Sheet metal splitting is a crucial manufacturing process that involves cutting sheet metal without removing any material. It offers numerous benefits, including cost-effectiveness, speedy production, and the ability to create intricate designs. However, as with any manufacturing process, it’s susceptible to various defects affecting the final product’s quality. Understanding these defects is the first step to implementing effective solutions and ensuring optimal manufacturing outcomes.

This article will describe the common defects in the sheet metal splitting process, including their root causes and innovative solutions to overcome these challenges.

Common Machining Defects in the Splitting Process

The splitting process is a vital part of sheet metal manufacturing, but it can also cause several common machining defects that impact the final product’s quality. Understanding these defects is essential for effective troubleshooting and prevention.

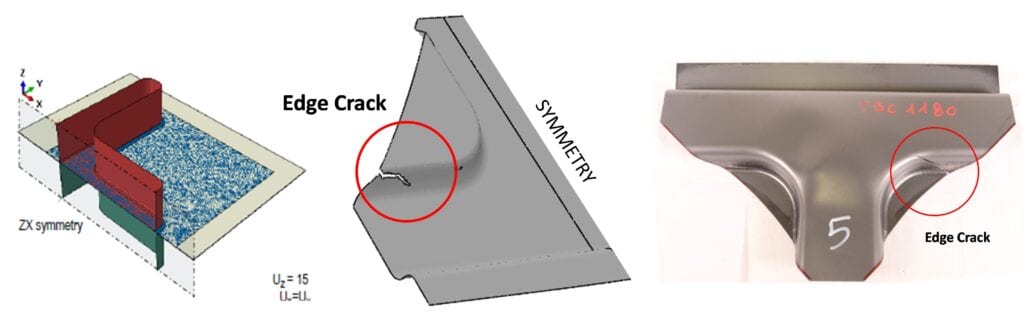

1. Edge Cracks

Edge cracks are unintended fractures on the sheet metal’s edges during the splitting process. These fractures significantly compromise the product’s structural integrity and visual appeal.

- Impact: These defects can lead to failure under load or an undesired aesthetic finish.

- Prevention: Regular tool maintenance and using the right tools can minimize the risk of edge cracks.

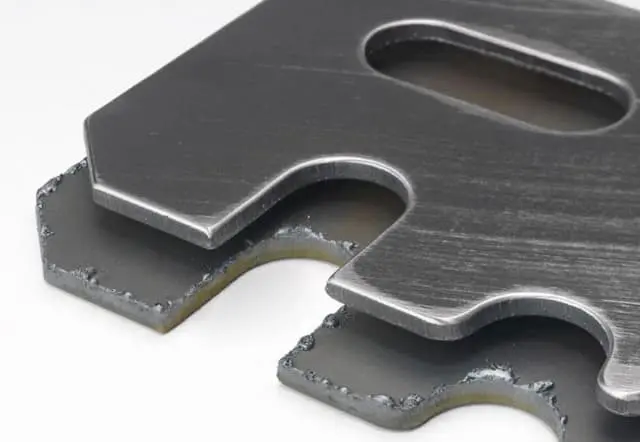

2. Burrs

Burrs are small protrusions or rough edges on the sheet metal post-splitting process. They affect the aesthetic appeal of the product and pose a safety hazard due to their sharp edges.

- Impact: Apart from being aesthetically displeasing, burrs can also cause fitment issues and safety risks.

- Prevention: Using precise splitting techniques and post-splitting treatments like deburring can help.

3. Dimensional Inaccuracies

Dimensional inaccuracies refer to instances where the final product does not align with the original design specifications. This could lead to products not fitting into place or functioning as intended.

- Impact: This defect can compromise the final assembly and function of the product.

- Prevention: Rigorous quality checks and accurate measuring tools can reduce dimensional inaccuracies.

4. Surface Imperfections

Surface imperfections like scratches, pits, and dents can occur during the splitting process. These imperfections can detract from the final product’s aesthetic appeal and, in severe cases, impact its functionality.

- Impact: These affect both the visual quality and, potentially, the functional aspects of the product.

- Prevention: Gentle handling of materials and careful operational practices can minimize surface imperfections.

Root Causes of These Defects

Understanding the root causes of these defects is an essential step in their prevention and mitigation. Several factors contribute to forming these defects during the sheet metal splitting process.

Inappropriate Tool Selection

Tools that aren’t suitable for the splitting process, either because they’re not designed for it or because they’re worn or damaged, can cause multiple issues like burrs and edge cracks.

Inadequate Machine Calibration

Machines that aren’t calibrated correctly may exert too much or too little force during the splitting process, leading to issues like dimensional inaccuracies and surface imperfections.

Unregulated Pressure

Too high pressure can lead to cracks, while too low may not split the sheet metal accurately, leading to dimensional inaccuracies.

Improper Material Handling

Rough or improper handling of sheet metal before and during the splitting process can lead to surface imperfections like scratches and dents.

Inadequate Material Preparation

Materials that aren’t prepared correctly, like those that aren’t adequately cleaned or those with uneven surfaces, can contribute to several defects during the splitting process.

Table: Root Causes of Defects in Sheet Metal Splitting Process

| Defect | Root Cause |

|---|---|

| Edge Cracks | Inappropriate Tool Selection |

| Burrs | Inadequate Machine Calibration |

| Dimensional Inaccuracies | Unregulated Pressure |

| Surface Imperfections | Improper Material Handling and Inadequate Preparation |

The key to managing these defects effectively lies in understanding their root causes and putting in place preventive measures, such as using the right tools, ensuring the proper machine

Try Prolean Now!

Mitigating Measures for Splitting Defects

Several preventative measures can help avoid common defects associated with the splitting process in sheet metal manufacturing. Let’s explore a few critical ones.

| Mitigating Measures | Purpose | Defects Addressed |

|---|---|---|

| Use of Appropriate and Well-Maintained Tools | Reduce defects such as edge cracks and burrs | Edge Cracks, Burrs |

| Machine Calibration | Maintain accuracy of the splitting process and mitigate dimensional inaccuracies and surface imperfections | Dimensional Inaccuracies, Surface Imperfections |

| Correct Pressure Regulation | Minimize edge cracks and dimensional inaccuracies by avoiding too high or too low pressure | Edge Cracks, Dimensional Inaccuracies |

| Proper Material Handling | Reduce surface imperfections | Surface Imperfections |

| Thorough Material Preparation | Prevent several splitting defects | All Defects |

The Role of Inspections in the Splitting Process

Regular inspections are essential in the splitting process. They help identify and rectify defects early, ensuring high-quality end products.

| Inspection Type | Purpose | When It Occurs |

|---|---|---|

| Pre-process Inspections | Check for pre-existing issues and prepare materials before the splitting process | Before the splitting process begins |

| In-process Inspections | Monitor the splitting process and quickly identify any arising issues for immediate mitigation | During the splitting process |

| Post-process Inspections | Verify the quality of the final product and identify any defects for future process improvements and quality control | After the splitting process is complete |

| Routine Equipment Inspections | Regularly maintain equipment in optimal condition, reducing the likelihood of defects due to equipment malfunction | Regularly |

By integrating defect mitigation measures and regular inspections into the splitting process, manufacturers can significantly improve the quality and efficiency of their operations, resulting in higher-quality end products.

Summing Up

In conclusion, common defects in the sheet metal splitting process can significantly impact the quality of the final products and the efficiency of the manufacturing process. However, with a deep understanding of these defects and their root causes, manufacturers can adopt several mitigation strategies and establish regular inspections to identify and rectify issues early. The combination of these strategies ensures the production of high-quality end products, efficient processes, and high customer satisfaction levels.

At Prolean, we take pride in our comprehensive sheet metal manufacturing services. With our state-of-the-art technology, skilled workforce, and a relentless focus on quality, we strive to minimize defects and deliver superior manufacturing outcomes. Our sheet metal splitting services uphold these high standards, ensuring consistent, high-quality results for our clients.

FAQ’s

1. What are the common defects in the sheet metal splitting process?

Common defects in the splitting process include edge cracks, burrs, dimensional inaccuracies, and surface imperfections, among others.

2. What are some root causes of these defects?

The root causes of these defects can range from improper tool usage and machine calibration to incorrect pressure regulation and improper material handling.

3. How can these defects be mitigated?

Mitigation measures include the use of appropriate and well-maintained tools, regular machine calibration, correct pressure regulation, proper material handling, and thorough material preparation.

4. What is the role of inspections in the splitting process?

Inspections play a critical role in identifying and rectifying defects early in the splitting process. They include pre-process, in-process, post-process, and routine equipment inspections.

5. How do regular inspections improve the quality of the end products?

Regular inspections help identify issues at different stages of the splitting process, allowing for early rectification and minimizing the impact of defects. This ensures the production of high-quality end products.

6. Can defects completely be eliminated in the splitting process?

While it might be challenging to completely eliminate defects, their occurrence can be significantly reduced with the right mitigation measures and regular inspections.

0 Comments