Laser welding is a modern welding technique that uses a laser beam as the heat source to join materials together. This advanced technology offers numerous advantages, including high precision, fast processing speed, and the ability to weld challenging materials. Over the past few decades, laser welding has gained popularity across various industries, including automotive, aerospace, electronics, and medical devices, due to its versatility and efficiency.

This article delves into the laser welding process, its different types, technical insights, and applications. By the end of this guide, you will have a thorough understanding of laser welding and its significance in today’s manufacturing world.

Decoding the Fundamentals of Laser Welding

Laser welding process

Laser welding, also known as laser beam welding (LBW), is a fusion welding process that employs a laser beam to melt and fuse materials together. This advanced metal welding technique provides numerous benefits, including high precision, speed, and the ability to weld challenging materials.

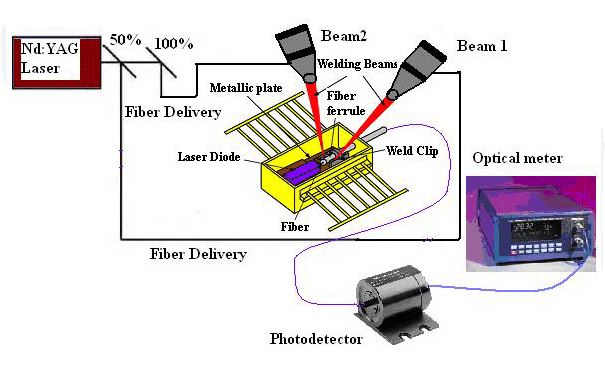

The term ‘laser‘ stands for ‘Light Amplification by Stimulated Emission of Radiation.’ In laser welding, the laser serves as a concentrated heat source that provides the energy required to melt the materials at the joint. The laser beam is generated in a laser resonator and then directed onto the workpiece using a series of mirrors or optical fibers.

Weld Formation & Heat Flow

The laser beam is focused onto the workpiece, creating a small spot with high energy density. As the laser beam interacts with the material, it heats the surface, causing it to melt and form a weld pool. The weld pool consists of molten material from both workpieces that mix and fuse together. As the laser beam moves along the joint, the molten material solidifies, forming a strong, permanent bond. The heat flow during the laser welding process plays a crucial role in determining the weld quality. Heat is conducted from the weld pool into the surrounding material, resulting in a temperature gradient. The temperature decreases as the distance from the weld pool increases. The heat-affected zone (HAZ) is the region adjacent to the weld pool that experiences thermal cycles but does not melt. The properties of the material in the HAZ may change due to the thermal cycles, affecting the overall performance of the welded joint.

Materials Suitability

Not all materials are suitable for laser welding. Materials with high reflectivity, like aluminum and copper, require higher laser power to achieve proper welding. Similarly, materials with high thermal conductivity dissipate heat quickly, affecting the weld quality. Additionally, the compatibility of materials is essential for creating a strong bond. For example, welding dissimilar metals with different thermal expansion coefficients can lead to residual stresses and distortions in the welded joint.

Types of Laser Welding

Laser welding is primarily classified into four categories based on the mode of operation, conduction mode, keyhole, laser brazing, and percussion welding.

- Conduction Mode Welding: In conduction mode welding, the laser beam is absorbed on the surface of the material, and the heat is conducted through the material to create a weld. The weld depth is relatively shallow, and the width is broader. This mode is suitable for thin-walled parts and applications requiring low penetration welding.

- Keyhole Mode Welding: In keyhole mode welding, the laser beam penetrates deep into the material, creating a vapor cavity or ‘keyhole.’ The walls of the keyhole absorb the laser energy, melting the material and forming a weld. The keyhole acts as a waveguide, directing the laser energy into the material, resulting in deep penetration and a narrow weld bead.

- Laser Brazing: Laser brazing is a process where the laser is used as a heat source to melt a filler metal that wets the surface of the workpieces and forms a joint. The workpieces do not melt in this process. It is often used for joining dissimilar materials and creating joints with high aesthetic quality. The process requires precise control of the laser power and speed to ensure proper wetting and spreading of the filler metal.

- Percussion Welding: Percussion welding is a process in which a series of laser pulses are used to create a weld. Each pulse melts a small portion of the material, and the subsequent pulse overlaps with the previous one, creating a continuous weld. This process is suitable for spot welding or creating small, precise welds on thin materials. It is often used in electronic and medical device manufacturing where precision and minimal heat input are critical.

Next, We will explore the detailed process of laser welding process with step-by-step discussion.

The Initial Stride: Material Preparation for Laser Welding

Material preparation is the most crucial first step in the laser welding process. The quality of the final weld is significantly influenced by the cleanliness and proper alignment of the materials to be welded. It is important to ensure that the materials’ surface is free from contaminants like dirt, oil, rust, and oxide layers. Any residue on the surface can lead to welding defects, such as pores, cracks, or incomplete fusion. Therefore, meticulous preparation of the materials is essential for achieving strong and durable welds.

1. Material Selection

The first sub-step in preparing the materials is selecting the appropriate materials to be welded. Not all materials are suitable for laser welding. Commonly welded materials include various types of steel, aluminum, and titanium. However, the material selection depends on several factors such as the application, cost, and required weld properties. It is also important to consider the material’s thermal conductivity, melting point, and absorption characteristics for the laser wavelength

2. Surface Cleaning

Once the materials are selected, the surface to be welded must be meticulously cleaned. The presence of contaminants like dirt, oil, grease, oxide layers, and any coatings can negatively impact the weld quality. Cleaning can be done using various methods such as mechanical cleaning (abrasive blasting, wire brushing), chemical cleaning (solvents, acids), or thermal cleaning (flame cleaning, laser ablation). The chosen method depends on the material, the nature of the contaminants, and the required weld quality..

3. Joint Design

The joint design is another important aspect of material preparation. The type of joint (butt joint, lap joint, T-joint, etc.), joint gap, and joint angle can all influence the weld quality. It is important to design the joint such that it allows for proper penetration of the laser beam and complete fusion of the materials. Computer-aided design (CAD) software can be helpful in designing the joint and simulating the welding process to optimize the joint design for laser welding.

4. Material Thickness

The thickness of the material is another important consideration. The laser power, welding speed, and focus position must be adjusted according to the material thickness to achieve the desired weld depth and width. Thicker materials may require higher laser power and slower welding speed, while thinner materials may require lower power and faster speed.

5. Preheating

Preheating the materials before welding can be beneficial in some cases, particularly for materials that are prone to cracking or distortion. Preheating can help to reduce the temperature gradient across the material, minimizing thermal stresses and distortion. However, excessive preheating can lead to a reduction in the mechanical properties of the material, so it must be done carefully and controlled.

Gearing Up: Configuring the Laser Welding Apparatus

CNC laser welding machine & its components

After preparing the materials for welding, the next crucial step is setting up the laser welding machine. This involves configuring various parameters such as laser power, pulse duration, welding speed, and focal position. Each of these parameters can significantly influence the weld quality, so it is important to adjust them carefully based on the material type, thickness, and desired weld characteristics.

Table: Sub-steps in laser welding machine set-up

| Setting Parameter | Description | Considerations | Example |

|---|---|---|---|

| Selecting the Laser Source | Choose the appropriate laser source. | Material, required welding speed, desired weld quality. | CO2 lasers for non-reflective materials like steel; Nd:YAG and fiber lasers for reflective materials like aluminum. |

| Adjusting the Laser Power | Adjust the laser power. | Material type, thickness, and welding speed. | Higher power for thicker materials and higher welding speeds. |

| Setting the Pulse Duration | Adjust the duration of each laser pulse. | Material type, thickness, and desired weld characteristics. | Shorter durations for narrower and deeper welds; longer durations for wider and shallower welds. |

| Adjusting the Welding Speed | Adjust the speed at which the laser beam moves along the joint. | Material type, thickness, and desired weld characteristics. | Slower speeds for deeper and wider welds; faster speeds for shallower and narrower welds. |

| Setting the Focal Position | Adjust the position at which the laser beam is focused onto the material. | Material type, thickness, and desired weld characteristics. | Above surface for shallower welds; at surface for medium depth welds; below surface for deeper welds. |

| Setting the Shielding Gas | Select the appropriate shielding gas. | Material being welded, welding speed, and surrounding environment. | Argon, helium, or mixtures of argon and helium. Adjust flow rate based on welding speed and surrounding environment. |

Perfecting Precision: Aligning the Laser Beam

Aligning of the laser beam

The alignment of the laser beam is a critical step in the laser welding process. Proper alignment ensures that the laser beam is precisely focused onto the joint to be welded, resulting in high-quality welds. Misalignment of the laser beam can lead to incomplete fusion, excessive spatter, or even damage to the workpiece or the laser welding machine.

The process of aligning the laser beam involves several key steps:

- Adjusting the Beam Expander: The beam expander is a lens system that enlarges the diameter of the laser beam. Adjusting the beam expander allows you to control the diameter of the laser beam at the focal point. A larger beam diameter results in shallower welds, while a smaller beam diameter results in deeper welds. The ideal beam diameter depends on the material thickness and the desired weld characteristics.

- Setting the Focus: The focus is the point at which the laser beam is most concentrated. The focal position should be adjusted so that the focus is at the surface of the material or slightly below it. This will result in a weld with the desired depth and width. If the focus is too shallow, it can lead to incomplete fusion or excessive spatter. If the focus is too deep, it can lead to excessive penetration or burn-through.

- Aligning the Beam: The laser beam should be aligned so that it is centered on the joint to be welded. This can be done manually by adjusting the position of the laser head or automatically using a computer-controlled system. Some laser welding machines have built-in cameras or sensors that can detect the position of the joint and automatically adjust the laser head accordingly.

Try Prolean Now!

Executing Excellence: Performing the Laser Weld

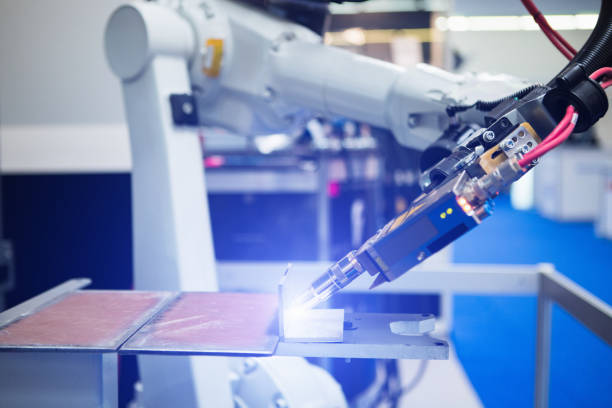

Automatic welding robot in a modern factory

The robotic arm performing the laser welding

Performing the weld is the most crucial step in the laser welding process. This is where all the prior preparations and settings culminate into the actual welding of the materials. Executing the weld involves several essential steps and considerations to ensure a high-quality weld.

Table: Critical steps involved in performing a laser weld

| Step | Task | Purpose | Risk if not done properly |

|---|---|---|---|

| Positioning the Workpieces | Align joint with laser beam | Ensures proper fusion and minimizes weld defects | Incomplete fusion, excessive spatter, other weld defects |

| Starting the Laser | Gradually increase laser power | Prevents thermal shock and minimizes risk of material cracking or other defects | Cracking or other defects |

| Performing the Weld | Move laser beam along the joint | Ensures adequate heat input for complete fusion | Excessive heat input leading to burn-through or excessive penetration, or insufficient heat input leading to incomplete fusion |

| Monitoring the Weld | Visually or using sensors | Ensures proper formation of weld pool and detects signs of excessive spatter, cracking, or other defects | Formation of excessive spatter, cracking, or other defects |

| Stopping the Laser | Gradually decrease laser power | Prevents thermal shock and minimizes risk of material cracking or other defects | Cracking or other defects |

| Inspecting the Weld | Visually or using non-destructive testing methods | Ensures the weld is free of defects and is structurally sound | Quality compromise |

Ensuring the Optimal Weld Quality and Post-Processing

Once the weld is complete, it’s not the end of the road. The final, and one of the most critical steps in the laser welding process, is assessing the weld quality and conducting any necessary post-weld processing. This phase ensures that the welded joint is of the highest quality and suitable for its intended application.

Laser weld on steel

Assessing Weld Quality

After the welding process, it is essential to assess the quality of the weld to ensure it meets the required standards and specifications. This involves both visual inspection and non-destructive testing (NDT).

- Visual Inspection: This is the most basic form of inspection and involves looking at the weld with the naked eye or using magnifying tools to check for surface defects such as cracks, porosity, or incomplete fusion.

- Non-Destructive Testing (NDT): This involves using various methods to examine the weld without causing any damage to the material. Common NDT methods include X-ray testing, ultrasonic testing, and magnetic particle testing. These methods can reveal subsurface defects that are not visible to the naked eye.

Each inspection method has its advantages and limitations, and the choice of method depends on the material, the application, and the required quality standards.

Post-Weld Processing

After the weld has been inspected and approved, it may need to undergo post-weld processing to improve its mechanical properties or aesthetic appearance. This can involve several different processes:

- Stress Relieving: Welding introduces residual stresses into the material, which can lead to distortion or cracking over time. Stress relieving involves heating the welded joint to a specific temperature and then slowly cooling it to reduce these residual stresses.

- Heat Treatment: This involves heating the material to a specific temperature and then cooling it at a controlled rate to alter its mechanical properties. This can improve the strength, hardness, or ductility of the welded joint.

- Surface Finishing: This involves removing any surface irregularities, such as rough spots or discoloration, to improve the aesthetic appearance of the weld. This can be done using various methods, such as grinding, polishing, or applying a surface coating.

Prolean’s Welding Services: Precision and Quality

Prolean is a popular name in the domain of Laser Welding services, synonymous with precision, quality, and technical expertise. Equipped with the latest laser machinery, a team of seasoned technicians, and a dedication to client satisfaction, Prolean guarantees the success of your welding endeavors.

Leveraging the latest in laser innovations, including high-intensity lasers and sophisticated beam transmission systems, we delivers welds of unmatched precision and quality. Our team, comprised of skilled technicians with a deep understanding of Laser Welding methodologies, possesses the expertise required to manage intricate projects and guarantee outstanding welding outcomes.

At Prolean, we are committed to upholding the pinnacle of quality standards and are proud to be ISO-certified. Rigorous quality assurance protocols and comprehensive inspections are meticulously conducted to ensure the durability and dependability of the welds.

Conclusion

In conclusion, laser welding is a critical technology that offers several advantages over traditional welding methods, including precision, speed, and the ability to weld dissimilar materials or thin-walled sections. Understanding the basics of laser welding, from the different types such as conduction mode welding and keyhole mode welding to the detailed steps involved in preparing the materials, setting up the machine, aligning the beam, performing the weld, and assessing the quality and post-weld processing, is essential for anyone involved in manufacturing or engineering fields.

FAQs

What is laser welding?

Laser welding is a process that uses a concentrated laser beam as the heat source to fuse materials together.

What are the types of laser welding?

The two main types of laser welding are conduction mode welding and keyhole mode welding.

What are the key applications of laser welding?

Laser welding is widely used in the automotive, aerospace, electronics, and medical device industries.

What are the key parameters to consider in laser welding?

The key parameters to consider in laser welding include laser power, beam diameter, welding speed, and focal point position.

What are the advantages of laser welding?

Laser welding offers several advantages, including high precision, fast processing speed, and the ability to weld challenging materials.

0 Comments