CNC software

Computer Numerical Control (CNC) software creates codes that CNC machines use to manipulate the relative movement between the cutting tool and workpiece to produce accurate and precise parts.

It is used to control all manner of CNC machines, hence the availability of CNC milling software, lathe programming software, the best CNC router software, and other options.

CNC software has grown in popularity due to the accuracy, precision, versatility, and speed it brings to manufacturing. There are options for both experienced and less experienced users, with each option having its pros and cons.

This guide outlines these CNC software options, plus the basics of software, and how to choose the best one. Read on for more insights.

What is CNC Software?

Computer Numerical Control (CNC) software refers to a set of programs, instructions, or data used to control Computer Numerical Control machines for cutting, milling, shaping, and drilling operations. The software is designed to derive machine instructions from digital designs.

CNC software enables automated manufacturing, which is common in aerospace, automotive, defence, marine, sheet metal design, and many other industries that use CNC-machined parts. Whether it is through turning operations, milling operations, or drilling operations, CNC software has significantly transformed many industries.

How CNC Software Works

The CNC software operating principle follows three major steps: CAD software design, CAM software toolpath generation, and machine control using CNC control software.

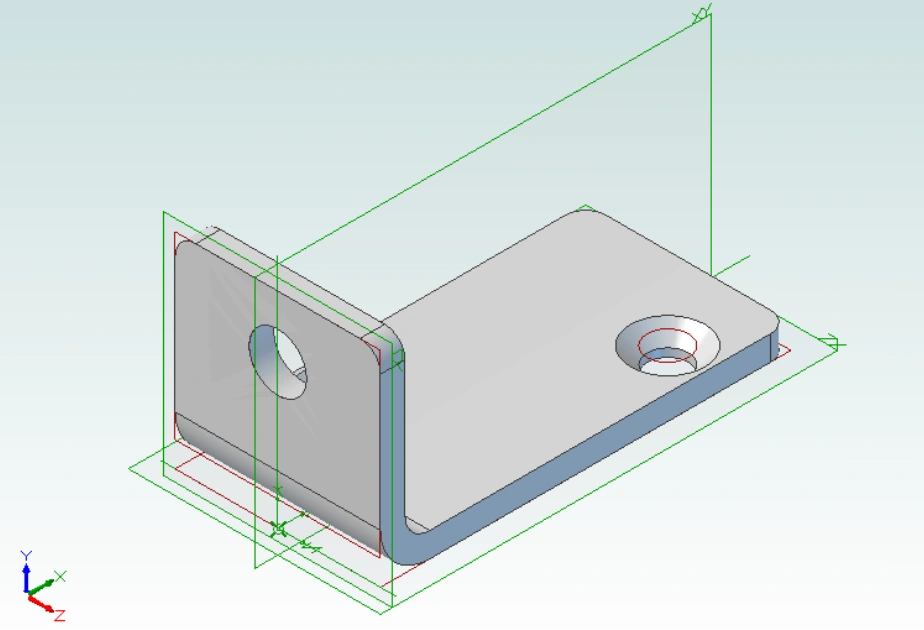

CAD model

It all starts with a 2D or 3D model, which is then converted to G code and M code. These specialized instructions are relayed to the CNC machine, which executes them as CNC machining operations.

The Computer-aided design (CAD) software produces the model of the part to be CNC machined. This model is imported into the Computer-Aided Manufacturing (CAM) software for toolpath generation.

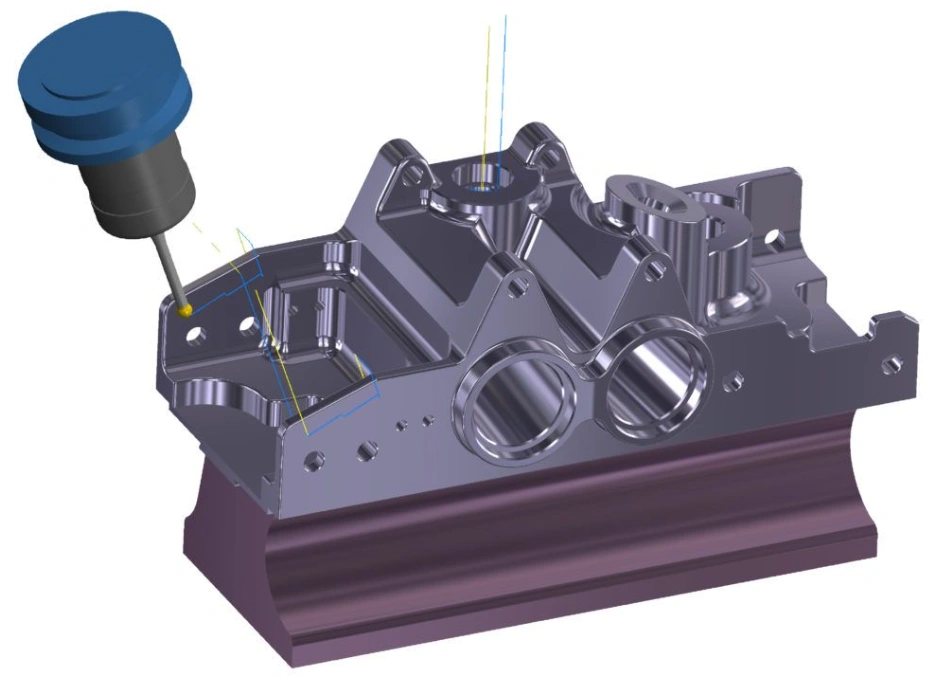

Note: Toolpath not for the previous CAD model

CAM software

Toolpaths are Cartesian coordinates that guide the cutting tool’s tip during machining. The CAM software derives instructions that the CNC machine can understand from these toolpaths.

Try Prolean Now!

Advantages of CNC Software

The use of lathe programming software and other software solutions is often compared with the alternative, which is manual machining, highlighting advantages such as higher capacity, lower machining costs, uniform parts, and increased safety.

Higher Capacity And More Options

CNC software increases the manufacturer’s capacity and the possible varieties of products. The CNC machining services provider can update the software at will according to the production demands.

Even if it sometimes means investing in an advanced CNC machine, the fact is that software provides the options and versatility necessary in today’s manufacturing environment.

The best CAM software for CNC and types of CAD software minimize the need for manual setup and programming. Overall, this also enhances production.

Lower Machining Costs

The toolpath strategies and virtual simulation solutions of CNC software make machining resource management simpler and cost-effective. Manufacturers are able to save resources and use machines for longer. These cost savings are instrumental in getting the return on investment faster.

Uniform Parts

CNC software enables the production of uniform or identical parts, which is the hallmark of mass manufacturing. The best CNC coding software options facilitate exceptional machining accuracy and precision, regardless of the number of parts.

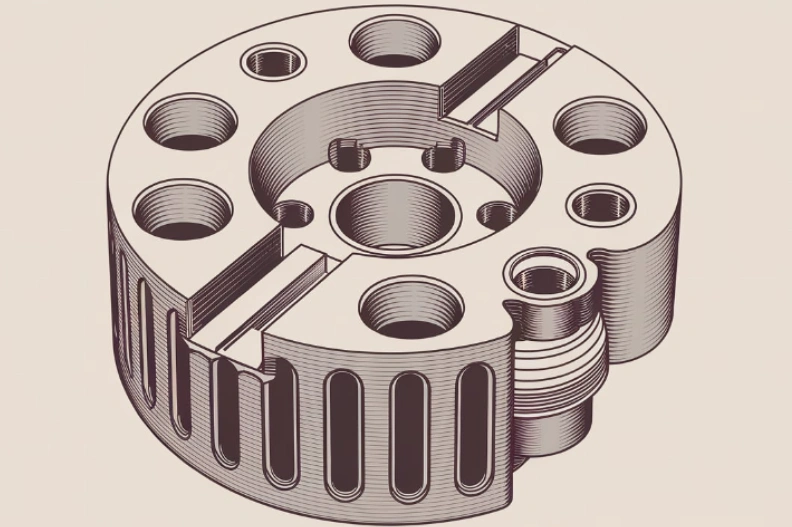

Identical CNC-machined parts

A tolerance of 0.0005 inches is achievable, which is necessary for mass manufacture of complex parts in aerospace, medical, and automotive industries. With software, the machines do not rely on the consistency of the operator, like in manual CNC machining.

Increased Safety

The simulation feature in CNC software enhances machining safety by creating a virtual machining environment. Programmers and machinists use this feature to simulate processes and identify potential issues before they occur.

The accident-prevention capability is particularly crucial for users who are still not conversant with the CNC machine.

Limitations of CNC Software

CNC software solutions have a high initial cost and can have a significant effect on production when faulty, as explained below.

High Investment Cost

A major limitation of CNC software for machining is the usually high price it attracts.

The software and the accompanying automation capabilities contribute to the high upfront cost of CNC machines. The training, setup, and maintenance of the whole setup can be significantly expensive.

Overdependence on Technology

Software, as part of the advanced technology in modern machines, can result in lengthy production delays and downtimes if it is faulty. The software must be updated, something that is inevitable but also expensive for some CNC machining service providers.

Try Prolean Now!

Types of CNC Software

In the CNC software comparison, you will come across three major categories of CNC software, namely CAD (Computer-Aided Design), CAM (Computer-Aided Manufacturing), and CNC Control software. CAD generates digital models, CAM produces toolpaths, while CNC control software is designed for machine operation.

CAD (Computer-Aided Design)

CAD software is where the design ideas are generated. Its tools help in modeling, sketching, dimensioning, and many other means to help the user create 2D or 3D designs.

Some CAD software options are specialized, only designed for one product type. A perfect example is the software used for printed circuit board (PCB) design.

The list of the best CAD software for CNC includes:

- BobCAD-CAM

- FreeCAD

- Rhino 3D

- AutoCAD

- SolidWorks

- Mastercam

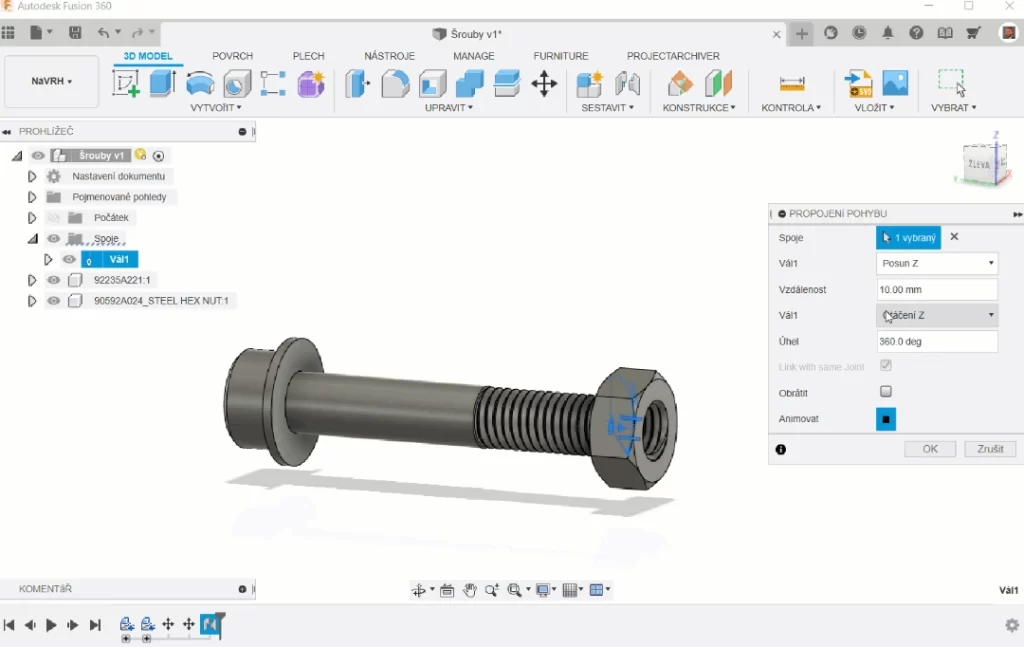

- Fusion 360

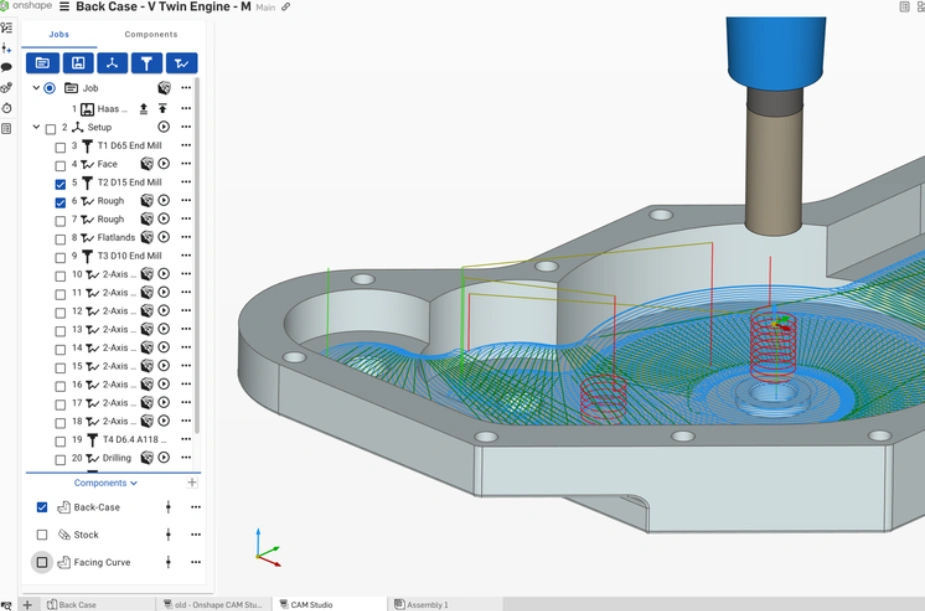

Fusion 360 to CNC

CAM (Computer-Aided Manufacturing)

CAM software is used to prepare CAD designs for CNC manufacturing. The basic transformations provided by the software are rotation, scaling, and position. Some CAM programs have CAD features, and vice versa.

The best CAM software for CNC includes;

- HSMWorks/CAM

- Siemens NX CAM

- Fusion 360

- Mastercam

- SolidCAM

- Edgecam

- GibbsCAM

- Vectric VCarve Pro/Aspire

Siemen NX CAM

CNC Control software

The function of control software is to read G-code and form signals for stepper motor drives. As the ‘brain’ of the CNC machine, this software dictates the actions of the machine.

The software uses commands from the G-code file to generate electrical signals for the machine.

The most popular CNC control software options for the industrial environment are;

- Mitsubishi

- Siemens Sinumerik

- Fanuc

- Haas NGC

- Heidenhain (TNC)

- Mazatrol

FANUC CNC systems

Which Software Is Used for CNC Programming?

There are many software options for CNC programming available for different expertise levels. Professional users have solutions like SolidWorks CAM, Fusion 360, and Mastercam. Hobbyists can use less complex options, such as Carbide Create and Easel.

More details about these software options are in the next section.

CNC Software Levels

CNC software can be grouped into three: Entry level (sometimes free), professional level, and enterprise level. While entry-level is for beginners and hobbyists, professional-level and enterprise-level are for complex production operations.

Apart from the complexity difference, these levels are also priced differently, with the enterprise level being the most expensive.

Entry-level CNC Software

Entry-level CNC software solutions are user-friendly and affordable, the perfect characteristics for a user who is just starting with simple CNC models. The options in this category include Fusion 360, Carbide Create, and Easel.

A simple CAD model

Fusion 360: This software has 3D modelling, CAM toolpath, and simulation features. It is widely considered the best CNC software for beginners. Yes, it requires a little learning, but it becomes free-flowing for the user after some time. Its learning curve is well defined, with more complexity available according to progress made.

Carbide Create: This is another reliable CNC software for beginners. Its basic design features, alongside free CAM and CAD solutions, are ideal for anyone using CNC software for the first time.

Easel: This one is web-based and is mostly associated with woodworkers. It has straightforward design elements and a simple G-code feature.

Professional-level CNC Software

For higher-level CNC software, the common options include SolidCAM and Mastercam.

These products are designed to offer superior features such as advanced toolpath strategies, tool management, automation, and specialized features for the industry.

Here is a list of the best professional-level CNC software;

- Mastercam

- Siemens NX CAM

- Hypermill

- SolidCAM

- GibbsCAM

- Fusion 360

- CAMWorks

Complex part on Mastercam CNC software

Is There Free CNC software?

Yes, various free CNC software options are available with basic design and machining capacities.

The most common ones are bCNC, OpenSCAD, and FreeCAD. While limited to basic features and may lack adequate technical support, these software solutions can provide fundamental 2D and 3D capabilities.

FreeCAD

The biggest benefit of free CNC software is the lower risk it presents. The user learns the fundamentals of CAD and CAM manufacturing without having to incur any cost.

The free solutions are usually easier to access and use, and thus are a friendly introduction to the CNC programming world.

However, users must remember that the complexity of the advanced versions is not a problem. It is indeed a necessity when dealing with complex CNC machining projects.

Furthermore, free CNC software usually lacks reliable customer support that is synonymous with more advanced solutions. It might be difficult to handle compatibility issues when they occur.

Also, the speed of large-scale EDM machining, turning operations, and other CNC machining projects can be too much for basic CNC programs.

How Do I Program a CNC Machine?

Programming a CNC machine is a series of activities that start with the generation of the CAD design. Once the CAD design is available, CAM software is used to produce toolpaths that the CNC machine will follow during machining.

The code is then processed for the uniqueness of the CNC machine, and then the code is fed into the CNC controller. After setup, the CNC machining process is ready for execution under the monitoring of the machinist.

Choosing the Right CNC Software

Choosing the right CNC software should be guided by user experience/skill set, part complexity, compatibility of the CNC machine, and the available budget.

ProleanTech looks for the following features when choosing the best CNC software;

- Intuitive User Interface

- Advanced simulation features

- Customization features

- Compatibility with the CNC machine

- Design for Manufacturability (DFM) analysis tools

CNC Software Advanced Features and Future Trends

The best lathe programming software and other types of CNC coding software products are increasingly being defined by AI-oriented toolpath optimization, modern multi-axis machining capabilities, technological merger, and cloud-based collaboration.

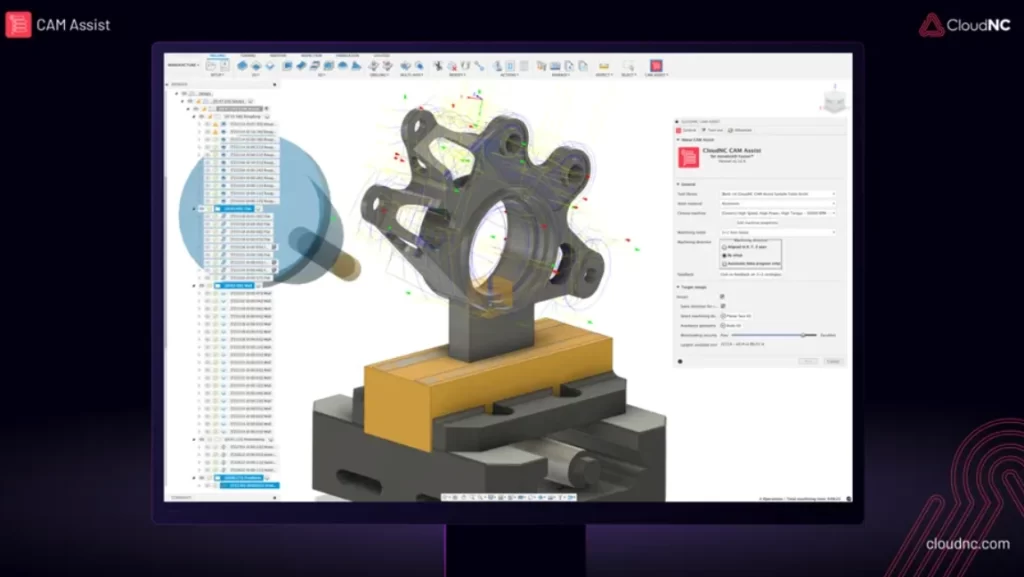

AI-Oriented Toolpath Optimization

CAM systems are now using AI capability to optimize toolpaths, control cutting parameters, and predict tool wear. The product created by CloudNC, called the CAM Assist, is a perfect example.

AI for CAM software

The results in CNC machining parts are impressive – improved surface finish, reduced programming time, and extended tool life.

Modern Multi-axis Machining Capabilities

There are modern machining capabilities, such as automatic tool optimization and collision detection, which not only enhance machining effectiveness but also improve safety.

Technological Merger

Modern CNC software solutions are facilitating the merger of additive manufacturing and subtractive manufacturing. For instance, 3D printing combined with CNC machining to apply the good qualities of both. The design versatility of 3D printing and the renowned precision of CNC machining form an unmatched manufacturing method.

Cloud-based Collaboration

Cloud-based handling of CNC machining projects is now a reality. Teams can collaborate on a project and recommend design changes in real-time. Decisions are made faster, and the manufacturing processes are completed in time.

In Conclusion

The options and possibilities for CNC software are limitless. You only need to search for the top 10 CNC programming software to discover the array of solutions available for any machining project.

Since a CNC software solution is only as effective as the person handling it and the CNC machine using it, partnering with trailblazers in CNC machining services is worthwhile.

To learn more about how the best of these solutions can transform your machining projects, contact us today to get a quote.

0 Comments