CNC Milling

Many products today, from smartphone covers to critical components for supersonic jets, are shaped by CNC milling. It is an automated subtractive manufacturing process that uses a cutting tool to remove material in a controlled, pre-programmed way. Almost any material can be processed, including metal, plastic, and wood. It is an ideal process for rapid prototyping and supporting full-scale production, and can shape several metals and plastics.

At ProleanTech, we combine advanced CNC milling machines with skilled engineers to provide high-quality, complex parts every time. However, manufacturers often ask how to produce complex, high-precision parts consistently. The answer is CNC milling. By automating machining processes, we reduce errors, save time, and ensure parts meet exact specifications.

Unlike manual milling, CNC milling removes material from a solid block automatically. Computer instructions guide it. Our 3, 4, and 5-axis milling machines allow you to create intricate designs, including undercuts, grooves, curved surfaces, and complex contours, while maintaining tight tolerances and uniform finishes.

In this article, you will learn the benefits of CNC milling, the types of CNC milling we offer at ProleanTech, the materials and finishes available, our process from design upload to delivery, and the industries that benefit from our services.

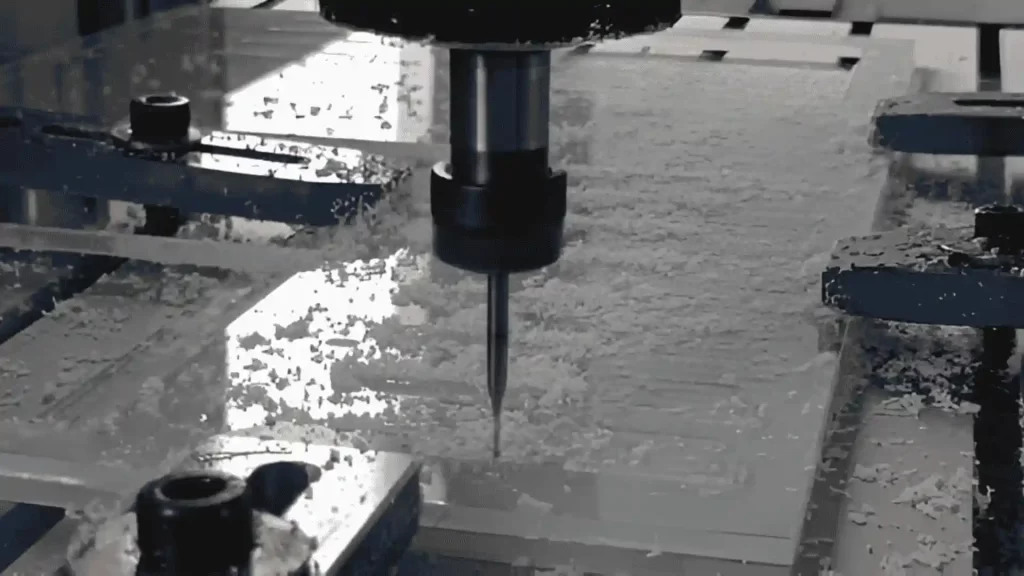

What Is CNC Milling Machining? A Quick Look

Acrylic CNC Milling

Custom CNC milling is a method of creating parts by cutting material from a solid block. A rotating cutting tool removes the material while the workpiece stays on a table. The table can be moved or rotated to allow the tool to reach different angles and shapes.

This process uses a computer to control the machine. The computer decides the tool’s path, speed, and order of cuts. This makes the parts accurate and consistent, much more than manual milling.

Machines can have different numbers of axes. Basic machines have three axes, while advanced ones can have five or more. More axes enable the machine to create complex shapes without requiring the workpiece to be moved. CNC milling applies to a wide range of materials, including metals, plastics, wood, glass, and others, making it a versatile tool for many industries. (See more about: CNC milling basics).

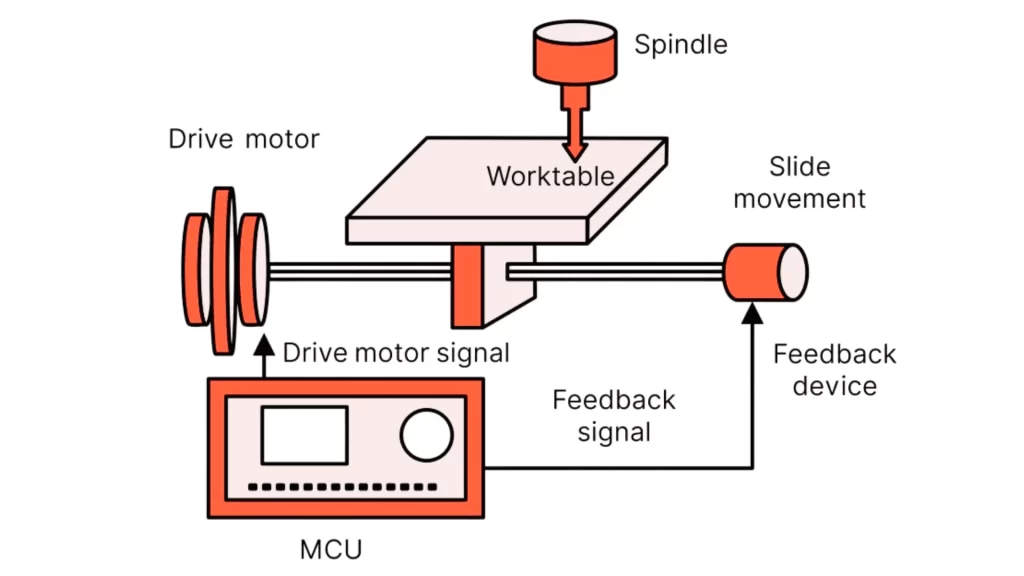

Common CNC Milling Machine Components

CNC Milling Machine Components

A milling machine has a few core parts that combine to shape raw material into finished parts. Some of the standard CNC milling components are listed below:

- Spindle: The spindle holds the cutting tool and spins it at a high speed. It actually removes material from the workpiece.

- Tool Changer: The tool changer automatically swaps tool cutters. This saves time and avoids manual work during production.

- Control Panel: The control panel is where you control the machine. You can set up and adjust programs to guide the milling process.

- Worktable: The worktable maintains the material’s stability, often utilizing clamps or vices to ensure the tool cuts accurately.

What are the Steps involved in the CNC Milling Process?

Some critical steps are involved in turning a CAD design into a physical part. Here’s how the process works:

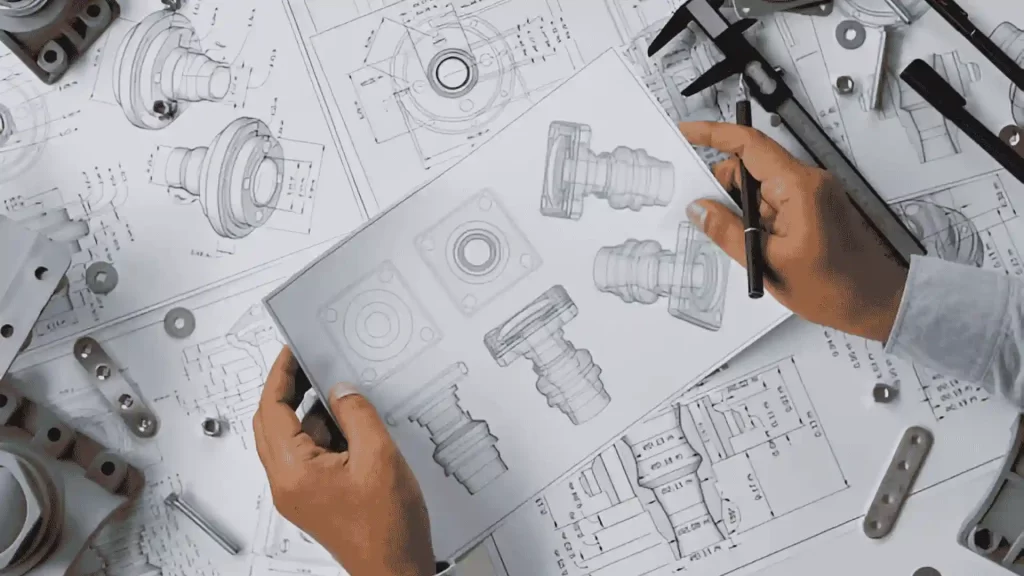

Create Your CAD Model

Technical Drawing

The initial process involves creating a 3D CAD drawing of your desired piece. Add all the essential information, such as size, shape, and geometry. One should also consider the capabilities of the CNC milling machine. The characteristics, such as undercuts and deep or recessed features, may require special equipment or multiple-axis machines. Planning them and the component can be produced correctly is better to accommodate such expenses.

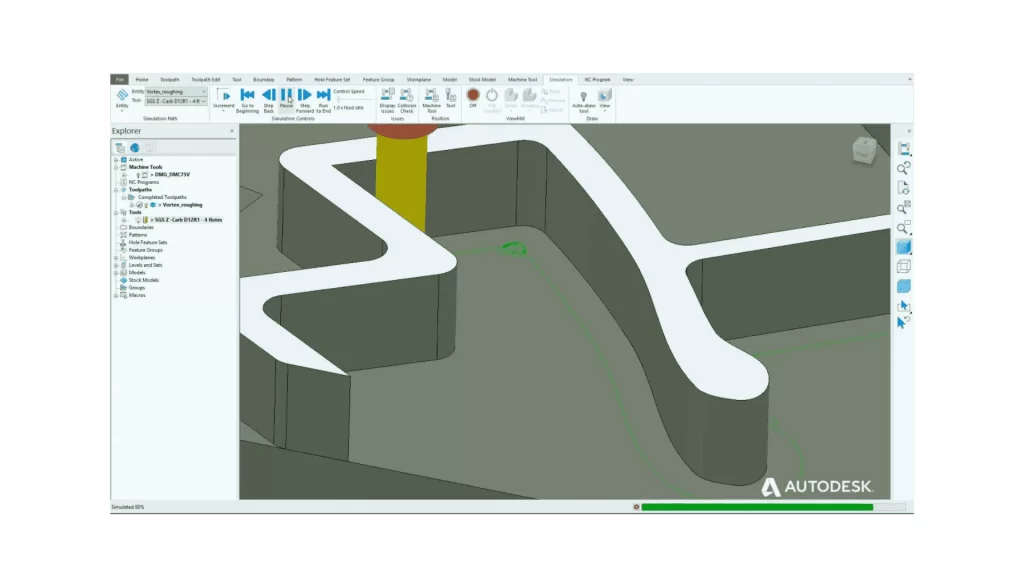

Convert CAD to CNC Program

CNC Programming

Now, once you have your CAD model, you should transfer it into the instructions to be followed by the CNC machine. With CAM software, one can produce accurate programs that guide the tool’s movement. Such programs are generally in G-code and M-code. G-code regulates the cutting activities, including the spindle speed, tool movement, and depth of cut. M code processes auxiliary functions, such as tool change commands and machine start-stop commands. Most CAM software contains simulators. These ensure that the program will correctly generate the part before the part is actually machined.

Prepare the CNC Milling Machine

Horizontal CNC Milling Machine with the Controller Panel

The milling machine is then installed to produce the part. The CNC program has been loaded, and the raw material or blank is securely clamped or vised on the worktable. The required spindles, fixtures, and correct tools are installed to meet the part’s requirements. This cautious preparation ensures the machine will cut accurately and effectively.

Execute the Program

Lastly, the CNC program is run. The machine operates consecutively, line by line, and cuts the material to mimic the CAD model exactly. There is also minimal human intervention, as the machine performs all movements automatically. After the program is completed, the parts are further inspected.

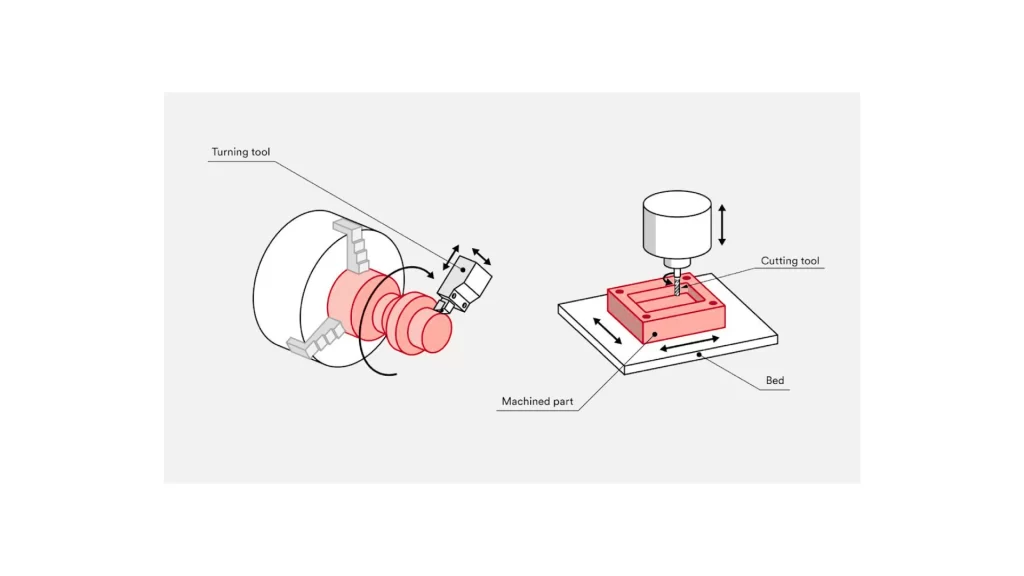

What Is the Difference between CNC Milling Vs Turning Techniques?

CNC Milling Vs Turning

CNC machining, milling, and turning are computer-controlled machining processes; however, they perform differently and are suitable for different parts. In CNC Turning, the workpiece rotates on a lathe, and a single-point cutting tool is used to shape it. This is best suited to cylindrical or conical parts, including shafts, bushings, or threaded components. The instrument cuts, drills, threads, and turns, always in contact with the material.

CNC Milling involves a rotating multi-point cutting tool that cuts material from a fixed workpiece. This enables the production of flat surfaces, grooves, pockets, and complex 3D shapes. Milling is more effective in irregular shape geometries, fine features, and those parts that need more than one angle or curve.

Concisely, round or symmetrical components are best suited to turning, whereas more complex and multi-dimensional designs are best suited to milling. (Related to: Mill Vs. Lathe)

Try Prolean Now!

3-Axis Vs 4 Axis and 5-Axis CNC Milling Machines? What’s the Difference?

5-Axis CNC Milling

- 3-Axis Milling Machines: This type of machine moves the cutting tool in three directions: X, Y, and Z. They can be used with simple shapes or flat surfaces on simple parts. They are simple to install, less expensive, and valuable for small batches or simple designs.

- 4-Axis Milling Machines: A 4-axis machine is equipped with an additional rotary axis, typically referred to as the A-axis. This enables the workpiece to spin, thus the tool can access more sides or rounded surfaces without re-aligning the workpiece. It is ideal for components that are more intricate than those that a 3-axis machine can handle.

- 5-Axis Milling Machines: These machines move in three linear directions and two rotary axes. This allows the tool to approach the part from nearly any angle. They are employed in cases involving extremely complicated parts, such as aerospace components, medical implants, and precision titanium parts. In 5-axis milling, the complex parts are sometimes machined within the same setup, which saves time and enhances accuracy. (See also: CNC Milling vs Drilling)

What to Keep in Mind When Designing Parts for CNC Milling?

CNC Milling Part

When designing parts for CNC milling, you can save time, money, and improve quality by following the tips below. For example:

- Minimise Setups: Try to minimise the number of setups as far as possible. Reduced setups imply expedited production, lower expenses, and easier outsourcing.

- Internal Corners: Internal corner radii should not exceed a quarter of the depth of cut, preferably less than half. Radii with larger sizes are cheaper to machine and cut. Drilled holes should be used in place of thread milling deep pockets.

- Thin Walls and Sections: In micro milling, Thin sections may be bent or warped during machining, even in soft metals. Thickened parts enhance stability, surface finish, and efficiency.

- Part Size: Small parts require delicate tools, which cut slowly and are more expensive. The bigger features are easier to machine and cheaper, provided the design permits it.

- Standardisation: Standard thread sizes, radii at corners, material, and tolerances. This will reduce costs and accelerate production, as parts can be sourced more easily from multiple suppliers.

Best Software Practices for CNC Milling Operations

CNC Software for CNC Machining

Innovative application of CAD software can simplify and reduce the cost of parts. For example, in SolidWorks, tools such as Hole Wizard enable the creation of standard-size holes quickly and with precision. Features created from simple shapes, such as Extrude or Revolve, are easier to machine than those created from complex shapes, such as Loft or Sweep.

Overall, components with fewer features are more predictable and can be manufactured in larger volumes. This is because, provided that a complex design is not required, a more straightforward approach can help save time, minimize costs, and avoid possible errors.

Common CNC Milling Types You Should Know About

CNC milling can be performed in various forms, depending on the part and the required finish.

Vertical Milling

Vertical milling involves positioning the spindle over the workpiece, allowing it to move up and down along the Z-axis. The table travels on the X and Y axes.

- Turret Vertical Mill: The spindle remains stationary, but the table is moved.

- Vertical Bed Mill: The arm is moved by the spindle, and the table is only moved on X.

Vertical milling is appropriate with a significant number of moderately complex parts.

Horizontal Milling

Horizontal milling contains a spindle that spins horizontally. It works best with heavier or longer components and enables the chips of materials to slide off the workpiece, making cutting easier.

Face Milling

Face Milling

Face milling involves a perpendicular cutter. The face of the tool and its edges have teeth that form flat surfaces and smooth finishes. It operates both vertical and horizontal machines.

Plain Milling

Plain Milling

Surface or plain milling has the cutter at right angles to the surface. It can cut deeper and work on more areas. Coarse cutters cut faster, whereas delicate cutters provide finer finishes.

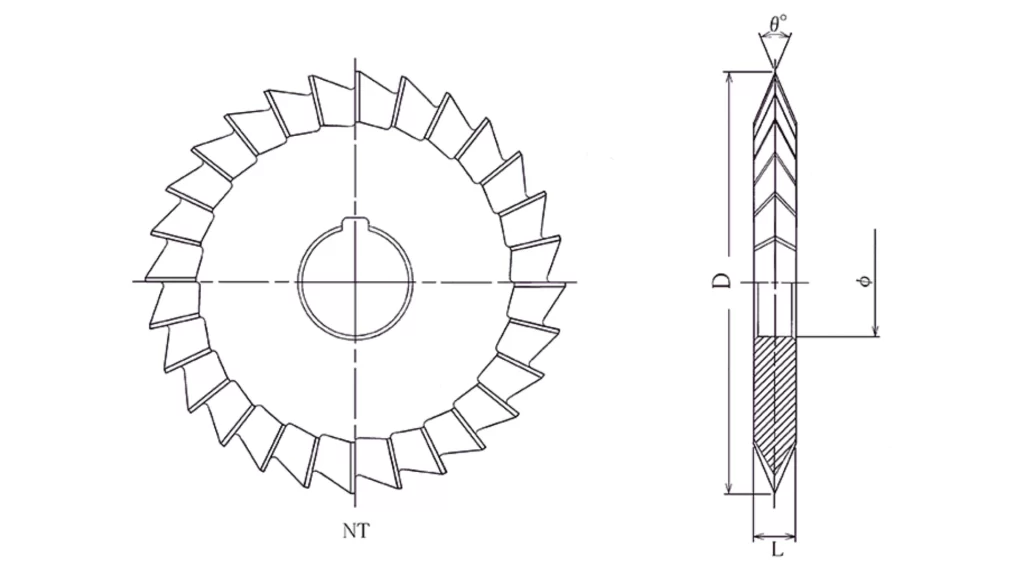

Angular Milling

Angular Milling

The cutter is angled using Angular milling. It is applied to form angled shapes such as grooves, chamfering, and serrations.

Form Milling

Irregular or contoured surfaces are milled in form. Special cutters, such as concave, corner-rounding, or hemispherical shapes, are used for complex shapes. It is best suited for designs that are curved or complex.

Try Prolean Now!

Common Types of Milling Machines & Their Uses

Various milling machines are specifically designed for tasks and parts with specific geometries. Here are the main types:

Ram-Type

With ram-type machines, the spindle is fixed on a movable arm on the column. It has two axes over which the arm can move, the X and Y axes. This is typically applicable in horizontal milling and provides flexibility when positioning the cutting tool.

Knee-Type

In knee-type machines, the spindle remains stationary and does not move; the worktable moves up and down. The knee lifts or drops the table up or down the column to align the part to be machined. It is a popular type applied in plain milling.

Planner-Type

The planner-type machines possess a fixed worktable in the Y and Z directions, and the spindle can move along the X, Y, and Z directions. Specific planner machines can have four spindles running simultaneously, allowing more than one tool to operate simultaneously.

Bed-Type

In Bed-type machines, the tool is attached to the workpiece at the bottom. The machine can move about the X, Y, and Z axes to machine the part. This category is commonly applied to heavy or broad workpieces.

Types of Parts That CNC Milling Machines Can Produce?

CNC Milled Parts

CNC milling machines are exact and can produce parts with complex shapes and tight tolerances.

Some of the common examples of parts include:

- Aerospace components like landing gear and fuselage structures

- Automotive parts such as control panels, axles, and molds (See more: CNC Milling for Automotive Parts)

- Consumer electronics enclosures and housings

- Medical instruments, surgical tools, and orthotics

- Oil and gas components like valves, rods, and pins

- Prototypes and models for product development

- Sculptures, furniture, and woodworking pieces

CNC milling can work with many materials, including aluminum, bronze, copper, steel, ceramics, stone, wood, zinc, titanium, plastics, and other engineering materials.

Get Your CNC Milled Parts Delivered On Time: ProleanTech’s CNC Milling Services

To save time and milling cost, keep your designs simple. Parts with standard features and common tooling are quicker to machine and take less time. Complex designs are possible but take longer and cost more. For example, a tight-tolerance part in aluminum is easier than the same part in plastic for large runs. Simple, standard designs work best, while special features or materials should only be added when needed.

ProleanTech uses advanced 3-axis, 3+2-axis, and 5-axis milling centres. We provide accurate, high-quality parts fast, with free instant quotes to help you plan your production.

The details of CNC here on the website is excellent and appreciated and will help me in our studies significantly. It looks like all of the article and technology blogs expertise regarding this technology. Typically i’m not on the internet very much although when I get a break I am always perusing for this type of factual information and things similarly concerning it.

It is great to know that our articles were helpful for you!