Cutting by waterjet is now one of the most popular processes in the contemporary market. There are many benefits associated with waterjet cutters and more manufacturers are now using them.

These machines can make parts of high precision for any manufacturing sector. Whether it’s waterjet aerospace or automotive parts cutting, the accuracy of water jet cutting machines is indispensable. The industrial waterjet cutting machines are well-rounded as they can cut any material without any problem. But it is not as simple as sawing metal using these machines.

To be able to operate a waterjet cutter, you have to familiarize yourself with certain terms. One such term is waterjet cutting tolerances. This guide will provide all the information about waterjet cutting tolerance you need to know. You will also find out why it is important and how to do it. Read on to find more information.

Why It Is Essential to Have High-Precision Waterjet Cutting?

It is imperative to note that precision and accuracy play a vital role in every manufacturing process. A little leeway is usually allowed for this degree of accuracy. For instance, aerospace and automotive industries require high-tolerance cutting through waterjet cutting techniques.

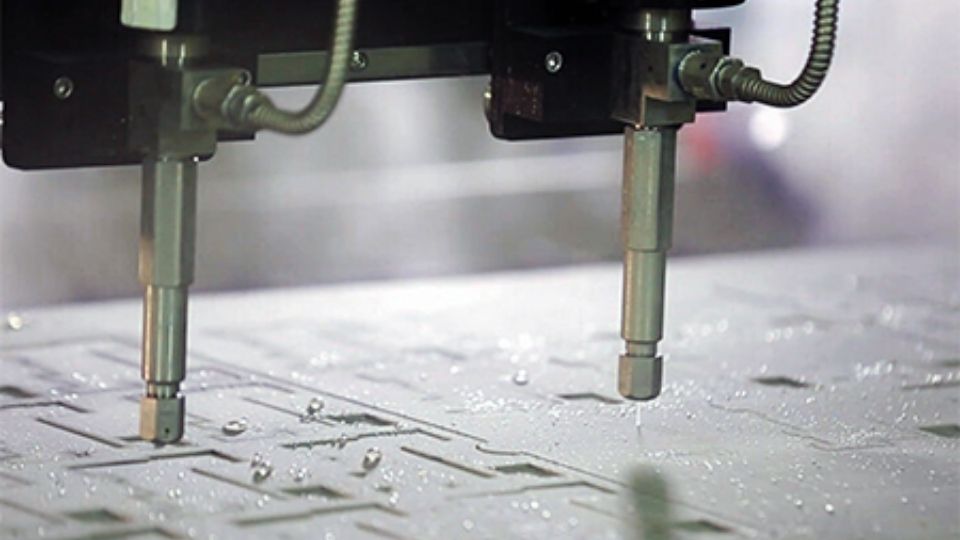

Precision water jet cutting

In these fields, there are occasions when the parts are manufactured independently and joined together at an advanced level. Waterjet cutting is most appropriate for this because it has a low tolerance which makes it cut smoothly. This also tends to make assembly of the parts a lot easier and much more efficient.

Not all industries require high-precision waterjet cutting tolerance levels. However, waterjet cutting is the best when accuracy and precision are an essential factor to consider.

Try Prolean Now!

Degree of Precision In Waterjet Cutting Technology?

Another benefit of the water jet machining process is that it can provide maximum precision, and meet exact design measurements. Why is accuracy important?

It is important because cutting tolerance is directly proportional to accuracy. The term cutting tolerance is used to refer to the small difference between the actual and the desired cut. Each cutting method has some shift, but in the case of waterjet technology, it is almost negligible.

What are the General Waterjet cutting Tolerances?

Waterjet cutting tolerance

In general, the cutting accuracy of waterjet machines ranges from ± 0.002” (0.05 mm). Some can even go up to ± 0.001” (0.025 mm).

This shift is so slight that one cannot even notice changes with an ordinary lighted magnifying glass. With a normal ruler, you cannot measure this small scale.

Key Factors Impacting Waterjet Cutting Tolerances

Various elements may predispose the precision and cutting tolerance of waterjet cutting. One of them is cutting speed. However, if the speed of the machine is increased, the accuracy is reduced and a higher tolerance is produced.

The second key attribute is its abrasive nature. Inferior abrasives are not of uniform quality; they result in poor cutting and high tolerance. Using high-quality abrasives that have a uniform grain size will result in low tolerance and high precision.

The thickness of the material used is also an influencing factor. Thicker materials have a higher tolerance than thin materials because controlling the waterjet stream becomes difficult when it comes out of thick material. Thinner materials on the other hand are easier to cut with high precision.

Material hardness also affects the accuracy of the item being produced in the process. Harder materials tend to have less taper and hence there is a small difference in kerf in the entry and exit points. This results in high accuracy and low tolerance.

Another major aspect is the machine positioning. A large error tolerance results from improper positioning; therefore, it is necessary to adjust the machine accurately, taking into account waterjet kerf and shift.

Also, the status of the cutter plays a role In this regard. A cutter that has been maintained properly will give better accuracy. Malfunctioning nozzles or parts that have been used for a while are not as accurate, so replacement is required.

Moreover, the aspect of stability of the table is also a critical role-player. Vibrations in the workpiece can result in marks called witness marks, thus increasing the tolerance to an undesirable level.

Operator skills are one of the significant factors affecting the process. Although waterjet cutters are computer-controlled, an experienced operator will fine-tune the machine to eliminate any tolerance problems.

The software that runs the machine also determines the precision of the results. Better positioning is achieved with the help of advanced software, which reduces tolerance.

Lastly, the type of controller used in the machine has a great contribution to it. High-end controllers have higher accuracy and lower tolerance than the cheaper types of controllers.

What is Positioning Accuracy?

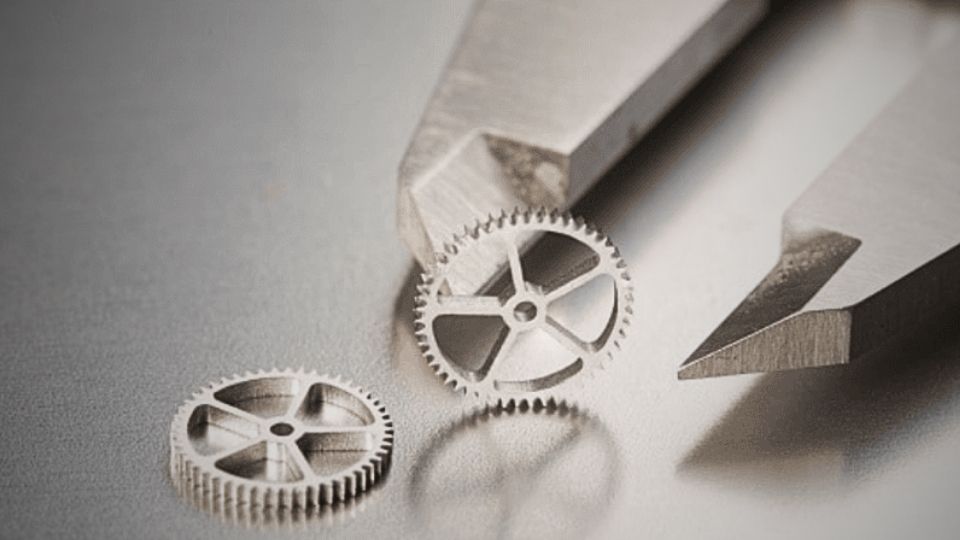

Water jet cutting Accuracy

Positioning accuracy gives information about how accurately the waterjet machine positions itself. Cutting precision is the measure of the deviation of the final cut from the design.

In waterjet machines, positioning accuracy reveals the offset between desired and achieved positions. A Finepart micro abrasive waterjet enables high precision hence enabling accurate cuts. These machines show good reproducibility; it is easy to get close tolerances when using these machines.

What is Repeatability?

Accuracy is a machine’s ability to make the same cut over and over again. This happens with the same conditions and parameters as the preceding type of assessment. It comprises the precision of the cutting head and water pressure. High repeatability is important because it gives one assurance of high quality particularly when it comes to precision-based organizations.

What is Cutting Precision?

Positioning accuracy is a measure of the machine’s ability to know where it should be cutting. Accurate trim is the measure of the accuracy of the cut made to the intended design.

Precision is defined as the extent of departure of the final cut from the ideal line. A high-precision micro abrasive water jet cuts very close to the actual shape. While using high-precision tools, the cut line is well defined, and machines that are worn or whose precision is low deviate from the cut line.

Significance of Accuracy

If the positioning is not accurate then the parts will not fit correctly. This may make that part useless, and consequently, lead to wastage. Consequently, wasted material, time, and energy can greatly affect efficiency. So, accuracy is a key factor in ensuring quality and reducing the amount of waste produced.

Etching/Partial Cutting Accuracy

Water jets have limitations in cutting precision or carving material to certain depths or in making an incision. Their design enables them to provide maximum accuracy in cutting through the material at once up to its full depth. The problem of regulating the depth of the water jet’s movement to stabilize its etching depth is challenging. This lack of control, in turn, may influence the precision of partial cuts.

Categories of Waterjet Cutting Tolerances

Tolerance measures the difference between the actual cut and the intended cut. There are two main ways to measure this precision:

Typical Cutting Tolerances

Tolerances with waterjet cutting machines are very low and difficult to measure with the naked eye. In general, these machines create tolerances of ±0.002” (0.05 mm) to ±0.001” (0.025 mm).

Optimal Cutting Tolerances

Accurate cutting tolerances are the best that a waterjet machine can provide to a client or customer. This depends on the specific machine and the company that manufactured that given machine. Most machines are capable of holding dimensional tolerances in the range of ± 0.001″ (0.025 mm).

Comparing Waterjet Cutting Tolerances with other Cutting Processes

However, waterjet cutting offers very small tolerances in comparison with other cutting technologies. One of the benefits is that the cutting head does not touch the workpiece. On the other hand, other processes raise the part temperature during cutting, which in turn, decreases tolerance.

This is achievable through waterjet cutting, making it suitable for many industrial uses given that the cutting tolerance is 0.0015”. Below is a comparison of cutting techniques and their tolerances:

Machining Process and Tolerances

Waterjet cutting: ±0.001″

Laser cutting: ±0.005″

EDM cutting: ±0.0001″

Oxy-fuel cutting: ±0.06″

Plasma cutting: ±0.02″

Related To: water jet cutting vs laser cutting cost

Try Prolean Now!

Endnotes

When working on parts with a waterjet cutter, even a difference of a couple of tenths of a millimeter can affect results. As such, waterjet cutting tolerances should be taken into consideration.

In general, the accuracy of water jet cutting is recognized as the most precise among similar methods available in the market. As mentioned, the best quality machine can produce the smallest tolerances.

For those customers who are interested in more accurate cutting, ProLeanTech provides a precision waterjet cutting service. Their machines are dependable and also come with sophisticated software to meet all the required specifications. The software comes with preset designs with cuts and the possibility to develop your design to fit your requirements.

FAQ’s

Q1. What is water jet cutting?

In contemporary manufacturing, the waterjet cutting process uses a high-pressure water jet to cut through materials. It involves abrasive materials for high-performance cutting and shaping intricate patterns.

Q2. Should one cut tolerance?

Yes, reducing tolerance is necessary if high-quality cutting processes are to be achieved. This makes it especially important in applications with high accuracy needs, including the automotive and aerospace industries. In these cases, one will find that even the difference of a millimeter can affect the final part produced.

Q3. How do you define kerf and cutting tolerance and how are they related?

Kerf means the thickness of the material cut off and always has a positive value. On the other hand, cutting tolerance is determined by how much the actual cut is away from the desired cut. This deviation can be positive or negative.

Q4. Can you name any type of cutting process that does not allow for any cutting tolerance?

Unfortunately, no cutting process can realize a cutting tolerance of zero. The nature of every method is that it has some tolerance level inherent to it. But at the same time, waterjet cutting tolerance levels are optimal compared to other cutting means.

0 Comments