Face Milling Vs Peripheral Milling

In contemporary manufacturing, using the wrong milling method often causes high tool wear and breakage. As a result, the surface gets rough and uneven, and additional processes add more cost to production and delivery delays. To avoid these problems, you must match the milling method with the intended part geometry.

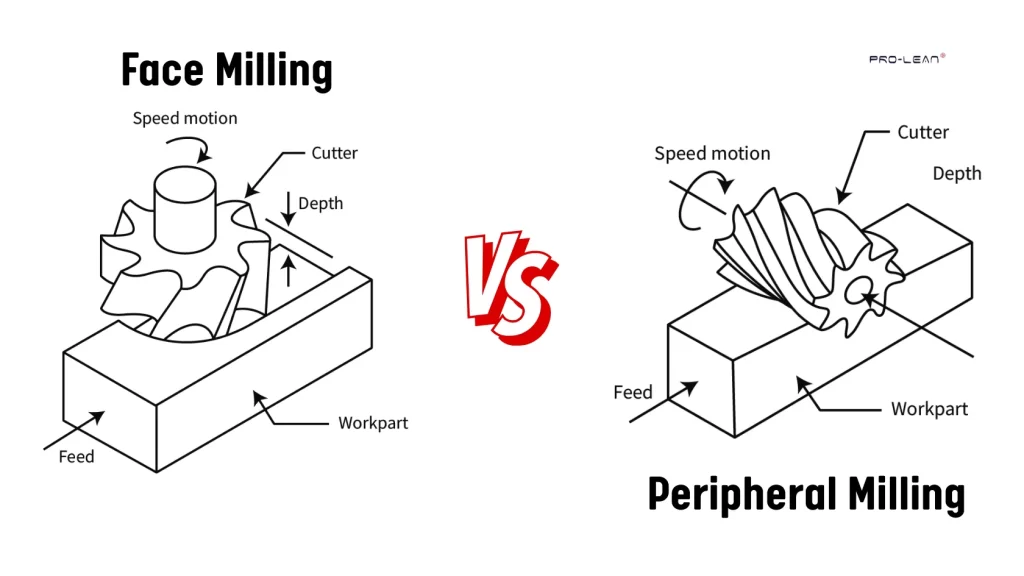

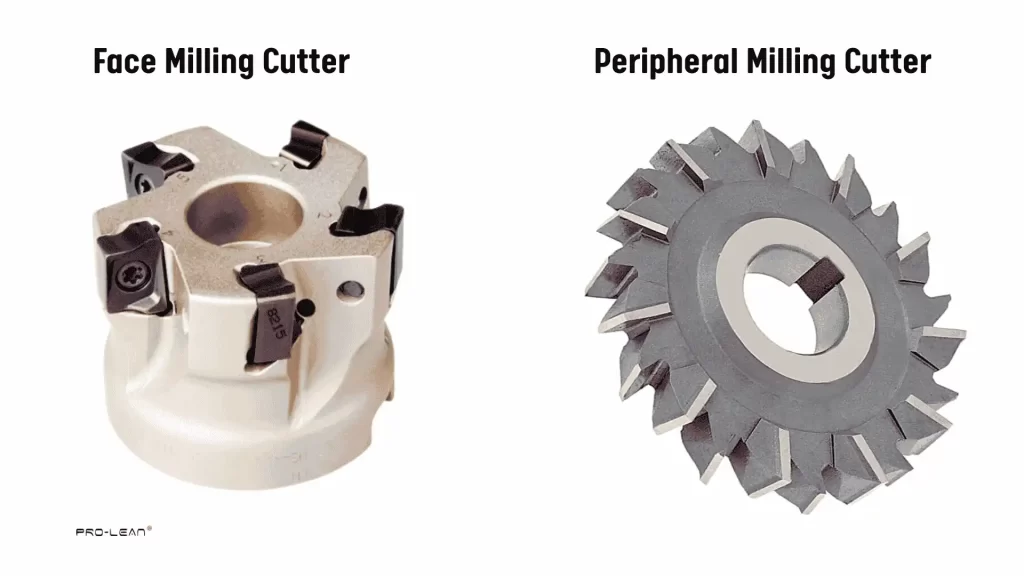

Face milling and peripheral milling differ primarily in cutter orientation and contact with the workpiece. In face milling, material cutting is done along the tool face, and the surface is mainly produced on a broad flat.

On the other hand, in peripheral milling, the cutter is kept perpendicular to the work surface. So, the cutting occurs along the tool edge. It is best used to produce grooves, slots, and complex profiles.

Moreover, Face milling produces shorter and smaller chips and distributes forces across a wider geographic area. Therefore, it minimises tool wear. On the contrary, peripheral milling generates longer chips, concentrates troops at the edge, and allows for cutting narrow and fine features.

At Proleantech, we offer 3, 4, and 5-axis CNC milling services to handle simple to complex parts production. Whether you need a quick prototype or are looking for a scale production run, we can achieve part tolerances as tight as ±0.0002″ (0.005mm) with minimal lead times as short as 1 day

This guide has covered clear insights on the differences between face milling vs peripheral milling, their applications, and how to make a choice.

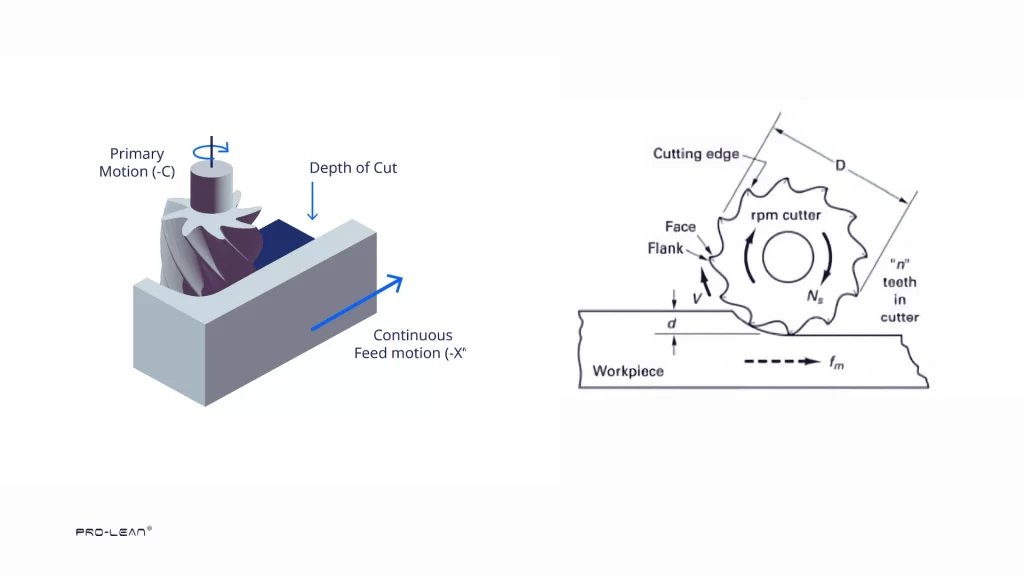

What Is Face Milling in Machining?

Face Milling

In face milling, a rotating cutter removes material on a workpiece using the flat cutter face. The axis of the cutter lies perpendicular to the surface. So, the majority of the cutting occurs along the tool face. The process produces smooth and flat surfaces and is ideal where precision and smoothness are paramount.

A face milling tool typically has multiple inserts designed for rapid material removal in CNC milling operations. The operation distributes cutting forces among several teeth, minimizing the tool wear and increasing the feed rate without damaging the surface.

How does Face Milling Work?

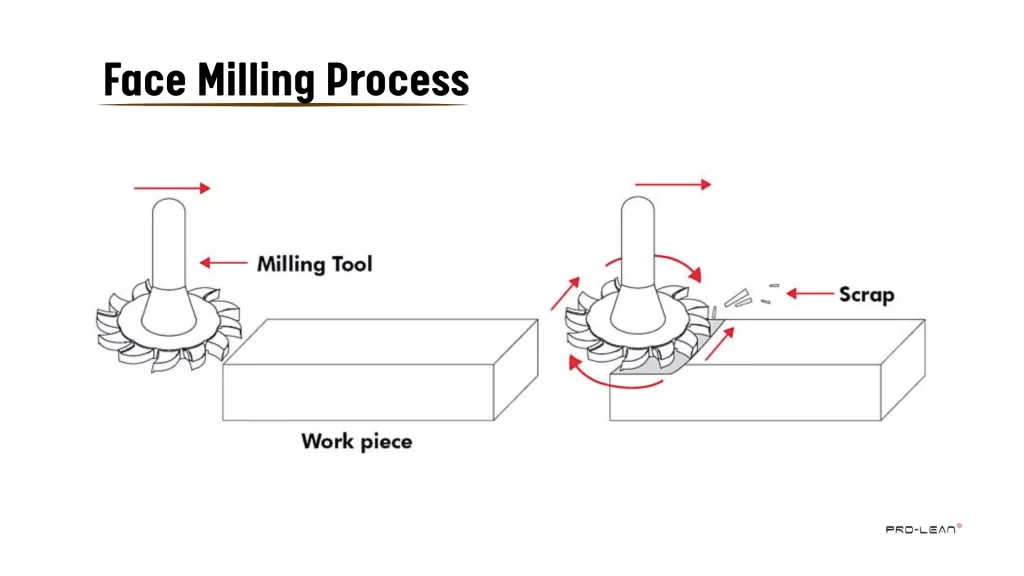

Face Milling Process Illustration

Face CNC milling begins by securing the workpiece on the machine table. Then, the face mill is positioned with its axis at the right angle to the workpiece surface.

The spindle speed and feed rate are then determined, depending on the material and surface finish required. The CNC program directs the tool over the surface, trimming material off evenly and precisely.

Lastly, the final part of the surface is examined in terms of smoothness and dimensionality. The correct setting and parameters create uniform and exact surfaces and render effective material removal.

What Is the Purpose of Face Milling?

Face milling is primarily used to make a flat surface as smooth as possible. Material is removed principally at the ends of the cutter as opposed to the sides. This process is applied when a high level of accuracy and a smooth finish are required, like on plates, blocks, or bars. The step-over distance is usually smaller than face mills, allowing rapid material clearing and early surface coverage.

Applications of Face Milling In CNC Milling

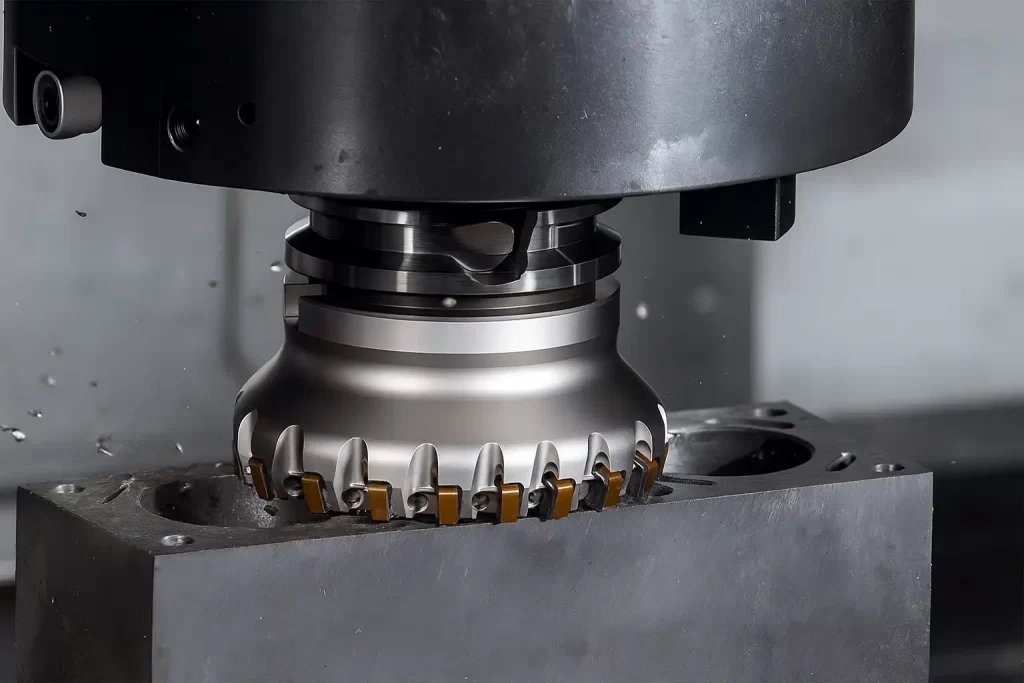

Face Milling Machining

Flat and precise metal and wooden surfaces are made by using face milling. It can produce holes, recesses, patterns, and a completed edge all in a single setup. It is used in workshops for small parts and larger plates. In woodworking, face milling finishes surfaces, including tabletops or cutting boards. The technique can also produce multiple holes with one drill.

What Is Peripheral Milling in Machining?

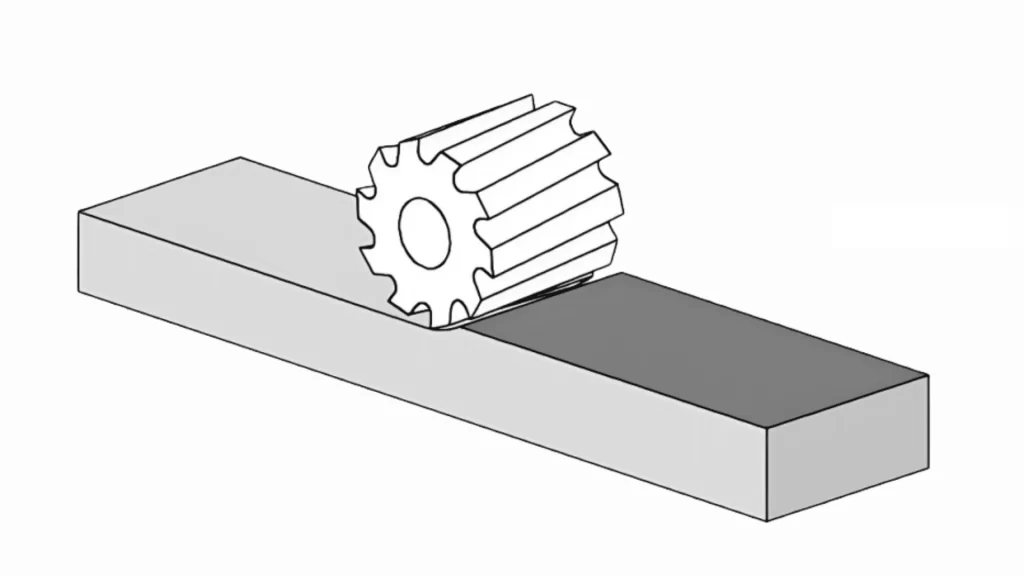

Peripheral Milling

Peripheral milling cuts material along the sides of the milling cutter, not the face. The blade teeth on its circumference excavate material as the workpiece is retained parallel to the axis of the cutter.

The peripheral technique applies to carving edges, grooves, and intricate profiles more accurately. It is generally used in industries where precision is needed in contours and fine machining.

Try Prolean Now!

How Does Peripheral Milling Work?

Peripheral Milling Operation

In peripheral milling, a rotating cutter removes material using its edges. The workpiece is clamped firmly and aligned so the blade can cut the side. A slab mill, helical cutter, or staggered tooth cutter is selected depending on the operation.

The cutter spins around the length or edge of the workpiece and then cuts material. It can shape parts accurately for tasks like contouring, slotting, and shoulder milling. Machining is followed by checking the workpiece to verify whether it is of the required dimensions and surface quality.

What Is the Purpose of Peripheral Milling?

Peripheral milling cuts material away on the sides of a workpiece. The cutter cuts with its edges rather than the tip, making it cut faster. It is the best fit for forming grooves, shoulders, and profiles. It is generally used when speed and accuracy are of the essence.

Applications of Peripheral Milling In CNC Machining

Peripheral milling can cut large slabs, form complex profiles, and make grooves or slots. It can also be applied to a straddle mill on two parallel surfaces simultaneously, as well as gauge slitting. Moreover, it is used in rough machining, mold making, and shaping angled or sloped surfaces where high speed is crucial and high accuracy is demanded.

Note: The job type decides whether face or peripheral milling is needed. Face milling cuts are made with the tool end and are most effective on flat surfaces and smooth finishes. Peripheral milling cuts through the sides of the cutter and is best used on deeper, contoured, or profiled features.

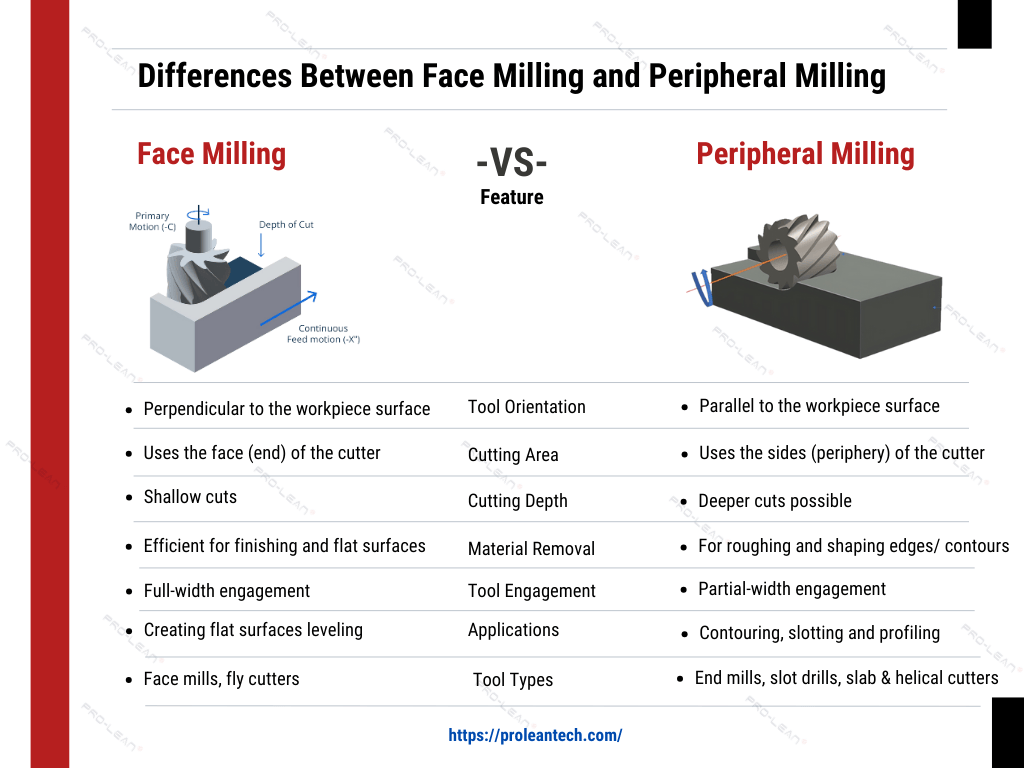

What Is the Difference Between Peripheral Milling and Face Milling?

Face Milling Vs Peripheral Milling Difference

The table and the infographic image seem to provide almost the same information. You can decide whether to use the infographic for social media instead. Let’s see the core difference between face milling vs peripheral milling with respect to multiple aspects.

Table # 01: face milling vs peripheral milling

| Parameters | Face Milling | Peripheral Milling |

| Tool Orientation | Cutter axis perpendicular to workpiece. It cuts mainly with the tool face | Cutter axis parallel to workpiece; It cuts mainly with tool sides (flutes) |

| Primary Use | Flat surfaces, finishing, establishing datum (Z0) | Contouring, slotting, grooving, shoulders, roughing |

| Cutting Depth | Shallow; focused on surface finish | Deeper removes material from edges and profiles |

| Surface Finish | Uniform finish, full-width engagement | Slightly less smooth, partial contact can cause scallops |

| Tool Types | Face mills, fly cutters | End mills, shell mills |

| Feed and Speed | Determined by cutter diameter, tooth count, and material hardness | Determined by spindle power, feed per tooth, depth of cut, and material |

| Applications | Plates, blocks, planar surfaces; finishing passes | External edges, grooves, 3D contours, mold cavities; roughing passes |

Also Read: Face Mill vs End Mill

Try Prolean Now!

How To Choose Between Face Milling Vs. Peripheral Milling

Custom milling services often combine both face milling and peripheral milling to achieve precision and efficiency.

The choice between face milling vs peripheral milling is based on three key factors: part geometry, quantity of material to remove, and required finish. Face milling is used where surface quality and precision are important. For roughing, edge shaping, or removing large material, peripheral milling is a go-to choice.

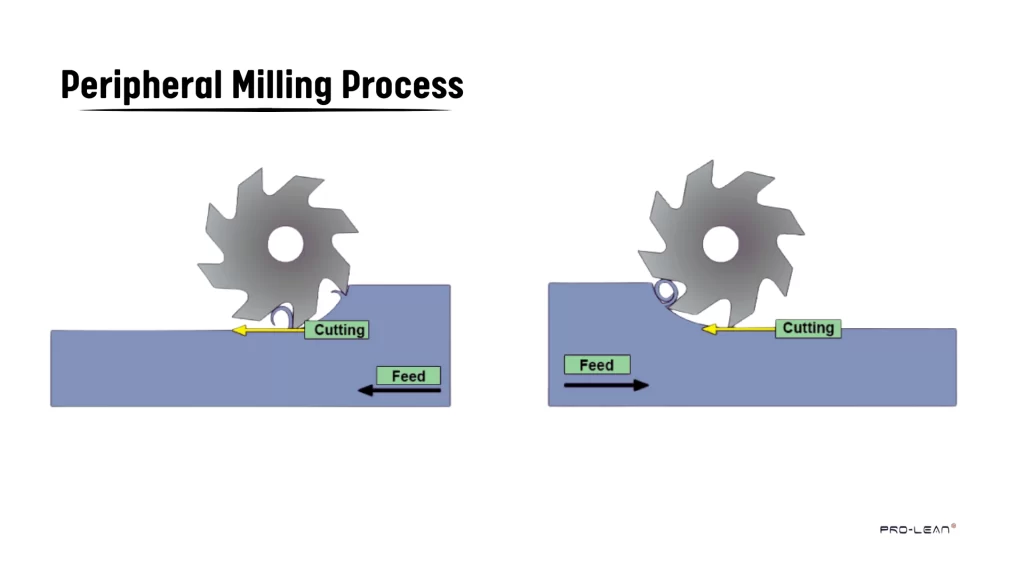

Cutting Direction

The cutter is set at a right angle (90°) to the workpiece surface in face milling. This enables a tool to come into direct contact with the material to create flat surfaces.

Peripheral milling works with the cutter parallel to the workpiece surface. The cutting occurs along the tool’s edge, which can be used to cut grooves, slots, and contoured profiles. This orientation difference defines the type of surfaces and features each method can create.

Cutting Depth

Cutting Depth in Face and Peripheral Milling

Shallow cuts are made using face milling tools. These are usually used to achieve a flat, even finish. While the deeper cuts are made with peripheral milling. The tool can cut the material along edges, grooves, and contours. So, it is used in roughing or where large volumes of material must be removed.

Tool Engagement

During face milling, a slight bottom of the cutter is in contact with the workpiece at a given moment. This diffuses the cutting forces and provides a smooth, even surface with low vibrations.

Peripheral milling is partially engaged. To make contact with the workpiece, only a portion of the cutter edge is in contact. This may leave stronger tool impressions and less refined finishes, but permits deeper or contoured cuts.

Surface Finish

The resulting finish on face milling is typically smoother and more uniform since the cutter contacts the entire flat surface. It is best suited for surfaces with extreme accuracy and coarse surfaces.

Peripheral milling can leave a slightly rough finish. Since the cutter only touches part of the workpiece at any time. Nevertheless, it is an excellent tool to cut complex shapes, grooves, and edges that milling cannot get at.

Tool Differences

Face and Peripheral Milling Cutters

Face milling cuts are intended to cut a flat. They can be multiple-insert, multi-faced to strip away material fast. Face mills and fly cutters are commonly used.

The peripheral milling tools are shaped to slice across the workpiece’s edges. They tend to be shorter in teeth and smaller. Popular tools are end mills, slot drills, and side cutters. These machines are appropriate for contouring, slotting, and edge profiling.

Material Removal Rate

Face milling is not necessarily capable of removing material more quickly than peripheral milling. Removal rate depends on the;

- Tool type

- Spindle speed

- Feed rate

- Workpiece material

Roughing operations with peripheral milling can incorporate more material removal as the cutter interacts with the sides and can cut deeper. High-volume cutting is ideal for peripheral milling.

Common Use in Machining

Both face and peripheral milling are conventional machining methods for surface flattening and plate finishing. Plates and blocks are commonly finished using face milling. Shaping edges, slots, grooves, and complicated profiles uses peripheral milling. (Read More: types of milling)

Summary

In this article, we looked at face milling vs peripheral milling and explained how each works. We also covered the primary distinctions in tool setup, cutting depth, and surface finish. Knowing these points helps you choose the proper method for your machining project.

Prolen Tech offers various manufacturing services for prototypes and production parts, including custom milling. Our in-house facility is equipped with multi-axis machines to produce simple designs to complicated shapes, no matter the narrow tolerance you need. Our strict quality control and ISO certified service ensure you get standard parts/components at an affordable price and with minimal turnaround. Check out our website to learn more or get a free quote.

FAQ’s

Q1: What is the difference between plain milling and shoulder milling?

Plain milling makes flat horizontal surfaces. Cutter is parallel to the workpiece. Shoulder milling makes vertical or stepped surfaces. Cutter is perpendicular to the workpiece.

Q2: What is the difference between plain milling and face milling?

Plain milling produces flat surfaces along the length of a workpiece with the cutter parallel to it. Face milling creates flat faces on the surface with the cutter perpendicular to the workpiece.

Q3: What is the angle difference between face milling and peripheral milling?

In face milling, the cutter axis is (90°) perpendicular to the workpiece. While the cutter axis is at (0°), parallel to the workpiece in peripheral milling.

0 Comments