Steel sheet metal fabrication is the raw process of the manufacturing sector, which in turn helps produce the various metal products required in industries ranging from automobile, construction, aerospace, and even consumer goods. Some of the applications for fabricated steel sheet metal products include car bodies, kitchen appliances, etc. In these products, all these fabricated items play a crucial role in delivering wear-resistant and precise, and high-quality metal components.

This article delves into an in-depth analysis of steel sheet metal fabrication. It covers all the properties involved, as well as the materials used within the process; techniques are also found in bringing designs to reality.

What is Steel Sheet Metal Fabrication?

Fabrication of sheet metal, particularly steel sheet, is the production of parts or finished products from flat steel sheets using cutting, bending, and joining processes. The term “fabrication” applies to these transformations in which the original material-manipulated shapes and forms of steel sheet metal are fabricated into shapes and forms required for certain applications.

Try Prolean Now!

Benefits of Steel Sheet Metal Fabrication

Versatility: Flexibility to fabricate steel in nearly any shape or size to cover hundreds of applications.

Strength and Toughness: Steel’s inherent properties make it robust and capable of bearing heavy loads and withstanding complex interactions with the environment.

Accuracy: The new techniques in fabrication, especially the application of CNC and laser technology, allow very accurate cuts and shapes with exact specified specifications.

Steel sheet metal fabrication plays an important role in industries, specifically those where products need to possess strength, durability, and precision. It’s often preferred for high-quality and reliable metal parts work.

Understanding Steel Sheet Metal Properties

Steel Sheet Metal Durability

The basic properties of steel sheet metal tell why it is used in as much fabrication work as it is. Here are some important steel sheet metal properties that make it very useful for a range of purposes:

1. Strength:

Steel has incredible tensile strength-that is, and it can take on extreme stress and weight. This is very true in construction and the car industry, where it has to last long.

2. Durability:

Steel resists wear and tear well; hence, its use may be justified for components used frequently or subject to heavy usage. This also results in an increased product life cycle, with many instances resulting in savings on replacements.

3. Ductility:

It can be bent, stretched, or drawn before it starts breaking. This property makes it easily formable into complex shapes along with fine details without any loss of structural integrity.

4. Corrosion Resistance:

Stainless steel resists corrosion; these variants even have applications. The surface would remain intact in moist or chemical environments. This is very important in food processing, where cleanliness and material resistance are essential.

5. Thermal Conductivity:

Steel is a good conductor of heat. Some manufacturing processes require regulating heat or even resistance to heat.

This combination of properties makes steel sheet metal extremely well-suited for applications that require strength, longevity, and adaptability. These same qualities also mean you can pick materials with specific properties tailored to a project’s requirements.

Types of Steel in Sheet Metal Fabrication

A wide variety of steel may be used for steel sheet metal fabrication, each with its unique properties and application. Some of the most common types used in metal sheet fabrication are as follows:

1. Carbon Steel:

Highly tensile and hard, carbon steel is one of the more common tools used for automotive and construction applications. Affordability and versatility make it the most popular choice when a project doesn’t require high corrosion resistance.

Carbon Steel

2. Stainless Steel:

Stainless steel can reach the highest levels of corrosion protection, and because of this, it is used in the medical, food, and marine industries. For purposes where sanitation is required, tension for corrosion protection, and a finish are required, stainless steel sheet metal fabrication is more convenient.

Carbon steel and stainless steel are used in various applications requiring strong strength, and they also provide resistance to corrosion; aluminum sheet metal fabrication is also popular-always where lightweight takes precedence. Aluminum is categorized amongst the most valuable materials, which have high-value density and are easily mouldable. Due to application and accessibility today aluminum has become an essential material to use where ever weight can be shed in the aerospace industries as well as the car manufacturing industries.

Stainless Steel

3. Galvanized Steel:

The outer shell of galvanized steel contains a layer of zinc coat that provides the material with superior corrosion resistance. It is used in more outdoor applications such as roofing and wet areas where the moisture level is inescapable.

Galvanized Steel Sheet

The choice of steel type for a fabrication job will determine the desired properties and durability, which may depend on several factors, such as exposure to moisture, environmental conditions, and load requirements.

Try Prolean Now!

Fabrication Processes for Steel Sheet Metal

Steel sheet metal fabrication involves a myriad of specialized techniques that allow raw metal sheets to transform into functional parts and products. Each process does something unique:

Sheet Metal Process

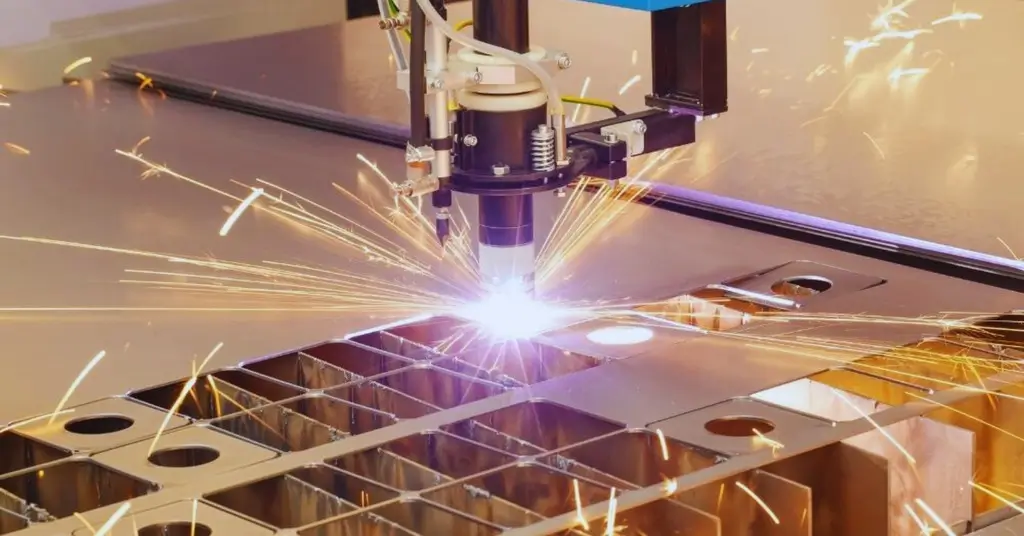

- Cutting: Often the first step in steel sheet metal fabrication, cutting defines the size of the final product with several methods used, including:

- Laser Cutting: Made by focusing laser beams for high precision cuts into sheet metal, this allows design detail with high accuracy.

- Plasma Cutting: In plasma cutting, a high velocity of an ionized gas stream is used for cutting, and it is fairly efficient for somewhat thicker steel sheets.

- Waterjet Cutting: It employs a jet of water under high pressure to cut the material by emitting water jets, which do not heat the material.

Plasma Cutting

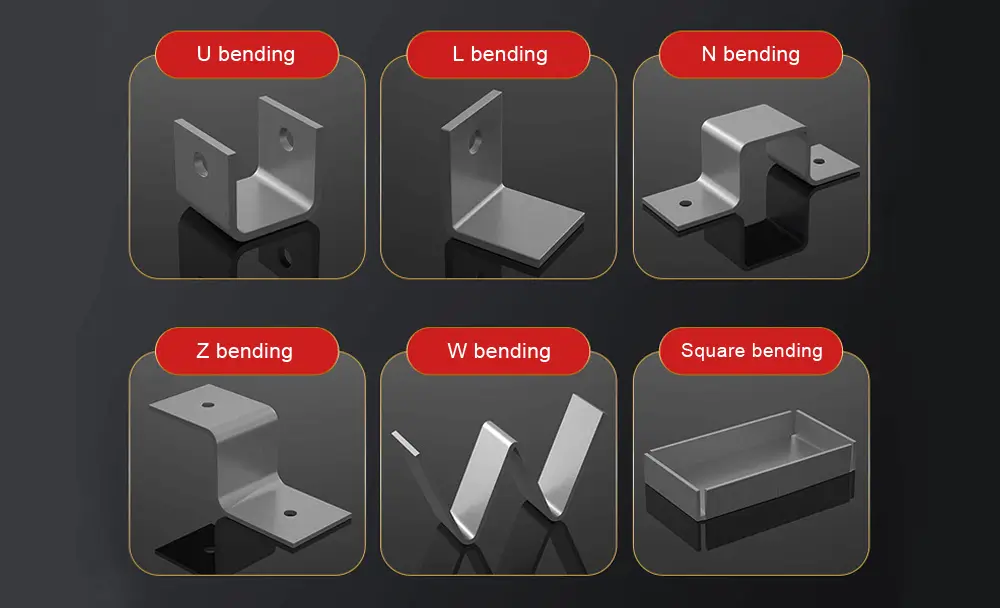

- Bending: Bending is the process where the flat sheet of metal assumes three-dimensional work, though the procedure is mainly done on a press brake where pressure is formed into a specific line to bend the metal. Bending requires some skill and sometimes precision not to make the material warp or crack.

- Welding: Welding combines two parts of steel sheet metal parts for a strong connection. Available welding techniques include MIG, TIG, and arc, among others, best to be applied to the kinds and thicknesses of the kind of steel.

- Punching and Stamping: Making holes or indentations in the sheet metal to attach or create special shapes on the part.

- Finishing: Finishing processes enhance the strength and appearance of the steel. Such processes can include coating, painting, or polishing, which enhances resistance against corrosion and aesthetic appearance.

Fabrication methods have become significant with technological developments in recent years. Such improvements involve accurate and efficient processes through the use of CNC machines and automation, improving productivity and accuracy within the fabrication process in steel sheet metal.

Choosing the Right Sheet Metal Material for Projects

Sheet Metal Bending

For fabrication, the proper sheet metal materials need to be chosen. In a material selection, the following points come into consideration:

Environmental Exposure:

Material choices for stainless steel or galvanized steel are chosen when the applications are for outdoor exposures, water, or chemical exposures because of their corrosion properties.

Structural Needs:

Applications where strength is an issue tend to utilize carbon steel as it is load-bearing. However, applications where weight is an issue could choose lighter metals like aluminum.

Budget:

The cost will influence the choice of material because stainless steel is very costly, especially when one considers that its main competitor in the application is corrosion-resistant carbon steel.

Applications of Steel Sheet Metal Fabrication

The versatility of steel sheet metal makes it appropriate for all varieties of applications across numerous industries, such as:

1. Construction:

It has applications in construction, such as structural pieces, cladding, and roofing. It is incredibly strong and robust, making it suitable for building bridges and other structures.

Sheet metal fabrication in construction

2. Automotive:

It is the primary basis of the automobile industry; it is used for frames and body panels for automobiles where strength and robustness require its application.

Sheet metal fabrication in the automotive industry

3. Aerospace:

When strength and weight are required simultaneously, steel sheet metal is used to fabricate varied parts that weigh little and ensure weight-critical aerospace construction.

4. Medical Equipment:

The medical field requests stainless steel primarily due to its tolerance toward corrosion and basic hygiene properties, where equipment, surgical tools, and hospital furniture are made.

5. HVAC Equipment:

Fabricated steel components are necessary to construct kitchen appliances, HVAC systems, and household and commercial appliances, ensuring sturdiness and resistance to heat.

These applications really show how versatile sheet metal is, which is why it is popular across so many different industries; its strength and ease of working make the material indispensable for manufacturers.

Try Prolean Now!

Conclusion

Steel sheet metal fabrication combines technology innovation with master craftsmanship to produce vital parts. Knowing the properties and types of steel and how they are fabricated is crucial in making a proper choice regarding manufacturing. If you’re looking to source construction, automotive, or even custom steel sheet metal fabrication, talking to the experts will ensure that the right material and technique are utilized.

If you’re interested in steel sheet metal fabrication or any other kind of metal fabrication, consider reaching out to ProleanTech for comprehensive sheet metal services and contact information about the right professional for your job, ensuring high-quality efficiency at all phases of your project!

FAQs on Steel Sheet Metal Fabrication

1. What are the primary benefits of steel sheet metal fabrication?

Steel sheet metal fabrication offers strength, durability, and flexibility in making accurate, intricate components. Some varieties of steel are corrosion adenine, and they are used in cooking, the health industry, and others.

2. How do I choose the right type of steel for my project?

Steel selections need to be done considering environmental conditions, load demands, and budget. Carbon steel is strong and relatively inexpensive for structural purposes, but stainless steel resists corrosion much better than carbon steel for food-grade applications. Your best resource for information on material selection will be through talking to sheet metal manufacturers.

3. What are some common challenges in steel sheet metal fabrication?

Challenges encompass weight control, rust prevention (especially in non-stainless steels), and additional surface finishes that consume additional time and cost.

4. Where is steel sheet metal commonly used in everyday products?

Steel sheet metal is widely used in the car, furniture, refrigerator, and air conditioner industries. It has wide applications in construction, roofing, and cladding. Stainless steels also have very wide applications in food industries, among others, especially when sanitation property is involved.

5. What are the key differences between stainless steel and aluminum in sheet metal fabrication?

Stainless steel is tough, resistant to corrosion, and hygienically suitable where moisture is present in sensitive areas. Aluminum is less dense, easier to process, and is favored by weight-conscious applications like space exploration and transport.

0 Comments