“As the backbone of civilization, agriculture has perpetually embraced technology and innovation. The industry’s shift towards mechanization has been significant, fuelled by supportive global policies and the need for increased productivity. This evolution has been marked by remarkable advancements in agricultural machinery and equipment, particularly in their automation and diversity.”

In the heart of this industrial revolution, sheet metal plays an instrumental role. Crafted from steel of various grades, including the highly-demanded stainless steel, as well as non-ferrous metals and their alloys, sheet metal is a common denominator in both industrial and domestic spheres. Whether created through forging or rolling mills, the versatility, resilience, and cost-effectiveness of sheet metal make it a mainstay in contemporary agricultural machinery and equipment manufacturing. This article dives into the integral role of sheet metal in the agricultural industry, exploring its processing, applications, and the benefits it offers.

The Evolution of Mechanization in Agriculture

As we trace the history of agriculture, it’s apparent that mechanization has always played a pivotal role in its advancement. The transition from manual labor to the use of machinery has marked significant milestones in the agricultural sector, paving the way for increased productivity, efficiency, and improved quality of produce.

Global policies have often worked in tandem with the needs of the agricultural sector, fueling the growth of agricultural machinery manufacturing. This symbiotic relationship has, over the years, resulted in the introduction of advanced machinery and equipment, designed to meet the evolving demands of agriculture.

What’s noteworthy is that sheet metal has found itself at the center of this evolution, becoming an integral part of many agricultural machinery and equipment. With each innovation, the use of sheet metal parts with brushed surface treatment and the like has expanded, hinting at the diversification of applications within the sector.

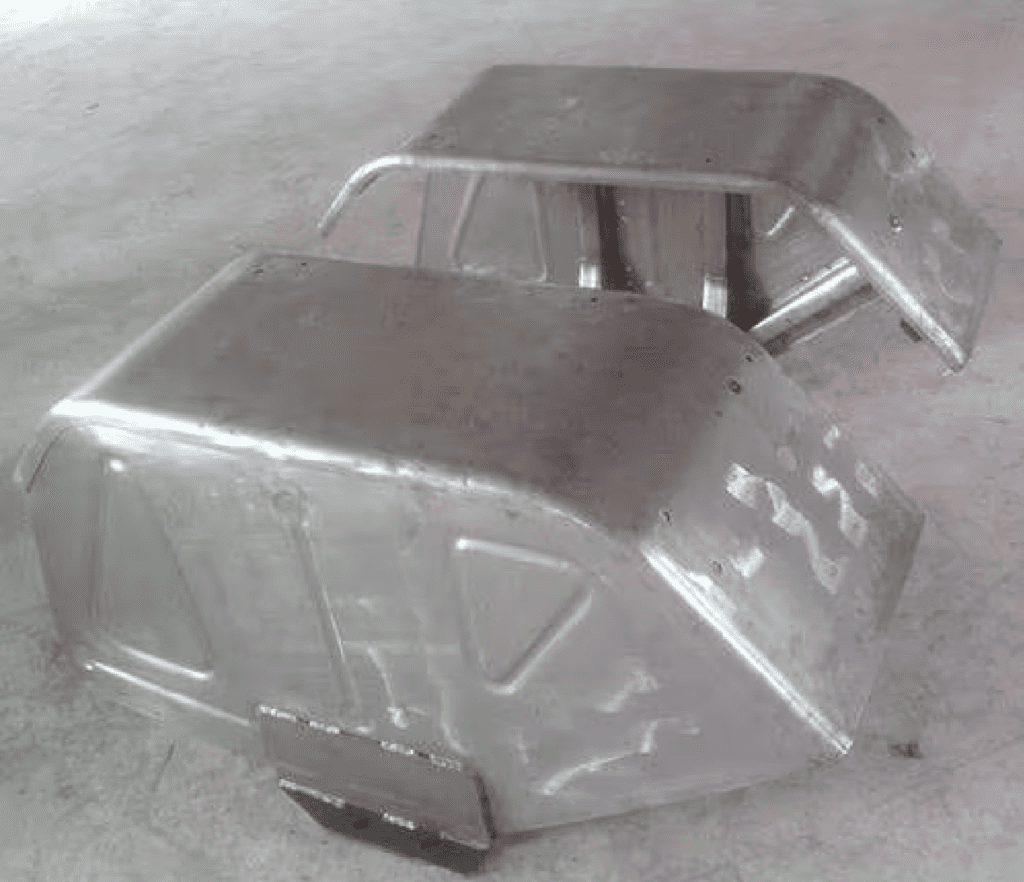

Sheet metal parts with brushed surface treatment

As we delve deeper into the world of sheet metal, we’ll understand more about its origins, its various types, and how it’s processed into the durable, versatile, and light parts that are so crucial in modern agricultural machinery.

Sheet Metal Origin and Types

Sheet metal, an essential material in various sectors including agriculture, has a fascinating origin. It is derived by forging or rolling metal on rolling mills, a process that can be employed with a variety of metals. This flexibility allows for the production of sheet metal from different grades of steel, including stainless steel, which is highly demanded for its robustness and resistance to corrosion. Moreover, non-ferrous metals and their alloys can also be transformed into sheet metal, further expanding its application scope.

The process of making sheet metal can yield different results depending on the metal and techniques used. The finished product could be a smooth sheet or a profiled one, providing different textures for different uses. The beauty of sheet metal lies in its adaptability; its dimensions and characteristics can be tailored to fit the precise needs of various industries. Consequently, we see its implementation in areas as diverse as aerospace, healthcare, and, notably, agricultural machinery manufacturing.

Sheet Metal Fabricating Aircraft Parts

Agricultural sheet metal work

To fully appreciate the utility of sheet metal in the agricultural sector, we need to delve into the processes that transform raw metal sheets into functional parts. Let’s look into the fascinating world of sheet metal processing.

What is Sheet Metal Processing? From Sheets to Parts

Sheet metal processing is a process for obtaining parts, including technologies for The transformation of simple sheet metal into complex parts is a feat of modern manufacturing. Sheet metal processing involves a variety of techniques to achieve this, including cutting and plastic deformation of a metal sheet.

CNC sheet metal fabrication

In the context of agriculture, sheet metal processing has a fundamental role in the production of machinery and equipment. Techniques like CNC (Computer Numerical Control) fabrication allow for high-precision manufacturing, resulting in both lightweight and durable parts. The resulting components are highly valuable due to the wide range of available materials, advanced manufacturing capabilities, and the flexibility of sheet metal.

There are many surprising applications of processed sheet metal that have found their place in everyday life. In our next section, we’ll explore some unexpected places where these products find their uses.

Surprising Applications of Sheet Metal

Sheet metal, despite its industrial origins, finds its way into many applications you may not have thought of. Its versatility and ease of fabrication allow it to be utilized in numerous ways beyond just agricultural machinery.

Ventilation pipes of an air condition

For instance, sheet metal is used extensively in the construction of ductwork for heating, ventilation, and air conditioning (HVAC) systems. It can also be found in the cabinetry of refrigerator units, providing a robust and durable structure. In the healthcare sector, sheet metal is often employed in creating medical tables and equipment storage, thanks to its hygienic properties and ease of cleaning.

The versatility of sheet metal extends to exterior applications as well, with facades of buildings often clad in sheet metal for both aesthetic and protective reasons. Additionally, it is used in making signs, hoods for exhaust systems, stacks, and even artistically decorated artwork.

These examples only begin to scratch the surface of the surprising and diverse applications of sheet metal. In our next section, we delve into the specific role of steel, especially galvanized steel, in agricultural applications.

The classification of sheet metal

The classification depends on its quality characteristics and is divided according to the following indicators:

- Technologies for the manufacture of sheet metal: In rolling mills, metal sheets are produced by the hot-rolled or cold-rolled method. The physical and mechanical properties of the sheet metal obtained in this way are excellent. Both methods are widely used in the metallurgical industry.

- Dimensions: Metal sheets have different thicknesses: thin and thick rolled products are distinguished. Standard dimensions for the length and width of the sheet are prescribed in GOST, although production of non-standard sizes is also allowed.

Related: China Sheet Metal Fabrication: Affordable & High-Quality Solutions

The Role of Steel and Galvanized Steel in Agriculture

Agriculture, being an industry of both substantial physical demands and continuous technological advancements, necessitates materials that are robust, versatile, and cost-effective. Steel, known for its long lifespan, low cost, and high strength, emerges as the ideal candidate.

The use of steel in the manufacturing of agricultural equipment is ubiquitous. It’s present in the most fundamental parts of agricultural machinery and tools, thanks to its unique blend of durability, strength, and cost-effectiveness. Additionally, it’s eco-friendly nature and broad availability make it a top choice for the sector.

What makes steel particularly attractive for agricultural applications is its versatility. Available in various grades, forms, and sizes, it offers an array of performance characteristics that can be matched to specific use cases. For instance, in areas where exposure to dampness, harsh chemicals, and extreme temperatures is expected – conditions typical of many agricultural operations – carbon steel with a galvanized surface finish is highly recommended.

Galvanized steel, a form of steel that has acquired a zinc coating to prevent corrosion, is a popular choice in agriculture. This zinc coating acts as a protective barrier, preventing moisture and other airborne elements from corroding the underlying steel. The result of this hot-dip galvanization process is a surface coating that shields the steel from corrosion, extending the lifespan of agricultural machinery and structures.

Related: Galvanization Process in Manufacturing: Everything You Need to Know

But the benefits of galvanized steel extend beyond its excellent anti-corrosive properties. It also offers good value for money, as it is less expensive than other treated steels and requires minimal maintenance, which in turn reduces the need for costly repairs or replacements.

In the realm of agriculture, galvanized steel’s performance qualities find a wide range of uses. It’s commonly used to construct metal structures like barns and fences, in creating wagons for transport, in fabricating storage spaces such as silos, and even in manufacture of components for harvesters and feeding machines.

Key Applications of Sheet Metal in Agriculture

Sheet metal, owing to its versatility, durability, and adaptability, has found a significant place in modern agriculture. As the industry becomes increasingly competitive, using superior metals like galvanized steel allows agricultural equipment manufacturers to produce more reliable and efficient machinery, thereby facilitating more productive farming.

barns and silos

One of the most common uses of sheet metal in agriculture is in the construction of barns and silos. These structures, often exposed to harsh weather conditions and the rigors of farming operations, require materials that can withstand significant wear and tear. Galvanized steel sheet metal is a perfect fit for this requirement due to its corrosion resistance and strength.

tractor mudguards

In the realm of harvesting tools, sheet metal is equally indispensable. From tractors and cotton pickers to hay balers and other implements, the resilience and durability of sheet metal make it a material of choice. It can be shaped and formed into the intricate parts of these machines, ensuring they perform optimally and stand the test of time.

Sheet metal fences

Livestock management equipment, such as fences, feeding troughs, and milking machines, also heavily rely on sheet metal. These pieces of equipment are constantly exposed to the elements and the demands of livestock, requiring materials that can handle this environment.

Sheet metal also finds application in more general operations. Forklifts, irrigation systems, drainage pipes, and more – these essential pieces of equipment are often crafted from sheet metal, further highlighting the material’s central role in modern farming.

Which Metal Is Used to Make Agricultural Tools?

Even though there are many different kinds of metals used in agriculture, hot-dip galvanized steel is frequently employed because of its overall strength and affordability. Galvanized steel is steel that has acquired a zinc coating to prevent degradation.

When zinc is coated to a surface, it stops moisture and other airborne elements from corroding the underlying steel.

The name “hot-dip galvanized steel” comes from a subsequent procedure. A metallurgical bond is created by dipping steel into a molten puddle of hot zinc. The end result is a surface coating that shields the underlying steel from corrosion caused by moisture and other airborne substances.

Galvanized steel also offers good value for the money. It costs less than other treated steels and needs little upkeep, so there is less need for repairs or replacements.

Galvanized steel has special performance qualities that make it useful for a variety of agricultural uses, including:

- Metal structures

- Fences

- Wagons

- Silos

- Storage Spaces

- Components for harvesters

- Feeding Machines

- Balers

- System of conveyors

Benefits and Uses of Sheet Metal Across Industries

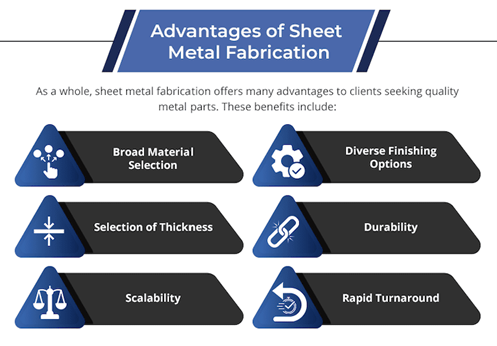

The use of sheet metal is not confined to agriculture alone. Its unique properties have made it a go-to resource for many industries. Here, we’ll explore some of the main operational characteristics that make sheet metal a versatile and indispensable material.

- High Adaptability: Sheet metal is highly adaptable to various types of processing, including cutting, welding, and forming. Its precise geometry allows for accurate design calculations, helping reduce material costs.

- Durability: One of the major strengths of sheet metal is its wear resistance. While this property largely depends on the grade of steel or alloy used, sheet metal generally provides high durability.

- Versatility: Sheet metal comes in many different types, including smooth, profiled, and perforated. Metal surfaces can be galvanized, painted, and treated in various ways, making it possible to select the optimal option for any purpose.

- Industry Use: Sheet metal plays a crucial role in many industries. Mechanical engineering, automotive, shipbuilding, instrumentation, defense, chemical, food industry, and household appliance manufacturing all employ sheet metal in their production processes. Its use in constructing equipment, containers, and reservoirs is particularly notable.

What Are the Major Applications of Sheet Metal in Agriculture?

Due to the effectiveness of the operations, the agriculture industry is getting more and more competitive. Using superior metals, agricultural equipment makers may produce more dependable, effective machinery that leads to improved farming. Numerous pieces of farming equipment, including:

- barns and silos

- Harvesting tools, including cotton pickers, tractors, hay balers, etc.

- Greenhouses

- Equipment for managing livestock, such as fences, feeding troughs, and milking machines.

- Equipment used in general operations, such as forklifts, irrigation systems, and drainage.

Despite its many strengths, it’s essential to note that sheet metal must be used for its intended purpose to realize these advantages. For instance, a perforated stainless steel sheet, while excellent in corrosive environments, would not provide insulating properties.

Prolean: Your Trusted Partner for Sheet Metal Processing

In the competitive landscape of modern industries, having a reliable partner for metal fabrication is essential. Prolean offers a wide range of sheet metal processing services, specializing in precision parts production.

- Comprehensive Services: Prolean provides a comprehensive range of services, from the processing of galvanized steel to modern high-strength steel. We also offer steel processing services like blanking and pickling, ensuring you get the exact finished product you need.

- Expertise: Our team consists of seasoned professionals who bring a wealth of expertise to every project. They possess a deep understanding of materials and their properties, enabling them to deliver designs with optimal corrosion resistance and other desired characteristics.

- Customer-focused: At Prolean, we are committed to delivering exceptional customer service. Our team will work closely with you throughout the project, ensuring we meet your specific requirements and deliver a product that fits your needs perfectly.

Whether you’re in the agricultural industry looking to build reliable machinery or operate in a different sector requiring high-quality sheet metal components, Prolean is here to help. Let’s start your new project today.

Case Studies in Agricultural Sheet Metal Use

Project 1: Advanced Harvesting Tools

One of Prolean’s groundbreaking projects was the development of advanced harvesting tools. Using top-grade galvanized steel, we manufactured sturdy, efficient, and highly durable harvesting tools that not only made the harvesting process quicker but also significantly reduced the cost of maintenance. The success of this project exemplified the potential for innovation and efficiency that sheet metal brings to agriculture.

Project 2: Durable Storage Spaces

In another endeavor, we collaborated with a farm storage company to create robust, weather-resistant storage facilities. Using our expertise in sheet metal processing, we designed and produced durable structures capable of withstanding harsh environmental conditions, providing farmers with reliable storage solutions for their produce.

Project 3: Efficient Conveyor Systems

Prolean was instrumental in the development of a sophisticated conveyor system for a potato processing factory. We utilized sheet metal in creating a high-speed, efficient conveyor system that drastically improved the factory’s production rate and reduced manual labor.

Each of these case studies demonstrates how the appropriate use of sheet metal, with the right expertise, can revolutionize the agricultural industry. With Prolean, you’re not just getting a service provider – you’re gaining a partner dedicated to innovation and your success.

Summing Up

As our journey from understanding sheet metal to seeing its application in agriculture ends, it becomes abundantly clear that sheet metal plays an instrumental role in this vital industry. Its versatility, durability, and cost-effectiveness make it an unbeatable choice for manufacturing agricultural machinery and infrastructure.

Prolean’s proficiency in sheet metal processing brings precision, innovation, and efficiency to the table, ensuring the delivery of superior-quality, high-performance products that can withstand the challenges of modern agriculture. Our dedicated team of experts is ready to assist you with all your sheet metal needs, ensuring the best outcomes for your agricultural machinery and infrastructure.

The future of agriculture is here, and sheet metal is at its core. Start a new project with Prolean today and experience the difference that precision, expertise, and dedication can make. Together, let’s reshape agriculture with sheet metal.

FAQs

What is sheet metal and how is it produced?

Sheet metal is a material manufactured by rolling or forging metal, which can be made from different types of steel, non-ferrous metals, and their alloys.

Why is sheet metal important in agriculture?

Sheet metal is crucial in agriculture due to its durability, lightness, and versatility. It’s used in the manufacture of various types of agricultural machinery and equipment, enhancing the efficiency and effectiveness of agricultural operations.

What is the role of steel and galvanized steel in agriculture?

Steel, particularly galvanized steel, is the top choice for manufacturing agricultural equipment due to its long lifespan, low cost, and high strength. The zinc coating on galvanized steel prevents degradation, making it suitable for harsh agricultural conditions.

What are some surprising applications of sheet metal?

Beyond the expected uses, sheet metal also finds application in creating ductwork, refrigerator cabinetry, medical tables, equipment storage, building facades, signs, exhaust hoods, stacks, and even decorated artwork.

How is sheet metal processed?

Sheet metal processing includes technologies for cutting and plastic deformation of a metal sheet to obtain parts used in various fields like aerospace, mechanical engineering, healthcare, construction, and agriculture.

What types of agricultural equipment are made from sheet metal?

Sheet metal is used in the creation of a wide variety of agricultural equipment, such as barns, silos, harvesting tools (including tractors and hay balers), greenhouses, livestock management equipment, and general operation equipment like forklifts and irrigation systems.

What are the benefits of sheet metal in agriculture?

Sheet metal provides many benefits including high technological adaptability, wear resistance, and a wide variety of options. It can be processed in various ways to create precise designs, reduce material costs, and withstand tough conditions.

I am looking for prototyping of corn harvester parts. So, which material can i use to fabricate prototype??

For metal prototyping of corn harvester parts, aluminum or mild steel are excellent choices, offering durability, machinability, and cost-effectiveness for both CNC machining and welding. They can be post-process to make them highly corrosion resistive.