An injection molding gate is a critical component in mold design, acting as the passage through which molten plastic travels from the runners into the mold cavity. Its design significantly impacts the final product’s appearance, strength, and functionality, making it crucial for manufacturers to understand its intricacies and variations thoroughly.

The concept of an injection molding gate is pivotal in molding processes, as it stands out as the gateway to precision, efficiency, and quality in product development. This article will traverse the maze of injection molding gates, unearthing their types, designs, functions, and joint defects. We will also discuss the considerations and strategies for optimizing gate design to minimize flaws and ensure impeccable quality.

The Anatomy of an Injection Molding Gate

In the injection molding process, the gate is not just a physical component; it is the strategic point in molding that holds sway over the quality, appearance, and structural integrity of the final product.

Gate position in injection mold

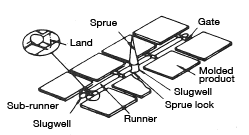

An injection molding gate is the designed opening in a mold through which molten plastic is introduced into the mold cavity, initiating the process of taking the shape of the desired part. The gate is the critical bridge between the runners (the channels through which the molten plastic travels) and the actual mold cavity, serving as the regulator of the flow and pressure of the molten material.

- Structure and Components

The injection molding gate is not a complex component in its physical form, yet its design requires meticulous attention to detail. It is usually a constricted section, often smaller than the runners, which ensures that the molten plastic remains contained within the mold cavity once it solidifies, allowing the gate to be easily detached from the finished product.

The gate’s structure is inherently linked to its type, with various gate types like edge gates, submarine gates, and tab gates each having unique structural attributes suited to different applications and molding requirements.

For example, an edge gate is located on the parting line and is suitable for flat parts, whereas a submarine gate is located below the parting line and allows automatic de-gating due to its design.

- Functionality of Injection molding gate

The gate’s functionality is multi-faceted, orchestrating the symphony of transformation that the plastic undergoes. Its primary role is to control the flow of the molten plastic into the mold cavity.

By dictating the flow rate and pressure, the gate ensures that the plastic fills the mold uniformly and efficiently, avoiding issues such as short shots or overpacking. This controlled flow is crucial for maintaining the structural integrity and dimensional accuracy of the molded part.

Relation of molding gate and molding parts

Moreover, the gate plays a pivotal role in determining the cooling rate of the plastic within the mold. The design and location of the gate affect how the plastic cools and solidifies, which in turn influences the appearance, strength, and potential stresses in the finished product. A well-designed gate ensures uniform cooling, minimizing defects like warping, sink marks, or weld lines.

Why Do You Need Injection Mold Gate Design?

Injection mold gate design is critical in the manufacturing process, as it directly impacts the quality, consistency, and integrity of the final product. A gate is the point at which the molten plastic is injected into the mold cavity, thus forming the desired component.

Example of injection molding gate design in CAD

The precision and efficacy of gate design are paramount, influencing the flow and cooling of the plastic within the mold, and subsequently affecting the overall cycle time, appearance, and performance of the produced part. Incorrect gate design can lead to multiple defects such as sink marks, weld lines, incomplete filling, and more.

Benefits of Optimal Gate Design:

- Enhanced Quality: Optimized gate design ensures uniform flow, reducing stresses and inconsistencies within the part.

- Reduced Cycle Time: Efficient design accelerates the process, impacting production time positively.

- Material Savings: Precision in design reduces material wastage, proving economically beneficial.

- Reduced Defects: An aptly designed gate mitigates the occurrence of defects, elevating the overall product quality.

Importance of Gate Location in Injection Molding

Strategically positioning the gate facilitates even distribution of plastic, minimizing inconsistencies, and ensuring optimal fill of the mold cavity. It also impacts the appearance of the finished part, affecting where weld lines appear and whether there are visible marks or deformities. Thus, the precise location of the gate is fundamental in mitigating defects and achieving a superior-quality product.

The following are the key factors Influencing Gate Location:

- Mold Cavity Geometry: The complexity of the mold dictates optimal gate placement to ensure consistent filling.

- Material Properties: The characteristics of the plastic material, such as viscosity and melting point, influence gate location.

- Aesthetic Considerations: For visible parts, gate location is critical in avoiding visible defects or marks on the final product.

- Ejection and Release: The gate location affects how the part is released from the mold, impacting the efficiency and cycle time of the process.

What are the Different Types of Injection Molding Gates?

Different types of injection molding gates

Understanding the different types of injection molding gates is pivotal for selecting the most suitable gate for a specific application, and balancing the functional requirements with the aesthetic considerations. Each type has its distinct characteristics, benefits, and potential challenges, enabling mold designers to optimize the quality and efficiency of the molding process.

Click to Download: Types of Gate design for injection molding

Table: Detailed Gate Types

| Gate Type | Description & Usage | Pros | Cons |

|---|---|---|---|

| Direct Gate | Also known as a sprue gate, it is directly attached to the sprue and is typically used for single-cavity molds. Suitable for thick-walled products requiring high injection pressure due to the straightforward and unrestricted flow of molten plastic. | Simple design, straightforward flow, suitable for high injection pressure and thick-walled products. | Leaves a large gate mark, limited usage due to advancements in gate design offering more precision and control. |

| Edge Gate | Located on the parting line of the mold between the core and the cavity, it is versatile and commonly used for flat parts and ideal for multi-cavity molds. The molten plastic flows linearly, allowing for uniform filling. | Versatile, ideal for flat parts and multi-cavity molds, allows uniform filling. | The visibility of the gate mark is a consideration, especially for aesthetically critical parts. |

| Submarine Gate | Located below the parting line, enabling automatic de-gating as the molded part is ejected. Advantageous for high-production runs and reduces post-molding operations. | Allows automatic de-gating, is suitable for high-production runs, and reduces post-molding operations. | Complex design, may not be suitable for certain materials due to the risk of gate blockage. |

| Tab Gate | A versatile gate type that is easy to design and implement, allowing for easy de-gating and particularly suitable for large parts with thick sections. | Easy to design and implement, suitable for large parts with thick sections, allows easy de-gating. | Often requires additional operations to remove the gate vestige post-molding, impacting the overall production efficiency. |

| Fan Gate | Characterized by its distinctive fan-like design, allowing for an even spread of the molten plastic. Suitable for wide, thin-walled parts and minimizes stress concentrations. | Allows even spread of molten plastic, minimizes stress concentrations, suitable for wide, thin-walled parts. | More visible due to its width, necessitates precise location selection to avoid aesthetic issues. |

| Diaphragm Gate | Ideal for molding cylindrical or tubular parts, allowing for uniform wall thickness and minimizing weld lines. Located at the center of the part, allowing the plastic to radiate outward uniformly. | Allows uniform wall thickness, minimizes weld lines, suitable for cylindrical or tubular parts. | Application is limited to parts with a central opening, restricting its usage to specific designs. |

How to Manufacture the Injection Molding Gates?

Manufacturing injection molding gates is a meticulous process that involves precision, knowledge and a keen understanding of materials and flow dynamics. The process revolves around creating a path through which the molten plastic can travel from the injection molding machine into the mold cavity. The method chosen for manufacturing, coupled with the type of gate, significantly influences the efficiency and quality of the injection molding process.

Methods for Manufacturing Injection Molding Gates

Injection mold manufacturing with EDM

The manufacturing of injection molding gates often employs varied methods, each chosen based on the gate type, material used, and specific requirements of the molded product. Here are some prevalent methods:

- CNC Machining CNC machining is a widely used method for creating gates. It employs computerized controls to remove material and shape the gate, ensuring high precision and accuracy. This method is versatile, allowing the creation of diverse gate types with tight tolerances. CNC machining can achieve tight tolerances up to ±0.005 inches, ensuring the accuracy and reliability of the gates manufactured.

- Electrical Discharge Machining (EDM) EDM is another popular method for creating intricate and detailed gates. It uses electrical discharges or sparks to remove material, allowing for high precision, especially for complex and detailed gate designs. This method can achieve even tighter tolerances up to ±0.0001 inches, making it suitable for manufacturing intricate and complex gates.

- Laser Cutting This method employs a high-power laser to cut and shape the gate. Laser cutting is known for its precision and ability to create intricate designs, making it suitable for various gate types, including those requiring extremely tight tolerances. Laser cutting provides precise tolerances up to ±0.002 inches, allowing the creation of detailed and specific gate designs.

Injection Molding Gate Type and Manufacturing Methods

Different gate types may necessitate specific manufacturing methods due to their unique designs, locations, and functionalities.

Table: Gate Type & Manufacturing Methods, and Precision

| Gate Type | Preferred Manufacturing Methods | Precision |

|---|---|---|

| Direct Gate | Generally manufactured using CNC machining. | High precision is attainable, ensuring that the gate aligns perfectly with the sprue. |

| Edge Gate | Usually created using CNC machining or laser cutting. | High precision is crucial to ensure uniform filling and to minimize gate marks on the finished product. |

| Submarine Gate | Often developed using EDM due to its complexity. | Extremely high precision is required to allow automatic de-gating and prevent gate blockage. |

| Tab Gate | Typically manufactured using CNC machining or laser cutting. | High precision ensures easy de-gating and reduces post-molding operations. |

| Fan Gate | Preferably created using laser cutting due to its intricate design. | Extremely high precision is required to ensure an even spread of molten plastic and minimize stress concentrations. |

| Diaphragm Gate | Primarily developed using EDM or CNC machining. | High precision is essential to maintain uniform wall thickness and minimize weld lines. |

The Orchestrator of Precision with Molding Gate

Precision in manufacturing gates is pivotal for several reasons. Firstly, it ensures the correct flow and pressure of molten plastic, which is crucial for the quality and integrity of the molded part. Secondly, precision is integral in minimizing defects and irregularities in the final product, such as warping, sink marks, and weld lines.

Moreover, the precision in manufacturing gates influences the visibility and removability of gate vestiges in the final product. For products where aesthetics are crucial, high precision is indispensable to ensure that any remnants of the gate are imperceptible or can be easily removed post-molding without affecting the product’s appearance.

Lastly, precision plays a vital role in achieving uniform cooling and solidification of the molten plastic within the mold. This is crucial for maintaining the dimensional accuracy and structural integrity of the final product, especially in applications where these factors are critical.

Try Prolean Now!

Seven Key Molding Gate Design Strategies

Anatomy for injection-molding gate design

Designing gates involves technical insights, practical considerations, and a profound understanding of material flow, mold structure, and product design. These strategies are integral to optimizing the molding process, mitigating defects, and ensuring the production of high-quality parts.

Strategy 1: Optimize Gate Location

Choosing an optimal location for the gate is pivotal. It should facilitate uniform flow and minimize the distance the plastic travels within the mold. This strategy reduces pressure losses and ensures consistent filling, which is crucial for maintaining the structural integrity and dimensional accuracy of the molded part.

Strategy 2: Material Consideration for injection molding gates

Different materials have unique flow properties, viscosities, and thermal characteristics. Understanding the material’s behavior is crucial for designing gates that can accommodate these properties, ensuring smooth flow and proper filling and cooling. Material consideration is also vital in determining gate size and type, which can significantly influence the appearance and performance of the final product.

Strategy 3: Minimize Gate Size

Gate size significantly affects the flow rate of the molten plastic and the occurrence of defects like jetting. The goal is to minimize the gate size to the extent that it allows for efficient filling while preventing defects. A smaller gate also reduces stress and ensures a cleaner separation of the molded part from the gate, minimizing post-molding operations.

Strategy 4: Evaluate Flow Simulations

Conducting flow simulations is a prudent strategy to predict the flow of molten plastic within the mold. It offers insights into potential issues related to filling, cooling, and warpage, enabling designers to make informed decisions and adjustments in gate design, location, and size before manufacturing the mold.

Strategy 5: Ensure Proper Gate Geometry

The geometry of the gate should complement the part design and molding conditions. A well-designed gate should promote uniform flow, minimize shear stress, and facilitate optimal packing. For instance, a fan gate can spread the flow across a wider area, reducing stress concentrations in thin-walled parts.

Strategy 6: Mitigate Stress Concentrations

Gates should be designed to minimize stress concentrations which can lead to structural weaknesses and failures in the final product. This involves considerations like rounding gate edges and optimizing gate land length, which can help in distributing the stress more evenly across the molded part.

Strategy 7: Optimize Cooling and Ejection

Designing gates that facilitate uniform cooling is vital for reducing cycle times and maintaining dimensional stability. Similarly, gate design should allow for efficient ejection, minimizing the risk of part damage and facilitating the removal of gate vestiges, if necessary.

Injection molding gate design

What Are the Common Injection Molding Gate Defects?

Injection molding does face certain challenges, especially concerning gate defects. As the conduits for the molten plastic to enter the mold cavity, gates play a pivotal role in the process, and any defects associated with them can significantly impact the quality and integrity of the final product. Following are the key gate defects ;

- Gate Blush: Gate blush is a common defect, characterized by discoloration or streaks near the gate area. It usually occurs due to excessive shear stress and rapid cooling. This defect not only affects the aesthetics of the part but can also compromise its structural integrity.

- Jetting: Jetting is a defect where the molten plastic does not fill the mold cavity uniformly, leading to wavy patterns or lines on the finished product. This occurs when the molten plastic’s velocity is too high, causing it to collide with the mold walls and cool rapidly in a snake-like manner.

- Burn Marks: Burn marks appear as black or brown discolorations on the part, typically occurring due to trapped air or excessive heating of the plastic material. This defect can compromise the aesthetic appeal and potentially affect the structural reliability of the molded product.

- Gate Vestige: A gate vestige is the small raised area left by the gate after the molding process. While not a defect per se, an untrimmed or poorly trimmed gate vestige can affect the part’s appearance and its fit in assemblies.

- Short Shot: A short shot occurs when the molten plastic fails to fill the mold cavity completely, resulting in an incomplete part. This defect is usually attributed to inadequate injection pressure, low plastic temperature, or obstructions in the mold cavity.

- Flash: Flash is the excess plastic that leaks out of the mold cavity, forming unwanted thin layers on the part’s edges. This defect arises due to excessive injection pressure, clamping force imbalance, or wear and tear in the mold.

How to Rectify Injection Molding Gate Defects?

Table: Rectification of molding gate defects

| Defects | Rectification |

|---|---|

| Gate Blush | Optimize the gate design to reduce shear stress, adjust injection speed and pressure, optimize cooling time, and consider material properties and proper drying to mitigate occurrences. |

| Jetting | Optimize injection speed and ensure gradual acceleration of the molten plastic. Utilize suitable gate designs for laminar flow, modify mold temperature, and employ the correct material to rectify jetting. |

| Burn Marks | Ensure adequate venting to allow trapped gases to escape and reduce injection speed to minimize overheating and material degradation. Addressing these aspects can prevent the appearance of burn marks. |

| Gate Vestige | Optimize gate design and employ precise gate cutting methods. Meticulous removal of vestiges is essential to maintain the part’s appearance and functionality. |

| Short Shot | Ensure the material is at the correct temperature and the injection pressure is adequate. Clearing any blockages and optimizing gate size is crucial for a consistent flow of molten plastic and rectification of short shots. |

| Flash | Maintain the mold in optimum condition and ensure sufficient clamping force to withstand the injection pressure. Regular inspections of the mold for wear and tear are crucial to prevent the occurrence of flash. |

Conclusion

Manufacturing injection molding gates is a nuanced process, entailing a harmonious interplay between method, type, and precision. The chosen manufacturing method, whether CNC machining, EDM, or laser cutting, must align with the gate type’s inherent requirements and the specific demands of the molded product. Pursuing precision in manufacturing gates is not merely a technical requisite but a commitment to quality, functionality, and aesthetic excellence. The meticulous attention to injection molding gate details and unwavering adherence to precision transform the theoretical concepts of gate design into tangible realities, shaping the form, structure, and essence of the molded products.

Since the Injection molding gate influences the flow of molten plastic, it affects the final product’s appearance, structural integrity, and performance. At ProleanTech, we produce high-quality molded components by optimizing the design within this process. We consider gate location and design to achieve consistent, high-quality outcomes in injection molding service.

Read More: Why is CNC Machining Better than Injection Molding for Thermoplastic Prototyping?

FAQs

What is the primary function of an injection molding gate?

The primary function of an injection molding gate is to act as the entry point for the molten plastic to flow into the mold cavity, influencing the flow rate, pressure, and cooling of the plastic.

How does gate design impact the final product in injection molding?

Gate design significantly impacts the final product’s appearance, structural integrity, and functionality by affecting the flow, cooling, and pressure of the molten plastic within the mold.

How can gate defects like gate blush and gate vestige be mitigated?

Gate defects can be mitigated by adjusting the gate location, modifying gate size, refining material selection, and optimizing processing parameters.

Can the gate type and design be chosen based on the aesthetic requirement of the product?

The selection of gate type and its design are often influenced by aesthetic considerations, especially for products where appearance is a critical factor.

Are injection molding gate defects always preventable?

While meticulous gate design and proper material selection can significantly reduce the likelihood of gate defects, some minor defects may still occur, requiring post-molding corrections.

Excellent post but I was wondering if you could write a litte more on this topic?

I’d be very thankful if you could elaborate a little bit further.

Many thanks!

Sure ! We will cover further topics in our upcoming articles.