Aluminum Welding is an efficient technique to unite two aluminum parts together. Aluminum, being a softer metal, usually permits significant welding challenges. However, precise control and weld conditions allow manufacturers to overcome these issues and help achieve optimal welds. Aerospace parts fabrication generally selects aluminum for its weightlessness, corrosion resistance, and superior durability. Therefore, it serves several manufacturing sectors compared to other metals.

Aluminum welds demand uniform warmth, welding materials, and skillful execution. Compared to steel welding, it requires more careful attention. Aluminum weld poses challenges due to its high thermal conductivity and inherent oxidation layer formation.

The article entails key details about aluminum welding, the difficulties, weld techniques, and useful tips for efficient wels.

How To Weld Aluminum? Aluminum Welding Basics

Aluminum Welding

Aluminum offers a unique combination of strengths, but it has challenges, too. The lightweight characteristic of aluminum maintains structural strength without adding any unnecessary weight. So, it serves well in outdoor applications because it demonstrates strong protection against rusting. Moreover, aluminium’s excellent heat conductivity enables quick thermal alterations. The ductility of aluminum is suitable for stretching into thin wires as it didn’t break during the process.

- Navigating Aluminum’s Oxidation Challenge

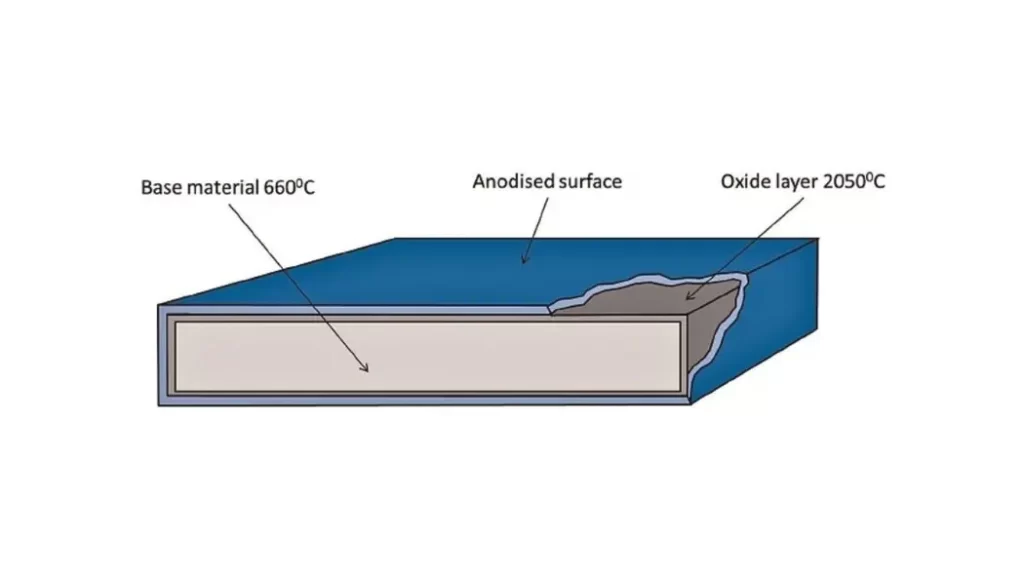

During the aluminum metal welding process, it develops a protective oxide layer that speeds up the reaction and preserves its surface from rust. The melting point of aluminum is about 660°C (1,220°F). The oxide layer itself melts at a much higher temperature, around 2,000°C (3,632°F). An optimal aluminum weld requires the removal of the oxide layer; otherwise, it penetrates the material. In general, two distinct approaches for oxide layer removal are used. These include wire brushing and chemical solution treatment.

- Aluminum Welding Techniques

TIG (Tungsten Inert Gas) is most commonly applied to thin aluminum profile welding. It uses non-consumable tungsten electrodes to give precise weld results. Usually, an alternative current(AC) helps balance the oxide removal and penetration. Meanwhile, thick aluminum sections often use MIG (Metal Inert Gas) welding. It provides rapid welding performance through unimpaired wire delivery.

- The Role of Shielding Gases

Shielding Gas

Shielding gases aids protective barriers and preserves welded areas from outdoor pollutants. TIG welding normally uses argon gas to maintain neat welds during the operation. Meanwhile, MIG welding uses a mixture of helium and argon-helium. These gases permit deeper penetration and promote a faster welding process to improve the final quality weld.

- Assessing the Quality of Aluminum Welds

Black soot should not appear during aluminum welds. This indicates proper oxide removal during welding. The welded area needs to exhibit homogeneous characteristics. It must maintain a consistent shape without bumps, gaps, and non-uniform areas. Creating quality welds depends on three primary factors: steady hand movement, constant speed control, and correct arc length.

Preparing Aluminum for Welding

Preparing Aluminum For Welding

The optimum aluminum process depends on choosing well-prepared materials. Handling aluminum preparation work before welding remains the critical factor determining the weld quality. The following steps show how to prepare aluminum correctly before welding begins.

- Understand Aluminum Alloy

Aluminum Alloy Welding

The first important step in welding is choosing the right aluminum alloy. Aluminum is usually an alloy, not pure, and needs to be mixed with other metals to improve its properties. The welding behavior of aluminum alloys varies based on their composition. Some alloys can be heat-treated, while others cannot. To get the best results, it’s essential to understand the alloy you’re working with so you can choose the right filler materials and welding techniques.

Read more: Different Aluminum Grades

- Addressing the Oxide Layer

Oxide Layer In Aluminum Welding

Aluminum automatically develops a tiny oxide film during contact with air. The oxide layer creates barriers that stop weld metals from properly joining. Thus, it produces vulnerable welds. Removing the oxide layer is an essential step before starting the welding process. A stainless steel brush is optimal for eliminating aluminum surface oxide. It only touches aluminum areas to avoid contamination. Besides, using chemical solvents allows complete cleaning by enabling oxide layer removal and other remaining impurities.

- Maintaining a Clean Surface

Aluminum naturally absorbs contaminants, like dirt, oil, and grease, that impair welding performance during welding. Foreign matters remaining on the surface usually create holes and vulnerable areas in the final weld. Therefore, the aluminum must be entirely cleaned before initiating the welding operation. Moreover, degreasing solvents and cleaning solutions must be used to remove dirt and oils during cleaning. A dry, lint-free cloth wipe should be used to clean aluminium to obtain a contaminant-free perfect surface.

- Proper Joint Preparation and Design

Rusting In Aluminum Weld

The joint configuration determines the weld quality. Different joint designs should be selected based on the type of aluminium alloy and its thickness. The edges of thick aluminum require beveling before welding because it improves penetration. The joint and proper preparation allow the filler material to blend perfectly with the base aluminum. Eventually, it produces stronger welded joints with enhanced reliability.

- Choosing the Right Filler Material

Filler Material For Aluminum Weld

Choosing suitable filler material also plays an important role in the final weld quality. The filler material generally selected based on aluminum alloy used and the intended properties of the resulting product. When filler material matches the base aluminum, it develops resistance against cracking by establishing a strong bond. In addition, its choice is also based on consulting compatibility charts. This chart helps choose materials for strong, reliable welds.

- Preheating

Preheating can help minimize cracking and forming porous areas in extensive aluminium sections and specific alloy types. However, excessive preheating can lead to negative consequences. Moreover, preheating aluminium helps prevent sudden temperature changes that can cause welding issues.

However, aluminium must not receive excessive heating because high temperatures can degrade its fundamental characteristics. Welders must understand both preheating timing and the right methodology to achieve perfect welding outcomes.

Ways To Weld Aluminum

To maintain aluminum welding standards, it’s essential to find a reliable expert for aluminum welding near me. Welders must use special welding techniques because of it’s inherent properties. It offers exceptional lightweight strength, but proper welding requires the right techniques and expertise. In this section, let’s analyze the top aluminum welding procedures.

TIG Welding Aluminum

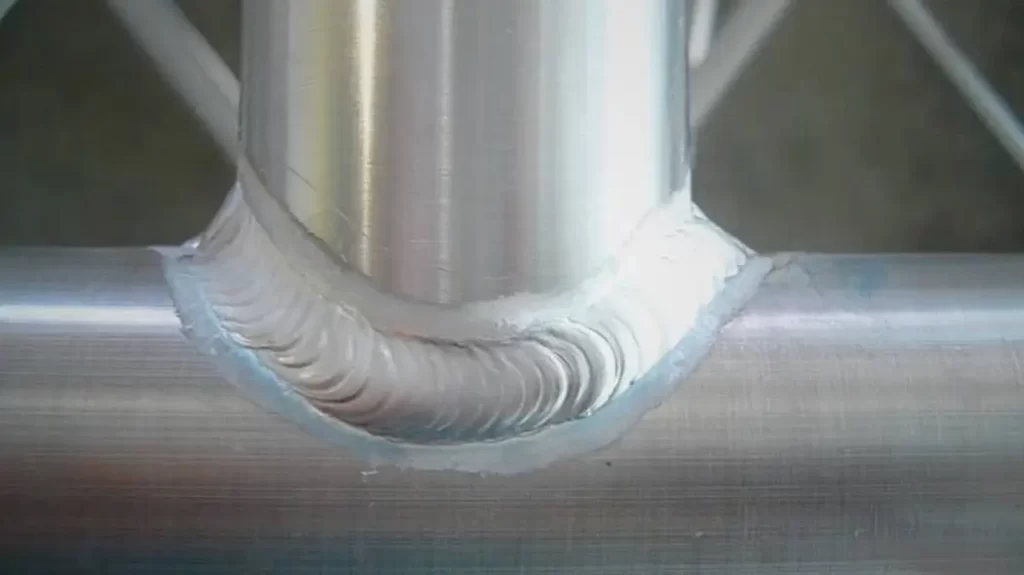

Aluminum TIG Welding

Professional welders favour the Tig welding procedure. It encompasses Gas Tungsten Arc Welding as their standard methodology for aluminium work. It delivers outstanding control features while operating on thin and thick aluminum parts.

- Torch and Electrode: A welding arc begins at a non-consumable tungsten electrode through torch and electrode mechanisms. A pointed electrode provides control, particularly for welding thin aluminum.

- Shielding Gas: Aluminum TIG welding relies on pure argon as its shield gas choice. This gas stabilizes the arc and minimizes welding process contamination.

- AC Welding: Applying alternating current (AC) in TIG aluminum welding disrupts the oxide layer, so the filler material and base aluminum create better fusion.

- Filler Rod Selection: The appropriate filler rod is significant because it determines weld strength and durability. Usually, the alloys 4043 and 5356 gained wide adoption because they deliver excellent flow characteristics and notable strength.

- Foot Pedal Control: A foot pedal allows the welder to modulate the power output. It ensures the right heat is applied for welding.

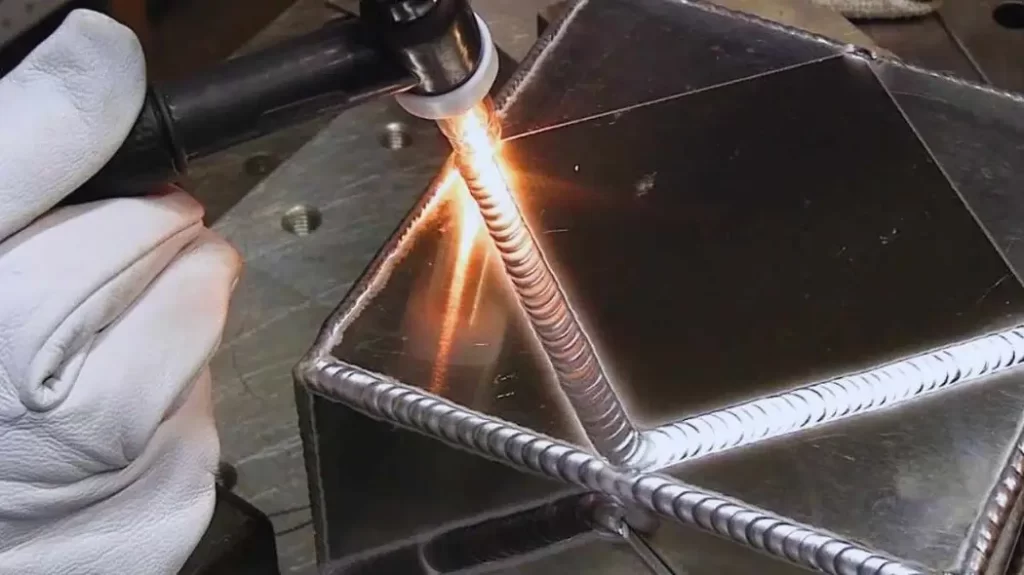

Aluminum MIG Welding

Aluminum MIG Welding

The Metal Inert Gas (MIG) welding process is also known as Gas Metal Arc Welding (GMAW). It is another effective technique for aluminum welding. MIG welding delivers speedier production in industrial situations than TIG welding because it works best for big manufacturing jobs.

- Optimal Parameter Controls: In MIG welding, the welder adjusts parameters like wire feed speed, voltage, current, travel speed, gas flow, electrode extension, polarity, and stick-out length.

- Choice of Wire: Among the main wires used for aluminum MIG welding are 4043, 5356, and 4943. The selected wires must encompass high strength, resistance to cracking, and demonstrate ideal fluidity features to produce welds with high integrity.

- Shielding Gas: A fusion of argon and helium serves as the shielding gas during MIG welding operations. The simultaneous use of these gases provides steady arcs and deep penetration results.

- Electrode Polarity: During MIG welding operations, the positive electrode phase should use a direct current designated as Direct Current Electrode Positive (DCEP). The setup design enables maximum penetration with faster wire deposition speed.

Gun and Liner: The MIG gun uses a Teflon liner. It safeguards the wire from abrasion. A spool gun and a push-pull system help minimize wire feeding problems and allow continuous welding operation.

Aluminum Spool Gun Welding

Aluminum Spool Gun Welding

Wire feeding issues can ruin a weld quickly. A spool gun with an effective Gas welding mechanism can resolve these issues by keeping the aluminium wire close to the weld gun. It avoids tangling, bird-nesting, and feeding inconsistencies. Here’s the demonstration of the spoon gun setup.

Feeding Mechanism

A spool gun feeds the wire directly from the gun itself. So, it eliminates the need for long cables used in standard MIG setups. The shorter the path, the fewer the chances of jams and more controlled weld.

Short Feed Distance

In the spool gun welding setup, the wire remains stationary, and it doesn’t travel through long cables. This helps prevent kinks, tangles, and wire drag. As per the rule of thumb, a short feed path means minimal disruptions and consistent quality weld.

Shielding Gas

Standard MIG welding uses spool guns that need shielding gas. Generally, a mixture of argon-helium is used to keep the weld clean and potent. Besides, it helps block contaminations and improves weld fusion.

Portability

Spool guns are compact and easy to handle. Their compact design makes welding in tight spaces more straightforward. So, welders can get better access to detailed welding jobs.

Compatibility

Remember that not all MIG welding machines support the spool gun mechanism. So, it is advised to check their compatibility before opting for it.

What Are the Challenges in Welding Aluminum?

Hot Cracking In Aluminum Welding

Aluminium is extensively used in welding applications due to its lightweight nature, corrosion resistance, and strong strength-to-weight ratio. Despite its enormous benefits, it has challenges, too. Let’s discuss the challenges with a comprehensive table.

Table: Detailed Challenges in Welding Aluminum

| Challenge | Description | Implications/Results | Potential Solutions/Considerations |

|---|---|---|---|

| Thermal Conductivity and Heat Sensitivity | Aluminum has high thermal conductivity, five times that of steel, and a melting point lower than its oxide layer. | Rapid heat dissipation can lead to warping, distortion, and residual stresses in the weld. Usually, it especially appears in thinner sheets and impacts the strength of joint. | Use higher amperage levels for proper fusion; maintain a fine balance during welding. |

| Formation of Aluminum Oxide | Aluminum naturally forms a thin, protective oxide layer on its surface, which has a melting point three times that of pure aluminum. | This oxide layer can inhibit fusion during welding. It may produce weaker welds, as a result. | Use AC TIG welding to disrupt oxide; ensure meticulous cleaning and preparation for other welding methods. |

| Susceptibility to Porosity | Presence of hydrocarbons and high solubility of hydrogen in molten aluminum lead to porosity. | As aluminum solidifies, hydrogen release causes tiny bubbles in the weld bead, undermining mechanical properties. | Minimize contaminants; use proper shielding gases; ensure clean base materials. |

| Cracking Concerns | Aluminum’s narrow melting range makes it prone to hot cracking, with certain alloys being more susceptible. | Cracks compromise the structural integrity of the weld and the component. | Choose appropriate filler material; optimize joint design; consider preheating. |

| Alloy-specific Challenges | Different aluminum alloys have unique welding characteristics and requirements. | Some alloys, especially those with high silicon or copper, can be challenging to weld. | Understand alloy properties; adapt techniques and materials based on specific alloy requirements. |

Try Prolean Now!

What Are the Advantages of Aluminum Welding?

Industrial Aluminum Piping Welding

Modern manufacturing companies widely rely on aluminium due to its commendable strength. The right welding techniques enable you to deliver products with superior quality and intended performance. Let’s analyze the major advantages of aluminum welding for your business operations.

Lightweight Yet Strong

Aluminum is a superior material because of its excellent strength-to-weight ratio. So, you can create lightweight yet durable components out of aluminum. When you apply the right technique and weld properly, it maintains its strength and resilience. Additionally, aluminum provides lightweight parts, which is why it’s commonly used in industries like aerospace and automotive. Reducing weight not only helps improve part performance but also maximizes the lifespan.

At Prolean Tech, we specialize in precision aluminum welding. Our team ensures that your components weld neatly as strong and lightweight as desired. By working with us, you benefit from our expertise, which translates into higher performance and affordable costs for your projects. Whether you’re in aerospace, automotive, or working in another industry, we can help you achieve the perfect balance of strength and weight.

Resistance to Corrosion

Aluminum Corrosion Resistance

Aluminum is naturally resistant to corrosion. It develops an oxide layer on its surface. This protective barrier guards its surface against corrosion and rust damage. Moreover, aluminium stands up well when deployed in rough sites. For example, when used under seafront operations and in backyard situations, welded aluminium provides corrosion resistance if the welding right-weld technique is applied. The protective layer on aluminum makes it strong and low maintenance. Therefore, aluminum parts last longer without much upkeep.

Flexibility and Formability

Aluminum demonstrates great flexibility. It proves to be excellent in manufacturing advanced elements that need intricate design details. Moreover, the material can easily adapt, which results in unlimited opportunities for designing products. The material’s adaptable nature enables innovative production and effective manufacturing practices.

Thermal Conductivity

Aluminum material transfers heat exceptionally well. This is due to its superior thermal conductivity properties. As such, it is found to be mainly used as a component in cooling systems alongside heat exchangers. Aluminum components offer excellent heat transfer properties, which prevent equipment temperature from rising inherently. Moreover, it maintains consistent operation in situations that require high thermal stability.

Cost-effectiveness

Although aluminum has a higher initial price than other materials. But it provides long-term benefits. Aluminum is highly durable and resistant to corrosion, which means it tends to incur lower maintenance and replacement costs. Besides, the automation of aluminum welding minimizes the total expenses of manufacturing operations. Therefore, manufacturers usually find aluminum cost-efficient for producing products on a large scale. In addition, the material offers a long service lifetime. On top of that, it requires minimal maintenance, making it a financially sound choice.

More Attractive Visuals

Aluminum Welding Art

Aluminum has natural, lustrous visuals. So, it provides components with a polished appearance. The finished outlay of welded aluminum products becomes elegant after receiving appropriate polishing. The premium outlook depends upon the way you weld and the employment of the right technique. Aluminum works well for electronics and industrial products. The welding process gives aluminum a clean, refined finish, making the product more attractive.

Prolean Tech: Your Trusted Partner In Aluminum Welding Services

Prolean Tech’s Welding Service

Prolean Tech is committed to offering top-tier welding service for every project. Our skilled workers, with decades of experience, use accurate techniques that result in solid and pure joints during the welding process.

We provide personlized solutions to our customers as we understand each project demands specific requirements. Our certified welders follow industry standards and perform regular quality checks to ensure top results.

We usually execute MIG and TIG welding procedures. Our organization makes safety a fundamental concern. We implement rigorous safety protocols to safeguard project sites alongside team members.

All communication and service from Prolean guarantees both clarity and excellence throughout the entire process. Contact us now to start developing your project through collaborative efforts.

FAQ’s

Q1: Why is aluminum welding harder than steel?

During welding, aluminum forms an oxide layer and pulls heat away quickly. This makes the welding tricky and challenging. Therefore, special techniques and equipment are required for appropriate welding.

Q2: What’s the best way to weld thin aluminum sheets?

TIG welding is usually considered the best option for thin aluminum sheets. It gives precise control and super clean welds. That’s why manufacturers use it for thin/delicate feature products.

Q3: Can you weld aluminum with a regular MIG welder?

Yes, you can, but you need an aluminum spool gun or a push-pull system. Otherwise, the wire can jam and ruin the weld.

Q4: Why does aluminum welding often have porosity issues?

Porosity happens when hydrogen gets trapped in the weld. Moisture and dirt make it worse. That’s why cleaning and the right gas are key.

Q5: How does Prolean ensure top-quality aluminum welding?

Our faculty employs advanced tools and is laced with skilled welders. Every weld follows strict quality checks for integrity and delivers spotless results every time.

Q6: Can you weld aluminum directly to steel?

No, you can not weld aluminum directly to steel. Because it normally creates brittleness and weakens the welds. However, a bimetallic insert and special coating work better. That way, the bond stays strong.

Q7: What is the most weldable aluminum?

Aluminum 5XXX series alloys, specifically 5052, 5083, and 5154, are considered the most weldable alloys.

Q8: What type of welding is used for aluminum?

Gas Tungsten Arc Welding (GTAW)/ TIG is widely adopted to unite aluminum parts. It does not require any mechanical wire feeding. So, feebabilty issues are comparatively lower in GTAW.

Q9: What is the trick to welding aluminum?

The optimal aluminum weld depends on various factors. Prepare or preheat the aluminum surface or clean it. Choose a pure tungsten electrode. Avoid argon’s excessive presence on the surface and use heat sinks to prevent warping issues.

0 Comments