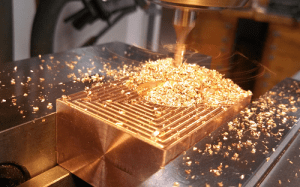

Copper CNC Machining

All uploads are secure and confidential.

Introduction to Copper

Copper is used in various applications, from heat and electrical appliances to aesthetic products, because of its excellent thermal and electrical properties, including its shiny reddish-brown appeal.

Copper is highly machinable with CNC machining operations, so it is easy to maintain the dimensional stability of products. Unlike steel and ferrous materials, it does not form rust on the surface but strengthens high strength once it gets alloyed with other metals. Copper also offers ductility, which makes it perfect for wire and cable applications.

Copper At a Glance

| Process compatibility | Applications | Alloys | Tolerances | Wall Thickness | Max Part Size | Strengths | Lead Time | Price |

| CNC Mill CNC Lathe | Bus bars, gaskets, wire connectors, and other electrical applications with High accuracy and repeatability. | Copper 101 Copper 110 | Not lower than ±0.125mm (±0.005″) based on the drawing ( ISO 2768) | Minimum 0.80 mm (~0.03”); may vary depending on alloy and wall thickness-to-planar dimension ratios | 200 x 80 x 100 cm | High Mechanical strength, with accuracy and repeatability | Minimum 3 days. Not more than 10 days; for all compex parts. | $$ |

Try Prolean Now!

Precision CNC Machining for Copper Components at Prolean

Prolean is a leading Copper CNC Machining Service provider with a reputation built on precision, quality, and customer satisfaction. Our array of services, from Custom Copper Parts Manufacturing to Copper Machining for Industrial Applications, is underpinned by our Copper CNC Machining Service commitment. Our clients can rely on us whether a single prototype or an entire production run.

1. Custom Copper Parts

Custom Copper Parts Manufacturing is a testament to our adaptability and customer-focused approach. At Prolean, we don’t just produce parts; we create bespoke solutions that resonate with our client’s unique vision. Our Expert Copper Machining Solutions are designed to accommodate any complex geometries.

2. Copper Prototype Machining Services

With our Copper Prototype Machining Services, we help clients transition from conceptual designs to tangible products. This service is essential for testing and refining product designs before they enter mass production. Our Prolean CNC machining services can produce prototypes with rapid turnaround times, a cornerstone of our Fast Copper CNC Machining Service. This speed does not come at the expense of quality; each prototype is crafted to exhibit the highest standards of our Top Copper CNC Machining Expertise.

Copper Machining for Industrial Applications involves creating parts that can withstand the rigors of industrial use. Our CNC Machining of Copper Alloys is precise and robust, ensuring each component functions flawlessly within complex machinery.

Industries ranging from aerospace to plumbing trust our Cost-effective Copper CNC Machining Service to supply parts that meet their budgetary and performance criteria. Furthermore, providing an Online Quote for Copper CNC Machining makes it easy for industries to begin their journey toward acquiring superior Copper components.

Cost-Effective Quality & Precision for Copper Components

Navigating the intricate balance between cost, quality, and precision in Copper machining is a craft that Prolean has mastered. Our approach to Copper CNC Machining marries affordability with the high standards of craftsmanship required to produce superior Copper components. This equilibrium ensures that our clients receive the best of both worlds: Cost-effective Copper CNC Machining Solutions that do not compromise on the meticulousness and durability needed for high-performance parts.

Ensuring Quality Without the Hefty Price Tag

In Copper CNC Machining, the belief that lower costs equate to lower quality is debunked at Prolean. We stand as a Copper CNC Machining service company that places equal emphasis on affordability and quality. This dual focus is achieved through:

- Streamlined Processes: We eliminate inefficiencies that often lead to unnecessary expenses by continuously refining our machining operations.

- Volume Economics: Leveraging the scale of operations allows us to offer competitive Copper CNC Machining Price points without sacrificing quality.

- Technological Advancements: Investing in the latest CNC technology enhances precision while reducing waste and operational costs.

Transparency and Trust in Copper CNC Machining Pricing

At Prolean, we understand that clarity in pricing is as important as the cost itself. That’s why we prioritize:

- Transparent Quoting: Our online quoting system provides a clear breakdown of the Copper CNC Machining Cost, ensuring clients know what they are paying for.

- No Hidden Fees: What you see is what you get. With Prolean, the quoted Copper CNC Machining Price is comprehensive, with no unexpected charges.

- Value-Added Services: Our expertise extends beyond machining; we offer design consultation and post-production analysis, adding value without additional costs.

ProleanTech provides Cost-effective Copper CNC Machining Solutions that set the industry benchmark for quality and precision at an accessible price point. Our Quality control team ensures the Quality Assurance in Copper CNC Machining that each component we produce reflects our Expertise in Copper CNC Machining Services. You can trust us to deliver top-tier Copper CNC Machining solutions aligned with their financial and engineering objectives, solidifying our status as a premier Copper CNC Machining service company.

Request a Quote and Start Your Copper CNC Machining Project

Embarking on a new Copper CNC Machining project begins with a simple step: requesting a quote. Prolean streamlines this initiation process, ensuring that obtaining an Online Quote for Copper CNC Machining is quick, easy, and transparent. This approach empowers clients to make informed decisions and kick-start their machining projects.

1. Simplifying the Quotation Process

The journey from concept to production is often complex, but it doesn’t have to be. Prolean, as an Online Copper CNC Machining service provider, has refined the quotation process to be as effortless as possible. The first step involves understanding the client’s needs and the specifics of their project. Then, leveraging our Precision Copper CNC Machining Techniques, we provide a detailed quote that encapsulates the scope and cost of the project. This system is designed to save time and provide clarity, setting a solid foundation for the project.

2. Instant Access to Global Expertise

We are committed to Fast Copper CNC Machining Services, and reliable customer support underscores our role as the biggest Copper CNC Machining quoting service. You can start your project with Prolean from anywhere in the world.

- Ease of Use: Our online platform is user-friendly and designed to guide you through the quotation process easily.

- Rapid Response: Receive Instant Quotes for Copper CNC Machining Services without the wait, allowing for swift project commencement.

- Global Reach: Regardless of your location, our international Copper CNC Machining services ensure that you have access to top-tier machining expertise.

3. Precision and Customization at Your Fingertips

Prolean’s dedication to precision and customization is evident in every quote we provide. Our clients benefit from the following:

- Tailored Solutions: Each quote is crafted to reflect the unique requirements of your Custom Copper CNC Machining project.

- Detailed Breakdowns: We believe in transparency, offering detailed cost breakdowns that help in planning and budgeting.

- Expert Consultation: Our team is available to discuss your project needs, ensuring your quote is accurate and all-inclusive.

By requesting a quote from Prolean, you’re not just inquiring about costs; you’re accessing a partnership that values precision, speed, and customization.

Get Your Parts Made Today

All uploads are secure and confidential.