Both CNC machining and EDM are important manufacturing processes. They are used on various materials, from metals to plastics.

CNC machining entails computerized control of machining tools and workpieces. Common machinery that uses this technology includes lathes, drills, and mills. EDM is an advanced machining method that works excellently where consistent machining is required for complex geometry, sharp corners, and deep molded areas.

Different from the CNC machining process, EDM machining cuts materials through electrical discharges, meaning that no material distortion happens during the process.

As manufacturing becomes more complex and demanding, the choice of machining method becomes even more critical. That’s why it is paramount to differentiate EDM vs CNC machining and work with a reputable manufacturer like Prolean Tech.

This article takes a brief exploratory journey to highlight the relationship between EDM and CNC.

EDM Insights for Your Business

Schematic Setup of EDM

Electrical Discharge Machining (EDM) is a special machining technique based on the erosion power of electrical discharges. The setup for this method comprises two electrodes inside an electrolyte, as the setup above shows.

In this method, the workpiece is the anode. It is connected to the tool electrode which is the cathode terminal.

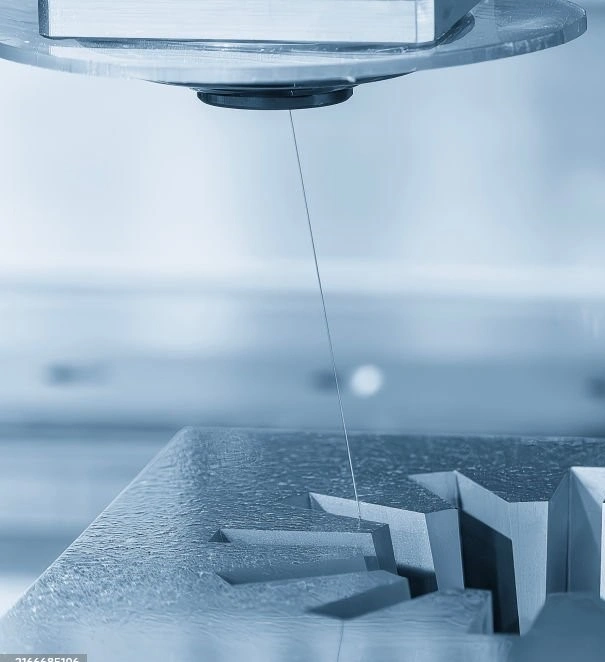

Wire EDM Machine in Operation

There is a spark gap between the workpiece and the tool. When an electric current is applied between the two, a spark forms. The spark is essentially powerful electrothermal heat. This heat is so high that some parts of the workpiece melt and erode – the spark erosion process.

Try Prolean Now!

Advantages of EDM to Consider

EDM machine manufacturers have repeatedly identified the following advantages of the EDM manufacturing process:

How Accurate is EDM Machining? Very Accurate.

EDM technology is ideal for precision machining where tight EDM machining tolerances are critical. One of the biggest advantages is that the workpiece is unlikely to deform. The tool and the workpiece do not come into contact.

While the cutting speed needs to be slow, several passes can produce EDM machining tolerances within +/- 0.0002 inches.

Can Cut Inside Sharp Corners

The EDM process, particularly the wire EDM variety, is excellent at cutting sharp corners in workpieces. You only need to choose the right wire type and other machining conditions.

Such corners are difficult to reach with a CNC process manufacturer and other conventional machining methods. Usually, the tools are round – they can only create rounded corners.

One may argue that the wire in the EDM method is also round. However, this roundness is so fine that it is usually unrecognizable. This method easily creates sharp corners internally with radiuses of 0.005 inches.

Ideal for Deep Shapes

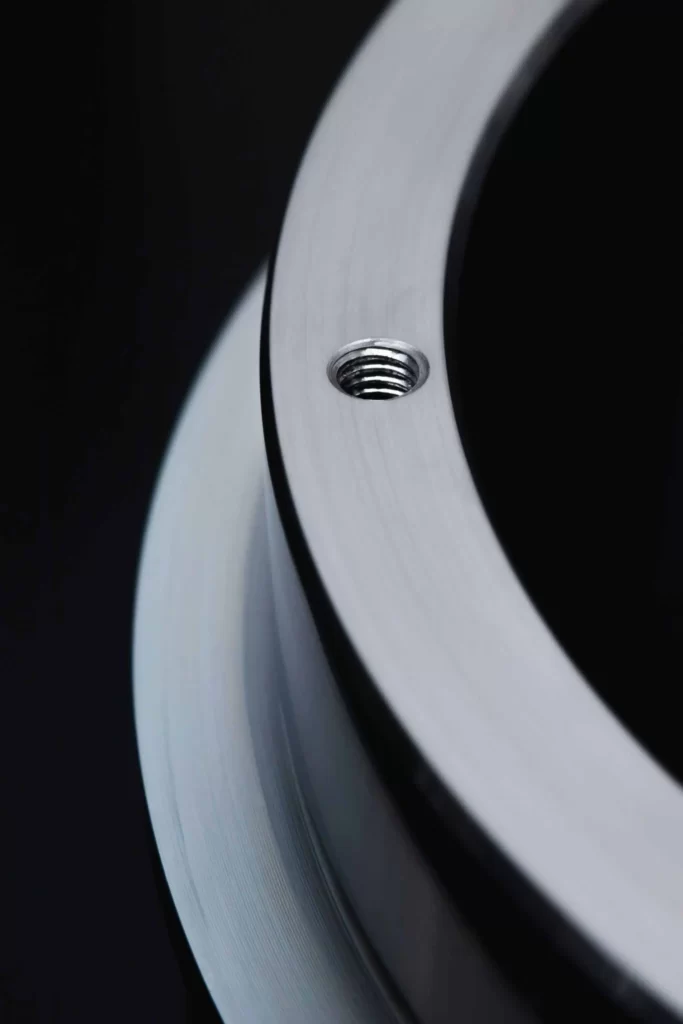

A deep threaded hole in a component

Some parts require deep cavities and cuts that conventional machining processes struggle to produce. For instance, CNC with its relatively long tools can cause dangerous chattering. Machining quality can be reduced.

One of the best solutions for machining deep shapes is EDM technology. There is no tool-chattering problem to worry about. The technique is so good in such situations that it can effortlessly handle a diameter-to-length ratio of 1:20. There are cases where ratios of about five times this one are achievable.

Requires Minimal Manual Intervention

EDM can be a good option in environments where manual attention to machining processes is limited. Its potential for errors is minimal.

You can easily automate the EDM technique for quality results with minimal manual involvement. Once you have fed the parameters and set the machine in motion, you can leave the machining operation for hours.

Some Disadvantages of EDM for a Business

Slow Machining Speed

EDM and milling technologies differ here because EDM is slower. Depending on the material you are machining, EDM can be as slow as 0.02 square inches per minute. CNC machines can operate at machining speeds as high as 50 inches per minute.

Material Limitation

Since this process is based on the formation of electrical discharges that erode the material away, material conductivity is a major requirement. EDM cannot machine nonconductive materials.

This means the EDM manufacturing process is unsuitable for wood, plastic, composites, and other non-conductive materials.

Wooden handrails and guardrails

Machining wood and other non-conductive materials is impossible with EDM

Is EDM More Expensive than CNC?

The EDM method can be prohibitively expensive for some projects for several factors. First, excessive power consumption for the electrical discharge is a major cost.

Tool wear is more pronounced in EDM than in conventional CNC manufacturing processes. Consider also the lengthy machining procedure. All these factors result in a high cost of machining.

Understanding CNC Suitability for Business

CNC turning on a CNC machine

Alt text: A metallic rod with varying cross-sections held by a CNC machine being machined to reduce the diameter

Computer Numerical Control (CNC) is a manufacturing method characterized by the automation of lathes, drills, and related machines. It is a relatively old technology that has advanced and suited many manufacturers. The machine operates according to codes typically fed via a control panel.

This capability comes from a microcomputer embedded within the CNC machine.

Some of the most prominent operations of a CNC machine are turning, drilling, milling, and cutting.

A CNC milling machine in action

Advantages of the CNC Manufacturing Process

Similar to EDM, the CNC method has its advantages and disadvantages. Here are the most notable ones:

Speed of Production:

If you are producing basic designs and need to compare EDM vs. CNC, CNC machining is faster than EDM.

This is a big advantage for large production runs. Even with some level of manual operation, automation, and controlled machining speeds by the CNC process manufacturer help achieve decent production speeds.

Repeatability:

Are you looking to produce numerous identical parts? CNC machining suits that role perfectly. The quality of the machined parts is usually very consistent. The programming element ensures that you can use the same machining parameters frequently.

Identical metal parts

Versatility:

The CNC method is more flexible than EDM vs CNC. It can work with various materials, from metals to nonmetals. That means the machinist doesn’t need to keep changing the machine setup to machine a different material.

Material compatibility aside, the CNC technique accommodates different part sizes, forms, and intricacies. With this capability, the CNC machine offers efficient production of parts.

Would you like to learn more about how CNC machining can enhance the precision and performance of custom motorcycle parts or any other part? Our team can help you take advantage of this versatility.

Is CNC Cutting Expensive?

Most machining methods involve consumables – you will need to replace some parts. For CNC machines, such parts include cutting tools. However, the replacement of tools is not as regular as in some alternative methods such as EDM. For the EDM technique, replacing electrodes and wires is a more frequent requirement.

Cutting tool, a consumable for CNC

Try Prolean Now!

Disadvantages of CNC Machining

Unsuitable for Specialised Materials

Challenges exist when you are CNC machining specialized materials. Some materials are advanced and require different machining techniques for good results. Examples are diamond, titanium, ceramics, tungsten carbide, and sapphire.

Decorative Blue Diamond

Some materials must be heat-treated before being machined. With CNC machining, such pretreatment may not work well. If you insist on using the CNC process for the materials, the process may become too expensive due to longer production time.

Comparison of EDM and CNC: What Point Matters for You?

Here are the main differences between EDM vs CNC machining methods. You may use them to choose the ideal process for your job.

| Element | EDM | CNC Machining |

| Process precision | If you are looking for extremely intricately machined parts, EDM is suitable. | Conventional CNC machining offers impressive precision, although not to the level of EDM. |

| Production speed | EDM is a slower metal removal process compared to CNC machining. | Typically faster than EDM |

| Surface finish | Excellent because the process eliminates workpiece distortion and the erosion is to the minutest detail. | Good but usually not to the level offered by EDM. Tool marks and roughness may prompt further processing to achieve the desired surface finish. |

| Production volume | Limited to low production volumes. | Ideal for higher production volumes. |

| Part complexity | Excellent method for producing complex parts that would otherwise be impossible with other machining methods. | May not match the part complexity offered by EDM. Producing such parts using this technology can be extremely lengthy and expensive. |

| Investment | Higher investment cost due to more specialization and complexity of equipment. | More cost-effective, especially if it is not a top-of-the-range model. |

| Applicable materials | Only suitable for electrically conductive materials. | Has a wider range of applicable materials. |

Which One, EDM vs CNC, Is Right for You?

Choosing the EDM or CNC method requires a thorough analysis of several factors. This is crucial because, as we have noted above, both materials have their benefits and drawbacks.

EDM is renowned for its suitability to produce accurate parts. Industries that demand part accuracy would prefer this machining method.

The use of electrical discharges to machine materials is highly effective and predictable. The workpiece and tool don’t come into contact, so the chances of imperfections caused by distortions during the cutting process are unheard of.

No Contact between Tool and Workpiece in EDM

Higher production speed and material versatility are some positives of CNC machining. It works perfectly for substantial production as long as the components are not so complex. However, challenges may arise when tough workpieces are involved.

Try Prolean Now!

In Conclusion

Have you been looking for the most professional and reliable machining services? Your search for EDM vs CNC machining ends at Prolean Tech Services. The company has a broad range of relevant services that can take your business to the next level.

Talk to our team today and get a quote forms!

FAQs

What are the types of EDM?

There are three categories of EDM namely sinker discharge machining, wire cut EDM, and hole drilling EDM.

What makes EDM different?

The technique is different because it erodes the surface by high-voltage electrical discharges delivered in rapid pulses.

0 Comments