Alodine coating process

Aluminum parts are prone to corrosion and oxidation when exposed to environmental elements such as moisture, humidity, and oxygen. This leads to a part or product’s damage, deterioration, and failure. Nevertheless, alodine coating can combat this issue.

The alodine coating on the part’s surface enhanced the smoothness, functionality, and lifespan. This article will provide a concise overview of the alodine coating process, including its significance, applications, maintenance, and removal process.

What is Alodine Coating?

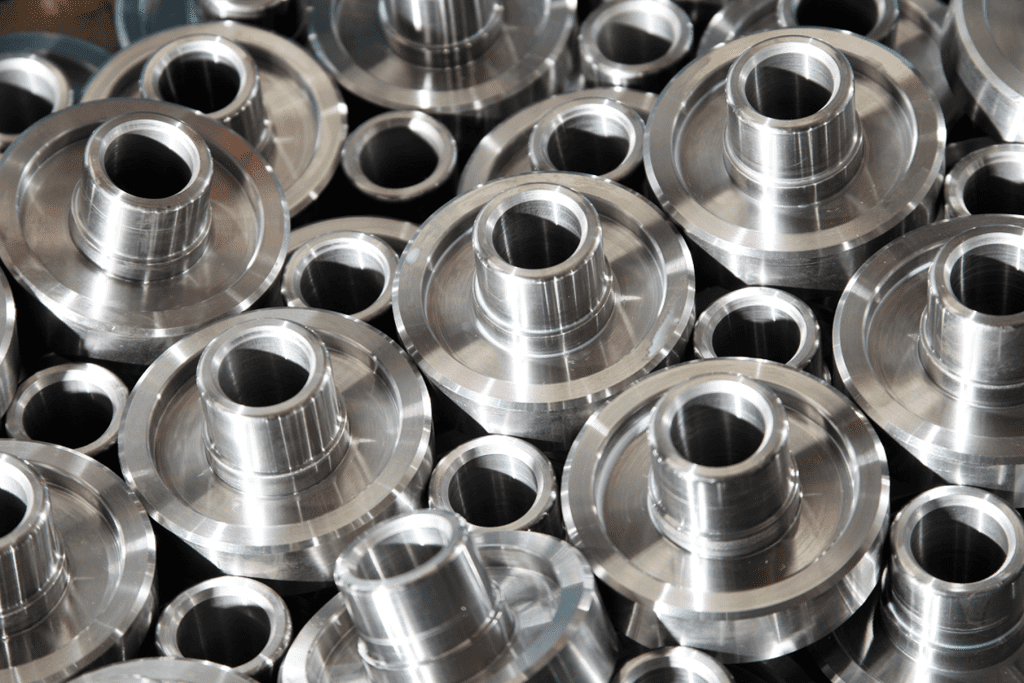

Alodine coated parts

Alodine coating is a chemical conversion coating used to finish the metal surfaces such as aluminum, copper, brass, and steel. Although it primarily applies to the aluminum parts. The process involves using chemicals to form a protective layer on metal surfaces. The chemicals used in alodine coating depend on the coating being used, but they generally include acidic solutions containing chromates or phosphates.

Aluminum alodine coating is vital in manufacturing and machining, as it offers the best surface protection for aluminum parts. The coating prevents corrosion, abrasion, and surface degradation, making the components more effective and durable. It is prevalent in applications where the metal is exposed to harsh or humid conditions, including aerospace, automotive, and marine industries.

Related resources:

CNC Machining for Automotive Industry: Applications and Advantages

Alodine coating thickness can be controlled according to a specific application and typically ranges from 0.00001 to 0.0001 inches. Furthermore, the color of the alodine coating can vary from gold to light green.

A brief history of alodine coating and its development

The” chemical-conversion coating principle” is the foundation for developing the alodine finishing technology. To clarify, chemical conversion coatings are produced by a chemical or electrochemical treatment of the metallic surface using coating solutions.

The process was first developed by a manufacturing company” Henkel Corporation” in the 1930s and had been evolving over the years. The process itself has been modifying time to time. For example, a new formulation of alodine was developed that used less hazardous chemicals to address the use of chromic acid raised environmental and safety concerns in the 1980s.

Today, alodine coatings are typically made using a combination of organic and inorganic chemicals that provide similar protection to the original chromate-based coatings. The coating is applied using various methods, including immersion, spray, and brush-on techniques.

Overall, it is consistently maintaining a great reputation in the manufacturing industry as an excellent prevention for corrosion.

Types of Alodine Coatings

There are several types of alodine coating under different standards, such as MIL-DTL-5541, AMS-C-5541, MIL-C-81706, and AMS 2473. However, types 1 and 2 of MIL-DTL-5541 are the most common in practice.

Type 1 MIL-DTL-5541

Type 1 MIL-DTL-5541 coating contains hexavalent chromium and leaves brown or gold color after the finish. This type of alodine coating is considered a hazardous chemical.

Therefore, many countries have restricted its use; some allow it with conditions and strong regulations. In addition, it requires special handling and disposal procedures.

Type 2 MIL-DTL-5541

Type 2 MIL-DTL-5541 alodine finish provides corrosion protection and facilitates paint adhesion without the use of hexavalent chromium. As a result, it is entirely safe and does not produce any environmental or health impacts.

Unlike Type 1, which produces a brown or gold-colored film, Type 2 makes an explicit or iridescent film. Type 2 also facilitates paint adhesion, which can be helpful for a different decorative finish.

Try Prolean Now!

The Alodine coating process

Aluminum parts

Like any other chemical coating process, the alodine coating involves dipping metal parts (mostly aluminum) into an alodine solution to create a thin protective layer.

Following are the different steps involved in the alodine coating process;

Step 1: Surface cleaning

Surface cleaning involves using a suitable solvent to remove any oils, grease, dirt, or other contaminants. Cleaning the surface can be done by immersing the substrate in a solvent bath, wiping it with a cloth, or using high-pressure water or steam cleaning to remove contaminants. The type of solvent used depends on the impurities present on the surface and the substrate’s material.

Step 2: Etching

After cleaning, the substrate goes through the etching process. An acid solution (typically sulfuric acid and chromic acid) is employed to remove any existing oxide layer and create a roughened surface, which improves the adhesion of the coating. However, the Type 2 MIL-DTL-5541 coating is also compatible with alkaline cleansing.

Step 3: Rinsing

Once the etching is complete, the substrate is thoroughly rinsed with water to remove any remaining acid and prepare it for the coating solution. The rinse water should be of high quality to avoid introducing new contaminants to the surface. Proper rinsing significantly influences the quality and longevity of the coating or treatment applied to the surface.

Step 4: Applying the solution

When the substrate is dipped into the tank containing the Alodine coating solution (Type 1 & 2), the solution reacts with the metal surface, forming a thin chromate layer on the substrate. The formation of the chromate layer occurs through a chemical reaction between the chromic acid in the Alodine solution and the metal substrate.

Step 5: Passivation

After the immersion, the coated parts are cleaned with water to remove any remaining coating solution from the surface, followed by passivation.

The passivation involves the neutralization of remaining acid and promotes the formation of a protective oxide layer on the surface using a chemical solution. This step ensures long-lasting protection.

Step 6: Drying

After passivation, the substrate is thoroughly dried to remove any moisture from the surface that can impact the adhesiveness of the coating. It can be achieved through several methods, such as air-drying or using compressed air to blow dry the surface.

Applications of Alodine coating

The applications of alodine coating are diverse and range from industrial to aerospace and military applications. Here are some most common uses of the alodine coating process for aluminum:

Aerospace

In the aerospace industry, alodine coating protects aircraft components from corrosion and improves their performance. Since the aerospace industry heavily utilizes aluminum, it is applied in various aircraft parts, such as wings, fuselages, landing gear, and other components made of aluminum.

Military Applications

=It is used in various military applications to protect equipment and machinery from corrosion, particularly in harsh environments. The coating typically applies to tanks, weapons, and other military vehicles to enhance durability and longevity.

Automotive

Alodine coating protects the various automotive parts from corrosion caused by exposure to harsh weather conditions, road salt, and other environmental factors. The coating also enhances the adhesion properties, making it easier to apply paint.

Typical automotive applications include the wheel, axles, body panels, engine block, and cylinder head.

Electronics

The alodine coating is applied to various electronic components such as connectors, enclosures, heat sinks, and printed circuit boards (PCBs) to enhance their durability and reliability.

Meanwhile, it protects from harsh environments that can cause corrosion, such as moisture, salt, and acidic gases.

Industrial Applications

Alodine coating is applied in industrial applications, such as manufacturing equipment, machine tools, and structural parts. The coating is essential to increase the lifespan of the components or mechanical systems.

Alodine coating Maintenance and Lifespan

The lifespan of an Alodine coating depends on several variables, such as substrate material, coating thickness, environmental conditions, and coating quality. Typically, a well-applied Alodine coating can last for many years, depending on the severity of the environment.

For example, aluminum alodine coating lasts at least four years without any maintenance, even in harsh environmental conditions. In addition, proper maintenance and care significantly contribute to coating life.

These are some tips for maintaining Alodine coatings.

- Consider additional protective measures in severe environmental conditions, such as high humidity, saltwater, or extreme temperatures.

- Keep the coated surface clean and free of debris, dirt, and grime. Regular cleaning with mild detergents and water prevents contaminants buildup.

- Avoid abrasive cleaning or harsh chemicals on the coated surface to prevent possible damage.

- Inspect the coating periodically for signs of damage or wear. If any damage is detected, repair as soon as possible.

How to Remove Alodine coating?

Alodine coating is a type of chemical treatment applied to metal surfaces for corrosion prevention. However, there could be situations where the coating needs to be removed. It may be damaged or worn, or you may need to apply a different type of coating. Above all, if you need to remove an Alodine coating from aluminum or another metallic surface, there are several ways to achieve this.

Abrasive blasting

The alodine coating from the aluminum surface can be removed using a high-pressure stream of abrasive particles, such as sand or glass beads. Abrasive blasting is a quick and efficient way to remove the coating without damaging the underlying metal substrate. However, it g can also create dust and debris, which can be hazardous to workers and the environment.

Thermal removal

Heating the alodine-coated parts also remove the coating layer. Generally, it involves heat to break down the coating, allowing it to be easily removed from the surface of the metal. There are two ways to achieve this, burning and heating.

Chemical stripping

Chemical stripping involves using a chemical solution that dissolves the coating from the metal surface. It is famous for thicker layers that cannot be removed with mechanical or abrasive methods. Some examples of solutions are sodium hydroxide, potassium hydroxide, sulfuric acid, hydrochloric acid, and methylene chloride.

Alodine Coating vs. Other Finishing Processes

Alodine coating is one of several finishing processes protecting aluminum or other metal surfaces. Here are some comparisons between Alodine coating and other finishing processes.

Alodine vs. Powder coating

The powder coating finish involves applying a dry powder to the metal’s surface, followed by heating, to create a durable and attractive finish. Alodine coating on the aluminum surface can provide better corrosion protection than powder coating, especially in high-salt or corrosive environments.

It is compatible with a broader range of metals, whereas powder coating may not adhere to certain metals.

Alodine vs Anodizing

Anodizing and alodine coating are similar because both processes create a protective layer on the metallic surface. However, alodine is easier and faster to apply than anodizing, which requires an electrolytic process.

It is also more suitable for small parts and intricate shapes, whereas anodizing may only be practical for some shapes or sizes. Alodine coating is less expensive than anodizing and provides adequate corrosion resistance for many applications.

Alodine vs. Conventional painting

Paint is another finishing process that involves spraying or applying a liquid coating to the surface of the metal. Conventional painting finishes provide different color options to address decorative purposes.

However, paint is less durable than Alodine coating and unsuitable for high-wear or high-corrosion applications.

Conclusion

Alodine coating, or alodine chemical conversion coating, is a popular surface-finishing process for aluminum and other metallic parts—the thick chromate layer on the surface. The chromate layer on the surface protects against corrosion and wear, especially in high-temperature or corrosive environments.

At Prolean, we offer professional alodine coating services for your aluminum and other metallic parts. We have experience in alodine chemical conversion coating for different manufactured parts. So, contact us if you’re looking for a manufacturing or surface finishing service.

FAQ

What is alodine coating?

Alodine coating is a chemical conversion coating used to finish metal surfaces such as aluminum, copper, brass, and steel. The process involves the chemical treatment of the substrate with the chromium-containing solution to create a thin chromate layer.

How long does alodine coating last?

The lifespan of alodine coating can vary depending on the application and environment. However, the aluminum alodine coating can last several years with proper maintenance and care.

How to remove alodine coating?

There are several approaches to removing alodine coating, chemical stripping, abrasive blasting, and thermal method. It is essential to note that the chemical removal process can be hazardous and requires special handling and disposal procedures.

What are the applications of alodine coating?

Alodine chemical conversion coating is particularly popular in applications where the metal will be exposed to harsh or humid conditions, including aerospace, automotive, and marine industries.

IS Type 1 MIL-DTL-5541 Alodine coating is hazardous? Reply

Type 1 MIL-DTL-5541 Alodine coating is considered hazardous due to its composition and environmental impact. This type of coating involves chromate conversion coatings in a hex chrome chemical bath, commonly resulting in a gold or brown finish on aluminum surfaces.

It contains hexavalent chromium, which is highly regulated due to its toxic and carcinogenic properties. It poses risks to human health and is a fire hazard when combined with certain materials. Additionally, it is treated as an environmental hazard by the US EPA.

Special working and safety standards are required when handling Type 1 coatings, and there are additional considerations for recycling and disposal due to its toxic nature.

We design aluminum enclosures for electronics company. We are in need of some parts to be fabricated and Alodine coated?

Yes , we provide aluminum sheet metal fabrication for enclosures and Alodine coating on that also.