“The material removal with EDM is similar to sort-circuit, exactly how short-circuit burns(erodes) the material.”

Electrical Discharge Machining( EDM) is a non-conventional manufacturing technique, which utilizes an electrical arc to remove the material. More commonly popular in conductive material machining. EDM Machining does not use any cutters, bits, or similar shear cutting tools, instead an electrode is responsible for the machining operations. An electric discharge is created by immersing the workpiece and electrode in a dielectric solution and supplying electricity.

This type of machining is beneficial for complex shapes and machining, especially for small sizes. The capability of accurate deep holes, micromachining, and intricate features makes it widely popular across various industrial applications.

In this article, we will discuss what is electrical discharge machining in detail, including its working principles, advantages, and disadvantages.

Introduction to EDM

All types of machining processes, especially late or milling tools are not accessablie to complex geometries and tiny features. Additionally, the hardness can be a challenging factor to remove the material and it can also cause rapid tool wear. In such situations, EDM can reach all the inaccessible areas that convention machining can not. The only thing a material needs to be compatible with EDM is the electrical conductivity.

During Electrical Discharge Machining(EDM), there is no physical contact between the machining tool and the workpiece. Both the workpiece and tool are submerged in the dielectric medium with a specific gap. Then, on a high-voltage electricity supply, the electric current generates a high-temperature arc( as high as 5700 K). Then, the arc erodes the material from a workpiece. Meanwhile, the electrode(tool) moves following the designed machining areas

Furthermore, the gap between the workpiece and the electrode inside the dielectric fluid determines the material removal rate and overall speed.

Try Prolean Now!

How Does EDM Work?

The Basic EDM science behind its working mechanism involves the use of voltage between the tool and conductive workpiece immersed in a dielectric medium, which creates an arc with intense thermal energy for material removal. You can understand this mechanism with an example of an electric short-circuit;

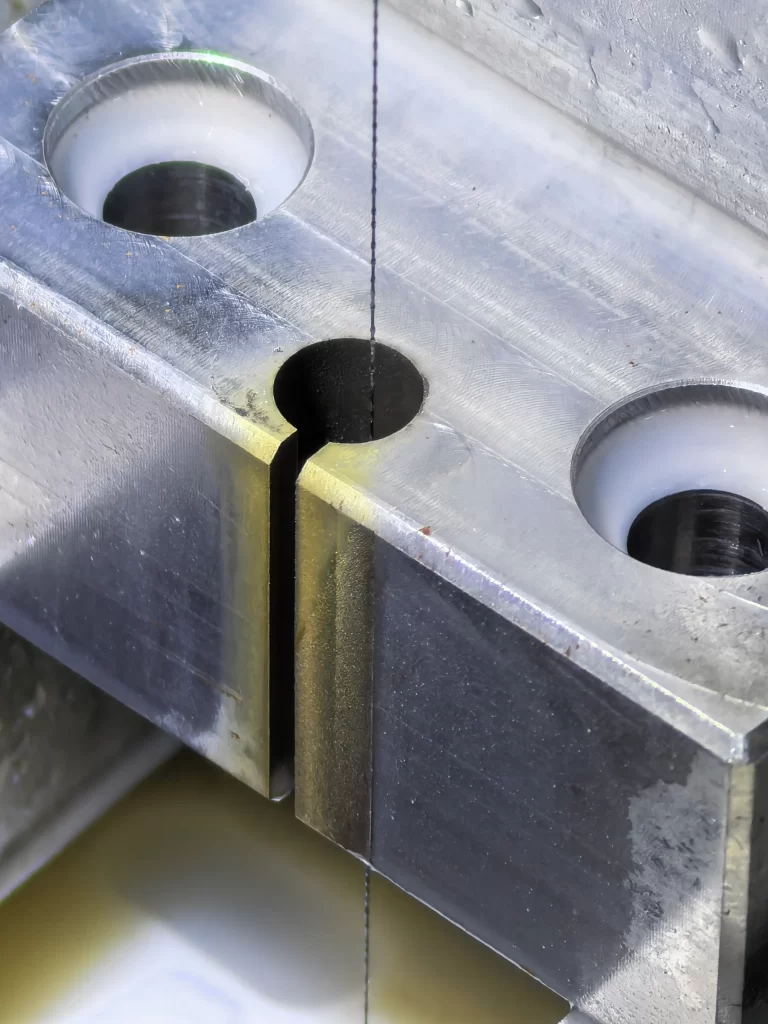

EDM machining process

The electrode ( cutting tool) is designed according to the shape of the desired cut and cavities, which can be fixed above the workpiece or it can travel along the workpiece. The CNC EDM machine can control the path and speed with pre-instructured G and M codes.

Furthermore, the list below summarizes the working of EDM machining;

- Electric Fied: The supplied voltage (V) generates the electrical field around the electrode and workpiece.

- Electron Emission: Free electrons on the tool are emitted due to electrostatic forces (cold emission) and accelerate toward the workpiece, gaining energy and velocity.

- Dielectric Ionization: Accelerated electrons collide with the dielectric molecules and create ions.

- Plasma Formation: High concentrations of electrons and ions form a plasma channel of high temperature due to repeated collisions, which are visualized as the arc or spark.

- Material Removal: The electrical energy is converted into thermal energy (heat) at the point of impact. Then, Intense localized heat (>10,000°C) causes vaporization and melting of the workpiece material.

- Crater Formation: Shock waves create craters on the workpiece surface around the spark site. Here, shockwaves are responsible for material erosion.

Furthermore, if you want to learn the step-by-step process of EDM, you can read the EDM guide here.

EDM Machining Components

An electrical discharge machining setup includes various components, each of them directly influencing the EDM Precision and quality of machined components. The following are the common EDM components;

- The Electrode or Cutting Tool

It is the main component that shapes the conductive workpiece. The electrode geometry corresponds to the geometry of the required cut, cavity, or pattern. They are typically available in the shape of wire, rod, tube, and die.

One of the key requirements for electrode material is its melting point, it must have a higher melting point than the workpiece material. They are made with high-conductive materials like graphite, tungsten, and tellurium copper. Consequently, the tool also needs to be denser to maintain the speed of machining.

- Dielectric Solution

The dielectric in EDM remains unconductive until the breakdown voltage. Once the circuit reaches the breakdown voltage, it ionizes the area of the gap between the electrode and the work part. The dielectric fluid should have how viscosity, high flash, high die-electric strength, and wetting properties. Some common dielectrics for EDM manufacturing are distilled water, kerosene, and tetraethyle glycol.

- Power Source and DC Pulse Generator

It consists of rectifiers and another arrangement to convert the AC source to DC, which provides the necessary voltage to create an electric field between the tool and the workpiece. The DC pulse generator modulates this voltage, delivering short, controlled pulses of current rather than a continuous flow. This pulsed approach prevents excessive heat buildup and helps in achieving precise material removal. You can also adjust pulse duration, frequency, and intensity with this generator.

- Working Tank

It is where dielectric fluid immerses the workpiece and electrode. The working tank contains a work holding device to clamp the workpiece. Meanwhile, the electrode could be half or fully immersed, positioned above the work. The common materials used to make EDM process tanks are plastics, composites, stainless steel with coating, etc.

Furthermore, it is attached to other components like a fluid circulation system(dielectric reservoir and pump), debris removal filter, and cooling mechanism. For instance, the circulation of dielectric fluid in the gap is essential to maintain the discharges.

EDM Types/ Techniques

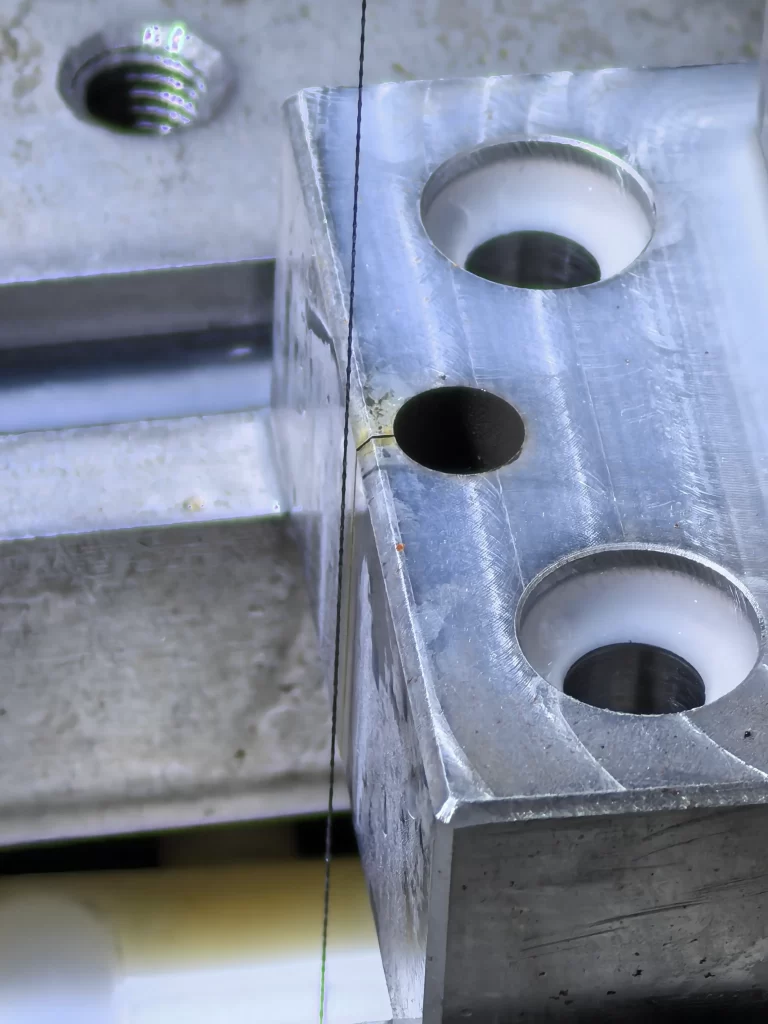

Wire and die-sinking EDM. Courtesy: ReaerchGate

To craft distinct features, you can use a suitable type of EDM based on your design and requirements. There are three major approaches; Wire cut, Sinker EDM, and EDM hole drilling.

The wire EDM uses a thin wire electrode, whereas the sinker EDM uses an electrode with the shape of required cavities or cuts. So, the fundamental difference between Wire EDM vs Sinker EDM is that Wire EDM uses a continuous wire to cut through material, and sinker EDM uses a custom-shaped electrode to form cavities or detailed shapes. Furthermore,

Table: Different Electrical Discharge Machining Techniques

| Aspect | Wire EDM | Sinker EDM | Hole Drilling EDM |

| Electrode Type | A continuous thin wire | Negative geometry of required cavity or cut (Custom) | Hollow tubular electrode |

| Control Mechanism | Computer-controlled with precise wire path | Gap voltage control during spark generation | Rotating electrode with controlled movement |

| Capabilities | Delicate and intricate shapes | Complex cavities and detailed shapes | Drilling small, precise holes |

| Typical Applications | Prototypes, micro-tooling, carbine tools | Parts with tight corner radius, various sizes | Precision parts for aerospace and medical |

| Finish Quality | Tight tolerances and smooth finish | Fine finishes with complex geometries | High precision and no need for deburring |

Common Materials Used in EDM Machining

As previously said, the conductive materials are compatible with the EDM machining. It allows the machining of several metals and alloys based on the desired properties and performance requirements. Stainless steel, copper, titanium, aluminum, brass, and zinc are some common examples.

Materials like titanium alloys, tool steel, and nickel superalloys are challenging to machine with traditional processes like CNC lathe and milling operations. However, this not-shear machining approach can process any hard alloy without compromising precision. Basically, it only needs to be electrically conductive to become an EDM Material.

Table: Materials for EDM Machining

| Material | Common Grades | Properties | Electrode Material |

| Steel | A2 Tool ,D2 Tool Steel, H13 Tool Steel, P20 Steel | High wear resistance, and toughness. It forms multiple metallurgical layers during EDM | Copper or graphite |

| Aluminum | 6061, 7075, and 2024 | Excellent strength-to-weight ratio, low cost, recyclable | Copper or graphite |

| Brass | C36000, C37700, C46400 | Good machinability, used in gears and fittings | Copper alloy or graphite |

| Copper | C10100, C11000 Copper, C14500 Copp | High thermal and electrical conductivity, good heat distribution | Graphite |

| Titanium | -Grade 5 (Ti-6Al-4V), Grade 2, and Grade 7 | Excellent corrosion resistance, high strength, low density | Copper, graphite, or tungsten alloy |

Try Prolean Now!

Advnatges and Disadvantges of EDM

We have mentioned that the EDM technology is flexible with sharp corners, thin walls, tapered holes, deep slots, blind holes, and complex 3D contours. And it can machine these features in micro-inches. Now, let’s point out the Advantages and Disadvantages of EDM objectively.

Table: EDM Advantages and Disadvantages

| Advantages | Disadvantages |

| It is compatible with hard and tough conductive materials | Limited to conductive materials only |

| EDM achieves high precision with complex geometries | Slower machining process, not ideal for large-scale production |

| The non-shear cutting ensures no mechanical stress on the workpiece | Higher energy consumption due to electricity-intensive process |

| Excellent surface finish with no chips and burrs | The electrode wear affects accuracy. So, it requires frequent adjustments or replacements |

| Suitable for intricate and fine shapes, thin walls, undercuts, tiny and long holes, etc. | Minimum corner radius is limited by electrode and machining gap |

| A simple electrodes can replicate complex workpiece geometries | Skilled operators are mandatory for setup and operation |

Applications of Electrical Discharge Machining

EDM machined parts

EDM manufacturing has different capabilities that other manufacturing processes can not deliver, like machining hardened metals, small holes of diameter <0.1mm, miro machining, deep pockets, precise and irregular cavities, complex geometrical features, etc. That’s why it has numerous applications across industrial manufacturing, from automotive to medical and defense.

The following are the EDM applications in different industries;

Aerospace

The aerospace industry requires high precision and complex geometries, often from hard metals like titanium alloys. EDM machining can create small features with high precision, which is essential for aerospace safety and reliability.

Application examples;

- Engine Components

- Landing gear parts

- Airframe brackets

- Nozzles

- Hydraulic components

- Turbine blade

Automotive

The automotive industry relies on electrical discharge machining for tight tolerance and complex parts that last for long periods, such as director nozzles for fuel injectors that directly affect the efficiency and performance of vehicles.

Application Examples;

- Precision gears

- Dashboard, bumper, and door

- AC components

- Valve steam

- Brake calipers

- Pistons

Tool and Die Making

EDM has countless applications in tool and die manufacturing. The precision, micromachining, deep cavities, and all capabilities required for tooling manufacturing can be achieved through this process. The wire EDM process is more popular in this industry than the Sinker EDM.

- Jigs, fixtures, and gauges

- Press tools, extrusion dies, forging dies, and stamping dies

- Injection molds, insert molds,

- Sintering dies

- Shaping of carbide or other hard tooling

Medical

Another critical application sector of EDM manufacturing is the medical industry, where precision and micro-machining matter more than anything other for patient safety and accurate testing results. Along with precision, EDM ensures fine details, no burrs, long holes, etc.

Here are some EDM medical Application Examples;

- Dental tools

- Small and serrated forceps

- Surgical blades

- Nuro and cardiovascular surgical instruments

- Components for diagnostic equipment

- Custom implants

Other Industries

Besides these, other industries like electronics, telecommunications, defense, and energy also utilize EDM machined parts—for example, nuclear reactor components, semiconductor parts, missile components, etc.

EDM Vs Other Machining Processes

One main distinction is non-contact machining when compared with shear-cutting or advanced machining processes. Additionally, EDM can make more tiny and complex features, For Example, EDM can drill holes less than 0.1 mm, and conventional drilling can not.

- EDM vs Milling: EDM shapes harder material into complex parts, whereas milling is limited due to tool accessibility to small and complex features. However, milling is more convenient if intricate micro features are not required.

- EDM Vs Laser Cutting: Instead of electric charges, laser cutting utilizes focused laser beams from sources like CO2, Nd: YAG/Nd: YVO, and fiber laser.

- EDM Vs Plasma Cutting: Plasma cutting uses ionized gas streams (plasms) to remove the material, whereas EDM erodes by electrical discharges(arcs). Plasma is suitable for speed cutting of thicker sheets.

Try Prolean Now!

Do I Need Strict EDM Safety Protocols?

Yes! Safety is a critical aspect of electrical discharge machining to avoid any risk to the operator and process. Regular maintenance, calibration, and arrangement of safety equipment, and training can only ensure EDM safety.

- Wear safety equipment and be aware of consequences of action you perform during the operation.

- Ensure there are no flammable materials, moisture, or any conductive items near the machining area.

- The EDM is a high-temperature process, so be safe in contact with the electrode and workpiece.

- Know your machine completely and maintain it in standard condition.

- Be aware of electric shock

- Never look at the discharge arc with your naked eye

Future Electrical Discharge Machining Trends

New equipment, EDM methods, quality control processes, and other capabilities are continuously evolving as demand for more precise and intricate parts is growing across the industries. Currently, computer numerical control, automatic feedback and adjustment, AI monitoring, advanced software for tool path optimization, and other technologies are popular in this sector.

Some possible trends regarding EDM future are;

- Innovations in materials like nanostructured electrodes and hybrid AM-EDM machines.

- Essential role of 3D printing in custom electrode manufacturing

- Adaptive control systems and robotic automation

- Integration of AI in tool path optimization and process monitoring.

Conclusion

Overall, EDM machining is ideal for precise dimensions, micromachining, and hard materials. Using the appropriate electrode material and dielectric fluid, you can achieve optimal machining results. Additionally, it also allows to crafting of detailed and intricate geometries that other teaching approaches found challenging.

Furthermore, the expertise and machining facility of the manufacturer also affects the final quality of the EDM application. At ProleanTech, we have advanced sinker and die EDM facilities to meet your requirements and industry standards. Our engineers and operators have experience working on diverse EDM machining projects for 10 years.

Our EDM Machining Service can handle 50+ metal and alloy grades. We have all types of EDM; hole drilling, sinker, and wire cut service. Choose your technique and material, then send us the EDM design, we will get back to you with a quote and further information about how we can execute your design.

FAQs

What is electrical discharge machining?

It is a precision machining process that removes material from a conductive workpiece using electrical sparks without physical touch. EDM is popular for machining hard or delicate materials.

What are the differences between traditional and EDM machining?

Tradition machining processes like CNC machining use rotating cutting tools that feeds the workpiece continuously to shape it. On the other hand, there is no physical contact between the tool and work during electrical discharge machining.

What is meant by the gap in EDM?

A gap in EDM refers to the distance between the workpiece surface and to electrode tip, both submerged in the workpiece. However, the electrode can be immersed only half sometimes.

Can EDM machine hard steel, titanium, incole, and other hard materials?

Yes! EDM can machine any electrically conductive and hard material including income, titanium, and steel.

Can EDM drill a 0.1 mm diameter hole?

Yes! Wire EDM can drill a hole with 0.1 mm or even less diameter.

0 Comments