | Low carbon grade offers better formability and weldability. | Machinery parts, automotive parts, screws, food handling equipment, and various household applications. |

| 316 | Offers excellent corrosion resistance as compared to other grades. It provides excellent wear and tear resistance. | Aerospace parts, medical and surgical equipment. |

| 416 | High machinability, less corrosion resistance, and more hardness. | Tough parts for different applications, electric motors, nuts, bolts, and many more. |

| 17-4PH | Excellent magnetic properties, high corrosion resistance, | General metal work applications, paper, petrochemical, aerospace, food processing, and medical. |

For property details please check the stainless material properties service, or you can also learn about fabrication projects with stainless steel for a close look at the real application.

Aluminum

The high strength-to-weight ratio of aluminum makes it a popular material for various CNC machining projects. It also has a broad spectrum of mechanical and physical qualities and high machinability. It is super corrosion-resistant and compatible with an extensive range of working temperatures.

Aluminum

Aluminum is used in many applications, from lightweight doors and windows to rocket components. Aluminum alloys are used in automotive, aerospace, construction, medical, defense, home appliances, and many more. Depending upon the particular application, some finishing or post-processing might be required.

- Machinability: Aluminum is easy to machine and can be cut at high speeds, reducing manufacturing time.

- Corrosion resistance: Naturally resistant to oxidation, suitable for harsh environments.

- Thermal conductivity: Ideal for applications requiring heat dissipation.

- Non-toxic: Safe for use in food-related and medical applications.

- Recyclability: Environmentally friendly due to its recyclability without loss of properties.

Two grades of aluminum alloys are most famous for CNC machining, 6061 and 7075. Learn more about aluminum alloy properties.

| Grade | Properties | Applications |

| 6061 | It contains magnesium and silicon, Excellent corrosion resistance, good formability & weldability, Lower strength than 7075. | Automotive, aircraft, electronics, ship buildings, hardware, sporting products, etc. |

| 7075 | It is alloyed with Zinc, has Higher strength than 6061, Good fatigue strength, and Excellent corrosion resistance. | Different automotive parts include meter shafts, gears, regulating valves, interiors, aircraft, defense, and many more. |

Related:

3003 Aluminum vs. 6061 Aluminum: A Comprehensive Comparison Guide

Copper

Copper is an excellent CNC machining material that offers outstanding thermal and electrical conductivity, including the shiny reddish brown appeal. It provides superior corrosion resistance, machinability, mechanical strength, and flexibility.

Copper

Copper & its alloys are used in wire& cable applications, electrical appliances, marine hardware, construction, vacuum equipment, and many more. Furthermore, over time, copper’s natural patina adds a protective layer against corrosion, ensuring longevity in harsh conditions.

- Electrical conductivity: Top choice for electrical components due to low resistance.

- Thermal conductivity: Efficient heat dissipation for cooling systems.

- Malleability: Enables the creation of complex and detailed designs.

- Antimicrobial properties: Reduces the spread of germs on frequently touched surfaces.

- Corrosion resistance: Forms a protective patina over time for enhanced durability.

- Aesthetic appeal: Unique color and finish for decorative elements.

Two alloys of copper are popular for CNC machining: alloy 101 and alloy 110.

| Grade | Properties | Applications |

| 101 | It is a pure copper alloy with high impact strength, ductility, and excellent electrical & thermal conductivity. It is less corrosion-resistant than 110. | Electrical & thermal applications, wire & cables, general engineering applications, |

| 110 | It is less pure, offers a high level of electrical and thermal properties, and is more corrosion-resistant than 101. | Superconductor magnets, jewelry, electrical and thermal applications, hardware, building materials, etc. |

Related:

Brass

Brass is a copper alloy that contains a mixture of zinc. Along with muscular tensile strength, impact resistance, and shear resistance, Brass also offers outstanding machinability properties. It’s a highly well-liked, low-friction, and gold-like material in CNC manufacturing.

CNC machined Brass

- Acoustic properties: Ideal for manufacturing musical instruments due to their sound resonance.

- Machinability: Easily machined into complex shapes and fine details.

- Non-sparking: Safe for use in explosive atmospheres.

- Corrosion resistance: Good resistance to water corrosion, making it suitable for marine applications.

- Antimicrobial: Naturally inhibits microbial growth and is helpful for sanitary applications.

Furthermore, it has numerous applications in heavy industrial components, musical instruments, automotive, electrical, aerospace, defense, medical, architecture, hardware, and many more sectors.

Related: The Definitive Guide to Brass Machining: Benefits, Tips, Finishes, and Crucial Factors

Brass has two popular alloy grades for CNC machining, C3604 and C3602.

| Grade | Properties | Applications |

| C3604 | Good machinability, high mechanical strength, compatibility with cold and hot pressure processing, and excellent wire and welding properties. | Electronics, hardware, architecture, hardware, and fittings. |

| C3602 | High plasticity, corrosion resistance, good machinability, and strength. | Automotive parts, waterworks, valves, shipbuilding, oil & gas, piping, energy industry, etc. |

Titanium

Titanium is most popular in the bio-medical industry. It has various automotive, medical, aerospace, and other applications.

CNC-machined titanium parts

Titanium is a rare material with various unique Mechanical and physical characteristics. It offers outstanding corrosion resistance, bio-compatibility, strength-to-weight ratio, and thermal & chemical stability. Although it is a rigid material, it can repeatedly flex in CNC conditions.

The biocompatibility of titanium is unparalleled, ensuring that it doesn’t react with the human body, which is essential for medical devices. Despite its higher cost and machining complexity, the advantages of titanium often outweigh all the challenges.

- High strength-to-weight ratio: Essential for applications where strength is crucial but weight is a limitation.

- Corrosion resistance: Immune to most environmental conditions, including seawater.

- Temperature resistance: Maintains its properties at extreme temperatures, suited for aerospace and automotive use.

- Biocompatibility: Ideal for medical implants and body-contact devices.

- Non-magnetic: Can be used in applications where magnetic interference is a concern.

- Durability: Parts last longer under stress, reducing replacement frequency

In CNC machining, Ti-6AI-4V is the most common alloy grade of titanium. There are more details about titanium properties.

| Grade | Properties | Applications |

| 6Ti-6AI-4V | Lightweight, High strength-to-weight ratio, high temperature & corrosion resistance, and bio-compatible | Medical instruments, jewelry, aircraft parts, medical implants, and many more. |

Related:

Alloy steel

Small amounts of iron, carbon, and other substances are used to create alloy steel depending on the desired mechanical and physical properties. Alloy steel is strengthened, structurally stable, and hardened by trace amounts of other components.

Alloy Steel parts

Alloy steel is ideal for various applications, including tooling, automotive, defense, and maritime, thanks to its low cost and high strength.

In CNC machining, 4041, 4130, and 4140 are the popular grades of alloy steel.

| Grade | Properties | Applications |

| 4041 | Good mechanical strength & toughness, heat treatable, excellent hardness. Ductility and wear resistance | High-stress applications, shafts, bolts, gears, coupling, piston rods. |

| 4130 (30CrMo in China) | High strength, hardenability, toughness, and low deformation | Bearings, automotive parts, crushing machinery, drill bits & cutters, and many more. |

| 4140 (structural steel 42CrMo in China) | High toughness, mechanical strength, machinability, fatigue strength, impact resistance, and abrasion resistance. | Shafts, gears, machinery parts, aerospace, oil & gas. |

Magnesium AZ31

Magnesium AZ31 is a lightweight alloy that brings the advantages of magnesium – low density and high strength – into CNC machining. This material is crucial in the automotive and aerospace industries, where weight reduction is paramount for fuel efficiency and performance.

CNC-machined Mg AZ-31

Mg AZ-31 is also amenable to detailed machining, making it suitable for intricate components. Despite being lightweight, it does not sacrifice strength, providing a desirable balance for dynamic applications. However, precautions during machining are necessary due to its flammability.

- Lightweight: Significantly lighter than steel or aluminum, reducing overall component weight.

- High strength-to-weight ratio: Offers durability without the bulk.

- Machinability: Can be finely machined for detailed components.

- Damping properties: Absorbs vibrations, contributing to smoother operation of machinery.

- Corrosion resistance: Good resistance to atmospheric corrosion.

Common Plastics for CNC Machining

The CNC machining process is compatible with various plastic materials, including ABS, Acrylic, Delrin, PPMA, and others. Because of their distinctive physical, mechanical, and chemical properties, plastics are used frequently in CNC machining projects for various applications.

Plastics are a low-cost material with several desirable qualities, including good strength, lightweight, thermal and heat insulation, flame resistance, dimensional stability, machinability, and many others. For various parts and equipment, the automotive, aerospace, electrical, medical, and many more industries rely on plastic machining.

Let’s review some of the plastics frequently used in CNC machining.

ABS

Acrylonitrile Butadiene Styrene (ABS) is a widely used thermoplastic in CNC machining projects. It offers high mechanical strength, toughness, chemical inertness, and electrical resistance. It can be readily painted, glued, or welded together.

ABS

After CNC machining, It leaves a shiny matte finish. ABS allows the production of strong and durable parts for automotive, electrical, electronics, home appliances, toys, fittings, and food processing. Plus, its resistance to chemicals and low moisture absorption rate broaden its application across industries.

- Impact resistance: Sustains durability under stress, making it suitable for robust parts.

- Machinability: Can be precision-machined with ease, allowing for complex designs.

- Surface finish: Yields smooth surfaces that can be easily painted or treated.

- Dimensional stability: Minimal warping, ensuring precise and consistent parts.

- Chemical resistance: Stands up well to various chemicals and substances.

- Versatility: Ideal for diverse applications, from automotive and aerospace to consumer goods.

Nylon

Nylon, particularly the widely used PA 6/6, is a synthetic polymer well-known for its strength, thermal stability, and resistance to wear and abrasion. In CNC machining, it’s a preferred material for parts that require durability and a lower coefficient of friction. It is used in electrical insulating equipment, medical devices, circuit boards, automotive & aerospace parts, and many more applications. It is an excellent alternative to metal.

Nylon Sheets

Nylon’s ability to resist impact and its self-lubricating properties make it a prime choice for gears, bearings, and insulators. It’s also resistant to chemicals and can be easily colored, which expands its utility in various industries.

- Wear resistance: Excellent for parts with sliding or moving components.

- Thermal stability: Maintains integrity under varying temperatures.

- Low friction: Self-lubricating properties ideal for gears and bearings.

- Impact resistance: Good toughness contributes to durability.

- Chemical resistance: Suitable for applications exposed to harsh substances.

- Colorability: Can be dyed for specific aesthetic requirements.

Acrylic

Acrylic is a transparent thermoplastic with various unique properties, making it suitable for multiple CNC machining projects. It is a lightweight material with excellent chemical resistance, Stiffness, thermo-formability, durability, and aesthetic appeal. In addition, Acrylic is also easy for CNC machining and fabrication.

Acrylic parts

Acrylic is used in various automotive components, including light tubes, panels, tanks, interior design, billboards, water-proof elements, shoes, tennis rackets, Fiber Optic Cabling, and chemical processing.

Delrin

The low-friction material Delrin is perfect for CNC machining with precise tolerances. It has good dimensional stability, Stiffness, rigidity, durability, chemical inertness, and resistance to impacts and moisture.

Delrin CNC machining

Its natural lubricity lends itself to applications requiring low friction and high wear resistance, such as gears, bearings, and sliding parts. Delrin also stands out for its excellent fatigue resistance, making it suitable for parts subjected to repeated stress. Its resistance to moisture and solvents further broadens its utility across various industries.

- Dimensional stability: Maintains shape and tolerance after machining and in use.

- High precision: Allows for tight tolerances in intricate parts.

- Natural lubricity: Reduces the need for additional lubricants in moving parts.

- Fatigue resistance: Durable in applications involving repetitive stress.

- Moisture resistance: Performs well in wet environments.

- Chemical resistance: Withstands solvents and other chemicals, preserving part integrity.

Polyethylene (PE)

Engineering thermoplastic Polyethylene (PE) offers a low mechanical strength and hardness but an excellent impact strength. It is well-recognized for being bendable, electrically insulated, highly thermally stable, and oil & steam-resistant.

Polyethylene is a flexible engineering material that works best in various applications, including food processing, medicines, packaging, agricultural products, cables, pipes, and fittings. Furthermore, its lightweight nature and ease of machining make it a cost-effective option for large-scale production.

- Impact resistance: Absorbs shock effectively, ensuring durability.

- Moisture resistance: Impervious to water, preventing material degradation.

- Low friction: Beneficial for parts requiring a smooth operation.

- Non-toxic: Safe for contact with food and beverages.

- Ease of machining: Simplifies the manufacturing process.

- Economic: Cost-efficient for producing high-volume parts.

Polyvinyl Chloride(PVC)

PVC (Polyvinyl Chloride) is a popular plastic material in CNC machining known for its mechanical strength and chemical resistance. It is a preferred choice for industrial and construction applications, including piping, valves, and fittings. PVC’s excellent fire-retardant properties make it suitable for applications requiring flame resistance. Its ability to be bonded with adhesives or welded allows for complex parts and assemblies. Additionally, PVC can be machined to tight tolerances and is available in rigid and flexible forms.

- Mechanical strength: Suitable for structural components.

- Chemical resistance: Ideal for handling corrosive substances.

- Fire retardant: Contributes to safety in fire-sensitive applications.

- Versatility in joining: Can be easily bonded or welded during assembly.

- Tight tolerances: Capable of precision machining for detailed parts.

- Variety of forms: Available in both rigid and flexible options for diverse applications.

Table: Existing table summarising the common plastic used in CNC machining

| Grade | Properties | Applications |

| ABS | High mechanical strength, toughness, chemical inertness, and electrical resistance. It can be readily painted, glued, or welded together. | Electrical, electronics, home appliances, toys, fittings, and food-processing parts. |

| Nylon | High strength, rigidity, electrical insulation, thermal stability, wear resistance, chemical inertness, dimensional stability, and plasticity. | Electrical insulating equipment, medical devices, circuit boards, automotive & aerospace parts |

| Acrylic | Lightweight material with excellent chemical resistance, Stiffness, thermo-formability, durability, and aesthetic appeal. | Various automotive components, including light tubes, panels, tanks, interior design, billboards, water-proof elements, shoes, tennis rackets, Fiber Optic Cabling, and chemical processing. |

| Delrin | High Stiffness, rigidity, durability, chemical inertness, and resistance to impacts and moisture. | Electric insulation, pumps, bushings, fasteners, automotive, construction, etc. |

| PE | Low mechanical strength and electrically insulated, oil and steam-resistant. | Food processing, medicines, packaging, agricultural products, cables, pipes, and fittings. |

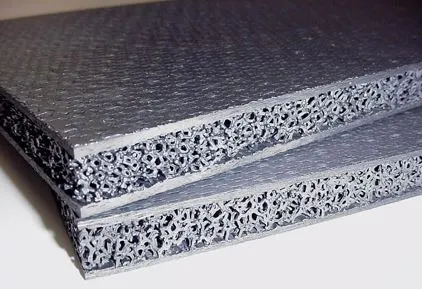

Common Composites for CNC Machining

Composite materials have become integral to CNC machining, offering enhanced properties compared to traditional materials. These engineered materials combine two or more constituent materials with differing physical or chemical properties to produce a material with characteristics superior to the individual components. Composites are known for their strength-to-weight ratios, durability, and resistance to environmental factors.

Composite CNC machining

Composite CNC machining is significant in different industries, such as aerospace, automotive, and sports equipment manufacturing, where performance and precision are paramount. The ability of composites to be machined into complex shapes while maintaining structural integrity allows for innovation in design and functionality. Advanced composites like carbon fiber reinforced plastics (CFRP), fiberglass, Kevlar-reinforced polymers, and metal matrix composites (MMC) are some of the common composites adapted for CNC machining to achieve high performance and reliability. Let’s discuss these common CNC machining composites in detail.

Carbon Fiber Reinforced Plastics (CFRP)

CFRP composites are renowned in CNC machining for their exceptional strength and lightweight properties. These composites consist of carbon fiber reinforcement in a polymer matrix, which gives them a high strength-to-weight ratio and stiffness. They are frequently used in high-performance applications, such as in the aerospace and automotive sectors.

- High strength-to-weight ratio: Ideal for lightweight construction without sacrificing strength.

- Stiffness: Maintains shape under load, essential for structural components.

- Versatility: Can be molded into complex shapes.

Fiberglass

Fiberglass is a composite material made from woven glass fibers bonded with resin. Its adaptability in CNC machining is due to its robust nature and cost-effectiveness compared to other composites. It is commonly used in boat hulls, automotive bodies, and construction.

- Cost-effective: Provides a less expensive alternative to carbon fiber.

- Durability: Resistant to impact and wear.

- Non-conductive: Suitable for electrical insulation applications.

Kevlar-reinforced polymers

Kevlar-reinforced polymers bring together the high tensile strength of Kevlar with the versatility of plastic materials. This combination results in a composite that is incredibly tough and has excellent resistance to impact and abrasion. Its use is widespread in military and safety applications, such as in bulletproof vests and protective gear.

- Impact resistance: Protects against high-velocity impacts.

- Abrasion resistance: Withstands wear and tear in harsh conditions.

- Lightweight: Easier to handle and use in mobile applications.

Metal Matrix Composites (MMC)

Custom Metal-matrix composite

Metal matrix composites combine metal with a secondary material like ceramic or another metal to enhance its properties. MMCs are chosen for their improved mechanical properties, such as increased strength at high temperatures and better wear resistance. They are ideal for use in the automotive and aerospace industries where high-performance materials are required.

- High-temperature performance: Retains strength even at elevated temperatures.

- Wear resistance: Suitable for parts that experience high levels of friction.

- Thermal conductivity: Can dissipate heat efficiently.

You might also be interested in:

Choose Your Material and Get Precise CNC Machined Parts at Prolean

Selecting the right material for CNC machining is crucial, as it determines not only the quality and performance of your parts but also the efficiency and cost-effectiveness. At Prolean, we understand the intricacies of material properties and how they can impact your final product. Whether you’re looking for the durability of metals, the flexibility of plastics, or the advanced properties of composites, our team of experts will guide you through the selection process to ensure that your CNC-machined parts meet your exact specifications.

With Prolean’s advanced CNC machinery and seasoned precision engineering, you can rest assured that any material you choose will be transformed into parts with utmost precision. We cater to various industries, including aerospace, automotive, medical, and consumer electronics.

Click here to download Prolean CNC material list

Table: Material Selection at Prolean

| Material Type | Properties | Common Applications |

| Aluminum | Lightweight, corrosion-resistant, excellent thermal conductivity | Aerospace, automotive parts, consumer electronics |

| Stainless Steel | Durable, corrosion-resistant, aesthetically pleasing finish | Medical devices, food processing equipment, marine parts |

| Brass | Aesthetic golden sheen, acoustic properties, antimicrobial | Decorative fixtures, musical instruments, marine fittings |

| Titanium | High strength-to-weight ratio, biocompatible, non-magnetic | Aerospace components, medical implants, automotive parts |

| ABS Plastic | Impact-resistant, machinable, good dimensional stability | Prototypes, consumer goods, automotive components |

| Nylon | Wear-resistant, low friction, chemical resistant | Gears, bearings, insulators |

| Acrylic | Clear, UV resistant, polishable | Lenses, display cases, automotive lighting |

| Delrin | Dimensionally stable, high precision, natural lubricity | Precision gears, bearings, high-performance parts |

| PE (Polyethylene) | Impact-resistant, moisture-resistant, economical | Cutting boards, tanks, outdoor gear |

| PVC (Polyvinyl Chloride) | Strong, chemical resistant, fire retardant | Piping, valves, medical equipment |

| CFRP (Carbon Fiber Reinforced Plastic) | High strength-to-weight ratio, stiff, moldable | Automotive body parts, aerospace components, sports equipment |

| Fiberglass | Cost-effective, durable, non-conductive | Boat hulls, automotive body parts, construction |

| Kevlar-Reinforced Polymer | Impact and abrasion-resistant, lightweight | Protective gear, military applications, automotive |

| Metal Matrix Composites (MMC) | High-temperature performance, wear-resistant, thermally conductive | Engine components, aerospace parts, heat sinks |

Read More:

- Machinability of Material and Relation with CNC Machining

- Navigating the Terrain of CNC Machining: Metal Vs. Plastic

- CNC Machining of Thermoplastics: A Comprehensive Guide

- CNC Machining of Composites: Everything You Need to Know

Summing Up

Material selection is the linchpin of CNC machining, impacting the trajectory from design to delivery. This essential guide has charted the landscape of common CNC materials, spotlighting the unique advantages and suitable applications. Stainless steel, Alloy steel, Aluminum, Copper, Brass, and Titanium are the most common metals and alloys used in CNC machining. ABS, Nylon, Acrylic, Delrin, and Polyethylene are the most common plastics. Carbon fiber-reinforced plastics (CFRP), fiberglass, Kevlar-reinforced polymers, and metal matrix composites (MMC) are some composites adapted for CNC machining.

This knowledge serves as a beacon for CNC decision-makers, guiding them to make informed choices that align with their project’s goals. The right material not only meets the demands of the industry but also exceeds the expectations of the end-user, cementing a legacy of excellence in CNC machining.

FAQ’s

What types of materials are compatible with CNC machining?

Different materials, such as wood, metals, polymers, textiles, and composites, are compatible with CNC machines. However, the majority of machining tasks use metal and plastic.

What are the most common metals and alloys used in CNC machining?

The most popular metals in CNC machining include titanium, copper, brass, stainless steel, aluminum, and stainless steel. Materials are chosen based on the desired features and properties.

What distinguishing qualities do metal, alloys, and plastics have?

Depending on the specific metal, metals and alloys provide mechanical strength, hardness, wear resistance, and electrical & thermal conductivity. However, some specific properties depend on the particular metal. At the same time, plastics have several other features, including strong strength, lightweight, and electrical insulation.

What factors should be considered when choosing materials for CNC machining?

The choice of material for CNC machining depends on the project’s specific requirements, including the mechanical and physical properties needed, the application of the part, and cost considerations.

Does Prolean offer a wide range of materials for CNC machining projects?

Yes, Prolean offers more than 100 material options for CNC machining projects, including various metals, alloys, and plastics.

Does the choice of material affect the final product quality in CNC machining?

Yes, the selection of material greatly impacts the final product’s quality, durability, and performance in its intended application.

What are the common grades of brass used in CNC machining?

In CNC machining, C3604 and C3602 are popular brass alloy grades due to their high plasticity, corrosion resistance, good machinability, and strength.

How does the hardness of a material impact CNC machining?

The hardness of a material plays a significant role in CNC machining. Materials with high hardness levels may cause tool damage and require specific cutting tools and parameters for effective machining.

Great article , and informative! Any way I need custom ball-baring for chemical processing equipment. It need to be made with 17-4PH stainless steel.

Yes! we provide CNC machining of all stainless alloys including 17-4PH with tolerance of +_0.006mm.