CAPABILITIES

CNC Machining Service

We provide CNC machining services of any complexity for rapid prototypes and production parts. Start a one-hour CNC quote from a real engineer, and get your parts made as fast as one day.

- Tolerances down to ±0.0002″ (0.005mm)

- Parts as Fast as one day

- Aluminum, Steel, Copper, Polymers & More

- 3 & 5-Axis Milling

All uploads are secure and confidential.

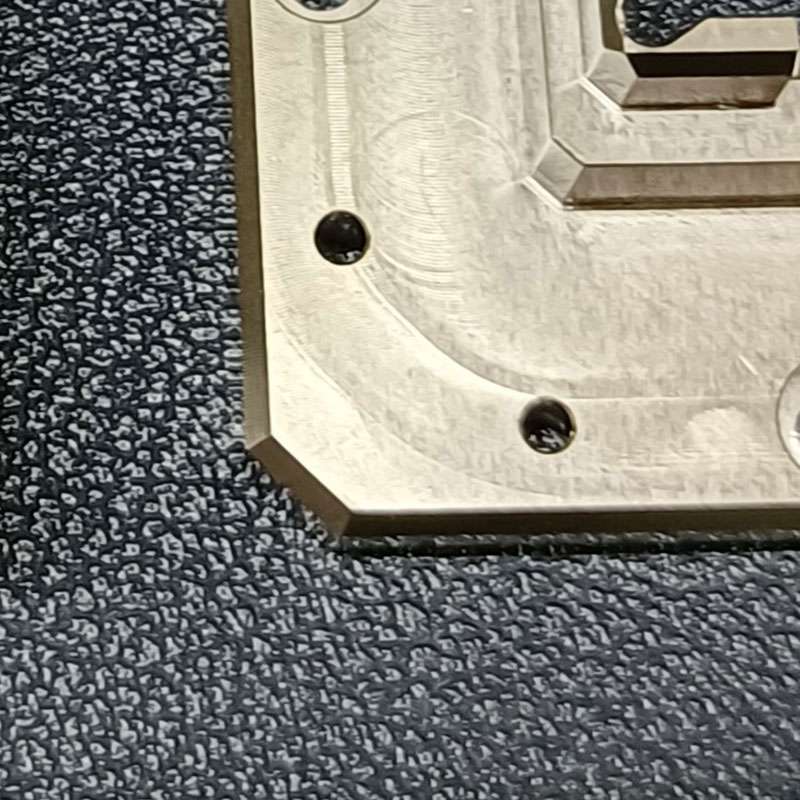

CNC Milling

Our 3-axis & 5-axis CNC milling center is dedicated to creating complex geometries and features.

CNC Turning

With our latest CNC lathes and turning centers, even the most complex turned parts are possible.

Turning-Milling

Allow multiple operations on a single machine, perfect for high-precision parts with complex geometries.

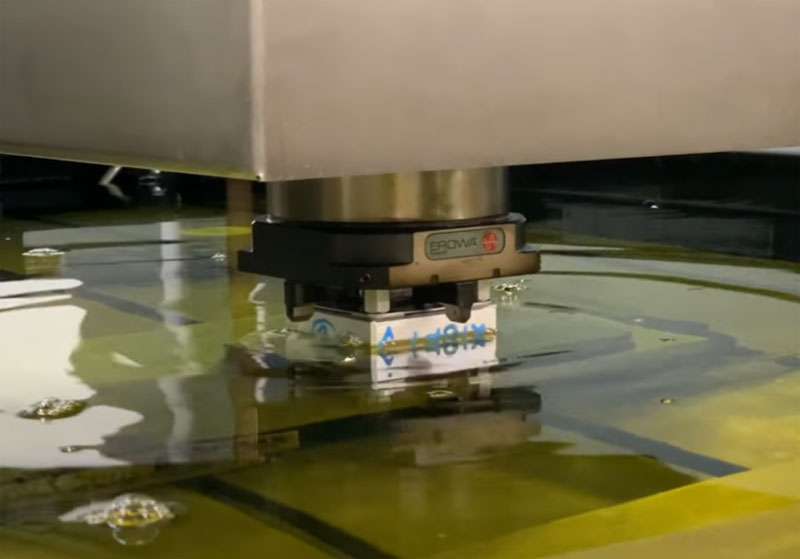

Electrical Discharge

Highly accurate machining service of cutting metal to precise shapes using electricity.

Wire Cut

Our wire cut services can provide high precision tolerances, as tight as ±0.0002″ for various industries and applications.

Why Choose Our CNC Machining Service

Are you looking for precise metal and plastic parts for your project? If So, CNC machining can produce all the complex shapes with high accuracy.

Prolean offers various CNC machining services with high precision and competitive prices for prototype development to large-scale production. According to your specifications, using our sophisticated CNC machine, we create precise parts from 100+ material options for all the industry, including automotive, aerospace, Defense, agriculture, and many more.

In addition, our quality control team closely supervises the Machining process to ensure the quality and standard of the parts.

How to Order Parts?

Get a free quote from a real engineer; once we receive your design, our engineer will review it and send you a quote as fast as one hour.

Get A Quote Within 12 Hours

Upload your design or email our engineer directly and get your quotes as fast as one hour.

Start Production

Your parts will be made once your orders are confirmed. Besides, you will get real-time order updates of the production status from our order tracking system.

Receive Your Part

After all parts pass QC inspection, they will be well packed from transportation accidents. Then, your custom parts are delivered straight to your doorstep.

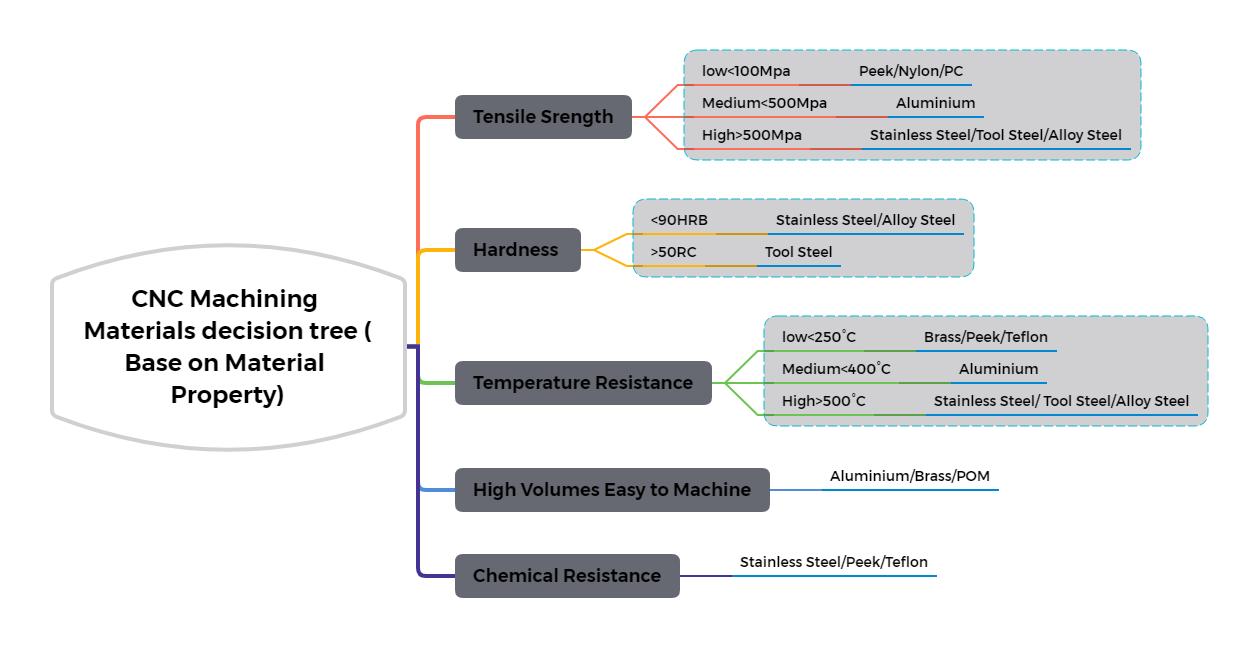

CNC Machining Materials Options

Metals

Aluminum

Aluminum is a superior metal in terms of strength-to-weight ratio. It offers High Machinability, ductility, and thermal & electrical conductivity. Parts with aluminium also become highly resistant to corrosion.Alloys

Aluminum (MIC6) Aluminum (2024) Aluminum (5052) Aluminum (5083) Aluminum (6082) Aluminum (6061-T6) Aluminum (6063) Aluminum (7075-T6) Learn more

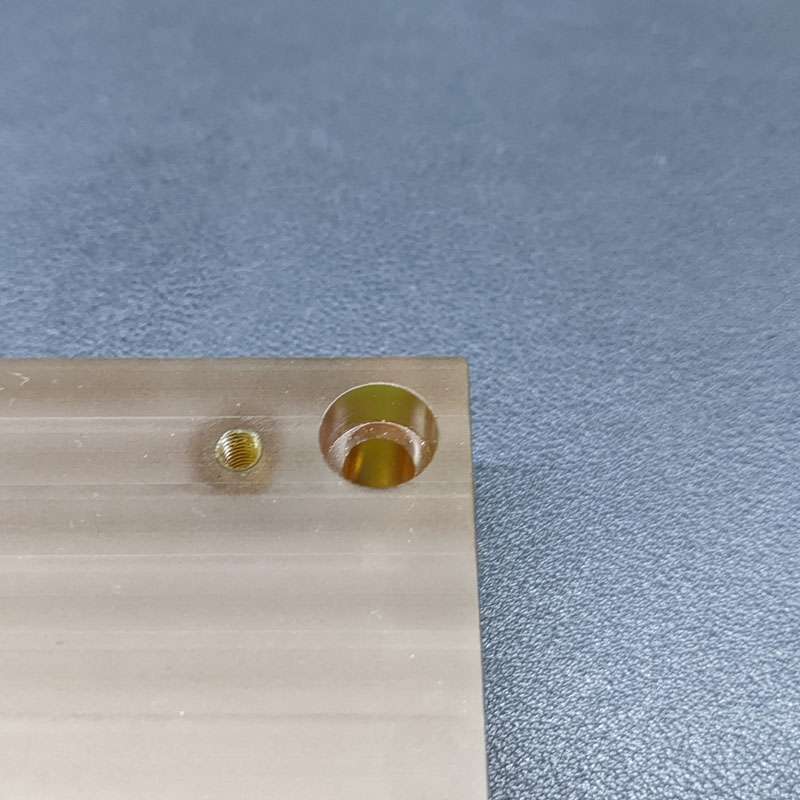

Brass

Golden shiny color, low friction, excellent Machinability, and high electrical & thermal conductivity. Brass can be easily machined and the best choice for low-friction applications.Alloys

Brass (360) Learn more

Copper

It offers good strength, hardness, and excellent corrosion resistance with superior heat and thermal conductivity. It also has a very appealing aesthetic.Alloys

Copper 101

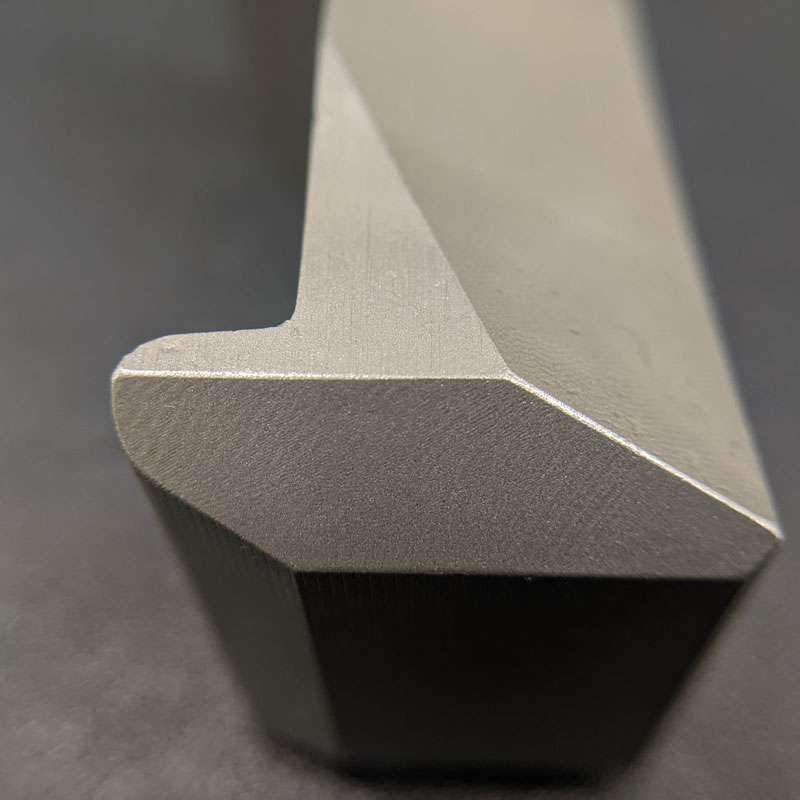

Titanium

40% more strength-to-weight ratio than steel, Excellent corrosion resistance, low thermal expansion, and biologically inert. These properties make it perfect for automotive, aerospace, and medical applications.Alloys

Grade 1 Titanium Grade 2 Titanium Grade 5 Titanium(TC4, Ti6Al4v) Learn more

Alloy Steel

High mechanical strength, toughness, resistance to wear and fatigue, and sturdiness. In addition to carbon, other alloying elements can be added depending on the needed mechanical and physical qualities.Alloys

Alloy Steel 4130 Alloy Steel 4340 Steel (4140 Alloy) Steel (1018 Low Carbon) Tool Steel (A2) m2 d2 20GR Zinc-Galvanized Low-Carbon Steel Carbon Steel (1045)

Stainless Steel

High mechanical strength, Thermal, Wear, and Corrosion resistance. Stainless steel is low-cost and can be machined easily. Parts made from Stainless steel are durable and do not lose that strength over time.Alloys

Stainless Steel 201 Stainless Steel 301 Stainless Steel 303 Stainless Steel (304L) Stainless Steel (316L) Stainless Steel (410) Stainless Steel (420) Stainless Steel (440C) Stainless Steel (17-4 PH) Learn more

Cast iron

It offers three to five times higher compression strength than steel. Low-notch sensitivity, Good Resistance to deformation, excellent anti-vibration, and consistent mechanical propertiesPlastics

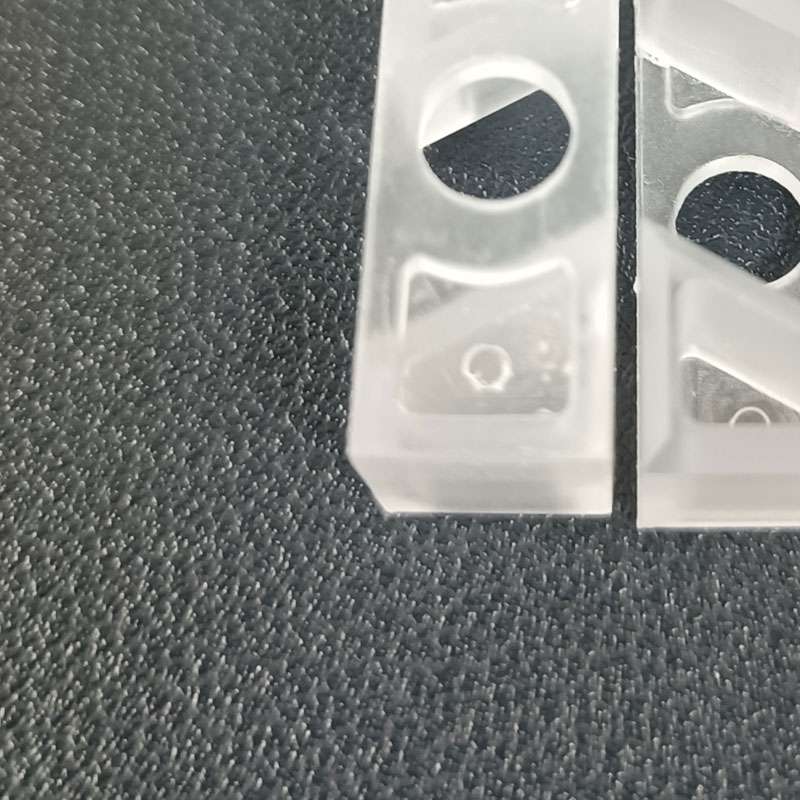

- ABS

- Acrylic

- Delrin

- Garolite G-10

- FR4

- Polyethylene (PE)

- Nylon

- PEEK

- Polycarbonate(PC)

- Polypropylene(PP)

- PPSU(Polyphenylene sulfone resins)

- PPS (Polyphenylene)

- PTFE (Teflon)

- polyetherimide (PEI)

- PMMA (Acrylic)

ABS

Excellent strength, extraordinary impact, and abrasion resistance with chemical inertness. ABS can be machined easily and is very easy to paint and glue.

Acrylic

Acrylic is a lightweight, rigid thermoplastic with optical clarity. It is one of the superior alternatives to glass, offering excellent weather and chemical stability.

Delrin

High tensile strength, excellent Machinability, Stiffness, wear resistance, creep resistance, and low friction. Overall, Delrin is the ideal replacement for metal.Subtypes

Delrin (30% Glass-Filled)

Garolite G-10

High strength-to-weight ratio, fire resistance, low thermal expansion coefficient, and water absorption coefficient are entirely free from corrosion risk. Garolite is perfect for insulating parts and electric circuit boards.

FR4

FR-4 is a manufacturing material with strength almost equal to steel and lightweight. It is a perfect fit for making parts for the electrical marine industry since it is flame retardant, has a negligible water absorption coefficient, and is machinable.

Polyethylene (PE)

Polyethylene is known for its malleable properties. It offers a high strength-to-weight ratio, impact strength, chemical inertness, temperature, and weather resistance.Subtypes

UHMW-PE HDPE

Nylon

Mechanical properties include high resilience, tensile strength, and fatigue resistance. Nylon is a flexible manufacturing material that is highly resistant to abrasion, heat, chemicals, water, and oils.Subtypes

Nylon (30% Glass-Filled)

PEEK

A versatile engineering material with high mechanical strength. It provides excellent thermal and chemical resistance. Parts from PEEKS are durable and can be operated at an extensive range of temperatures (up to 2600).Subtypes

PEEK (30% Glass-Filled)

Polycarbonate(PC)

Exceptional mechanical properties, including impact strength, toughness, Stiffness, and creep resistance. Because of its transparent nature, Polycarbonate (PC) is a lightweight alternative to glass. Learn more

Polypropylene(PP)

A low-cost material with good Stiffness, impact resistance, and chemical stability. PP also offers excellent wear resistance and elasticity.

PPSU(Polyphenylene sulfone resins)

PPSU is used in various sectors because of its lightweight, high toughness, excellent impact resistance, high heat resistance, chemical stability, transparent color, and wide operating temperature range

PPS (Polyphenylene)

The unique combination of Physical, mechanical, and chemical properties. Excellent strength, rigidity, fatigue endurance, creep resistance, chemical inertness, and a wide range of working temperatures for the fabricated parts make it a perfect choice for electrical applications with high operating temperatures.

PTFE (Teflon)

High chemical inertness, thermal stability, electrical insulation, and corrosion resistance. Teflon is a low-friction substance that is perfect for making non-sticky and sliding parts for various industries. Learn more

polyetherimide (PEI)

Semi-transparent, high strength, rigidity, thermal stability, chemical inertness, and dimensional stability. Parts made from PEI can work for an extended period without stress cracking.

PMMA (Acrylic)

Transparent, lightweight, strong mechanical strength, hardness, thermal stability, and chemical inertness. Transparent nature makes it an excellent alternative to glass.CNC Machining Material Guide

CNC Machining Service Finishing Options

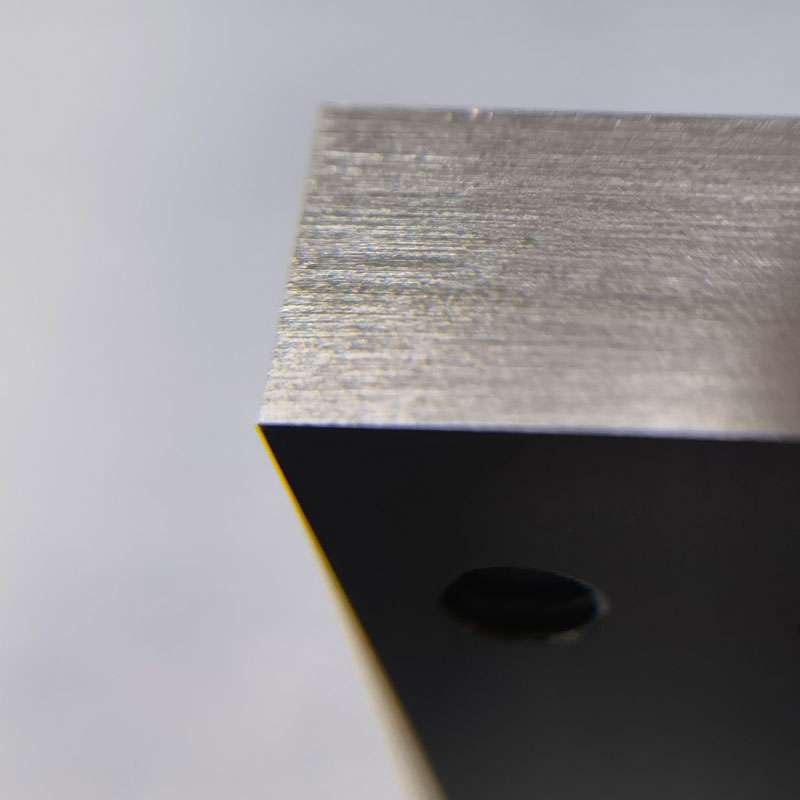

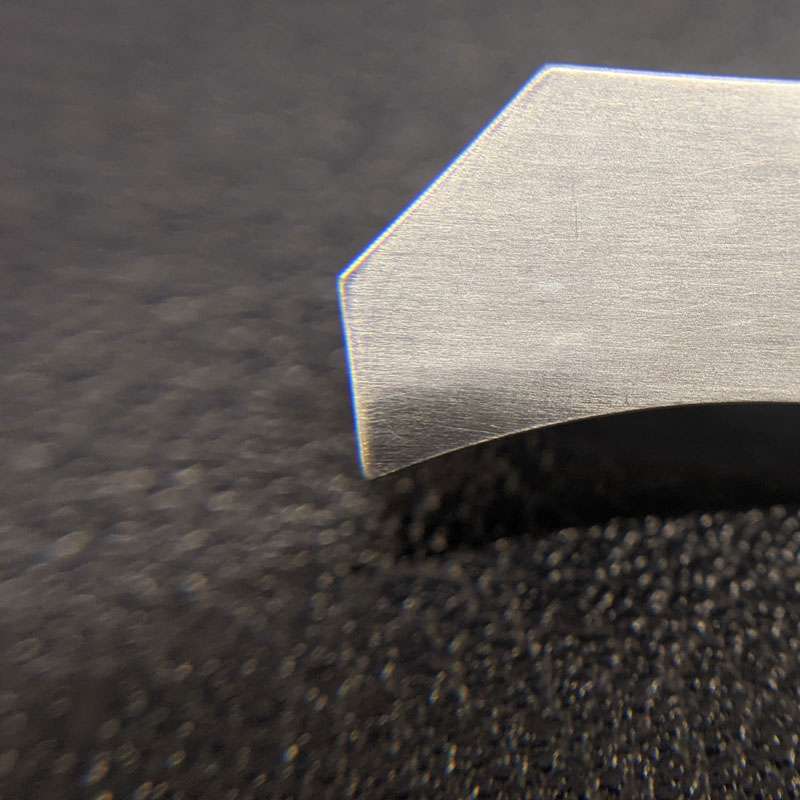

As the machined or deburring

The machined or deburring finish is the standard finish where unwanted attach chips are removed with deburring tools, and sharp edges are chamfered to smooth the surface (3.2 μm).

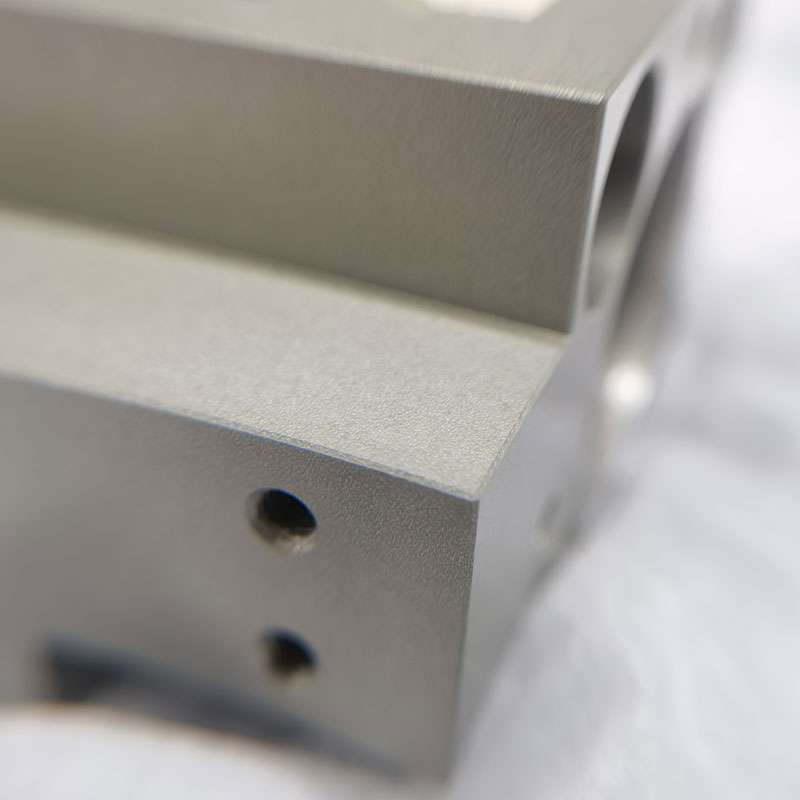

Bead Blasted

Bead blasting produces a matte texture, removing all the marks of machining tools. It applies to ABS, Aluminum, Brass, Stainless Steel, and Steel parts.

Anodizing

Anodizing involves adding an aluminum oxide coating to aluminum and its alloys. The layers, which come in various colors, increase strength and shield the surface from corrosion.

Powder coating

Powder coating is the electrostatically applying of dry powder to the surface. It produces a thin layer providing excellent resistance to wear, corrosion, and abrasion.

Polishing

Physical rubbing of a metal surface to create a shiny surface is called a polishing surface finish. It increases the reflectivity and does not affect the dimensional stability of parts.

Brushing

Brushing is achieved by applying an abrasive brush to the metal surface, which produces a unidirectional satin finish. And it is not recommended for highly corrosive materials.

Smooth machining

Smooth machining is done by controlling the machining process, such as feed rate & cutting speed. It minimizes the tool marks and risk of corrosion.

Black-Oxide

Black oxide finish reduces surface reflectivity and offers mild corrosion protection. It involves adding a thin layer of magnetite to the surface.

Electro-less Nickel Plating

A thin layer of Nickel is created on the surface from a nickel-containing solution without electrolysis. Electro-less nickel plating provides a shiny appearance, excellent hardness, abrasive, wear, and corrosion-resistance to the substrate material.

Alodine

Provides excellent corrosion resistance property to the aluminum parts with greenish-gold color. It is the low-cost and quick surface finishing approach.

Electroplating

Electroplating increases the hardness of the steel &aluminum parts. It offers excellent corrosion, wears, and abrasion resistance.

Nickel plating

Make the parts super resistive to corrosion. It enhances mechanical strength, hardness, wear resistance, lubricity, and ductility. Nickel plating is applicable in different materials, including Steel, aluminum, copper, and brass.

Passivation

Enhance the appearance and functionality of the parts. After Passivation, parts of Steel and its alloys become super resistive from corrosion.

Yellow Chromate conversion coating

A shiny appearance with goldish color provides excellent corrosion resistance. It is applied on the surface of aluminum, magnesium, and their alloys. A layer of chromate also enhances the conductivity of parts

PTFE (Teflon) Coating

The Teflon layer on the parts offers excellent corrosion resistance, water resistance, and non-stickiness with a non-reactive surface.

Fine machining

The higher-precision machines produce delicate machining surfaces by utilizing sharper tools and regulating feed rate and cutting speed. Surface roughness up to Ra 0.8 μm can be maintained with smooth machining.

Laser Cladding

Provides excellent corrosion, wear, and abrasion resistance. Laser Cladding is also effective for treating minor surface imperfections such as cavities, tiny cracks, and rust damage.

Sanding

Provides a random, non-linear texture with a shiny, high gloss finish. However, it might be unable to create sharp corners and pockets

More

Provides a random, non-linear texture with a shiny, high gloss finish. However, it might be unable to create sharp corners and pockets

Precision Machining Tolerances

CNC Machining Service

Type | Tolerance | No Drawing |

| Linear dimension | +/- 0.025 mm +/- 0.001 inch | ISO 2768 Medium |

| Hole diameters (not reamed) | +/- 0.025 mm +/- 0.001 inch | ISO 2768 Medium |

| Shaft diameters | +/- 0.025 mm +/- 0.001 inch | ISO 2768 Medium |

| Part size limit | 950 * 550 * 480 mm 37.0 * 21.5 * 18.5 inch | ISO 2768 Medium |

3 Ways to Ensure Perfection

Standards

Metals: ISO-2768 fH (fine)

Plastics: ISO-2768 mK (medium)

Metric threads tolerances: ISO 965-1 standard UN Threads Tolerances: ASME B1.1-2003 standard

Knurling: ISO13444:2012 standard.

Our factory is ISO 9001:2015 certificated

Inspection and Protection

Constant visual inspection conditions

Quantification of cosmetic surface quality

Process requirements

Part cleaning and Protection

Quality Inspection Report

Inspection Confirmation

Dimensional confirmation

Appearance confirmation

Quality documentation

Technology Overview

What is CNC machining?

CNC refers to Computer Numerical control. CNC machines are electro-mechanical devices that can manipulate tools around varying axes with high precision as per instructions from the computer. As a result, the CNC machine can create complex geometrical parts with high precision in less time. In addition, because all machining controls, such as feed rate, tool positioning, and speed, are automated, tight machining tolerance is achievable compared to labor-intensive machining approaches.

Principle of CNC machining

The operation working principle of a CNC machine consists of four primary steps:

• Uploading a CAD file

• Digital instructions

• Adjusting the workpiece position

• Running the machine with programming

The CAD file of the parts to be machined is first uploaded, and instructions are sent via digital command before the tool begins to form the shape with the attached workpiece.

Workpieces can be machined in multiple axes depending on machine capacity (3-axis, 4-axis, 5-axis, & 6-axis). An electric motor controls each axis’ movement.

The cutting tool moves following the digital command, and operations such as tool speed, feed, depth of cut, and others are controlled by coding (CNC programming). A warning system also alerts the operator to any operational errors or safety precautions throughout the machining process.

Different types of CNC Machining

Numerous (10+) types of CNC machines are designed for specific machining operations. For example, CNC milling creates complex geometries that allow up to six-axis machining. Milling rotates the workpiece and removes the tool following the uploaded drawing and command. CNC routers are functionally similar to CNC milling machines. Still, they are used for softer materials such as aluminum, wood, and plastics—the CNC routing machine routes the spindle and tool path.

CNC Turning is primarily used for cylindrical workpieces, and it renovates the material from the outer surface of the rotating workpiece for facing, chamfering, and other operations. Its caliber is generally measured by rotating speed. CNC plasma cutters use electronically ionized gas (plasma) to cut the workpiece precisely. The plasma beam strikes the metal and cuts it, even though the plasma temperature can reach 10,000 degrees Celsius.

The process of CNC machining

CNC machining is a type of manufacturing in which computer software dictates the movement of tools and machinery. CNC machining can control various complex machinery, including grinders, lathes, mills, and routers. Three or more dimensional cutting tasks can be completed using a single set of prompts with CNC machining.

Under CNC Machining, Machine tools function through numerical control. A computer program is customized for a workpiece. The machines are programmed with a CNC machining language called G-code that essentially controls all features like feed rate, coordinate, location, and speeds. In addition, the computer controls the exact positioning and velocity of the operation.

See why customers dig us

Yesterday, I received the parts for my musical instruments. These are incredibly consistent and accurate.

The delivery timing and quality of the CNC machining service amaze me. I would recommend Prolean with my other business friends too. Thank you!

-Ema Alves, Owner at Conserve the Sound

Prolean has been manufacturing numerous customized components for my metal-workshop machines for the past two years, and I have found that they are excellent with their CNC machining services.

I am delighted with the level of quality they offer and the precision of the customized machine parts.

-Mason Lucas, Purchasing manager at Alpha Manufacturing

ProLean has consistently provided me with excellent milling service using their 5-axis CNC machine. I've worked with many contract manufacturers, but other than ProLean, I've never found accurate tolerance on my parts.

We were able to satisfy our client's needs thanks to Prolean's prompt reaction. Additionally, I frequently found that their engineers are always willing to innovate creatively to deliver top-notch service.

-Tanesha Adesina, Technical manager at Bossard Technology

I needed a quick prototype for my research, but I had no idea that their CNC machines were so sophisticated and could produce it in just three days. The prototype was quite precise and fell within the tolerances of the CAD I provided.

Thumbs up! Not just selling, nothing else count for them; Service Service Service, first!

-Jason Barrett, Individual Mechanical Engineer

I have been collaborating with ProLean to produce PCB boards for our business For the last year. Continuous technical assistance and communication with the manufacturing.

Engineers and mechanics help us continuously satisfy our customers' expectations. I hope that this collaboration continues for a very long time.

-Rugen Thakur, Mechanical Engineer at Cipsa- Tech.

The heat sink was marvelous, within the critical tolerance, and the surface finish was excellent. The fan position, seal, and fin structure all performed as intended. I'll tell my friends and other electronics companies about your service.

I appreciate your exceptional communication and CNC-Machining service.

-Blake Henderson, Product Designer at MechaTronix,

It's challenging to describe the Prolean in a few words, but the three stand out: Fantastic, Amazing, and Perfect.

The best addition to our firm has been Prolean. With their cutting-edge 5-axis CNC machine, they are providing the service of replacing and installing new components in our pharmaceutical development industry with accuracy and cleanliness as their top concerns.

-Jose Gaonkar, Mechanical Engineer at Cadila Pharmaceuticals

I purchased several custom CNC-machined parts for mechanical tools from Prolean, and I want to remark that their quality and accuracy were far superior to those of some of the more prominent machine tool manufacturers.

Prolean's engineers could explain everything to me in a language I could comprehend, even though I am not a mechanist and may have asked the wrong questions.

-Evert Wagner, Product Designer at HYDAC Supplier

FAQ

Technical FAQ’s

What is the achievable tolerance limit for CNC machining?

What are the standard CNC machining tolerances available from Prolean?

How large of a part or panel can be CNC machined with Prolean?

General FAQ’s

Why choose CNC Machining

What are the industries where CNC machining is applicable?

What are the common types of CNC machining?

Related Blog

CNC Machining Titanium Vs Aluminum: Choose The Best Metal

Aluminum vs Titanium- which metal gives optimal strength and drives the cost of your projects?

Micro CNC Machining: Process, Types, and Advantages

The processes, types, and benefits of Micro CNC Machining.

CNC Machining Titanium Vs. Stainless Steel: Which Gives Quality Parts?

CNC Machining Titanium and stainless steel differences in different aspects.

Get Your Parts Made Today

All uploads are secure and confidential.