Rivet vs Screw

Both rivets and screws fasten materials, but they do so in very different ways. Rivets create a permanent joint that becomes an integral part of the structure, offering exceptional resistance against vibration, pressure, and time. Once fixed, they are not meant to be removed without damaging the assembly.

Screws, on the other hand, are designed for flexibility. They allow disassembly, adjustment, and maintenance whenever required. Their threaded design provides control over the level of tightness between two surfaces. It makes them suitable for joints that may need future modifications or replacements.

In-depth discussion of the rivet vs screw will be provided in this article, which demonstrates how all fittings determine a structure’s lifespan, upkeep, and kind.

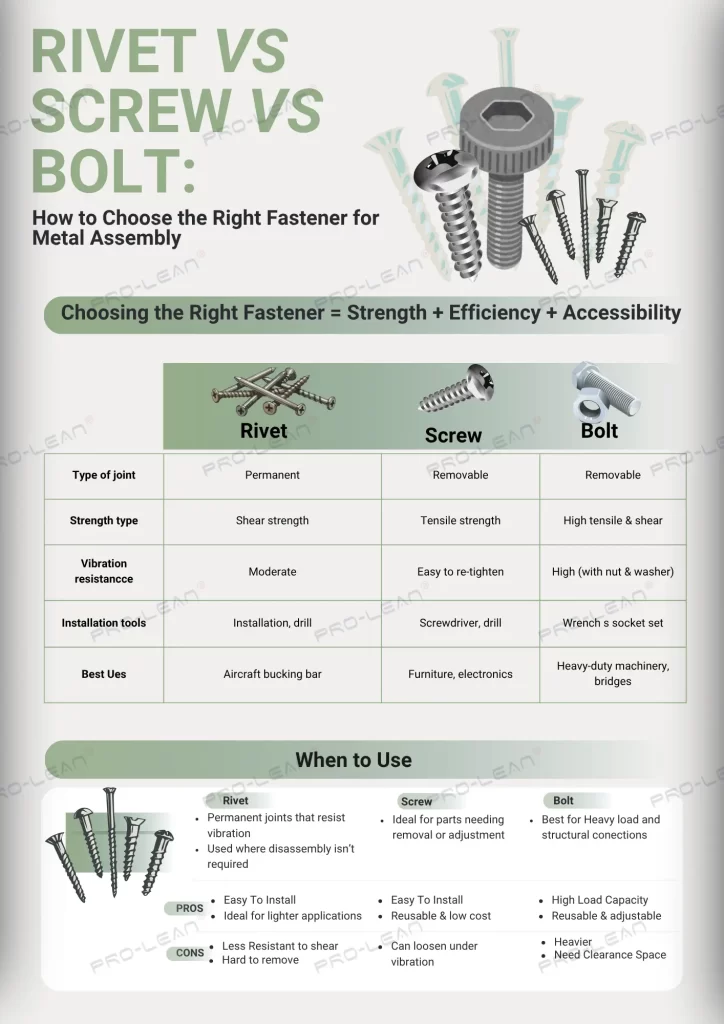

Rivet vs Screw vs Bolt: How to Choose the right Fastener for Metal Assembly

Definitions and Fundamental Mechanisms

It’s helpful to comprehend how each fastener is constructed and how it holds materials together before comparing which one performs better.

What is a Rivet?

Standard Rivet Structure

A rivet is a metal pin or fastener with a head on one end and a tail on the other, used to join two or more layers of material into a permanent connection. The rivet is inserted into holes that are either drilled or punched through the pieces being joined, with the head resting on one side and the tail extending through the aligned materials.

The tail is then deformed, or upset, to create a second head that holds the materials firmly together. During this process, the rivet and the joined materials become permanently locked in place, forming a solid connection that resists separation.

Because of this deformation, rivet joints tend to be permanent. The rivet cannot be detached, and in order to extract it, one must drill or destroy the rivet. It is one commonality to most of the sheet metal fasteners that are applied to the joints to become stable and not vibrate.

What is a Screw?

What is a Screw

A screw is a screwed fastener, the rod of which has a helical groove (thread) perforated through it. One of the ends of the screw is called the head and forms a surface that the driving tool (screwdriver, hex key, etc.) has. A threaded shaft may be screwed onto an internal thread already cut in a material, or may cut an internal thread by screwing.

The helical thread takes on the fastener, and as you screw, the screw’s threads convert torque into linear clamping force, which is then transferred to the material. It results in the movement and secure tightening of the joint. The joint may be removed or altered by reversing the rotation since the connection is made with the assistance of threads.

The Mechanics of Shear, Tension, and Durability

Their mechanics play a great role in the explanation of how the two fasteners work. The rivets create a bond of a mechanical kind that cannot be undone. The materials are attached with the deformed tail and the original head resisting the shear (sliding) and tensile (pulling) forces without a thread.

It is this deformation that makes a rivet permanent. By the time the tail has become large and dispersed, it is a fixed, irreparable joint. Loosening due to vibration does not take place to such an extent because of the absence of threads.

On the other hand, screws generate holding force by biting or engaging the material to its threads and translating the torque to the clamping force and friction, and interlocking. This makes the joints that may require the removal or relocation of screws flawless. However, they can be considered a liability in cases of high vibration or shear dominated situations where they can loosen in circumstances where it is not fixed.

Try Prolean Now!

Various kinds of Rivets and Screws

It is another examination of the different types of rivets and screws. We are discussing how each of them can be differentiated, and in what cases each of them makes sense.

Different Types of Rivets

The principle of rivets is easy. Once the rivets are supplied, the material is pressed to make sure the materials stick. This happens to be riveting in sheet metal. It is made to give a joint full of security and permanence, and it is not resistant to vibration and stress.

Types of Rivets

These various kinds are as follows:

Solid Rivets

Solid Rivet

The common ones are solid rivets. In this, the shank and head are mere parts to be inserted in a hole that has been pre-drilled after which the end is coiled to form a second head. They may be located in bridges, industrial machines, and airplanes because they are used in heavy-duty and structural buildings, where strength and durability are the most important factors.

Blind Rivets

Blind Rivet

The worn-out rivets are the blind rivets in cases where there is only one side of the joint. Respectively, there is a mandrel in a hollow body. When it is being drawn, it enlarges the body, and this traps the materials. They are extremely popular in automobiles, construction and manufacturing, which makes them so convenient and reliable in steel making.

Self Piercing Rivets

Self-piercing rivets

Self piercing rivets penetrate even deeper and cut holes in a material that does not already have a pre drilled hole. They are usually utilized in the manufacturing industry of automobiles where time and accuracy matter such as during the development of coated metal or aluminum sheets.

Remaining Rivet Varieties

The remainder of the rivets are of special purpose. The rivets are either semitubular or tubular wherein a moderate strength is required and the riveting is to be done rapidly. Soft materials like leather or wood are applied to the split rivets.

Flush rivets would be used to give it a smooth and aerodynamic coating. They are perfect cars and planes. A simple and fast method of fastening is also the hammered drive rivet, that is used for light use.

Different Types of Screws

Types of Screws

These are the broad categories of the numerous screw types and the extent to which they are usable and fit in various materials and activities.

Wood Screws

Wood Screws

It is expected that the timber to be joined will receive the wood screws. The screws are sharp at the end, and the threading is cut in such a way that it cuts into the wood without an existing pre drilled slot. The assemblies have designs that have a pull together force.

Machine Screws

Machine Screws

Machine screws refer to an all-thread screw with straight shank, which is produced out of tapped holes or a nut engaged. They may exist in metal structures, machineries, as well as electronics where a fine fastening would be required. Most of the industrial assemblies are assembled together with bolts and screws to become structurally stable and ensure that they become easy to maintain.

Self Tapping and Self Drilling Screws

Self tapping screws self drill are driven inwards. Self drilling screws are a step more ahead since they bore both the thread and the drill on one another. They are the finest in those circumstances where speed is actually significant, and you will not pre drill it based on the substrate.

Head, Drive, Material, and Coating differences

Besides the dominant ones, screws are differentiated in the shape of the head (flat, pan, hex), drive (Phillips, Torx, slotted), material (steel, stainless, brass), and finish/coat. These variations allow one to make decisions based on substrates, wood, metal, plastic, loads, environments, and the possibility or otherwise of the same requiring the removal or replacement of the same.

Try Prolean Now!

Merits and Depreciation of Rivets

Rivets have long been a trusted choice in construction and manufacturing, but like every fastening method, they come with both strengths and trade-offs.

- Strong and Durable Join

Rivets form a solid, lasting bond that doesn’t give in easily to vibration or shear forces. Their permanence makes them a dependable choice for structures that need to stay secure and stable over time.

- Smooth Appearance

Beyond their strength, rivets add a clean, polished finish. Their flush fit blends neatly with the surface, giving the assembly a smooth and refined look that’s often preferred in visible or precision applications.

- Difficult to Remove

Once in place, rivets are meant to stay. Removing them usually requires drilling or cutting, which can damage the material. This makes them less ideal for parts that might need frequent servicing.

- Higher Installation Effort

Rivets demand precision, special tools, and careful handling during installation. While this adds to setup time and labor, the result is a joint known for its consistency and long-term reliability.

Merits and Depreciation of Screws

Screws offer flexibility and convenience in assembly work, yet their performance depends greatly on how and where they’re used.

- Easy to Reuse

Screws offer the freedom to remove, adjust, and reuse them without damaging the material. This makes them a practical choice for assemblies that may need maintenance, upgrades, or quick fixes over time.

- Variety in Design

Available in countless sizes, lengths, and head types, screws adapt easily to different materials and project requirements. Their versatility allows engineers and builders to find the perfect fit for both precision work and large-scale applications.

- May Loosen Over Time

While reliable, screws can sometimes lose their grip when exposed to continuous vibration or movement. Regular tightening or the use of locking mechanisms can help maintain stability in such conditions.

- Requires Pre-drilling

Certain screw types demand pre-drilled or threaded holes for proper installation. In joints where shear forces are dominant, rivets often outperform screws by providing a stronger and more stable hold.

When to Use a Rivet vs When to Use a Screw

In simple terms, use rivets when you need a strong, permanent joint, and choose screws when flexibility or future disassembly is required. Nevertheless, while selecting, it is best to consider the major factors that define performance and suitability.

Permanence and Maintenance

First of all, the answer to the question about whether the joint is permanent or will be summoned at some point in the future to require disassembly or service needs to be discovered. Rivets become non reusable.

They are permanent, and in that regard, they are best applied where you do not have intentions of using the same joint again. Screws, on the other hand, can be removed or altered, and this is important in cases where future repairs or alterations are anticipated.

Load Type and Environment

Then there is the type of load the joint will be subjected to and the conditions in which it will be operating, due to the fact that its plasticity keeps the joint together and does not depend on threads, which can be loosened.

Screws, on the other hand, may prove to be more suitable for intension type use or where there is a general high frequency of access. Moreover, in the instances where the rivets cannot be fitted on both sides of the assembly, rivets (especially blind rivets) might prove to be an option.

Access, Cost, and Tooling

Finally, there are accessibility, costs, and tool requirements. Its screw is easy to install and needs a normal tool, and this can be used to potentially save costs on labour and training. Special tools were also needed to fix rivets, and when put in place, they become difficult to remove, which increases the repair costs.

Use Case Examples for Rivets

In heavy structural and aerospace applications, it is commonly desired to have a fastener that will not loosen, will be able to survive vibration, and will last as long as the structure itself. That’s where rivets shine.

As an illustration, solid rivets are often employed on the skins and fuselage sections of airplanes because they distribute the load, clamp when vibrated, and are virtually impervious to loosening once in position. These are the most reliable aerospace fasteners, and they are chosen because they are of a high strength to weight ratio and are durable.

The Rivets are used in prefabricated steel structures or parts that are required to resist shocks, vibration, and sand transit since they fit tightly even in rugged conditions.

Similarly, in the production of motor vehicles, automotive fasteners such as self piercing rivets are highly important in the assembly of the aluminum panels and stacked metals.

Use Case Examples for Screws

Use of the Screw

For furniture, electronics, modular machinery, or any system where there is a possibility that the components will need to be removed, screws are the recommended choice in the interim. Because they are threaded, the surrounding material won’t be harmed during installation, removal, adjustment, or reuse.

Because screws are bendable and easy to maintain, they are preferred in consumer product assemblies that need repairs or upgrades, where flexibility and assembly maintenance are necessary. Deconstruction does not imply destruction. The concept of installation is not new, and tool sets are ubiquitous.

Installation and Practical Considerations

The following is a breakdown of the factors to be taken into account when installing and maintaining a rivet or screw. It might assist you in selecting the appropriate fastener and in determining how best to use and maintain it.

Tools and Techniques

Having selected a rivet, you will probably need other special equipment. One of them is that a solid rivet must be installed, using a rivet gun which strikes the factory head and a bucking bar which supports the back of the shank. It is a little easier in the case of blind rivets, which can be attached on one side using a pulling machine.

Impact drivers, drills, and manual screwdrivers are the most prevalent screw-related equipment. Screw installation is also often faster and more accessible to a wide range of users, especially in the sheet metal fabrication business, where accuracy, consistency, and convenience of use are the top concerns for assembly quality.

Ease of Installation

Installing screws typically requires less effort and fewer specialized tools, making them quicker and more convenient to apply, even for beginners. Rivets, however, call for greater precision and dedicated equipment to ensure a secure hold, which can extend both the setup time and the amount of labor involved.

Removal and Repair

In case your project may need servicing, some adjustments, and even a disassembly, the choice of fasteners is very significant. A rivet entails an indestructible bond. One cannot simply unscrew it after it is stuck. It has to typically be dug out or destroyed to extract it.

It assumes that they are more labour intensive in the process of repairing or making changes when using rivets. The advantage of screws, in comparison, is the fact that they can be removed. They can be inverted, replaced, or refitted.

Initial Cost vs Lifecycle and Maintenance

At face of it, screws are more likely to be more costly and labour intensive. The screws are cheap, the equipment is generic, and the work performed to install it is not much. The majority of the work that involves screws is appealing.

Rivets are more labour consuming (special tools are used not just in their application, but also in a more delicate technique), and difficult to remove or reform.

On the other hand, rivets may turn out to be economically less expensive in the long run when the joint does not need to perform any maintenance. You save on rechecking and adjusting because a rivet joint does not loosen like a screw when it is vibrated.

Conclusion

At the end of the day, there is no single answer to the question of rivet vs screw. Rivets are best suited for applications that demand a permanent, vibration-resistant joint, while screws are ideal when flexibility, disassembly, or adjustments may be required later.

To determine what type of connection you require, e.g., permanent and able to withstand vibrations, or able to change and take off, it is important to match the fastener to your material, load, environment, and service requirements. Early access, maintenance, load direction, and cost are important. So, it is advised to take the time to evaluate and make a decision as per your needs.

In case you have a bigger project, our engineers at ProleanTech can help you choose the right fasteners and ensure precise, cost-efficient results. We offer suitable solutions for both small and large batch production.

You can request a sheet metal fabrication online quote to explore suitable solutions for both small and large batch production.

0 Comments