“The force and die setup in sheet metal bending transforms flat sheets into functional and aesthetic components, essential in everything from aerospace to consumer goods.”

The manipulation of metal sheets into the desired shape has many benefits in manufacturing. So, manufacturers use different fabrication methods to produce a rich range of items. Here, Sheet Metal Bending is one of the fundamental methods. This method utilizes many techniques to deform the sheets into a specific bend radius. Sometimes, bending alone can create the final geometry, whereas in some cases it combines with other fabrication methods to produce the final part or product.

Furthermore, we will briefly cover the different aspects of bending, including its working, methods, and compatible material sheets.

The Basics of Sheet Metal Bending

Working of metal bending involves applying force beyond its yield strength at a specific bend angle. So, the sheet gets deformed at that angle. The deformed section of the metal sheet is called a setback. Next, the bending method also makes specific curvatures, like U or V-shape, based on the applied Sheet Metal Bending Techniques.

If we look at the tooling or equipment setup for metal sheet bending, it includes three major components;

- Bending Die

- Press Brakes

- Punch

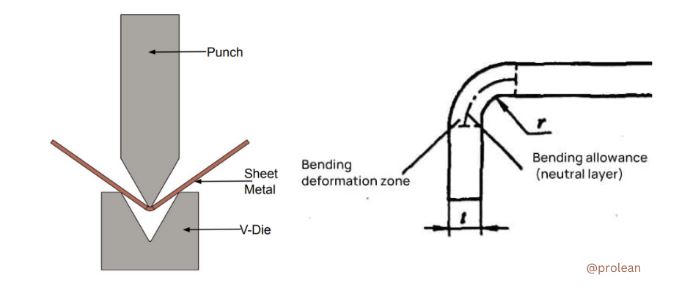

The Bending die refers to a specific shape where the worksheet is placed. A punch executes the forces on the sheet and deforms according to the geometry of the die. Meanwhile, the press brake controls the punch and bending force.

Sheet metal bending mechanism

It is the basic mechanism of air bending, where the punch forces the sheet into the die to achieve the bend. Next, here are the basic terminologies associated with the Working of Sheet Metal Bending.

Bend Allowance

It is the additional length of sheet metal added to accommodate a bend.

L= a ( r + kt )

a= Angle of bend (radian)

r= Ben radius

t=thickness

k= constant ( 1/2 to 1/3)

Bend Radius

The radius of the inner arc of a bend illustrates the material deformation area.

Minimum Bending Radius

The lower limit of achievable bending radius depends on the material type and thickness. Basically, if you fix the bend-radius lower than this ability, it will start to crack.

6t for Al alloys, 4-6t for steel alloys, etc.

Bending Force

The force needed to deform the sheet into the intended shape or force exerted by the punch.

F = k.Y.L.t2 / D

Related: The Basics of Sheet Metal Fabrication

Try Prolean Now!

The Process of Sheet Metal Bending

Achieving the final shape from raw sheets of metals involves different stages. First, it needs to be cut into a small size based on the design. Typically, Laser Cutting Sheet Metal is used to cut large sheets into the desired dimensions. The laser can cut precisely without any burrs or need of further finishing. Then, set up of die, punch, and press bake.

Sheet metal bending process

Here is the step-by-step elaboration for the process of sheet metal bending.

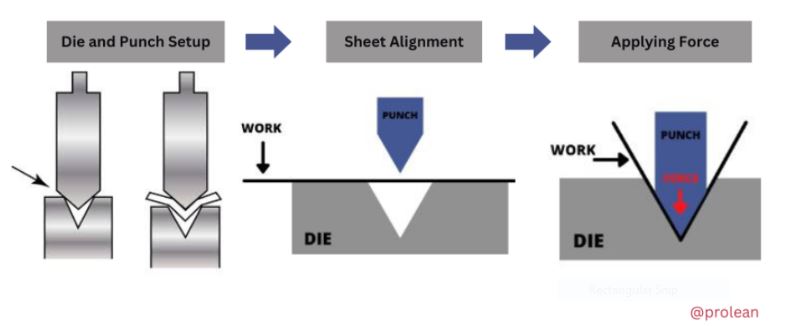

1. Fixing the Bending Parameters

First, different parameters need to be calculated, like required force, bending allowance, bending radius, etc. Some of the parameters are also specified on the 2D Technical drawing of the project.

2. Die and Punch Setup

The die and punch setup involves selecting the appropriate die and punch on the press brake. The die shape must match the desired bend profile, and the punch should be compatible in shape and size. Consequently, you need to customize the punch and die for Custom Metal Bending. It means if the bend is complex (i.e. not standard like V, L, U, or channel), the die needs to be customized first.

3. Worksheet Alignment

Next, maintain a proper alignment of the sheet metal on the press brake before bending. It is essential to ensure that the bend will occur at the correct angle relative to the neutral axis. Operators often mark on the metal or machine stops that position the workpiece accurately.

4. Applying the Force with Punch

Finally, time for the execution of the bending process. In this step, the machine’s ram drives the punch into the metal, forcing it into the die. As previously mentioned, the force needs to be accurately calculated based on the metal’s properties and the bending parameters. Otherwise, it will result in under or over-bending.

What are the Different Sheet Metal Bending Methods?

Different sheet metal bending methods can be used based on the specification of the required bend or shape. For example, V-bending creates a V-shape with angles like 30˚, 45˚, 60˚, 80, etc. On the other hand, roll bending is ideal for the curved surfaces. Here, the point is that each method has different bending implications.

Now, let’s discuss all the common Sheet Metal Bending Methods one by one;

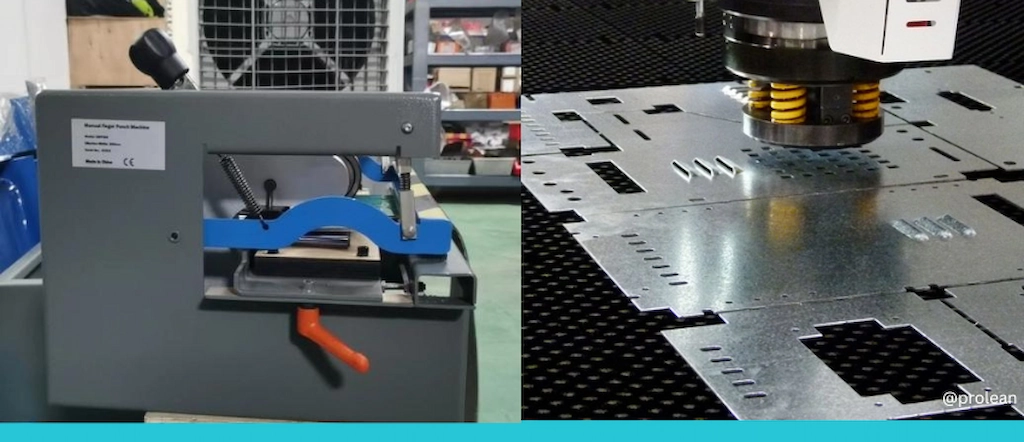

1. V-bending

This is among the most common metal bending services that can cater to various bending requirements. As the name suggested, V-bending involves a V-shape die, punch, and press breaks. This method creates bends at various angles on thin and moderately thick sheets. The press-break could be hydraulic, mechanical, or CNC.

The CNC Bending machines or press breaks can precisely impose stress on the worksheet (over the V-die).

Manual Vs automatic punching

Under this bending method, there are two specific techniques.

- Air Bending

In air bending, the punch pushes the workpiece to stand on the two points of the die. However, the punch descends less than the die depth. This mechanism provides flexibility in bending angles. It allows to adjust the stroke of the press brake without changing the tooling.

One disadvantage of air bending is ‘spring back’. The sheet can spring back, which impacts the angle accuracy.

- Bottom Bending

This technique is similar to air bending, except it exerts small forces after completion of bending to tackle the spring back. So, it is more accurate than the air bending. Additionally, the bottom bending requires relatively more bending force. It is compatible with thicker sheets.

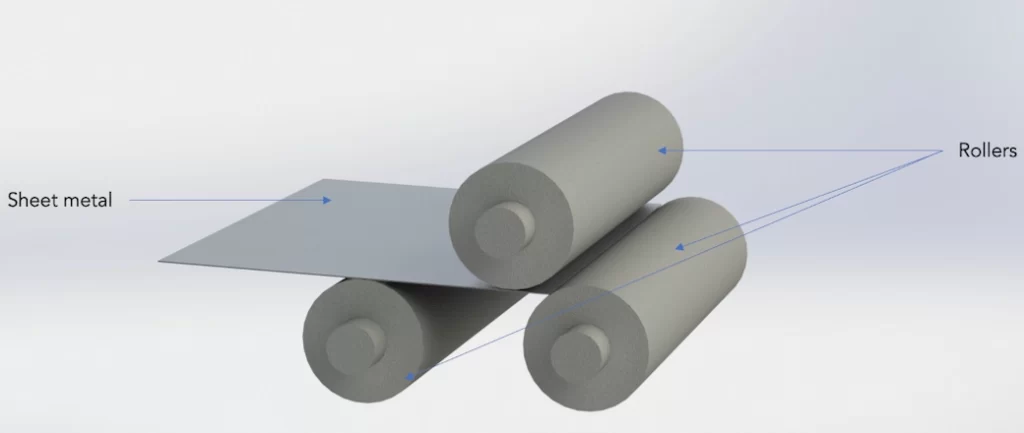

2. Roll Bending or Rolling

Roll bending process

This method converts worksheets into curvature shapes. It involves multiple rollers that curve the sheet metal as it passes through them. Meanwhile, they can be adjusted based on the required curvature.

It is ideal for;

- Cones

- Tubes

- Cones

The rolling method can also handle harder and thicker sheets as the rollers can exert higher stress.

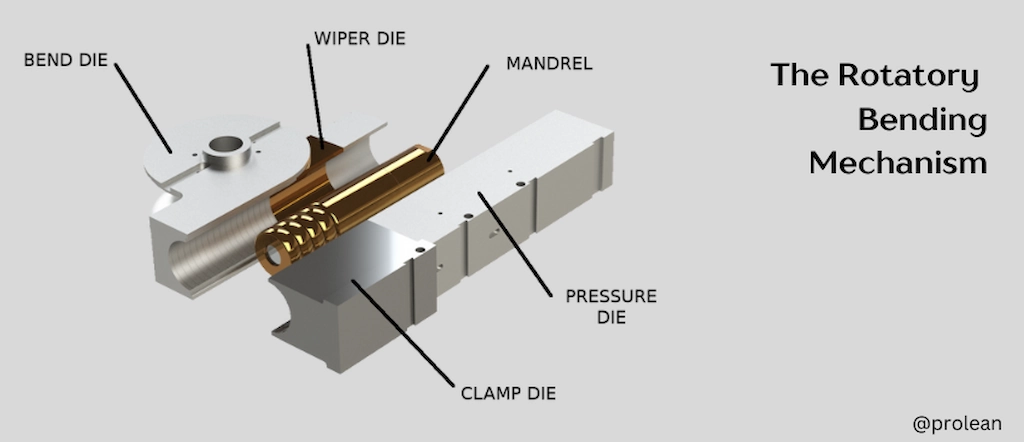

3. Rotatory Bending

Rotatory bending

The main difference in rotatory bending is its mechanism. The bending die rotates around the sheet metal in this method to create the desired bend. Unlike others, it does not involve the pressing of sheet metal, instead, the punch rotates around the fixed point on the sheet to exert a continuous force around the bending point.

- Handle large sheets and heavy materials

- Used in shipbuilding, aerospace, and Automotive.

- The number of rollers can be adjusted.

4. Step Bending

It refers to multiple small bends at varying intervals along the worksheet. Let’s look at the example of the step-bending part, a conical hopper. Here, the repetitive V-bends are required to form the steps in between the bends.

Consequently, the incremental nature of the bends reduces the spring-back effect for accurate results. It is also suitable for Custom Metal Bending as various complex and unique bends are possible using the step bending technique.

Application examples;

- The wing section of an aircraft

- Architectural and decorative items

- Automotive parts like fenders or door panels

- Building of bulkheads and hull sections in a Ship

Try Prolean Now!

Which Metal Sheets Can Be Bended? The Material Options

Another critical aspect of sheet metal bending is the compatibility of metal and alloys. This sheet metal fabrication technique can be applied to various material sheets. However, the selection varies on desired properties and intended bending method. Typically, bend aluminum sheets, Bending stainless steel, and copper sheets are the most common in fabrication projects.

The following table illustrates the Sheet Metal Bending Materials, common grades, and key properties.

Table: Metal & Alloys for Sheet Metal Bending

| Metal or Alloy | Grades | Key Properties |

| Aluminum | 1100, 3003, 5052, 6061 | Lightweight, corrosion-resistant, good formability, soft to medium strength, etc. |

| Stainless Steel | 304, 316, 410 | High strength, excellent corrosion resistance, heat resistance |

| Carbon Steel | A36, 1018, 1045 | High toughness, ductility, strength, and cost-effectiveness |

| Brass | C26000, C28000 | Good strength, highly malleable, corrosion resistance, etc. |

| Copper | C11000, C12200 | Excellent electrical & thermal conductivity, |

| Titanium | Grade 2, Grade 5 | High strength, exceptional corrosion resistance, and biocompatibility |

| Nickel Alloys | Inconel 625, Monel 400 | Thermal stability, corrosion resistance, and good strength. |

| Zinc | Zamak 3, Zamak 5 | Good toughness, high ductility, and impact strength. |

Related: Bending Stainless Steel Tubing: Details Explained

Other Sheet Metal Forming Processes

Other sheet metal bending processes, like stretching and shearing, have distinct implications for fabrication.

1. Sheet Metal Stretching

This forming method expands the surface area of the worksheet without significantly altering the thickness. Stretching is best to create large-radius curves and complex shapes.

Furthermore, there is a limit to how much a sheet can be stretched, which depends on the thickness and material type. If you stretch beyond ultimate tensile strength (UTS), it will cause cracks or the sheet might break down.

2. Notches & Tabs in Sheet Metal Fabrication

These are other critical features of sheet metal fabrication of the forming process. A notch refers to a cut-out section in the sheet, where a specific shape is removed from the edge or surface. Meanwhile, extensions are typically left on the edge of a sheet metal part.

Notches and Tabls are typically used in the assembly of sheet metal fabrication parts. For example, the notches facilitate welding access in complicated positions.

3. Sheet Metal Drawing or Deep Drawing

This process involves drawing a sheet metal blank into a forming die with a mechanical or hydraulic punch. It stretches the metal blank radially into a form-shaping die to form a deep and axially symmetric part like a cylinder or a box.

Here, the use of a die allows for consistent and repeatable results. So, this method is efficient for high-volume production.

Sheet Metal Bending Services at ProleanTech

Are you looking for expertise and advanced sheet metal fabrication facilities to execute your bending designs? At ProleanTech, our Sheet Metal Bending Services encompass a team of experienced engineers and CNC press brakes to handle your project.

We have 50+ metal and alloy options. You can choose any metal sheet with a specific grade for your requirements. Consequently, our sheet metal surface finishing approaches will also ensure the desired aesthetic and finish. So, upload your sheet metal design and request a quote. We will then contact you with detailed and accurate information.

Try Prolean Now!

Summing Up

Sheet metals can be manipulated into a rich range of bend shapes with different bending methods. The use of the right bending method and parameters like bending force, minimum bending radius, and bed allowance are essential to achieve the desired bend. Moreover, applications of Sheet Metal Bending are widespread, from consumer items to aerospace and shipbuilding.

FAQs

Are Sheet Metal Bending Products Durable?

Yes, they are generally considered durable Products. However, the lifespan( 5 to 25 years) primarily depends on the metal or alloy type and the post-processing treatments.

What is the use of CO2 Laser Cutter in the Sheet Metal Bending?

A CO2 laser cutter is the best way to precisely cut the large metal sheets into the required size before bending procedures. It provides high precision and clean cuts with minimal waste.

How Much Does Sheet Metal Bending Cost?

The cost might vary widely based on factors like the type of metal, thickness, bending complexity, and the quantity of parts needed. Saying that it is still more cost-effective than machining or casting.

Is Sheet Metal Bending Accurate?

Yes, sheet metal bending is a highly accurate process. Modern techniques and equipment, such as CNC press brakes can precisely control the bending angles, force, and positioning for accurate bends.

Resources

1. Ikumapayi, Madushele, N. (2020). A brief overview of bending operation in sheet metal forming. In Advances in Manufacturing Engineering (pp. 149-159). Springer Nature Singapore Pte Ltd. https://doi.org/10.1007/978-981-15-5753-8_14

2. Kuboki, T & Jin, Y. (2021). Asymmetric sheet-metal V-bending applying separate dies with different velocities for diversified bending shapes and operability. CIRP Annals, 70(1), 219-222. https://doi.org/10.1016/j.cirp.2021.03.015

Do you supply sheet metal prototype’s for startups? We are a small company based in Japan looking for some custom prototypes. What is your typical lead time for producing bending & stamping prototypes?

Hello George. Yes, we also work with startups and small businesses. Regarding your next question, Our quick lead time for prototypes is as low as 3 days , varying with material and complexity. Complex designs or specialized materials may extend this timeframe. We provide accurate cost and time estimates with quote.