CAPABILITIES

Production Tooling Service

Production tooling is the plastic injection molding process used for the mass production of precision plastic parts. Production tooling is the ultimate stage in manufacturing and the parts manufactured are for end-users. It is a sizable investment in terms of time and resources.

Prolean’s rapid production tooling services for plastic injection molded parts are a reliable option for sourcing mass-produced high-precision parts at a reasonable cost per unit.

All uploads are secure and confidential.

What is Production Tooling

Production tooling is the plastic injection molding process used for mass production of precision plastic parts. Production tooling is the ultimate stage in manufacturing and the parts manufactured are for end-users. It is a sizable investment in terms of time and resources.

Prolean’s production tooling services for plastic injection molded parts are a reliable option for sourcing mass produced high-precision parts at a reasonable cost per unit.

Try Prolean Now!

How to Order Parts?

Get a free quote from a real engineer; once we receive your design, our engineer will review it and send you a quote as fast as one hour.

Get A Quote Immediately

Upload your design or email our engineer directly and get your quotes as fast as one hour.

Start Production

Your parts will be made once your orders are confirmed. Besides, you will get real-time order updates of the production status from our order tracking system.

Receive Your Part

After all parts pass QC inspection, they will be well packed from transportation accidents. Then, your custom parts are delivered straight to your doorstep.

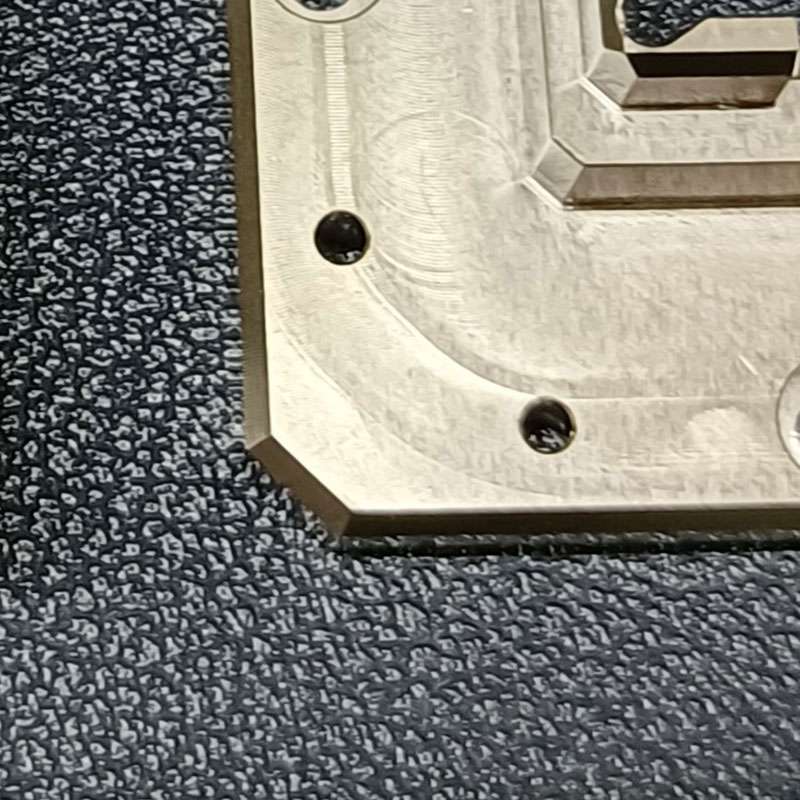

How Does Production Tooling Work?

The creation of molds for production tooling is a lengthy process. It can require 3-4 weeks, but the production tooling serves for many years, unlike prototype tooling which has only around 10,000 cycles life even in the case of steel tools. Production tooling proves more efficient in long term for mass production which is why it is the preferred process in the industries.

The injection molding process for production tooling is largely the same as simple injection molding. A machine injects molten plastic into the mold which cools down to solidify into the required part. The parts created with production tooling usually have better finishes and require little to no work on them after they come out of the mold.

Advantages of Rapid Production Tooling

- Production tooling has the best surface finishes and part quality of all injection molding processes.

- Production tooling costs more than rapid tooling initially but the extended life in fact makes production tooling cost per unit less than rapid tooling in the long run.

- Another key advantage for production tool is the exceptional quality of parts produced with production tooling.

- The surface finish and precision of production tooling is better than rapid tooling and often there is no additional work required on parts once they leave the mold.

What Materials Are Available For Production Tooling?

| Thermoplastics | |

| ABS | PET |

| PC | PMMA |

| Nylon (PA) | POM |

| Glass Filled Nylon (PA GF) | PP |

| PC/ABS | PVC |

| PE/HDPE/LDPE | TPU |

Production Tooling Part Finishing Options

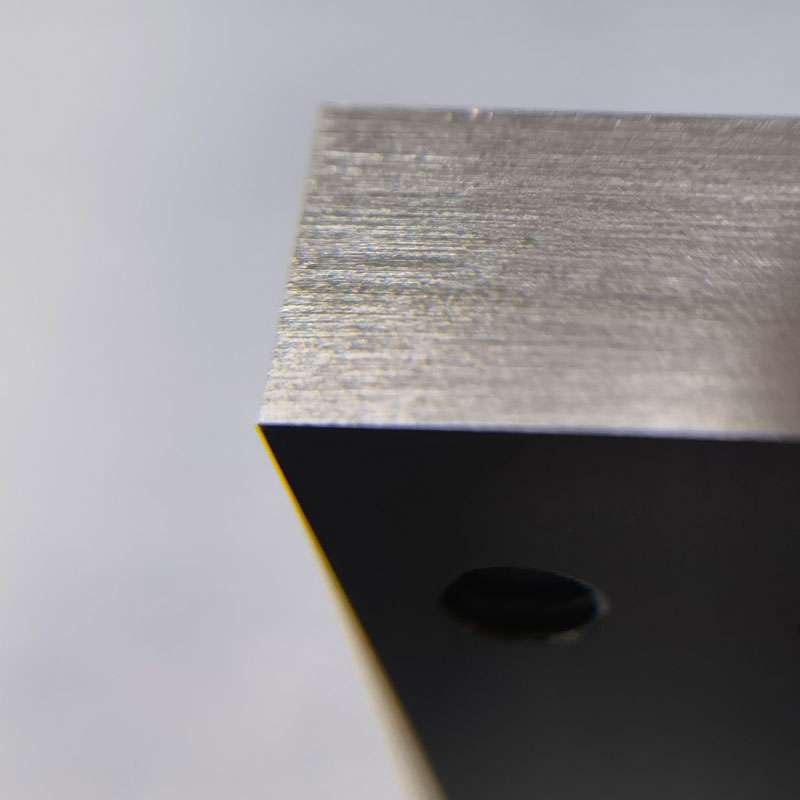

As the machined or deburring

The machined or deburring finish is the standard finish where unwanted attach chips are removed with deburring tools, and sharp edges are chamfered to smooth the surface (3.2 μm).

Bead Blasted

Bead blasting produces a matte texture, removing all the marks of machining tools. It applies to ABS, Aluminum, Brass, Stainless Steel, and Steel parts.

Anodizing

Anodizing involves adding an aluminum oxide coating to aluminum and its alloys. The layers, which come in various colors, increase strength and shield the surface from corrosion.

Powder coating

Powder coating is the electrostatically applying of dry powder to the surface. It produces a thin layer providing excellent resistance to wear, corrosion, and abrasion.

Polishing

Physical rubbing of a metal surface to create a shiny surface is called a polishing surface finish. It increases the reflectivity and does not affect the dimensional stability of parts.

Brushing

Brushing is achieved by applying an abrasive brush to the metal surface, which produces a unidirectional satin finish. And it is not recommended for highly corrosive materials.

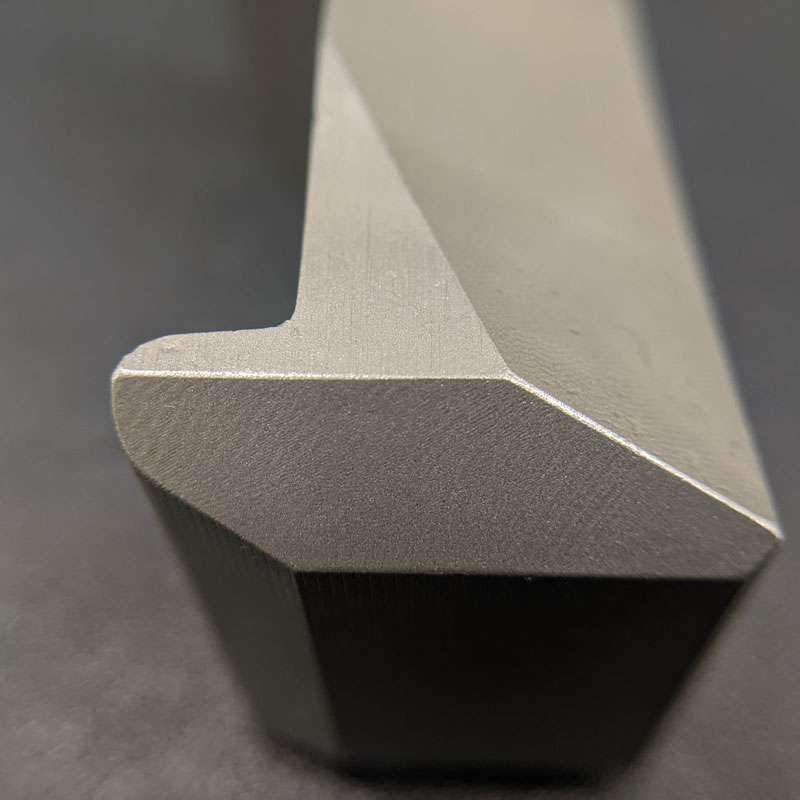

Smooth machining

Smooth machining is done by controlling the machining process, such as feed rate & cutting speed. It minimizes the tool marks and risk of corrosion.

Black-Oxide

Black oxide finish reduces surface reflectivity and offers mild corrosion protection. It involves adding a thin layer of magnetite to the surface.

Electro-less Nickel Plating

A thin layer of Nickel is created on the surface from a nickel-containing solution without electrolysis. Electro-less nickel plating provides a shiny appearance, excellent hardness, abrasive, wear, and corrosion-resistance to the substrate material.

Alodine

Provides excellent corrosion resistance property to the aluminum parts with greenish-gold color. It is the low-cost and quick surface finishing approach.

Electroplating

Electroplating increases the hardness of the steel &aluminum parts. It offers excellent corrosion, wears, and abrasion resistance.

Nickel plating

Make the parts super resistive to corrosion. It enhances mechanical strength, hardness, wear resistance, lubricity, and ductility. Nickel plating is applicable in different materials, including Steel, aluminum, copper, and brass.

Passivation

Enhance the appearance and functionality of the parts. After Passivation, parts of Steel and its alloys become super resistive from corrosion.

Yellow Chromate conversion coating

A shiny appearance with goldish color provides excellent corrosion resistance. It is applied on the surface of aluminum, magnesium, and their alloys. A layer of chromate also enhances the conductivity of parts

PTFE (Teflon) Coating

The Teflon layer on the parts offers excellent corrosion resistance, water resistance, and non-stickiness with a non-reactive surface.

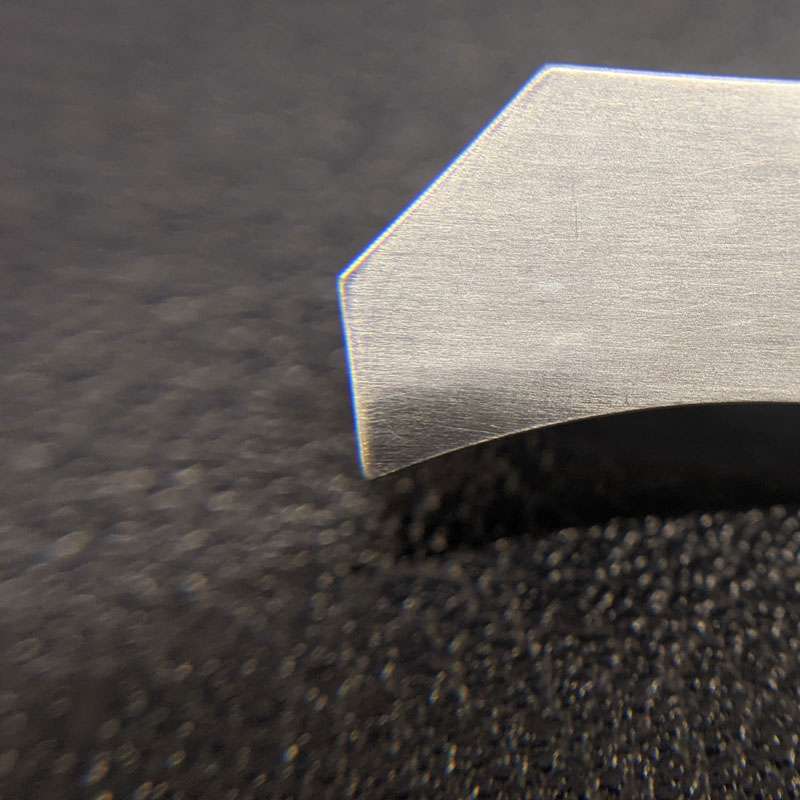

Fine machining

The higher-precision machines produce delicate machining surfaces by utilizing sharper tools and regulating feed rate and cutting speed. Surface roughness up to Ra 0.8 μm can be maintained with smooth machining.

Laser Cladding

Provides excellent corrosion, wear, and abrasion resistance. Laser Cladding is also effective for treating minor surface imperfections such as cavities, tiny cracks, and rust damage.

Sanding

Provides a random, non-linear texture with a shiny, high gloss finish. However, it might be unable to create sharp corners and pockets

More

Provides a random, non-linear texture with a shiny, high gloss finish. However, it might be unable to create sharp corners and pockets

3 Ways to Ensure Perfection

Standards

GENERAL TOLERANCE

For metals, the standard is ISO-2768 fH (fine)

For plastics, the standard is ISO-2768 mK (medium)

Metric threads tolerances:ISO 965-1 standard UN Threads Tolerances: ASME B1.1-2003 standard

knurling: ISO13444:2012 standard Our factory is ISO 9001:2015 certificated

Visual inspection and Protection

Constant visual inspection conditions

Quantification of cosmetic surface quality

Process requirements

Part cleaning and Protection

Quality Inspection Report

Inspection Confirmation

Dimensional confirmation

Appearance confirmation

Quality documentation

Try Prolean Now!

See why customers dig us

It has been a true pleasure working with ProleanTech for our Plastic Injection Molding needs. I appreciate your patience and the time you've dedicated to finalizing all the details.

-Steven Edwards, Lead Die Casting Engineer

We contacted ProleanTech for aluminum injection molds back in 2022. I can not believe, they deliver the first batch within a week.

-Jessica Scott, Product Development Manager at InnovateMetal Works

We are extremely pleased with your production tooling service, whether it was the first order of custom fixtures or a recent casting mold. And we will continuously work together in the future.

-Christopher Hill, PrecisionProto Labs

Your attention to detail and quality in plastic injection mold manufacturing is commendable. The services are reliable, and we are highly satisfied with the final results.

-Maria Turner, MolderWorks Manufacturing

As an US company I first hesitate to outsource from china due to misunderstanding about tarrifs. Later, i found why comapnies are partnering companies like proleanTech. Thank you!

-Andrew White, Surface Treatment Specialist at CoatPro Solutions

We're impressed with ProleanTech's exceptional service and quality in plastic injection molding. They delivered excellent results, which made them our trusted partner.

-Nicole Rogers, Director of Manufacturing at CustomMold Solutions

Related Blog

Injection Molding Vs Extrusion: What’s The Difference?

Injection molding creates complex 3D parts, extrusion produces continuous profiles efficiently.

Extrusion Molding vs Injection Molding: Which Works Best?

Injection molding makes complex plastic parts; extrusion molding creates long, uniform shapes

Exploring Hot Runner vs Cold Runner Injection Molding

Hot runner injection molding and cold runner injection molding

Get Your Parts Made Today