CAPABILITIES PROLEAN

Die Casting Service

All uploads are secure and confidential.

Prolean’s Die Casting Service

Aluminum Die Casting

Aluminum die casting enables high-volume production with excellent dimensional stability and without the formation of microcracks.

Zinc Die Casting

What is Die Casting?

Die casting is a forming process in which molten metal or metal alloys are injected into a permanent steel mold (die) at high pressures, typically ranging from 150 to 1200 bar, and at high injection speeds that can reach 40 to 100 m/s. The mold is made of high-strength steel and is designed according to the specific requirements of each part. After solidification, the part is released from the die, and the process is repeated to achieve large-scale production of consistent, high-quality components.

We have many years of experience in the die-casting field and have served dozens of business and individual clients.

Try Prolean Now!

How to Order Parts?

Get a free quote from a real engineer; once we receive your design, our engineer will review it and send you a quote as fast as one hour.

Get A Quote Immediately

Upload your design or email our engineer directly and get your quotes as fast as one hour.

Start Production

Your parts will be made once your orders are confirmed. Besides, you will get real-time order updates of the production status from our order tracking system.

Receive Your Part

After all parts pass QC inspection, they will be well packed from transportation accidents. Then, your custom parts are delivered straight to your doorstep.

Excellent service-With Proven Results

Besides the production, we provide all Die-casting related consultations from our experienced engineers who have been working in the field for more than 8 years.

Leading experience & Equipment

We have clients from a range of Industries, Automotive, Medical, Aerospace, Agriculture, Renewable energy, Defense, and many more. So, we are experienced in working with all industries and use computerized control for the casting process.

Testing & Supervision

We strongly believe in R & D. We test the material for various Physical, Mechanical, and Chemical properties to optimize the Quality. Then, before proceeding with the process, our designers simulate the product in computer software to ensure the Quality of the product and components you need.

Competitive Pricing

Our Pricing is very affordable. It is lower than what you find in the US, Europe, , and other based manufacturers. So, Get the Quotation from us within 24 Hours.

Materials Options For Die Casting

| Aluminum Alloys | Magnesium Alloys | Zin Alloys | Other Die Casting Alloys | Plastics |

| 380 | AZ91D | Zamak 3 | Silicon Tombac | N/A |

| 390 | AM60 | Zamak 2 | Copper | N/A |

| 413 | AS41B | Zamak 5 | lead | N/A |

| 443 | AE42 | Tin Alloy | N/A | |

| 518 | Zinc-Aluminum alloys | N/A |

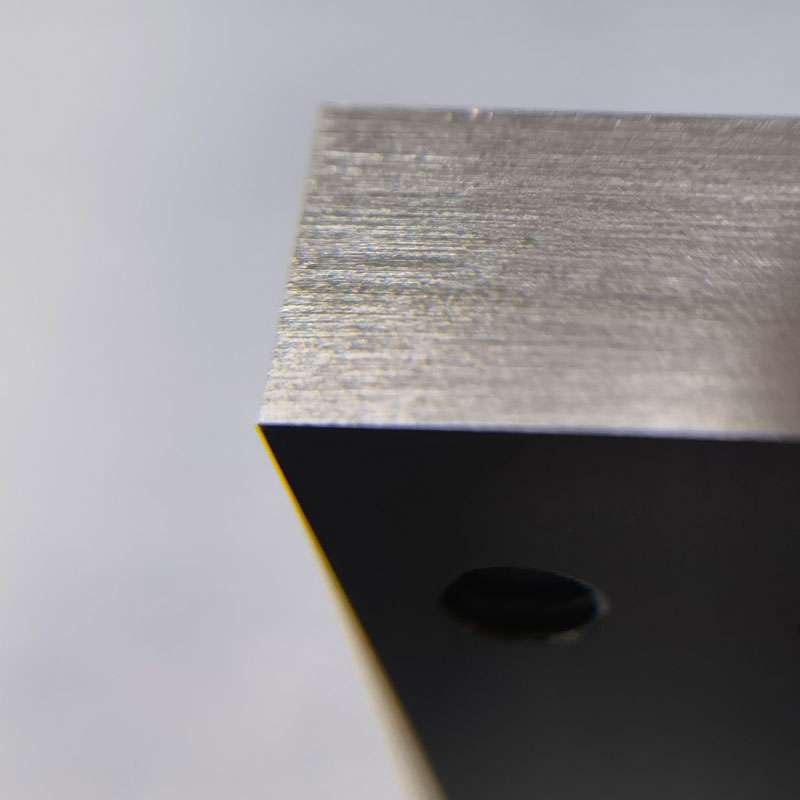

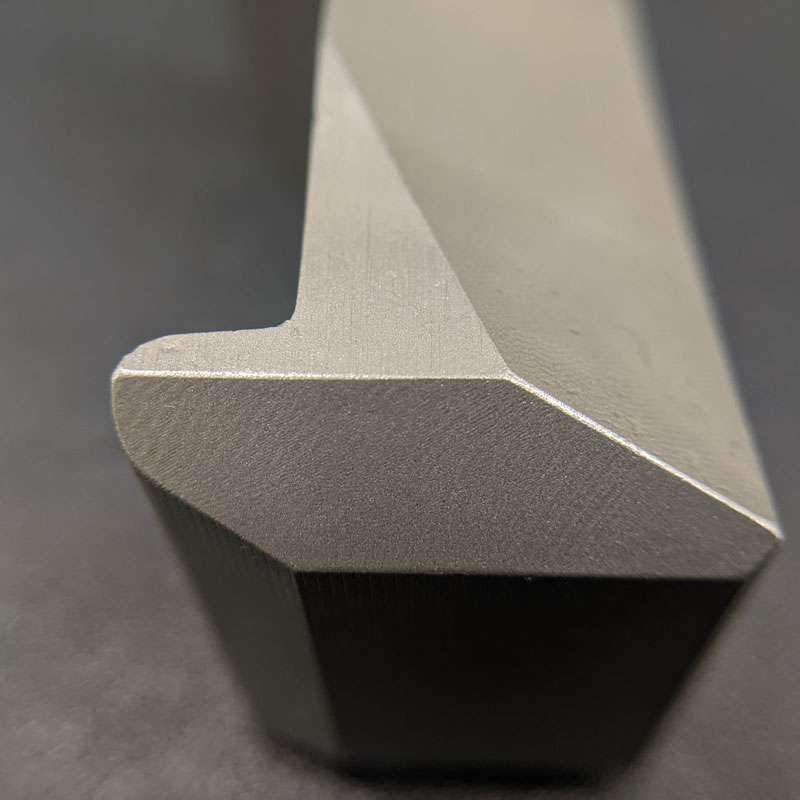

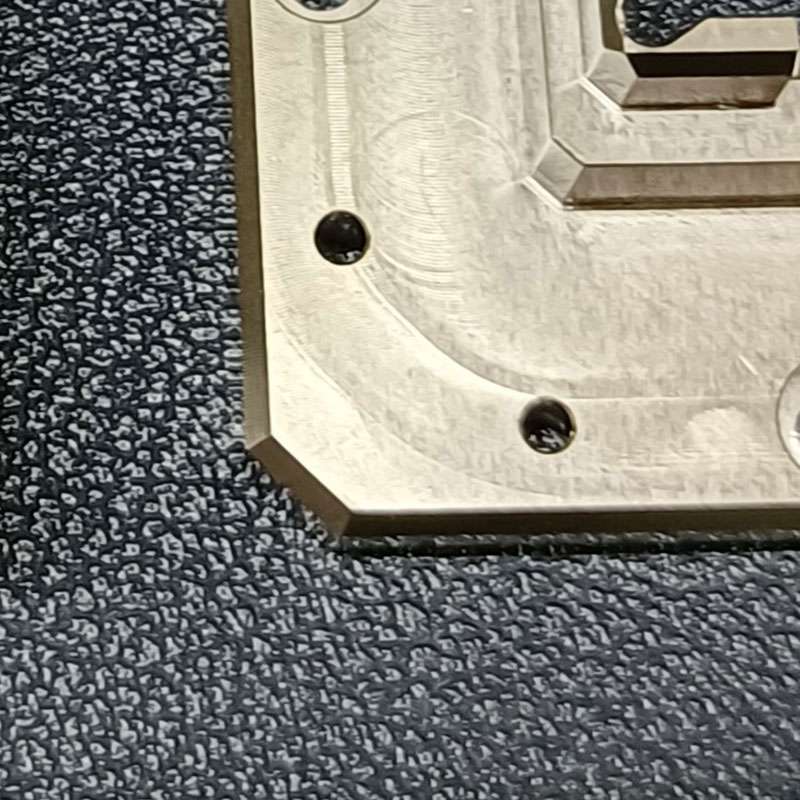

Post-Processing for High-Accuracy Die Castings

We provide CNC post-machining to achieve tighter tolerances and create features that die casting alone cannot produce, such as undercuts, small holes, threads, and precision mating surfaces. This ensures each part meets higher dimensional and functional requirements.

-

CNC milling for critical and reference surfaces

-

Drilling, tapping, and boring operations

-

Secondary machining to remove flash, gates, and excess material

-

Precision surface machining, including O-ring grooves and sealing surfaces

-

Dimensional refinement of shafts, holes, and mating features

-

Complex geometry machining for features not achievable in die casting

-

Multi-axis machining capabilities, including 3-axis, 4-axis, and 5-axis processing

Try Prolean Now!

Finishing Options For Die Casting Products

At Prolean, we understand that the right surface finish is essential to the performance and appearance of a machined part. Every project has its own requirements, and we offer a complete range of surface-treatment solutions to meet them. With dozens of finishing capabilities—from protective coatings to aesthetic enhancements—our team ensures that each component not only functions well but also meets your desired visual and durability standards. Explore our available finishing options to find the solution that best fits your application.

As the machined or deburring

The machined or deburring finish is the standard finish where unwanted attach chips are removed with deburring tools, and sharp edges are chamfered to smooth the surface (3.2 μm).

Bead Blasted

Bead blasting produces a matte texture, removing all the marks of machining tools. It applies to ABS, Aluminum, Brass, Stainless Steel, and Steel parts.

Anodizing

Anodizing involves adding an aluminum oxide coating to aluminum and its alloys. The layers, which come in various colors, increase strength and shield the surface from corrosion.

Powder coating

Powder coating is the electrostatically applying of dry powder to the surface. It produces a thin layer providing excellent resistance to wear, corrosion, and abrasion.

Electro-less Nickel Plating

A thin layer of Nickel is created on the surface from a nickel-containing solution without electrolysis. Electro-less nickel plating provides a shiny appearance, excellent hardness, abrasive, wear, and corrosion-resistance to the substrate material.

Alodine

Provides excellent corrosion resistance property to the aluminum parts with greenish-gold color. It is the low-cost and quick surface finishing approach.

Electroplating

Electroplating increases the hardness of the steel &aluminum parts. It offers excellent corrosion, wears, and abrasion resistance.

Nickel plating

Make the parts super resistive to corrosion. It enhances mechanical strength, hardness, wear resistance, lubricity, and ductility. Nickel plating is applicable in different materials, including Steel, aluminum, copper, and brass.

Passivation

Enhance the appearance and functionality of the parts. After Passivation, parts of Steel and its alloys become super resistive from corrosion.

Yellow Chromate conversion coating

A shiny appearance with goldish color provides excellent corrosion resistance. It is applied on the surface of aluminum, magnesium, and their alloys. A layer of chromate also enhances the conductivity of parts

PTFE (Teflon) Coating

The Teflon layer on the parts offers excellent corrosion resistance, water resistance, and non-stickiness with a non-reactive surface.

Black-Oxide

Black oxide finish reduces surface reflectivity and offers mild corrosion protection. It involves adding a thin layer of magnetite to the surface.

Die Cating Applications

Automotive

Die casting is widely used in the automotive industry for producing lightweight, durable parts such as engine housings, transmission cases, and structural brackets.

Industrial & Machinery

Die casting is ideal for producing durable, high-precision components used in industrial automation equipment. Typical parts include cylindrical housings, connectors, couplings, brackets, and actuator components, providing excellent dimensional stability and strength for long-term operational reliability.

Motors & Power Systems

Die casting is commonly used to manufacture robust motor housings, end covers, and heat-dissipation components. These parts offer excellent dimensional stability, strength, and thermal performance, making them ideal for electric motors, servo systems, and power-drive assemblies.

Lighting & LED Housings

Die casting is widely used in lighting applications to produce robust and thermally efficient housings. Aluminum die-cast heat-sink shells provide excellent heat dissipation, structural strength, and long-term durability, making them ideal for LED lamps, outdoor lighting fixtures, and high-power illumination systems.

Aerospace (Non-Critical Components)

Die casting is used in the aerospace industry to produce lightweight, durable non-critical components such as housings, brackets, covers, and structural supports. These parts offer excellent strength-to-weight performance and dimensional stability, making them suitable for auxiliary systems and interior assemblies.

Try Prolean Now!

See why customers dig us

I am very happy that I chose ProleanTech for my prototyping project. Everything from pattern-making to surface finishing was seamless due to frequent updates and close communications.

-Lisa Anderson, Materials Scientist

We are consistently collaborating with Prolean for the production of some home decor items. I do not hesitate to say that we are getting reliable and quality zinc die-casting services.

-David Wilson, Senior Project Manager at CustomToolWorks

The aluminum die-casting service at Prolean Technology has been helpful for our business. Their engineers and operation team always think out of the box to deliver the highest standard.

-Rachel Martinez, ProtoFab Industries

Awesome aluminum die-casting company. They take every minor detail seriously and provide comprehensive solutions from die manufacturing to surface finishing. I definitely recommend Proleantech for your die-casting parts!

-James Brown

Our wind turbine impellers work as we needed and also exceed the designed electrical efficiency by an extra 0.19%. Thank you prolean for every support you provide throughout the last six months.

-Natalie Reed, Injection Molding Engineer

I has been great expenice working with ProleanTech as out Die manufacturer for Aluminum casting dies. They know what designer had in mind and produce the accuraate dies.

-Kevin Mitchell, Surface Finishing Manager at PrecisionCoat Solutions

Latest Blog

ABS Plastic: Know the Properties, Processing, and Uses

ABS plastic is strong, durable, and widely versatile.

4340 Alloy Steel Machined Parts: Applications & Properties

High-strength 4340 alloy steel machined parts

Top 10 Laser Cutting Materials Compatibility & Thickness Limits

Laser cutting handles metals, plastics, wood, and leather

Get Your Parts Made Today