Ever wondered how cars go from an idea to a working machine on the road?

This is called product design in the automotive industry—a step by step process of planning, modeling, testing and finally building the vehicle.

Cars are getting smarter, safer and more fuel efficient. To keep up the design process has to get faster, more accurate and full of new ideas. From smooth, aerodynamic shapes to advanced safety features – every part of a car starts with a clear and careful design.

At ProleanTech we help car makers at every stage of the design process. We create concept models, improve engineering designs and get them ready for mass production. Our goal is to move ideas quickly and smoothly from design to production.

In this blog we’ll go through the key stages of product design development in the automotive industry – from the first idea to the final production ready model – and see how each stage shapes the cars we drive today.

Let’s get straight to the topic.

What Is Automotive Product Development?

Automotive product development is the way of transforming vehicle ideas into real products. It consists of multiple stages like:

- Concept

- Design

- Testing

- Production

- Launch

It requires consistent improvements and innovation as automakers always aim to bring quality cars to market faster.

The aim is to meet safety, performance, and environmental standards. However, it considers the time saving and budget controlling aspects also.

Interesting Read: Milling vs Drilling

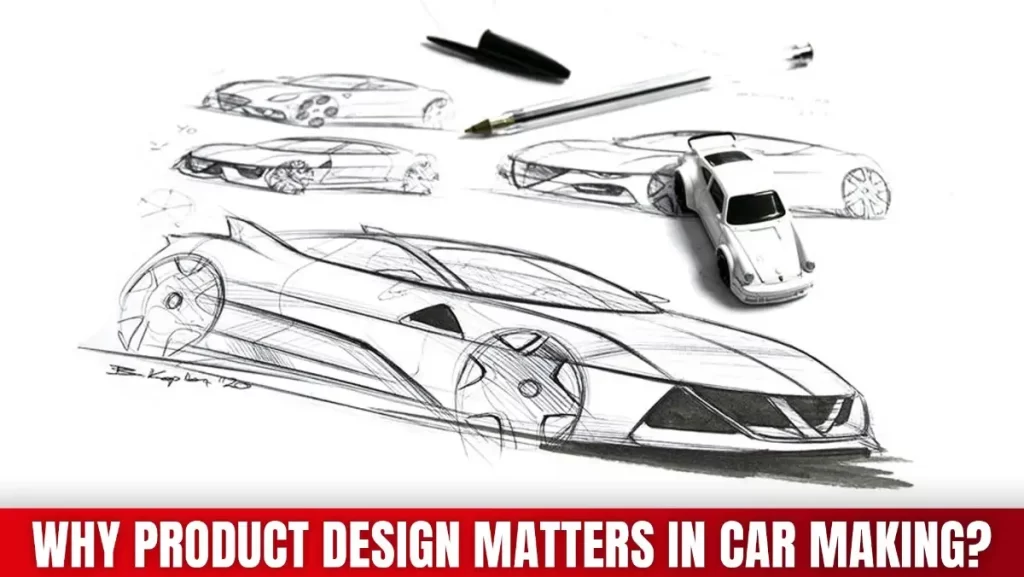

Why Product Design Matters in Car Making

Product Design in Car Making

Car design helps make cars that dont crash, work good and people want to buy them. It makes cars run better and makes people like the car company more.

1. Following Safety Rules and Laws

Car designs must follow hard safety rules and goverment laws. This way cars keep people safe and dont crash and meet law needs in all places where they sell cars.

2. Making Cars Work Better and Use Less Gas

Good design makes air move better around cars and makes them not heavy and helps them use less gas or power. It also makes sure engines and brakes and other parts work the best they can work.

3. Building Brand Name and Getting People to Buy

How a car looks and feels and gives comfort shows the brand name. Good design makes a car different from other cars and brings people who buy again and again.

Try Prolean Now!

Stages of Automotive Product Development Process

CNC machining is the car industry’s lifeline that supports every stage of the product design in the automotive industry, beginning with the initial drawing of the first concept and ending with the production of the last part.

Such flexibility makes it a perfect choice for those manufacturers who are targeting innovation.

1. Kick-Off & Requirements

Kick-Off & Requirements of Automotive

The first stage is to understand the client’s needs in detail. Automotive companies share their design files, material choices and part requirements.

This includes everything from the part’s size and shape to how strong and precise it needs to be.

At this point the CNC machining team reviews the technical data and makes a checklist of all the important details. A clear agreement is made on scope of work, delivery expectations and security of shared information.

Once the budget, timeline and technical requirements are approved the project moves to the next stage.

A Must Check-out Guide: CNC Machining Vs Injection Molding

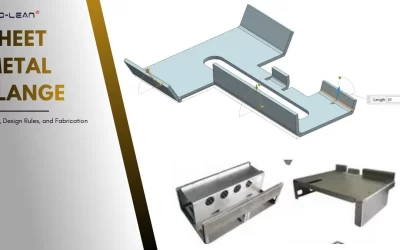

2. Concept Design for Machining

Concept Design for Machining

Here the initial design idea is created with CNC machining in mind. The part’s shape, size and structure is planned so it can be produced efficiently and error free.

This means thinking about how the material will be cut, what type of tooling will be used and how the part will be held during machining.

Making the design CNC friendly at this stage saves time and cost later. If needed small adjustments are made to improve accuracy and reduce waste.

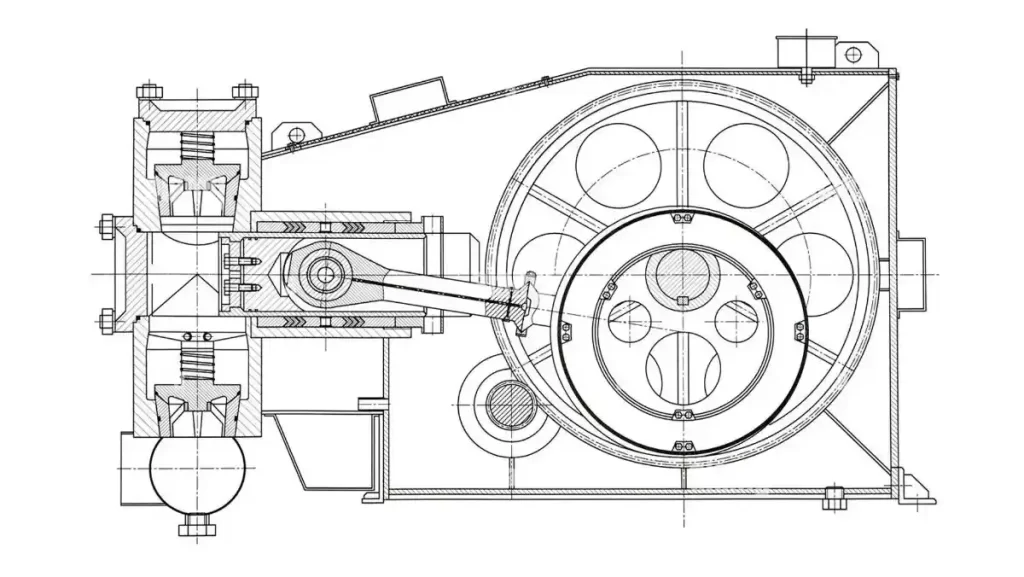

3. Mechanical Design & Machining Validation

Mechanical Design & Machining Validation

Here the design is taken to its final form. The focus is on getting the exact dimensions, structural strength and functionality right. Detailed design calculations are made to check if the part will work well under real life automotive conditions.

If required FEA is done to simulate stress, heat and load conditions. This ensures when the part is machined it will meet safety and performance standards for the automotive industry.

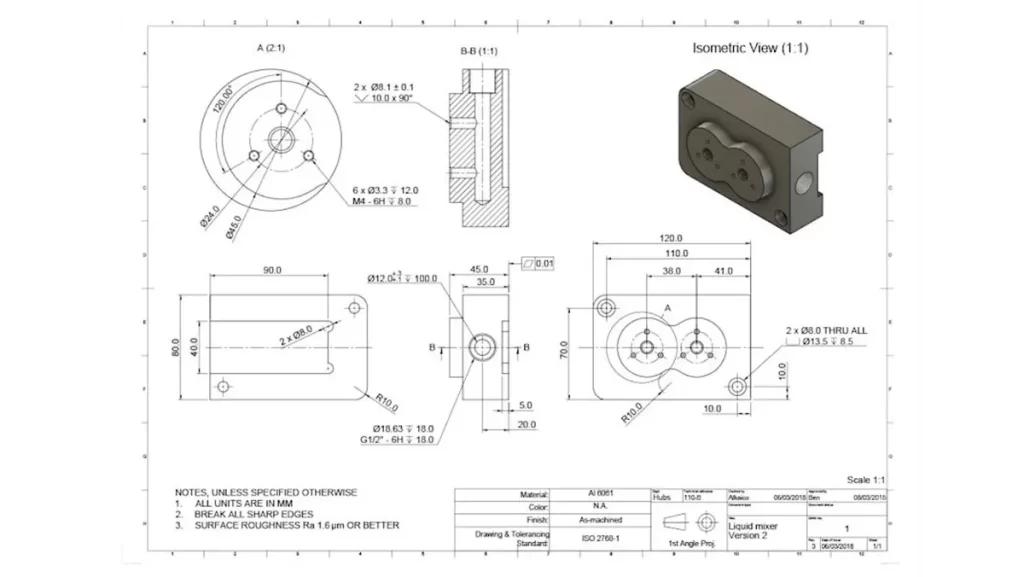

4. Drawing, Programming & Machining Setup

Drawing, Programming & Machining Setup

Once the design is finalised it is turned into 2D drawings from the 3D model. Geometric Dimensioning & Tolerancing (GD&T) is applied to guide the machining process with high accuracy.

The drawings are checked for quality and any errors are fixed. Then CNC programming is done using CAM software to create the exact tool paths.

The right cutting tools, fixtures and machine setup are prepared. This stage makes sure everything is ready before the first cut is made on the CNC machine.

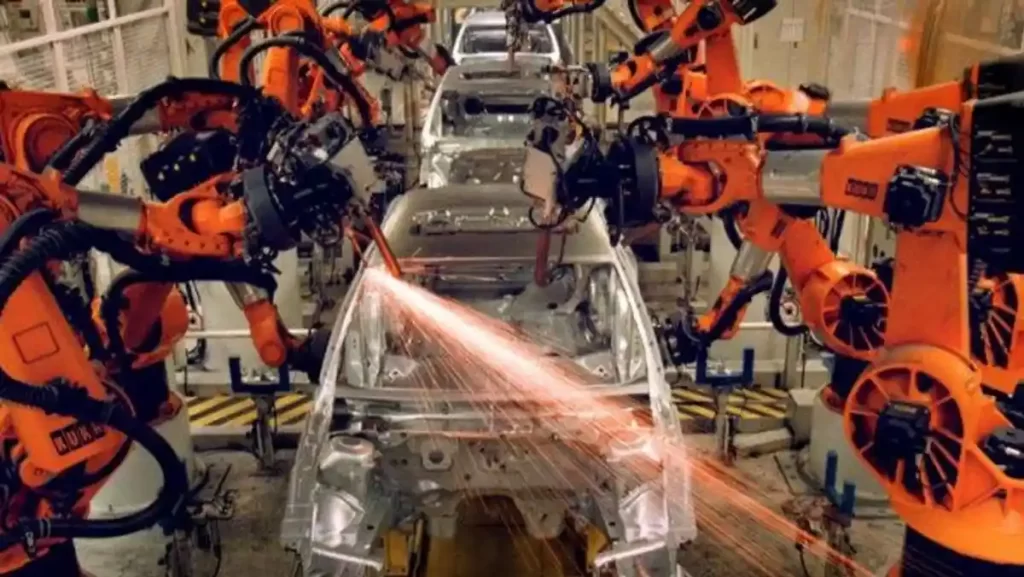

5. Machining, Inspection & Project Close

Machining starts here. The CNC machine cuts the part to the design. Quality checks are done during and after machining to ensure the part meets all requirements.

The parts are delivered to the client for review. If any changes are needed they are made before final approval.

Read More: Milling Machine Vs. Lathe

Overview: CNC Machining Across Development Phases

| Stage | Key Actions | Purpose |

| Kick-Off & Requirement Gathering | Collect client inputs, review technical data, finalize scope & agreement | Set clear goals and expectations |

| Concept Design for Machining | Create initial CNC-friendly design, adjust for efficiency | Ensure design is manufacturable |

| Mechanical Design & Machining Validation | Finalize dimensions, do calculations, run FEA if needed | Check strength, safety, and performance |

| Drawing, Programming & Machining Setup | Prepare detailed drawings, apply GD&T, program CNC, set up tools | Get ready for accurate machining |

| Machining, Inspection & Project Closure | Machine parts, inspect quality, deliver to client, collect feedback | Produce and finalize the project |

Check More: 3-Axis VS 5-Axis CNC Machines

Try Prolean Now!

Top Tips for Automotive Product Development

Top Tips for Automotive Product Development

Product design in the automotive industry is different from many others as it requires creativity, precision and strict safety checks. Whether you are working on car development or a full auto development project, you need to balance speed, quality and meeting standards.

Here are five key points to help you stay on track:

1. Use Modern Design and Manufacturing Tools

Today’s automotive product development works better with advanced design software, simulations and automated machines. If buying these machines is too expensive, work with a company that already has them. That way you can still use modern technology without breaking the bank.

2. Focus on Safety and Rules from the Start

The automobile manufacturing process has many strict rules and standards. Planning for these rules at the start of the product development process will save you time and money. Always make sure your designs and parts meet the required approvals before moving forward.

3. Test and Improve with Prototypes

Prototypes turn ideas into real products. Testing these prototypes will show if the design will work in real life. Using simulations and real world testing will help you find and fix problems early. In car development projects, improving prototypes will reduce product recalls.

4. Choose Reliable Suppliers

In automotive supplier development, reliable suppliers are key. Work with suppliers who have a good track record of delivering quality parts on time. A good supplier keeps auto development moving and avoids delays.

5. Keep Improving After Launch

The automotive market changes fast. Even after a product is launched, keep checking its performance, gathering feedback and updating. That will keep your automotive product development in line with new trends, customer needs and better technology.

Check Out: China CNC Machining Services Guide

Challenges in Product Design in Automotive Industry

Automotive Design Challenges

The car industry has big problems when making new cars. They must make good cars fast and cheap. Car makers need to deal with new rules and what people want. These problems need smart thinking and hard work.

1. Making Cars Faster Than Before

Car companies must make new car models quick. They want to beat other car companies. Teams must design and test cars fast but keep them safe. Good quality cars take time but companies need speed now.

2. Adding Electric Parts and Smart Computer Things

Cars now need electric motors and computer systems inside them. Car makers must learn how to put batteries and smart tech together. This makes cars harder to build than old cars. New electric parts cost more money and take more time.

3. Working with Part Makers Around the World

Design teams get car parts from many different countries now. They must talk with suppliers far away from them. Getting parts on time becomes hard when problems happen. Making sure all parts work good together needs lots of checking.

4. Keeping Costs Low But Making Good Cars

Car makers want to spend less money making cars. But people still want cars that look nice and work well. Cars must be safe and last long time too. Companies must find ways to save money without making bad cars.

Wrap Up

Product design in automotive industry goes through many steps from first ideas to final cars. Each step is key for making safe cars that work good and look nice.

CNC machining process help in every step by making parts that are exact and the same every time adn can change fast. It makes test parts quick and makes parts fit better and changes are easy to do.

At ProleanTech, we offer CNC machining services or rapid prototyping services to support you at any stage of your car design or production. Whether you need a prototype or ready to use parts, we’re here to help you fast, quality and care.

Contact with our experts team OR Get Your Quote to find Small-batch CNC Machining or CNC services that match your automotive needs.

FAQs

Q1. What is the role of a product designer in the car industry?

A product designer is involved with the shape, function and the experience of the car’s parts. They also cooperate with engineers to realize ideas through means such as CNC machining.

Q2. What is the difference between product design and automotive design?

Product design is concerned mainly with separate parts or systems. Automotive design comprises an entire vehicle, not only looks but also performance and integration.

Q3. What is product planning & development in the automotive industry?

It’s the systematic way of defining, designing, testing, and launching new vehicles or components. It involves R&D, market research, and engineering.

Q4. What are the types of product design?

Common types of product design include:

- Functional design

- Aesthetic design

- Ergonomic design

- Modular design

Each plays a role in building modern cars.

0 Comments