“Understanding how China harnesses the potential of ABS plastic injection molding can be pivotal for your manufacturing needs. It will help you to plan your project efficiently and make informed decisions.“

ABS plastic stands out for its versatility, efficiency, and quality in the manufacturing arena. Like other manufacturing sectors, China leads the ABS injection molding industry with unparalleled precision and competitive pricing. China ABS Plastic Injection Molding Services are renowned globally across diverse sectors for precise ABS parts and injection molds.

This article briefs the intricacies of China ABS Plastic Injection Molding, exploring its benefits, processes, cost considerations, and why it’s a preferred choice for many global businesses. Whether you’re a small enterprise or a large corporation,

Overview of ABS Plastic Injection Molding

ABS is a robust and versatile thermoplastic polymer. This material combines acrylonitrile and styrene’s strength with polybutadiene’s toughness. Consequently, ABS is suitable for injection molding, boasting high impact resistance and rigidity. It allows complex shapes, suiting various applications. Products range from automotive parts to consumer goods, showcasing their utility As a result ABS is a top choice material in China Injection Molding.

ABS plastic injection molding

The process starts with feeding ABS into a heated barrel. Here, it melts into a liquid state. The molten plastic is then injected into a mold under high pressure. Once in the mold, it cools and solidifies, forming the final product. Furthermore, automation makes this process efficient, ensuring consistent quality. China ABS Plastic Injection Molding excels in global manufacturing with advanced technology and a skilled workforce.

- High Impact Resistance: ABS exhibits exceptional durability, making it ideal for products requiring toughness.

- ABS plastic properties: Can be easily modified to enhance characteristics like UV resistance or flame retardancy.

- ABS plastic balances strength and rigidity and is suitable for various applications.

- Good Dimensional Stability: Maintains shape and form even under stress, ensuring product consistency.

- Ease of Processing: Can be molded into complex shapes and sizes, allowing for design flexibility in manufacturing.

- Cost-Effectiveness: Low material cost and efficient production make it a budget-friendly option.

- Recyclability and Environmental Sustainability: ABS can be recycled, reducing waste and promoting eco-friendly manufacturing practices.

Related: 9 Best Injection Molding Materials

Try Prolean Now!

China ABS Plastic Injection Molding Capabilities

China’s ABS plastic injection molding is crucial in crafting a vast range of robust and precise products. China is a popular destination with over 3,000 injection molding companies. Its annual output reaches millions of tons, contributing a substantial share of global ABS product exports.

1. Advanced Technological Infrastructure

China sets a high standard for precision and efficiency in ABS Machining. These advanced machines, coupled with robust automation and robotics, streamline production, reducing errors and enhancing consistency. This infrastructure places China at the forefront of innovative manufacturing solutions.

ABS Injection molding machine

The skilled workforce in China, comprising expert engineers and technicians, is a cornerstone of its ABS molding capabilities. Regular training programs ensure professionals stay updated with the latest technological advancements, fostering a culture of continuous improvement and innovation.

2. Large-Scale Production

China’s ABS injection molding industry can cater to large-scale global demands. This is possible because of the fusion of advanced technology and skilled labor. This efficiency enables custom injection molding services to meet urgent and voluminous orders without compromising tolerances.

Customization and flexibility are hallmarks of China’s ABS plastic injection molding. Chinese manufacturers are adept at tailoring designs to specific client needs, ensuring diverse applications. This versatility extends from automotive parts to consumer electronics, demonstrating the breadth of their molding expertise.

3. Quality Assurance

In China, strict testing and inspection protocols ensure product reliability and quality. Therefore, Chinese-manufactured products are competitive globally due to their compliance with international standards.

Economies of scale and efficient processes drive the injection molding cost in China. Moreover, the emphasis on reducing waste contributes to cost reduction, enhancing overall economic efficiency.

4. Sustainability Efforts

Sustainability is integral to China’s ABS molding operations. Many factories have adopted recycling initiatives, aligning with global environmental sustainability goals. Additionally, efforts to minimize energy consumption during production reduce the industry’s carbon footprint, reflecting a commitment to eco-friendly practices.

What Can You Make with ABS Injection Molding Services in China?

Injection molding services in China cater to various industry needs, producing parts and products integral to everyday life and advanced technological applications.

Here is a list of examples:

- Automotive dashboard panels

- Protective helmets for sports and construction

- Enclosures for electronic devices

- Toys, such as LEGO bricks

- Computer keyboard keys

- Wall socket faceplates

- Telephone handsets

- TV remote controls

- Vacuum cleaner components

- Kitchen appliances like blenders

- Power tool housings

- Medical devices like inhalers

- Luggage and suitcase shells

- Camera bodies and accessories

- Airplane interior components

How do you outsource ABS injection molding parts from China?

Outsourcing ABS injection molding parts from China is a strategic move for many businesses seeking cost-effective, high-quality manufacturing solutions. The process involves several key steps, each critical for successful outsourcing, from identifying reliable manufacturers to managing logistics.

1. Identify Reliable Manufacturers

The first step is to identify and shortlist reputable ABS injection molding manufacturers in China. Research their track record, customer reviews, and industry reputation. Attending trade shows or using B2B platforms can also provide valuable insights. Choose manufacturers who align with your quality standards and production needs.

Next, verify their certifications, production capabilities, and compliance with international quality standards. Direct communication is crucial; consider visiting the factories(if possible) to understand their operations and quality control processes.

2. Negotiate Terms and Pricing

After selecting a manufacturer, negotiate the terms such as pricing, payment terms, and delivery schedules. Be clear about your expectations and ensure the manufacturer understands your product specifications and quality requirements.

Next, discuss and finalize details like minimum order quantities, lead times, and shipping terms. A well-negotiated contract will protect your interests and set clear expectations for both parties. It’s advisable to seek legal advice to ensure the contract is comprehensive and binding.

3. Manage Production and Quality Control

Monitoring the production process is vital to ensure quality and adherence to specifications. Establish clear communication channels with the manufacturer for regular updates. Utilize quality control inspections at various production stages to identify and rectify issues early.

Consider hiring third-party quality control services for unbiased inspection of the products. They can provide detailed reports and ensure the manufacturing process meets your standards.

4. Handling Logistics and Customs

Navigating logistics and customs is a critical aspect of outsourcing from China. Decide on the shipping method that best suits your timeline and budget. Understanding and complying with customs regulations in China and your country is essential. Ensure all necessary documentation and duties or taxes. This will prevent delays and additional costs during shipping.

5. Seamless Communication

Utilize technology for efficient communication. Tools like video conferencing, instant messaging, and project management software can bridge the geographical and time zone differences. Regular updates and open lines of communication prevent misunderstandings and keep the project on track

6. Post-Production Review

Conduct a thorough review of the products after accepting the ABS parts. Assess the quality, packaging, and compliance with the agreed specifications. Next, provide feedback to the manufacturer, whether positive or negative. A post-production review also provides insights for continuous improvement and potential modifications for subsequent orders.

Related: Outsourcing the CNC Machining Service from China: Everything You Need to Know

Try Prolean Now!

How Much Does ABS Plastic Injection Molding Cost in China?

Understanding the cost of injection molding in China is crucial for businesses planning to outsource manufacturing. This process, widely used for producing high-volume plastic parts, varies in cost depending on several factors.

Automotive part created with ABS Injection Molding

ABS plastic is a cost-efficient option compared to other materials. Additionally, purchasing in bulk can significantly lower the unit cost, making large orders more economical. The complexity of mold design directly influences the cost; intricate molds are more expensive.

The choice of durable materials for mold construction adds to the overall expense. Production costs are impacted by machine usage time and labor expenses, although labor in China remains relatively affordable. Furthermore, overhead costs in the injection molding process include factory utilities and maintenance. These operational expenses are often overlooked and are essential components of the total cost.

Real-World Example: Producing 5000 ABS Parts

Let’s consider an example of outsourcing ABS Parts from China, discussing different costs with a detailed breakdown.

- Part Dimensions: 200 x 100 x 50 mm.

- Material: ABS plastic.

- Quantity: 5,000 units.

- Accuracy: ±0.125mm

Here is the cost breakdown for producing 5000 ABS injection molding parts

Table: China ABS Plastic Molding Cost Breakdown

| Cost Component | Details | Amount ($) |

| Mold Creation | One-time cost for part size and complexity | 5,000 |

| Material Cost | ABS cost ($2-3 per kg); Each part is 0.2 kg | 2,500 |

| Production Cost | Machine time and labor for 5000 parts | 2,500 |

| Overhead | Factory running costs for the batch | 1,000 |

| Total Cost | Total estimated cost for the batch | 11,000 |

It shows that the estimated cost per part for producing 5000 ABS injection molding parts in China is $2.20. This example demonstrates how material, mold, production, and overhead costs collectively determine the cost of Injection Molding ABS Parts in China.

Custom ABS Plastic Injection Molding in China

Custom ABS plastic injection molding in China brings product personalization. It allows unique designs and functionalities, catering to specific industry needs. This customization is achieved through precise control over the molding process. It ensures products meet exact client specifications.

Custom electronic housing from ABS injection molding

Chinese manufacturers excel in producing custom ABS plastic parts. They adapt to complex and varied design requirements. Their expertise extends to creating specialized components for diverse sectors. This adaptability ensures a broad application scope, from automotive to consumer electronics. The process involves close collaboration between clients and manufacturers. It ensures designs are feasible and cost-effective.

Here are some real-world examples of custom ABS injection molding parts

- Custom Automotive Dashboards that fit specific car models, featuring unique design elements and ergonomic layouts.

- Custom Electronic Housings for devices like smartphones, gaming consoles, or routers.

- Customized inhalers, hearing aids, or diagnostic equipment casings for patient comfort and specific medical requirements.

- Specialized sporting equipment like helmet shells and protective gear is designed for specific sports or athlete requirements.

- Housings or accessories for cameras

- Aircraft Interior Elements, such as customized cabin components such as overhead bins or seat parts, are designed for specific aircraft models.

- Custom ABS parts for instruments like keyboards or electronic drums, tailored for specific sound qualities or designs.

- Customized keyboard keys, mouse shells, or laptop stands designed for specific user preferences or ergonomic needs.

Related: The Benefits of Custom CNC Manufacturing for Specific Industry Applications: A Case Study

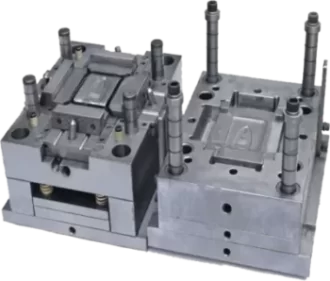

Injection Molds for ABS Injection Molding

Injection molds are pivotal in ABS injection molding, generally created with CNC machining and different types of EDM. These methods ensure the precision and durability of molds. Furthermore, Rapid prototyping allows quick validation of mold designs.

injection mold

CNC machining in creating injection molds ensures intricate details are accurately captured. This process is suitable for creating molds that require fine features or specific textures. EDM (Electrical Discharge Machining) complements CNC by handling complex shapes and hard materials, enhancing mold quality.

Injection molds from China stand out for their quality and cost-effectiveness. Leveraging advanced machining techniques, Chinese manufacturers produce molds that meet diverse industrial needs. Their expertise in rapid prototyping accelerates the development process, ensuring quicker market entry for ABS molded products.

Try Prolean Now!

From Mold Design to Surface Finishing of ABS Injection Molding Parts at Prolean

At Prolean, our expertise extends from mold design to the final surface finishing of ABS Plastic machining. Our process begins with mold design, ensuring each part meets precise specifications. We utilize advanced CNC and EDM machining for high-quality molds perfectly tailored to ABS materials.

Our commitment to excellence continues in the mold creation phase. Our advanced CNC Machining and EDM machining capabilities allow us to fabricate molds with exceptional precision. This attention to detail is crucial in producing ABS parts that meet and exceed client expectations.

When completing the manufacturing process, we offer different surface finishing options for injection-molded ABS parts, such as sandblasting, polishing, and more. This final step enhances the parts’ aesthetic and functional qualities. By choosing Prolean, you leverage the best of China ABS Plastic Injection Molding, benefiting from our comprehensive and high-quality service offerings.

Summing Up

China’s ABS plastic injection molding sector showcases its manufacturing excellence, blending affordability with quality. Technological progress and skilled labor contribute to this success. Businesses worldwide find China an attractive option for reliable, efficient injection molding services. China stands out in the global market with competitive and innovative offerings, This sector provides customizable solutions that add to its appeal. It is a top choice for companies in need of high-quality injection molding.

Read more:

FAQs

Which country is best for injection molding?

China is often considered a global leader due to its cost efficiency, technological advancement, and vast production capacity in injection molding.

How much does plastic injection molding cost in China?

Pricing varies, but China is known for offering cost-effective solutions, especially for large-scale production, making it an attractive option.

What are the key benefits of China ABS plastic injection molding?

It offers unmatched cost-effectiveness, superior quality, and broad versatility across various applications, making it highly sought-after globally.

How does China maintain a competitive edge in ABS injection molding?

China leads with advanced technologies, highly skilled labor, and streamlined production processes, ensuring top-notch quality and efficiency.

Is custom ABS plastic injection molding available in China?

Yes, numerous companies in China specialize in offering customizable ABS plastic injection molding services to meet diverse needs.

Can ABS injection molds be designed for specific applications?

Molds can be intricately customized to meet unique industry requirements, offering flexibility and precision in manufacturing.

Six month back, i outsourced some Custom ABS Camera bodies from China, and i definitely recommend. However, the cost was not that significantly lower than here in Dublin.

Liam, the cost might be not low as you expected if you order in small batch! However, at Prolean We balance the cost in prototyping and small batch manufacturing also.