“PEEK plastic stands out for its remarkable durability and resistance to extreme conditions in high-performance applications. It is a prime choice for industries requiring materials that can withstand challenging environments. “

Do you know What is PEEK Plastic Material? PEEK(Polyether Ether Ketone) is a semi-crystalline thermoplastic with excellent mechanical and chemical resistance properties retained at high temperatures. It’s part of the polyaryletherketone (PAEK) family and is known for its robustness and versatility. PEEK is used in many industries for diverse applications, mostly produced with injection molding and CNC machining.

In this article, we will discuss the properties of PEEK, the stages involved in PEEK CNC machining, several considerations & tips, and applications.

What is PEEK Plastic?

Polyetheretherketone (PEEK) is a popular engineering thermoplastic created with step-growth polymerization. It consists of repeating monomers, two ether, and a ketone group, resulting in semi-crystalline manners. Although PEEK is a colorless plastic, PEEK is predominantly available in three colors, brown, tan, and black. These colors are the results of mixing pigments during the molding.

The robustness of PEEK plastic arises from its aromatic ring structure, which provides high thermal stability and mechanical strength. Its Young’s modulus of elasticity is 3.6 GPa, its tensile strength is 170 MPa, and it melts around 350°C. Source.

The ketone and ether linkages allow rigidity and some flexibility, contributing to PEEK’s resistance to fatigue and crack propagation. Additionally, the symmetry and regular spacing of the ketone groups along the polymer backbone facilitate strong interchain interactions, providing excellent chemical resistance.

Table: PEEK at a Glance

| Applications | Subtypes | Tolerances | Wall Thickness | Part Size | Strengths | Lead Time |

| Durable and low-cost parts for medical, automotive, and aerospace industries as well as semiconductor handling equipment. | PEEK (30% Glass-Filled) | Not lower than ±0.25 mm (±0.010″), based on the drawing ( ISO 2768) | Minimum 0.80 mm (0.03″), but this can change depending on the proportion of the wall thickness to the linear dimension. | 200 x 80 x 100 cm | High mechanical strength and excellent thermal & chemical resistance. | Minimum 3 days. Not more than 10 days; for all complex parts. |

What Are the Common PEEK Grades?

PEEK plastics are available in various grades, each tailored for specific applications and performance requirements. Here’s an overview of some common grades:

Table: Common Grades of PEEK Plastic

| Unfilled PEEK | The unfilled PEEK offers an excellent chemical, heat, and wear resistance combination. It meets all the requirements for food & chemical processing, aerospace, and other industries. |

| 30% Glass-Fiber Reinforced | Compared to the un-filled grade, it offers high strength and stiffness. In addition, reinforcing glass and fiber increases thermal and electrical insulation. This grade is suitable for structural applications. |

| 30% Carbon-Fiber Reinforced | Reinforcement of high-strength carbon fiber makes it exceptionally strong. This grade can withstand heavy loads without any cracking or failures. Additionally, it provides a high stiffness and heat dissipation rate. This grade is suitable for semiconductor processing, aerospace, and other applications. |

| 10-10-10 Bearing grade | It comprises 10% each of carbon fiber, graphite, and PTFE. It is highly machinable and well-known for its low friction coefficient and wear performance. This grade is suitable for medical, aerospace, and bearing parts. |

Related: The Clash of Plastics: Thermoset vs. Thermoplastic – A Comprehensive Guide

Try Prolean Now!

How to Process PEEK with a CNC Machine?

Converting the 3D model into accurate PEEK parts using CNC technology involves several steps and considerations.

Step 1: Review your 3D model

Simplify all of the complexity in a 3D model of the part. Maintain a decent thickness (a minimum of 0.8 mm is recommended). Before finalizing the design, check the tolerance to ensure whether it is possible to achieve or not. Over-tolerance might cause defects and failure. Review all the features present in a design, such as edges, cavities, undercuts, and many more.

Step 2: Finalize the tool path

After analyzing the 3D model, decide on the necessary CNC operations (milling, turning, drilling, etc.). Next, you need to fix and optimize the tool path. Avoid any intersections and long-complicated paths. The CAM software can simulate and find the best route for machining PEEK parts.

PEEK CNC machining

Step 3: Digital instructions & machining parameters

Upload the digital instruction (G-code) into the computer that will dictate the tools to move according to the finalized tool path.

Additionally, you should input machining parameters, such as cutting speed, feed rate, cutting depth, and more. Only correct machining parameters can produce the best result with PEEK plastic. So, select the cutting speed and feed rate according to the type of CNC operation.

- Milling: Feed rate 0.05 – 0.02 mm/ tooth, cutting speed 50- 300 m/ minute.

- Turning: Feed rate 0.1 – 0.5 mm/ tooth, cutting speed 150- 500 m/ minute.

- Drilling: Feed rate 0.1 – 0.3 mm/ tooth, cutting speed 50- 100 m/ minute.

Source: (Machining Guidelines – PEEK)

Step 4: Start the machining

Finally, hold the workpiece & position the cutting tool, and start the machining operation to convert the Raw PEEK into functional parts. Keep a close eye on the control panel and CNC machine to ensure everything is going according to planning.

Related: ABS CNC Machining: Everything You Need to Know

Considerations for Accurate PEEK Machining

Minor considerations during the machining of PEEK can significantly impact the quality of the final result. Following are some crucial considerations for PEEK CNC machining.

1. Consider heat treatment with the workpiece.

Consider the annealing heat treatment before proceeding with the raw material of PEEK plastic. The internal build-up stress of the sheet, rod, or bar of PEEK might cause cracking during CNC machining. Hence, heating it for a specified temperature and cooling it at room temperature release the stress and prevent possible cracking.

2. Choose the appropriate machining tools.

PEEK is a rigid thermoplastic, as was already explained. The tools that can process the workpiece without wear are necessary. It is best to utilize poly-crystalline tools for long-run machining and carbide tools for general operations.

3. Use suitable coolants.

Coolants are mandatory in CNC machining because PEEK does not dissipate heat efficiently. Use air, oil, or water as coolant to eliminate the risk of deformation because of thermal stress. Although medical-grade PEEK requires extra attention when choosing the coolant, go with biocompatible coolants like pressurized air.

Tips for PEEK CNC Machining

Here are some tips you can follow during PEEK CNC machining to obtain the desired quality.

- Avoid deep drilling holes since the PEEK workpiece might crack due to low elastic properties.

- While machining the medical grade PEEK, wear clean gloves and handle the parts maintaining hygiene to avoid possible contamination.

- Use soft jaws or pie jaws for the creation of thin walls.

- Spiral carbide cutting tools– thread taps with two flutes are the best choice for the tapped hole.

- Implement coolant systems or periodic pauses during machining to prevent excessive heat build-up, which can cause PEEK to soften and potentially degrade.

- Fine-tune the cutting speeds and feeds to minimize stress on the PEEK material. Slower speeds may reduce the risk of cracking or chipping during machining.

- Always use sharp, high-quality tools to cut PEEK. Dull tools can increase friction, generate more heat, and result in a poor-quality finish.

Click here to download: Guidelines for PEEK Plastic Machining

Try Prolean Now!

PEEK CNC Machining Applications

PEEK plastics come in various grades and can be precisely machined to meet the needs of multiple industries. It can be utilized for everything from large-scale production to quick prototyping. Let’s go further into the PEEK CNC machining applications.

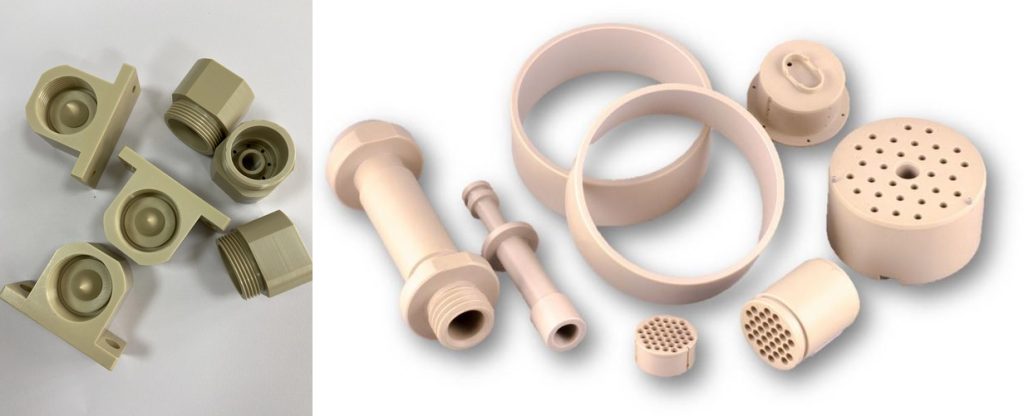

CNC-machined PEEK parts

Automotive Industry

The automotive industry employs PEEK CNC machining to produce components subjected to high wear and stress, such as bearings, seals, and wear pads. The excellent noise-damping properties, thermal stability, and strength of PEEK are crucial for these parts. Its durability and low weight help to manufacture more efficient and longer-lasting automotive components, driving the industry towards lighter, more fuel-efficient vehicles.

Aerospace Industry

The precision of PEEK CNC machining produces critical aerospace components like blocker door bushings, exterior aircraft parts, and various fasteners such as nuts and bolts. PEEK’s considerable weight reduction and thermal isolation properties make it a suitable replacement for metals.

Electrical and Electronics Industry

PEEK CNC machining is crucial in the electrical and electronics industry for producing insulative and structural components like cable insulation, circuit boards, and parts for semiconductor processing. Its innate electrical insulation, chemical resistance, and ability to withstand high temperatures make it suitable for intricate components that require precise dimensional stability and reliability under thermal stress.

Medical Industry

The medical sector uses PEEK CNC machining to produce implants and surgical equipment. PEEK is biocompatible plastic and can be safely used in the human body. Its chemical resistance ensures it can withstand rigorous sterilization processes. Furthermore, the precision of CNC machining allows for complex shapes required for medical devices while maintaining the material’s structural integrity.

PEEK Injection Molding

PEEK is one of the popular injection molding materials in manufacturing. The process begins with heating PEEK pellets until molten. Then, the molten PEEK is injected into a mold at high pressure. Once it cools, the material solidifies, taking the shape of the mold cavity. This process is highly efficient for high-volume production of complex parts with tight tolerances.

“PEEK’s performance in extreme temperatures is unparalleled,” says an industry expert. It’s also resistant to chemicals and wear, adding to its desirability.”

PEEK’s properties make it highly sought after for injection molding. It exhibits remarkable strength and thermal stability. This robustness makes it a candidate for replacing metals in the automotive, aerospace, electronics, and medical industries.

Injection molding PEEK parts

The PEEK Injection Molding process yields components that boast exceptional strength, thermal resistance, and chemical stability.

Here’s a list of 20 parts produced using PEEK Injection Molding across different industries:

- Surgical instrument handles

- Dental healing caps

- Endoscopic surgery components

- Spinal fusion cages

- Orthopedic implant devices

- Drug delivery systems

- Seals for aerospace fuel systems

- Electrical connector bodies for aviation

- Thermal insulators for space shuttles

- Sensor housings for automotive applications

- High-temperature electrical connectors

- Wear rings for high-performance engines

- Valve seats for chemical processing equipment

- Gears for electronic drive systems

- Pump impellers for industrial machinery

- Bearings for marine equipment

- Bushings for high-speed trains

- Cable insulation for oil and gas exploration

- Nozzle tips for hot runner systems

- Components for liquid crystal display (LCD) panels

Related: How much does Injection Molding Cost?

PEEK Injection Molding Vs. CNC Machining

PEEK injection molding is a process for large-scale manufacturing, enabling the production of complex parts with a high degree of repeatability and consistency. It is more economical in the long run due to lower material costs and reduced waste. However, it does require significant upfront investment in tooling, which can be costly and time-consuming. But, it is offset by lower per-part costs in high-volume production.

PEEK CNC vs Injection molding parts

Conversely, PEEK CNC machining is highly adaptable and excels in custom and low-volume manufacturing with intricate details. This method boasts rapid prototyping capabilities, allowing for swift design modifications without additional tooling costs. Although the per-unit cost remains higher compared to injection molding. So, CNC machining is ideal for custom solutions, prototypes, and specialized industrial applications.

Table: PEEK CNC Machining Vs. PEEK Injection Molding

| Aspect | PEEK Injection Molding | PEEK CNC Machining |

| Production Volume | High | Low to Medium |

| Part Complexity | High | Medium to High |

| Lead Time | Longer (due to mold making) | Shorter |

| Material Waste | Less | More |

In choosing between PEEK injection molding and CNC machining, consider several factors, such as production volume, part complexity, cost considerations, and lead times. While injection molding is optimal for high-volume, consistent part production, CNC machining offers the flexibility and precision needed for intricate, custom, or limited-run items. The decision ultimately hinges on the specific requirements of the project and the desired balance between upfront costs, production efficiency, and part complexity.

Try Prolean Now!

Manufacture your Precise PEEK Parts at Prolean

At Prolean, the focus is on transforming your innovative ideas into tangible products with professional ease and speed. We offer CNC machining and injection molding with advanced technology to fabricate PEEK parts. Our expertise spans a wide range of machining processes tailored to meet the changing demands of the industry.

We offer a comprehensive suite of services, including CNC machining, injection molding, and rapid prototyping. The company’s in-house manufacturing capabilities, complemented by a network of precision-connected suppliers, enable us to handle projects of various complexities. Whether it’s turning, milling, or more intricate processes, Prolean’s skilled engineers and technicians are equipped to deliver top-notch PEEK components.

Read more:

Laser Cutting PEEK: Precision, Advantages, and Applications

Summing Up

PEEK is a superior thermoplastic with versatile physical, mechanical, and chemical properties. It is considered a metal replacement in many applications. The capability of working at high temperatures and high mechanical strength makes it a go-to option for different CNC machining and Injection Molding projects. It is vital for several industries as a replacement for metal and alloys due to its superior strength and low-weight properties.

FAQs

Why is PEEK considered the superior thermoplastic?

PEEK can work at high temperatures without losing any properties, while other thermoplastics are unable to do so. It offers excellent mechanical strength, stiffness, impact resistance, abrasion resistance, and chemical inertness.

Is it easy to process PEEK with CNC machining?

Yes, PEEK has decent machinability. It can be processed with CNC machining operations like milling, turning, routing, drilling, and more. However, PEEK machining requires several considerations, from tool selection to the use of coolants.

What are the manufacturing methods for PEEK processing?

PEEK can be processed with CNC machining, Injection Molding, Laser Cutting, etc.

What are the essential factors for precision PEEK machining?

Precise machining of PEEKs demands few considerations. Carbide tools are suitable for PEEK machining. The selection of coolants needs to be done with a grade of PEEK. Machining variables need to be fixed according to the type of operations and require annealing of the workpiece before machining begins.

What are the applications of PEEK CNC machining?

PEEK CNC machining is significant in manufacturing parts for automotive, aerospace, medical, electrical & electronics, food processing, oil & gas, and other industries.

Can you provide some PEEK machining tips to optimize the process?

Some PEEK machining tips include:

- Use sharp tools to reduce cutting forces.

- Apply coolant to minimize heat generation.

- Maintain proper speeds and feeds to avoid excessive heat buildup.

- Use climb milling to minimize burrs and improve surface finish.

Is laser cutting PEEK a viable option, and how does it compare to traditional machining methods?

Laser-cutting PEEK is a viable option for applications requiring intricate shapes and high precision. It offers advantages such as minimal material waste, no tool wear, and reduced setup time. However, it may not be suitable for thicker materials and may introduce thermal stress to the part.

Resources

RanvijayKumar, R. (2022). Thermoplastic Containers for Disposal of Radioactive Waste. ScienceDirect. Retrieved from https://www.researchgate.net/publication/342755139_Thermoplastic_Containers_for_Disposal_of_Radioactive_Waste

How different PEEKS are machined to create various applications was very clear. Thanks for the this concise information’s regarding PEEK CNC machining. I am developing some food-processing machines for my start-up and we are at the initial phase. Are also provide related consultations?

You can contact us for consultation Prolean@hub.com

you have mentioned the machining parameters for PEEK

Milling: Feed rate 0.05 – 0.02 mm/ tooth, cutting speed 50- 300 m/ minute.

Turning: Feed rate 0.1 – 0.5 mm/ tooth, cutting speed 150- 500 m/ minute.

Drilling: Feed rate 0.1 – 0.3 mm/ tooth, cutting speed 50- 100 m/ minute.

Does these work in all conditions?

these are the general values, for optimum result you have to consider the factors like required Ra value, complexity, and machining conditions to optimize the feed rate, cutting speed and other parameters.

I found this article very informative. Do you have any specific suggestions for Creating spiked washers with PEEK CNC machining?

Thanks Choi Hye! Creating spiked washers using PEEK (Polyether ether ketone) in CNC machining involves several considerations to ensure quality and precision:

1. Tool Selection: Use sharp, carbide-tipped or diamond-coated tools for cutting PEEK. These materials offer the required hardness and heat resistance for machining this thermoplastic.

2. Cutting Parameters: Set optimal cutting speeds and feeds. PEEK can be sensitive to heat generated during machining, so a balance between speed and heat generation is crucial. Slower speeds and higher feeds are often recommended.

3. Coolant Usage: Utilize a coolant to manage heat buildup. However, ensure that the coolant is compatible with PEEK to avoid chemical reactions or material degradation.

4. Design of Spikes: Carefully design the spikes on the washers, considering the end application. The dimensions and sharpness of spikes should be tailored for the intended use while ensuring they can be reliably machined.

How much for machining of PEEK nut and bolts? reply please

Amelia, it depends on many factors, size, complexity, precision, and more. If you can upload your design and request a quote for detail budgeting of your project.