Materials

Material Options For Machining

Prolean has a wide range of materials for your machining project, which offers plastic and metal with various strengths, infill, stiffness, colour, and other physical, mechanical, and chemical properties.

These versatile materials are matched with an analysis of each material’s CNC machining and fabrication capabilities to fulfil the project’s specifications. Feel free to contact our engineers for more details.

All uploads are secure and confidential.

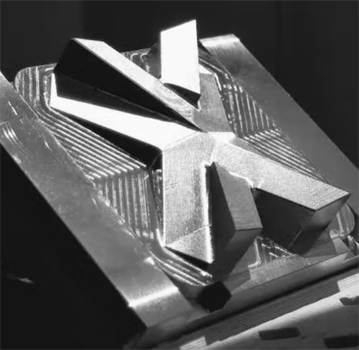

Our Metal CNC capabilities

Metal Machining at Prolean

Prolean offers Metal CNC machining services for various applications, from straightforward tools to complex aerospace components. We have been working to supply the parts for their operational machinery and other equipment for multiple industries, including automotive, aerospace, medical, pharmaceutical, oil & gas, and renewable energy.

To create required parts accurately and consistently, we have more than 100+ advanced CNC machines with various metal and alloy options, including steel, copper, aluminum, titanium, brass, and others. These can maintain a high accuracy level despite the complexity and volume of production.

Our manufacturing and quality control team ensures the products’ standards by scrutinizing each stage of the machining process. Even for complex items, we believe in maintaining the supply chain so that you receive delivery within 10 days of ordering. We will send you a pricing estimate within 24 hours. All you have to do is upload your parts’ CAD designs in any format.

Metal Milling

Metal machining is the process of converting raw metal sheets into desired functional shapes. CNC refers to Computerized Numerical Control and can produce accurate parts with tight tolerance according to uploading the CAD file. All the instructions are digital, and machines manipulate tools around a varying number of axis with high precision. Prolean provides 3-axis and 5-axis CNC machines that fabricate intricate geometric designs out of sheet metal to meet your needs.

We provide Metal milling, turning, drilling, and all the machining operations you need for your project.

You are just four steps behind getting your metal parts.

1. Upload your Design

Upload the CAD file in any format (. DWG, DWX, DXNX, or any popular form) to get the quotation. If you have multiple designs, upload them all simultaneously; we will send you a combined cost estimation.

2. Choose the metal and process

We have 50+ metals and alloys with a range of surface finish and quality options for you. Select the metal according to your requirements and the CNC machining process.

3. Payment and Order

Once you select the metal and manufacturing approach to confirm your production volume, our engineers will analyze the CAD file and proceed further. You can pay through Bank wire transfer, PayPal, and more.

4. Get the package to your door

You will receive your delivery at your shipping address within 10 days, depending on the complexity of the parts. However, thanks to our automated tracking system, you can use your Prolean account to track your package whenever you wish.

Advantages of collaborating with Prolean for your metal parts

- Metal selections: We have 50+ metal & alloy options for you. Choose one that meets the physical & mechanical properties of your requirements.

- Quick Turnaround: Our advanced 3-axis & 5-axis CNC machines can produce highly accurate parts within 10 days.

- Custom finishes: Choose the required Finishes on your metal parts from various alternatives.

- Quality & Standard: Our expert engineers inspect each manufacturing stage to ensure the quality and standard of your metal parts.

- Tolerance & Precision: We maintain the tolerance under ISO 2768 and ISO 286.

- Fast Delivery: We have an extensive shipment network to deliver your parts quickly. Check the time on the quotation.

CNC Machined Metals

Our Plastic machining capabilities

Plastic for Machining

Plastic is the best alternative for metal parts for many reasons, such as being lightweight, low cost, and excellent machinability. Each type of plastic involves different beneficial properties such as strength and hardness. There are numerous types of plastic materials that Prolean offers, with a range of physical and mechanical properties to match the requirements for different applications.

CNC Plastic Machining at Prolean

The process of shaping raw plastic sheets and blocks into the desired functional shapes is known as plastic machining. Computerized Numerical Control, or CNC, can create precise parts based on CAD files with strict tolerances. Plastic CNC machining entails accurately producing the desired shape while removing undesirable geometries from the workpiece using various cutting tools.

Prolean has been collaborating with different industries to supply simple Home appliance parts to complex aerospace parts. We are a professional service provider of plastic machining for almost every application with a CAD file. Using advanced 3-axis and 5-axis CNC machines, we can create precise plastic parts with 50+ plastic material options for any ordered volume and complexity of parts. Upload your CAD file and get the quotation to start working with us.

Advantages of working with us for Plastic Machining

- 50+ plastic options: We have different machining material options, including ABS, PEEK, Nylon, PVC, Delrin, Acrylic, Polystyrene, Polypropylene, and many more. You can choose any plastic that justifies the physical & mechanical properties of the required parts.

- Quick Turnaround: Our advanced 3- axis & 5-axis CNC machines can produce highly accurate parts within 10 days, even for the complex ones.

- Tolerance & Precision: We maintain the tolerance under ISO 2768 and ISO 286.

- Quality control: Engineers from the quality control department closely inspect each stage of the plastic machining process.

- Fast Delivery: We have an extensive shipment network to quickly deliver your parts. Check the time on the quotation.

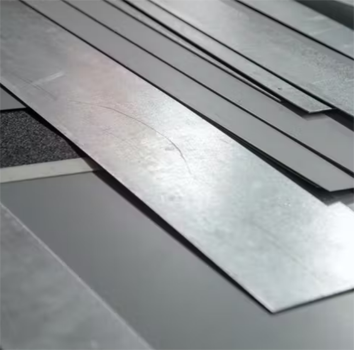

Sheet Metal Fabrication Capabilities

Sheet Metal Fabrication at Prolean

Prolean offers a wide range of Sheet metal fabrication capabilities to meet the needs of different industries: Automotive, Aerospace, Electrical, Electronics, medical, hardware, and many more.

We specialize in highly accurate CNC machining, welding, assembly, and surface finishing of simple to complicated mechanical parts. Here, we have a team of qualified engineers and operators for precise cutting, punching, Hardware Insertion, forming, bending, tapping, stamping, and many other services depending on the needs of your project.

We place high importance on quality, tolerance, life-cycle, and delivery time since we think only professional service can truly offer value for our clients.

How does it Work?

You send us the design of your sheet metal fabrication project. However, our engineers will also consult you to optimize the design if you think so once you get the quotation.

After the finalization of the design, we identify the fabrication steps. The process begins with cutting sheet metal into various sizes and completing the essential machining operations with different horizontal, vertical, and turning machining centers. After that, we assembled the pieces and finished the surface as needed.

Why Choose Prolean for Sheet Metal Fabrication?

High Range of Working Capacity: We can work with 50+ metal sheet options, which can be as thin as 0.008″ (0.203 mm) and as thick as 0.750″. (20 mm). And can be as much as 200 pounds (90.75 kg).

Tight Tolerance: We maintain the tolerance under ISO 2768 and ISO 286. ± 0.003” (0.075mm) a reasonable and functional tolerance. Hole to Hole ± 0. 005” (0.27mm).

Range of operations: precise cutting, punching, Hardware Insertion, forming, bending, tapping, stamping, and many others.

Custom finishes: Choose the required Finishes on your metal parts from various alternatives.

Quality & Standard: Our expert engineers inspect each manufacturing stage to ensure the quality and standard of your metal parts.

Sheet Metal Materials

- Aluminum (5052)

- Aluminum (6061-T6)

- Copper 101

- Copper 110

- Steel (1018 Low Carbon)

- Stainless Steel (301

- high Carbon)

- Stainless Steel (304L)

- Stainless Steel (316L)

FAQ

Are your materials certified?

Yes, ProLean offers certified materials. We have material under ISO, AMS, EN, ASME, ASTM, and other certifications. You let us know your required material certification while requesting the quotation. Our experienced engineers are willing to make the process simple for you if you need assistance with selecting material standards or other design & technical issues.

What if the material I need does not appear on the list?

Yes, we offer all the materials that are CNC machinable. If you did not find the material on the list, you could still send us the quote request. However, there is the chance that we have the material on the list, but you miss out because the material has a different name in different countries. For example, A204 Gr. B Carbon steel is American (ASTM / ASME / SAE) standard, while the same material has a different name according to the standard in other countries, Europe (EN) 16Mo3, France (NF) 15D3.

Do you provide help throughout the process?

Yes, we believe in regular communication with the customers. Once you get the quote, our engineers will consult you to finalize the design. The contact will be on until you get ordered in your door to optimize the quality and functionality of parts.

What is the best metal for CNC machining?

Aluminum is the most common metal in CNC machining because it has an excellent strength-to-weight ratio and machinability. However, the ideal option for you will rely on the parts’ needed properties and functionality. We have more than 50 different metals that are machinable.

What is the best plastic for CNC machining?

ABS is the most common material used in CNC machining because it has low cost, high mechanical strength, and excellent Machinability. However, the ideal option for you will rely on the parts’ needed propertiesand functionality. We have more than 50 different plastic that is machinable.

Related Blog

ABS Plastic: Know the Properties, Processing, and Uses

ABS plastic is strong, durable, and widely versatile.

4340 Alloy Steel Machined Parts: Applications & Properties

High-strength 4340 alloy steel machined parts

Comprehensive Guide to CNC Turning Titanium 2026

CNC turning fundamentals for titanium alloys

Get Your Parts Made Today

All uploads are secure and confidential.