Galvanized sheet metal has many uses since it is durable, long-lasting, and resistant to corrosion. Several types of galvanized sheet metal are covered in this article. It includes iron sheets, steel, and aluminum. Galvanized metal finishing services will also be covered. They may enhance their beauty and durability.

There is a protective zinc layer on a galvanized steel sheet. It protects against rust, moisture, and exposure. Galvanized sheet metal has an outstanding reputation for being durable and impervious to corrosion. Its long-lasting zinc coating makes it a favorite in many fields, including building, farming, light manufacturing, fishing, and commerce. In this way, the zinc layer serves as a precautionary barrier. It provides good protection from things that cause rust.

Galvanized Metal

What is a Galvanized Steel Sheet?

Galvanized steel is a type of metal sheet. It is rust-proof due to its zinc coating. Zinc functions as a protective layer, which prolongs its useful life. Zinc immersion is a method by which metals can be galvanized. The outcome is a zinc-iron alloy that cannot be separated from steel. The zinc coating is responsible for the distinctive aspect of galvanized steel. Additionally, it protects it from external factors that cause it to deteriorate. The same as any other steel sheet, it can be drilled, punched, and cut. Additionally, it is zinc-coated, rendering it corrosion-resistant.

Galvanized Steel Sheets

Try Prolean Now!

Types of Galvanized Sheet Metal

A galvanized steel sheet is used in building structures, gadgets, and motor vehicles. It is robust and long-lasting, making it perfect for corrosion-proof designs.

Galvanized Steel Plate

The most common way to make hot dip galvanized steel plates is to use the continuous galvanizing process. It involves immersing rolled steel plates in a zinc melting bath. Not only are galvanized steel plates thick and robust, but they are also very long-lasting. There is no other option available for industrial and marine tools that can compare to them.

Galvanized Steel Plate

Insulated Galvanized Aluminum Sheet

Galvanized aluminum sheet plate is made using the hot-dip process. But it is heated to about 500 ℃ after being grooved. This creates an iron-zinc alloy layer. These sheets are ideal for lightweight applications such as roofing, cladding, and automotive components, as well as for insulated aluminum foil. Coating adherence and weldability are high on this galvanized sheet. At the same time as they are as lightweight as aluminum, they provide corrosion protection comparable to that of galvanized steel.

Insulated Aluminum Foil

Single Sided Galvanized Sheet Plate

Products that are galvanized on a single side, such as single-side galvanized steel plate. It is more versatile than double-sided galvanized sheet. It welds, paints, treats for rust, and processes better. A double-sided difference galvanized sheet is an option. It has a small layer of zinc on one side to compensate for the lack of a zinc coating on the other side.

Electroplating Galvanized steel sheets

Electroplating creates galvanized steel sheets that are easy to work with. However, the coating is thinner than hot-dip galvanized sheets. It does not resist corrosion as well.

Composite Galvanized Sheet Plate

Composite plating, lead, zinc, and aluminum are some of the metals used to make this steel plate. This steel plate has good coating and rust prevention. The above varieties are not exhaustive. Other options include colored and printed galvanized steel plates, and PVC laminates. Meanwhile, hot-dip galvanized plate is still the most popular choice.

Coated Iron Plate

Galvanized iron sheets are used in sewerage and the farming industry. They are a cheap solution for corrosion-proof, long-lasting purposes.

Molten Zinc

Application of Galvanization Sheet

Galvanized sheet metal is robust and appreciated in many industries—some key benefits.

- Produces car bodies and trunks. Strong and corrosion-resistant. It streamlines bus and tram servicing.

- Electrical, mechanical, packaging, measuring, home appliances, and enclosures are manufactured.

- Used for environmentally friendly insulation, light metal structures, and medium-to-low-rise building components. The strength and weather resistance benefit front doors, lifts, PVC openings, siding, piping, plastic door characteristics, and fences.

- In the agricultural industry, it is perfect for water storage containers, divisions, and cages for livestock since it is long-lasting and can withstand high levels of moisture and outside conditions.

- Dishes, jars, basins, refrigerators, and devices utilize household goods.

Applications of Galvanization Sheet

Methods for Metal Surface Finishes

There are many methods for getting the metal surface finishing. Here are a few common techniques:

Powder Coating:

Powder coating is a great way to transform the look of metals and protect them from corrosion. Electrostatically coating a metal surface with a dry, powdered material is a widespread professional coating procedure known as powder coating. The machined components are first coated with color powder. As soon as the material melts and creates a protective layer, the components are heated. For polishing metal, powder coating is the preferred method of choice.

Powder Coating

Galvanization finish:

Galvanization coats metal with zinc to prevent rust. It is used in construction, transit, and shipping, where metals are often exposed to harsh environments and require shielding to maintain strength.

Cleaning the metal surface allows hot-dip or spray galvanization. Depending on the application, coating thickness might be microns to millimeters.

Galvanized Steel

Anodizing Finish:

Enhances the durability and aesthetics of machined components, particularly in industrial and aerospace applications. Electrochemical oxide deposition protects the metal. Anodizing typically affects aluminum. However, zinc, magnesium, and titanium are alternatives.

Anodizing is better than powder coating for complex-geometry machined parts. The final components are long-lastingly colored.

Anodized Steel

Plating Finish:

The surface of the material may be attractive and resistant to corrosion by plating it with a thin metal layer. Zinc, nickel, and gold are among the varieties of plating metals. Aluminum sheets are perfect for this use since they are both attractive in appearance and exceptionally resilient following the anodizing process.

Decorative items, jewelry, transportation, and aviation equipment might all benefit from metal plating. This procedure delivers a mirror-like polish to metals, leaving them excellent for displays.

Laser Finish

Laser coated material is the practice of placing a coating layer on an object’s surface by heating and integrating metallic particles with a laser beam. Surface damage, oxidation, resistance, and stiffness are all improved through laser cladding.

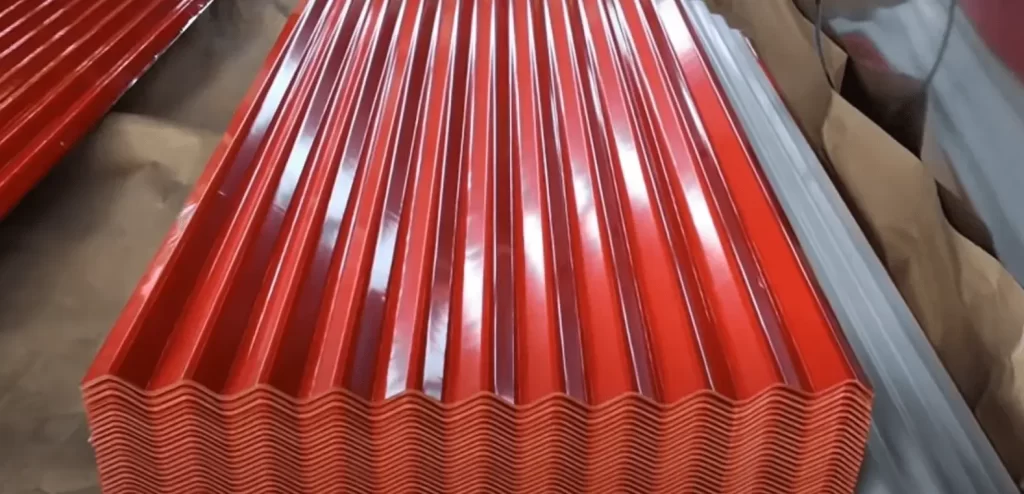

Advantages of Galvanized Steel Metal

Galvanized steel has many benefits. It is durable, cheap, and versatile. So, it is a good choice for many industrial uses.

Multilayer: The different layers that make up galvanized steel. Metals, most often zinc or zinc-iron alloys, create the outer layer. It functions as an additional shield against corrosion.

Reusable: Some galvanized metals are very reusable, which renders them an eco-friendly choice.

Rust resistance: A protective zinc coating could maintain rust away for as long as 30 years. So, it helps the metal last a bit longer and requires less painting.

Economical: Stainless steel may be expensive, but galvanized sheet metal is an amazing cost-effective choice.

Versatile: Operating and fabricating a cutting machine is one of its multiple qualities. It offers all dimensions and shapes.

Steel Roof Sheet

Try Prolean Now!

Professional Galvanized Metal Finishing

Professional finishing services could enhance the overall look and rigidity of galvanized metals. Even under the most extreme situations, anti-corrosive coatings can offer protection against corrosion as well as rust. An attractive and long-lasting surface may be achieved using a patterned coating. Also, with additional options for customized touches, companies may make their products exactly what their customers want. This enhances their vivacity and artistic value.

FAQs

- What is the difference between galvanized steel sheets and plates?

Galvanized steel sheets are ideal for lightweight buildings and other versatile uses due to their malleability and thinness. The thick and resilient galvanized steel plates, on the other hand, are more suitable for heavy-duty use.

- What finishing services are recommended for galvanized metals?

Galvanized finishing services for galvanized metals include powder coating, anodizing, and electroplating. When comparing the approaches’ endurance and aesthetic benefits, each one stands out.

- How does surface finishing improve galvanized sheet metal?

Polishing and powder coating are two surface finishing methods that galvanized sheet metal uses to make it more aesthetically pleasing and corrosion-resistant. Because of this, it lasts longer and performs better in many settings.

- Can Galvanized Steel Rust?

Although it may seem unbelievable, galvanized steel practically never rusts due to its unique chemical characteristics. However, if it is exposed to harsh conditions for a long enough period of time, it just might.

- Can you use a magnet on galvanized sheet metal?

The magnetic nature of the primary steel metal imparts this property to galvanized steel. The magnetic properties of galvanized steel are unaffected by the application of the thin zinc coating.

- How is galvanized metal different from non-galvanized metal?

A zinc coating makes galvanized steel resistant to corrosion. This aids in avoiding rust, a potentially problematic process that reduces metal strength. Due to the lack of this coating, non-galvanized steel may require more regular maintenance to prevent corrosion.

0 Comments