Traditional Manufacturing

For centuries, manufacturing has been synonymous with huge machines, warehouses, and thousands of products. This traditional manufacturing method is capital-intensive and involves a process that cannot be altered. Until the rise and prevalence of the online shopper experience, this traditional manufacturing process remained the status quo.

However, in recent times, consumers and end-users are now demanding faster delivery times and accurate production. The traditional manufacturing process couldn’t keep up with these demands. This led to the birth of the manufacturing on-demand process.

This article will address every facet of this new manufacturing system, its advantages, challenges, and the various technologies involved. If you want to understand the manufacturing on-demand system fully, this article contains everything you need to know.

What is Manufacturing on Demand?

On-Demand Manufacturing

Just as the name implies, Manufacturing on Demand (MOD) involves manufacturing parts or products only when the consumer needs them and in the quantities that it is needed. This is in contrast to the traditional manufacturing method, where manufacturing companies make products in large quantities in anticipation of demand. This system is also known as on-demand manufacturing, custom manufacturing, or cloud manufacturing.

Advantages of Manufacturing on Demand

Manufacturing on demand has proven to be an advantageous method of manufacturing products compared to the traditional system. Explained below are the various advantages that come with the system:

Flexibility and Scalability

One of the major advantages of manufacturing on demand is that it offers flexibility. Due to the smaller setups involved in manufacturing, manufacturers can easily change parts for new products with minimal costs. This is not possible with traditional manufacturing setups, as changes in the production setup would be costly. Also, manufacturing on demand allows testing the product’s feasibility before scaling it to larger quantities. Since the process can allow for the production of smaller quantities, properly examining the product’s scalability is easier.

Reduced Lead Times

Traditional manufacturing is synonymous with longer lead times, with many processes taking months before delivery. However, with on-demand manufacturing, manufacturers can deliver much faster due to the speed associated with the whole process.

Cost Effectiveness

Traditional manufacturing is capital-intensive, as larger machines, storage, and logistics systems always raise manufacturing costs. However, with custom manufacturing, products are only made based on demand; hence they can be shipped immediately after production, eliminating the need for storage.

Customization

One element that was largely hindered in traditional manufacturing was an innovation. Due to the rigidity of the process, users couldn’t make changes to product designs to large extents. However, with on-demand manufacturing, consumers can easily customize their products and make design iterations as needed.

Reduced Inventory Costs

As products were made in large quantities in traditional manufacturing, they didn’t only require storage but also inventory keeping. This meant extra labor was needed to keep inventory and move the products. This also contributes to increased costs. However, manufacturers do not need to worry about inventory with manufacturing on demand as products go straight to the clients after production.

Increased Production Efficiency

One risk of traditional manufacturing is overproduction, as manufacturers can accurately predict demand trends. This leads to reduced efficiency in production as some products might go to waste. However, with manufacturing on demand, production is fully efficient as they are only produced based on need.

Technologies Used in Manufacturing on Demand

There are various machining technologies and techniques that are utilized in on-demand manufacturing. Examples of such technologies include:

Additive Manufacturing

Additive manufacturing (3D printing) has become very popular in the manufacturing industry. Known especially for its use in prototyping, this process creates 3D parts by depositing materials in layers.

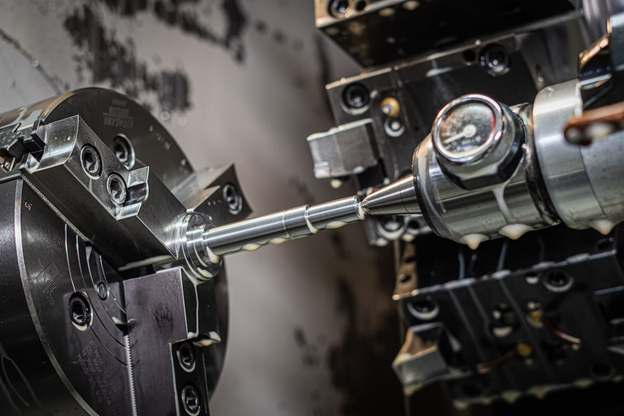

Computer Numerical Control (CNC) Machining

CNC Machining

CNC Machining is one of the most common technologies in manufacturing. This process uses programmed computers to control the machining process. The process works for manufacturing all types of parts with complex shapes and high accuracy. Various procedures like milling, turning, and electrical discharge are also used in CNC machining.

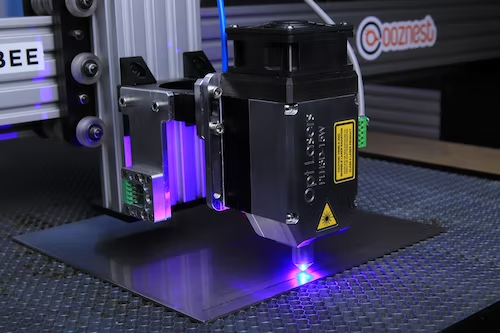

Sheet Metal Fabrication

Laser Printing on Sheet Metal

As the name implies, this process involves manipulating sheet metal to produce various parts. Such processes include waterjet cutting, sheet metal bending, laser cutting, etc.

Injection Molding

Injection molding involves using plastics to make parts by injecting molting plastic into premanufactured molds. Once the plastic cools and solidifies, it fully forms the products, and the machinist ejects it from the mold. This process is only used for plastic materials.

Challenges of Manufacturing on Demand

Despite its various advantages over the traditional manufacturing method, it has limitations. Examples include:

Quality Control

While clients get more control in the production process due to the ability to revise designs, the procedure generally has a risk of poor quality. This is because many manufacturers could outsource the production to smaller manufacturers, increasing the risk of quality drops. At Prolean, quality is our watchword, and we make sure we carry out the production ourselves to ensure total quality control.

Intellectual Property Protection

With on-demand manufacturing, you must send your blueprints and CAD models to the manufacturer. This means you have to divulge personal intellectual property to the manufacturer, who could have malicious intent to copy your designs. However, you can eliminate this risk by dealing with reputable companies such as Prolean.

Dependence on Technology

Manufacturing on Demand is a process that depends heavily on several technologies. While many manufacturers could offer various services, some are limited in their services. Therefore, technology could be a limiting factor in producing some parts.

Skilled Labor Shortage

Being a newer manufacturing method, there are some processes involved with on-demand manufacturing which many operators might still have to learn. Hence, finding proficient operators in this field could be challenging.

Legal and Safety Regulations

The relative newness of this process means many of the legal and safety regulations around it aren’t fully ironed out. While many manufacturers use existing manufacturing regulations, many of these rules still need to be revised.

How to Use Prolean for On-Demand Quotes and Orders

When you plan to use Prolean for your on-demand manufacturing orders, here are the steps to follow:

Input Your Details

First, you need to add your name, email, and company name. This helps us to reach out to you for further communications.

Add Additional Information

In this section, you can mention that this is manufacturing on-demand order so that we can understand the urgency.

Add CAD Models

Finally, you should submit your CAD files so we can prepare a quote for you. The files could be in PDF, STEP, SLDPRT, or SLT formats. After you’ve submitted all this, we can prepare your quote within an hour, which will be emailed.

After receiving the quote, we can discuss further details, such as feedback on the design, shipping options, etc.

Future of Manufacturing on Demand

If there’s anything that’s sure, it’s that there are a lot of explorable possibilities with the manufacturing on-demand system. Explained below are some future advancements we hope to see in the on-demand manufacturing space:

Advancements in Technology

As mentioned earlier, many manufacturers are still limited in the spectrum of services they can offer as on-demand manufacturing orders. However, in the future, there’ll be advancements in the technology used in this manufacturing method. This will help to incorporate more manufacturing technologies in the space.

Industry Trends and Predictions

While the adoption of this manufacturing method is not full-blown, we’re [predicting it to be an industry trend later on. As more demand comes for products to be made within shorter time scales, many manufacturing companies will have to pivot faster to meet these demands. This will help push for further adoption of the method.

Implications for the Workforce

Manufacturing on Demand will also have some likely negative effects on the workforce. Due to the requirement of less manual labor and more skilled labor involved in the manufacturing method, it might cause mass worker layoffs in the future.

Importance of Adopting Manufacturing on Demand

The Future of On-Demand Manufacturing

Adopting manufacturing on demand for production could bring advantages you might not have thought of as a manufacturer or client. Apart from its evident cost-saving benefits, you could also have much more control over the production process. Also, its positive effect on production efficiency makes it a much more attractive method. However, to get the process going, you need the services of an expert.

This is why Prolean is an excellent choice for you to work with. At Prolean, we have experts that specialize in various on-demand manufacturing technologies. Once you upload a CAD file, we’ll provide an instant quotation. We’re the best choice to work with if you need any on-demand manufacturing products.

Conclusion

Manufacturing on demand is becoming a mainstay in manufacturing, and joining the trend can offer major benefits. If you’ll like to speak to an expert about the finer details of the manufacturing process, contact us.

FAQs

What are the Examples of On Demand Manufacturing?

Technologies such as 3D printing and CNC machining are typical examples of technologies commonly used in the on-demand manufacturing space.

What are the Examples of On Demand Manufacturing Companies?

Various manufacturing companies offer on-demand services. A good example is Prolean Manufacturing Company.

0 Comments