CAPABILITIES

Aluminum die casting Service

All uploads are secure and confidential.

Properties of Aluminum alloys Components

The most frequently used aluminum alloys for die casting are A380, 383, B390, A413, A360, and CC401; however, the Selection of the right one depends on the end-use application of the products. For example, A360 has excellent corrosion resistance, pressure tightness, and fluidity during the injection. B390 is ideal for casting automotive engine blocks due to its wear resistance, hardness, and lower ductility properties, The A380 is the ideal jack-of-all, with large properties that allow it to be used for a wide range of products.

- The 7000 series Aluminum alloys have tensile strengths of up to 700 MPa, making them stronger than steel and more than copper and steel in terms of strength-to-weight ratio.

- Aluminum die-casting components withstand static and dynamic loads due to their high elasticity properties.

- Its strength increases as the temperature drops, allowing it to withstand icy conditions.

- Aluminum alloys have high reflectivity, reflecting more than 80% of visible light.

Aluminum alloy components are Non-magnetic, electrical conductors, and non-toxic.

Try Prolean Now!

How to Order Parts?

Get a free quote from a real engineer; once we receive your design, our engineer will review it and send you a quote as fast as one hour.

Get A Quote Immediately

Upload your design or email our engineer directly and get your quotes as fast as one hour.

Start Production

Your parts will be made once your orders are confirmed. Besides, you will get real-time order updates of the production status from our order tracking system.

Receive Your Part

After all parts pass QC inspection, they will be well packed from transportation accidents. Then, your custom parts are delivered straight to your doorstep.

Energy industry

Aluminum die-casting is used extensively in the energy industry to produce power generation equipment, solar panel enclosures and bases, distribution components, and many more.

Automotive

Engine block made from die-casting

Vehicle parts include structural and functional components such as chassis, undercarriage, counter mounts, liner plugs, hoods, and other items.

Aircraft

Aircraft components must-have characteristics such as lightweight, high durability, high strength-to-weight ratio, and the capacity to endure extreme conditions. Aircraft structure, wings, skins, and cowls are all made from Aluminum die casting.

Agriculture

Tractors, equipment covers, pesticide tanks, and other agricultural Equipment are made from Aluminum die casting.

Military

Various components of artillery such as armor plates, trigger guards, Remington receivers, ships, and others

Industrial

Bearings, connecting rods, and pistons are examples of industrial Equipment.

Medical

Everything from beds to surgical instruments to diagnostic and treatment Equipment contains aluminum components.

What Materials Are Available For Die Casting?

| Aluminum Alloys | Magnesium Alloys | Zin | Other Die Casting Alloys | Plastics |

| 380 | AZ91D | Zamak 3 | Silicon Tombac | ABS |

| 390 | AM60 | Zamak 2 | Copper | PP |

| 413 | AS41B | Zamak 5 | lead | POM-M, POM-C |

| 443 | AE42 | Tin Alloy | PC | |

| 518 | Zinc-Aluminum alloys | PEEK |

Finishing Options For Die Casting Products

At Prolean, we understand that achieving the perfect finish on a machined part can make all the difference. Every project presents unique demands; perhaps a glossy sheen, a tactile texture, or even a resilient protective layer. With a commitment to craftsmanship, our team ensures that the resulting piece isn’t just functional, but also aesthetically in line with your aspirations. Delve further to discover the array of specialized finishing options we proudly present, curated to elevate the resilience, allure, and performance of each machined component.

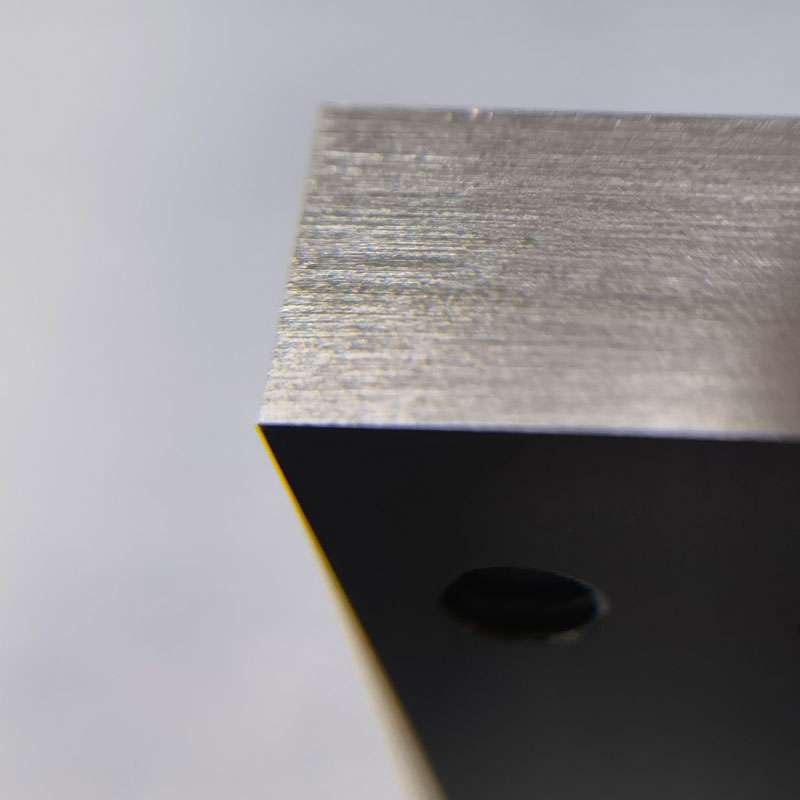

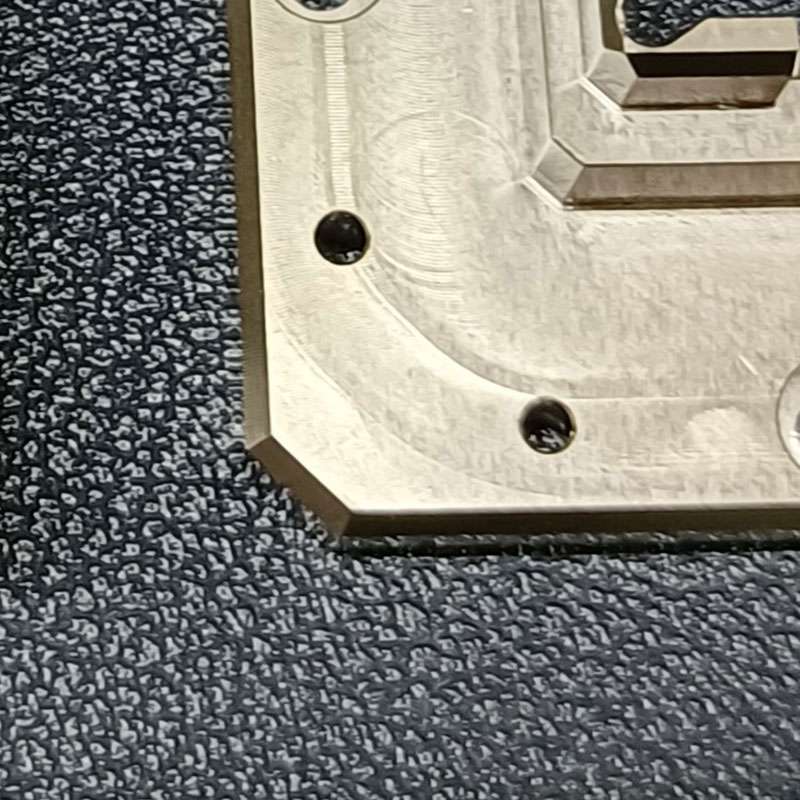

As the machined or deburring

The machined or deburring finish is the standard finish where unwanted attach chips are removed with deburring tools, and sharp edges are chamfered to smooth the surface (3.2 μm).

Bead Blasted

Bead blasting produces a matte texture, removing all the marks of machining tools. It applies to ABS, Aluminum, Brass, Stainless Steel, and Steel parts.

Anodizing

Anodizing involves adding an aluminum oxide coating to aluminum and its alloys. The layers, which come in various colors, increase strength and shield the surface from corrosion.

Powder coating

Powder coating is the electrostatically applying of dry powder to the surface. It produces a thin layer providing excellent resistance to wear, corrosion, and abrasion.

Polishing

Physical rubbing of a metal surface to create a shiny surface is called a polishing surface finish. It increases the reflectivity and does not affect the dimensional stability of parts.

Brushing

Brushing is achieved by applying an abrasive brush to the metal surface, which produces a unidirectional satin finish. And it is not recommended for highly corrosive materials.

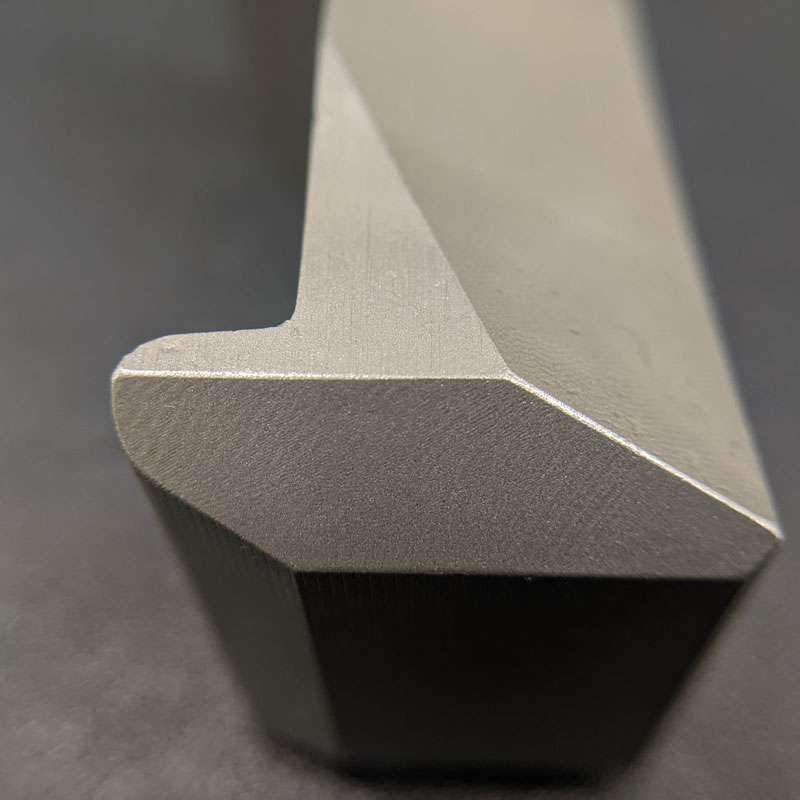

Smooth machining

Smooth machining is done by controlling the machining process, such as feed rate & cutting speed. It minimizes the tool marks and risk of corrosion.

Black-Oxide

Black oxide finish reduces surface reflectivity and offers mild corrosion protection. It involves adding a thin layer of magnetite to the surface.

Electro-less Nickel Plating

A thin layer of Nickel is created on the surface from a nickel-containing solution without electrolysis. Electro-less nickel plating provides a shiny appearance, excellent hardness, abrasive, wear, and corrosion-resistance to the substrate material.

Alodine

Provides excellent corrosion resistance property to the aluminum parts with greenish-gold color. It is the low-cost and quick surface finishing approach.

Electroplating

Electroplating increases the hardness of the steel &aluminum parts. It offers excellent corrosion, wears, and abrasion resistance.

Nickel plating

Make the parts super resistive to corrosion. It enhances mechanical strength, hardness, wear resistance, lubricity, and ductility. Nickel plating is applicable in different materials, including Steel, aluminum, copper, and brass.

Passivation

Enhance the appearance and functionality of the parts. After Passivation, parts of Steel and its alloys become super resistive from corrosion.

Yellow Chromate conversion coating

A shiny appearance with goldish color provides excellent corrosion resistance. It is applied on the surface of aluminum, magnesium, and their alloys. A layer of chromate also enhances the conductivity of parts

PTFE (Teflon) Coating

The Teflon layer on the parts offers excellent corrosion resistance, water resistance, and non-stickiness with a non-reactive surface.

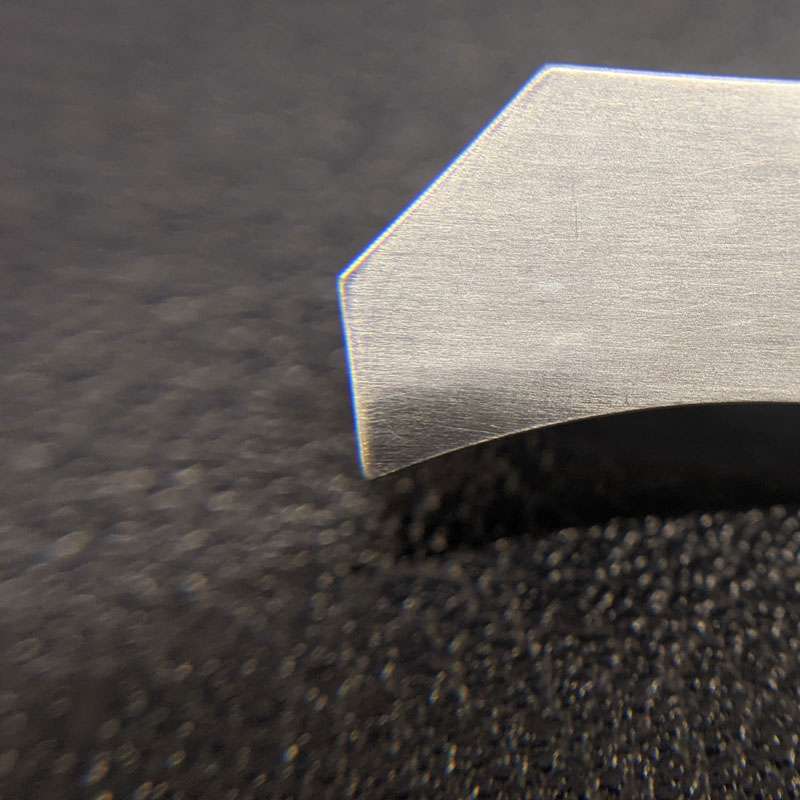

Fine machining

The higher-precision machines produce delicate machining surfaces by utilizing sharper tools and regulating feed rate and cutting speed. Surface roughness up to Ra 0.8 μm can be maintained with smooth machining.

Laser Cladding

Provides excellent corrosion, wear, and abrasion resistance. Laser Cladding is also effective for treating minor surface imperfections such as cavities, tiny cracks, and rust damage.

Sanding

Provides a random, non-linear texture with a shiny, high gloss finish. However, it might be unable to create sharp corners and pockets

More

Provides a random, non-linear texture with a shiny, high gloss finish. However, it might be unable to create sharp corners and pockets

3 Ways to Ensure Perfection

Standards

GENERAL TOLERANCE

For metals, the standard is ISO-2768 fH (fine)

For plastics, the standard is ISO-2768 mK (medium)

Metric threads tolerances:ISO 965-1 standard UN Threads Tolerances: ASME B1.1-2003 standard

knurling: ISO13444:2012 standard Our factory is ISO 9001:2015 certificated

Visual inspection and Protection

Constant visual inspection conditions

Quantification of cosmetic surface quality

Process requirements

Part cleaning and Protection

Quality Inspection Report

Inspection Confirmation

Dimensional confirmation

Appearance confirmation

Quality documentation

Try Prolean Now!

See why customers dig us

I am very happy that I chose ProleanTech for my prototyping project. Everything from pattern-making to surface finishing was seamless due to frequent updates and close communications.

-Lisa Anderson, Materials Scientist

We are consistently collaborating with Prolean for the production of some home decor items. I do not hesitate to say that we are getting reliable and quality zinc die-casting services.

-David Wilson, Senior Project Manager at CustomToolWorks

The aluminum die-casting service at Prolean Technology has been helpful for our business. Their engineers and operation team always think out of the box to deliver the highest standard.

-Rachel Martinez, ProtoFab Industries

Awesome aluminum die-casting company. They take every minor detail seriously and provide comprehensive solutions from die manufacturing to surface finishing. I definitely recommend Proleantech for your die-casting parts!

-James Brown

Our wind turbine impellers work as we needed and also exceed the designed electrical efficiency by an extra 0.19%. Thank you prolean for every support you provide throughout the last six months.

-Natalie Reed, Injection Molding Engineer

I has been great expenice working with ProleanTech as out Die manufacturer for Aluminum casting dies. They know what designer had in mind and produce the accuraate dies.

-Kevin Mitchell, Surface Finishing Manager at PrecisionCoat Solutions

Latest Blog

ABS Plastic: Know the Properties, Processing, and Uses

ABS plastic is strong, durable, and widely versatile.

4340 Alloy Steel Machined Parts: Applications & Properties

High-strength 4340 alloy steel machined parts

Top 10 Laser Cutting Materials Compatibility & Thickness Limits

Laser cutting handles metals, plastics, wood, and leather

Get Your Parts Made Today