Profiles from aluminum extrusion are classified into various series based on the dimensions of the profile’s cross section, such as 20, 30, 40, 60, and 80 series. They are defined by the size of the shorter side(height) on the cross-section. For example, 2020 refers to aluminum extrusion with 20mm width and 20 mm height.

Basically, series are a way to define dimensions of extruded profiles. Each of them has a distinct level of physical and mechanical properties, like 8020 aluminum extrusion is stronger than 2020.

This article discusses 2020, 2040, 4040, and 8020 aluminum extrusion with their comparative elaborations. So, you can decide which one is the perfect fit for your project. Let’s get started.

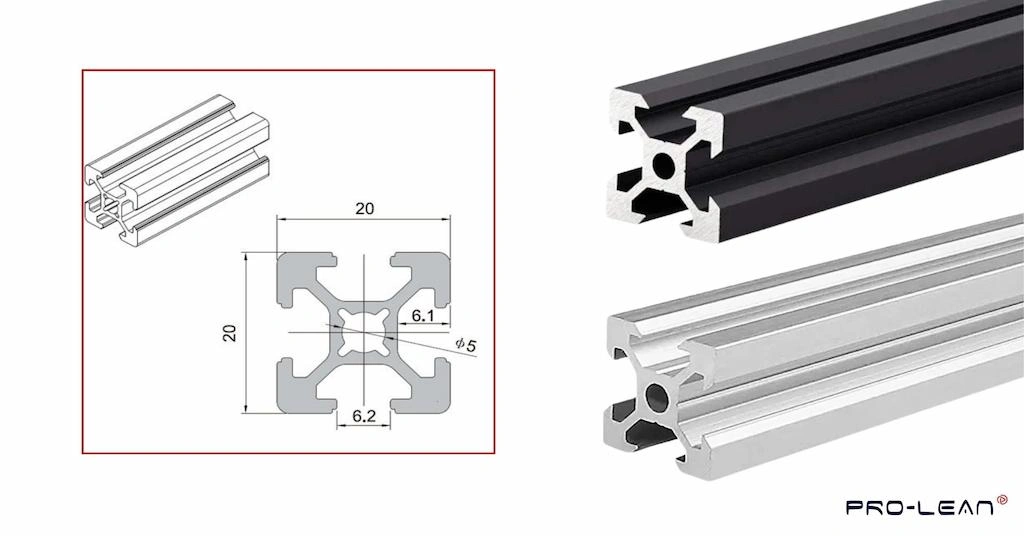

What is 2020 Aluminum Extrusion?

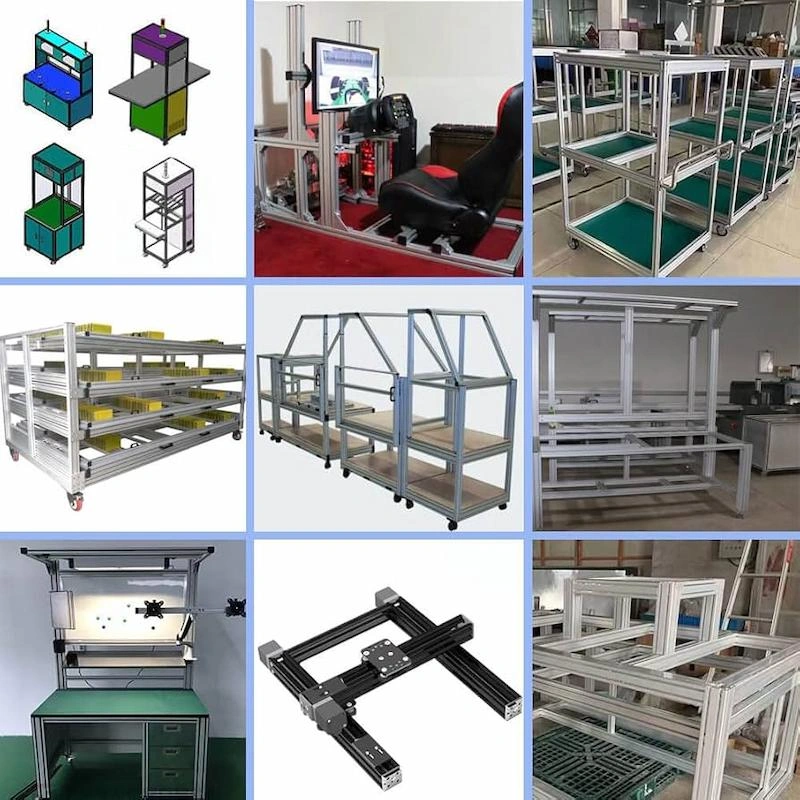

2020 aluminum extrusion

First, the dimensions of the 2020 aluminum extrusion are 20 mm in height and 20 mm in width, with a custom length. Each side contains one slot with a width of 6mm, depth of 5 mm, and wall thickness of 1.5 to 3mm, approximately, or can be customized. This compact design and sizing allow for faster assembly and are a cost-friendly option for many light load applications.

This standard type of aluminum extrusion mainly uses 6063-T6 and 6061 6061 Aluminum. You can also get these profiles with a through hole at the centre. If you are further interested in material, read 6061 vs. 7075 Aluminum for their comparison here.

Applications: Chassis for small robots, frames for 3D printers, jigs, fixtures, and camera sliders.

Advantages

- Compact design and highly space-efficient

- Good rigidity for short spans of frames

- Lower material cost and easy assembly

- V-slot 2020 aluminum profiles are compatible with guide rails.

- Relatively minimal lateral deflection under load

- More flexible for modularity and customization

Limitations

- They can not sustain moderate-to-high loads in heavy-duty applications

- The small size of the profile’s cross-section restricts its use in many systems/equipment.

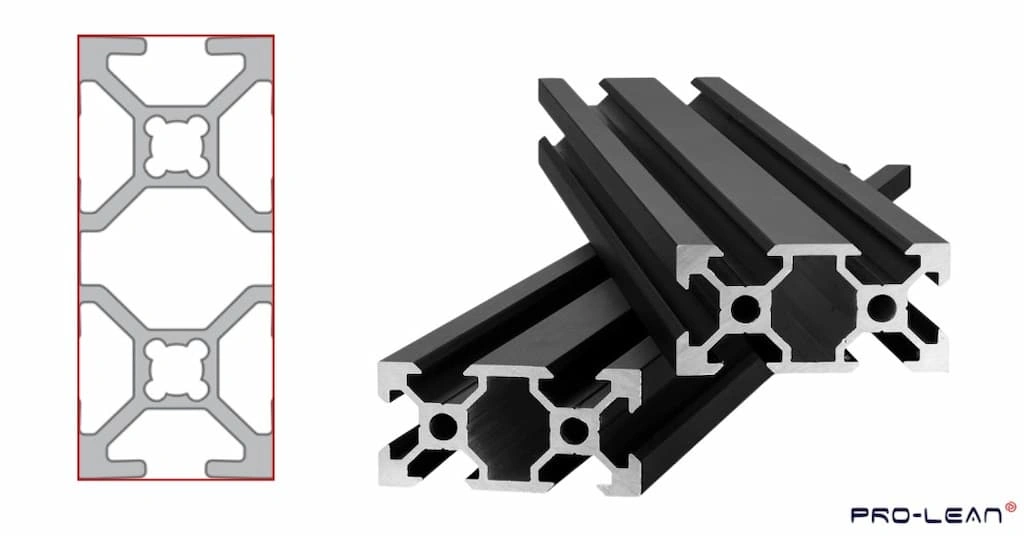

What is 2040 Aluminum Extrusion?

2040 aluminum extrusion

It is another 20 series aluminum extrusion, characterized by dimensions of profile cross-section 20 mm in height and 40 mm in width. Slot width and depth are the same as 2020, 6, and 5.5. mm approximately.

You can clearly see that height is the same, but width is twice that of the 2020 aluminum. This means 2040 aluminum extrusion involves six open T or V-slots. If you compare 2020 vs 2040 aluminum extrusion, the added width on 2040 increases the stiffness and rigidity. Additionally, a large area of mounting face also improves the torsional strength.

Applications: Machine guards, custom displays, frames, small 3D printer work benches, robotics, and custom stands.

Advantages

- It provides higher bending strength and structural rigidity.

- You can fit 2040 aluminums with 2020 profiles in series.

- It is lightweight and flexible for adjustment & modifications.

- Profiles/components can be finished with anodizing for a sleek appearance.

Disadvantages

- Although 2040 extrusion provides higher strength, it is not sufficient for high-duty loads.

- This aluminum does not perform well under high thermal stress.

- The shape is limited to a bar profile and has lower design flexibility.

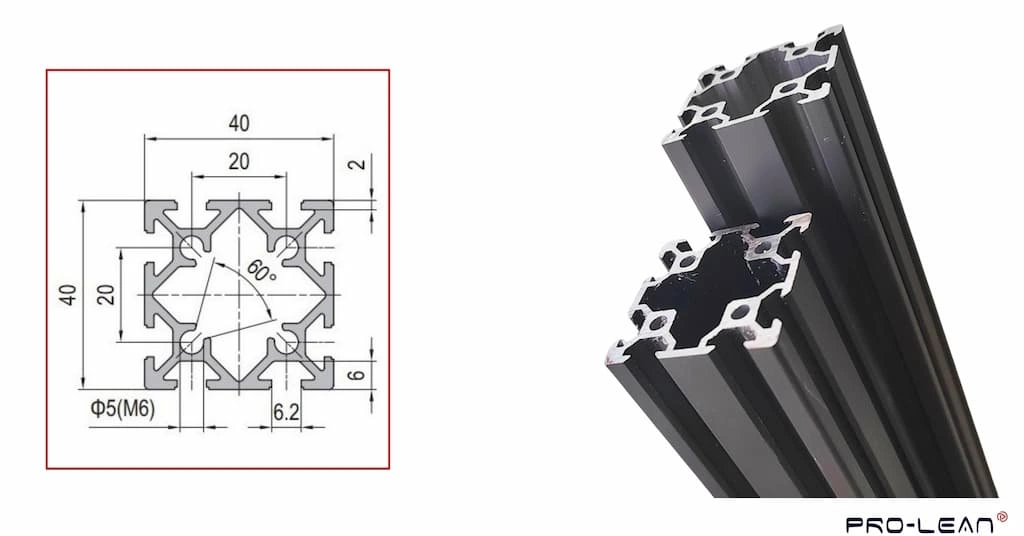

What is 4040 Aluminium Extrusion?

4040 aluminum extrusion

The 4040 aluminum extrusion dimensions are 40 mm in width and 40 mm in height, whereas T-slots on each side are 8 mm wider and 6 mm in depth (approximately). Meanwhile, the thickness can vary from 1.5 to 10mm.

The square geometry allows for modularity, enhanced strength, and easy attachment. Furthermore, a straight bore on the centres can also accommodate the M6, M8, or any other fasteners, depending on the bore sizing.

Applications: Workbenches, light construction, automation setups, industrial equipment, industrial racks, and medium-sized 3D printers.

Advantages

- Due to modularity, 4040 extrusions are flexible and versatile.

- Assembled structures can be modified by adding additional profiles or removing the existing ones.

- Lightweight and compact design compared to others, in terms of per unit load bearing capacity.

- Cost-effective and easy to assemble using compatible N nuts.

- Larger surface area makes it easy to dissipate heat, especially in high-temperature conditions.

Disadvantages

- Still, the load capacity is not high enough for heavy-duty uses like 2080.

- An extensive length of 4040 aluminum might not fit inside an anodizing tank.

Try Prolean Now!

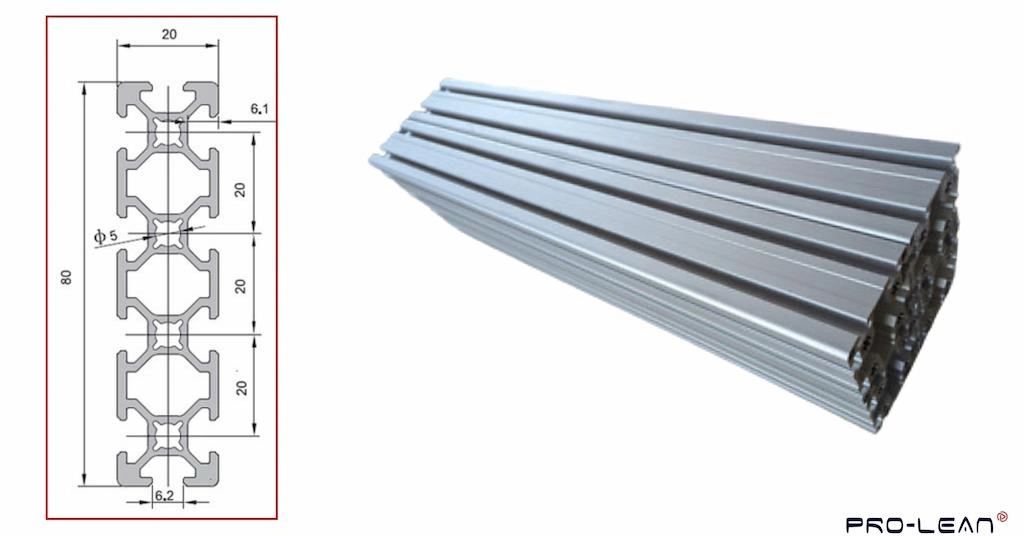

What is 8020 Aluminium Extrusion?

8020 aluminum extrusion

The 8020 aluminum extrusion is a high-strength and heavy-duty profile with a size of large sides 80 mm and smaller sides 20 mm. For the I-type variant, there are 5 mm wide slots, whereas for the T-slot variants, there are 6 to 10 mm wide slots. You can extensively find 8020 aluminum on various machines and custom structures.

The slot configurations in 8020 aluminum are;

| Variant | No. of Slots | Slot Width | Slot Depth | Remarks |

| I-Type | 10 | 5 mm | 6.35 mm | 5 per long side |

| T-Slot | 8 | 6 & 10 mm | 6–10 mm | Mixed configuration |

Often, it is also referred to as “80/20” extrusion, which means 80 % of structural work is already done, and only the remaining 20% needs to be done during assembly.

Applications: Heavy machine frames, structural elements for construction, enclosures, work stations, etc.

Advantages

- 8020 extruded aluminum can withstand high loads and is suitable for heavy-duty applications.

- It provides structural stability and good strength.

- The assembly of the 8020 aluminum is precise and accurate, and can be used for complex frames.

- Excellent bending stiffness and torsional rigidity

- You can customize the assembly with a variety of connectors, fasteners, and supporting elements.

Disadvantages

- These types of extrusions are relatively costlier to assemble, and a larger weight also increases logistic costs.

- In heavy-duty uses, it requires periodic maintenance, like checking fasteners and connections to avoid deflection.

Read more: 2024 Aluminum Extrusion

2020 Vs 4040 Vs 8020 Aluminum Extrusion

Since we have discussed different series of aluminum extrusions individually, let’s look at the comparative scenarios between them. How they differ from each other in strength, flexibility, customization, cost, and structural stability.

2020 vs 2040 Aluminum Extrusion

Applications of 2040 aluminum extrusion

2040 involves a wider cross-section than 2020, improving torsional resistance and strength. They also contain larger faces that allow for easy assembly or re-configuration. The table below outlines the key differences.

| Criteria | 2020 Aluminum Extrusion | 2040 Aluminum Extrusion |

| Cross-section (H × W) | 20 mm × 20 mm | 20 mm × 40 mm |

| No. of open T-slots | 4 (one on each face) | 6, 4 on one side and 2 on the other |

| Slot width | width ≈6 mm that fits an M5 fastener, and depth up to 6 mm | 6 mm, same as 2020 |

| Alloy/finish | Aluminum grades like 6063-T6 and 6061/Anodized finish | 6063-T6 and 6061, anodized finish |

| Strength | Moderate and suitable for light structures and small load machinery | Relatively higher and supports medium loads |

| Structural stability | Stable for compact assemblies | Good stability, improved twisting and bending resistance. |

| Fatigue resistance | Only suitable for light cyclic loading with low vibrations | Higher due to stiffness and better stress distribution |

2020 vs 8020 Aluminum Extrusion

Automation in the workstation

The main difference is that 8020 aluminum extrusion profiles are much wider and provide higher strength, suited for heavy-duty loads.

The 2020 vs 820 aluminum extrusion table below compares these two.

| Criteria | 2020 Aluminum Extrusion | 8020 Aluminum Extrusion |

| Cross-section (H × W) | 20 × 20 mm. | 20 × 80 mm |

| No. of open T-slots | 4, one per face | 10 I-type or 8 T-type |

| Slot width | ≈ 6 mm slot opening | I type 5 mm and T-type 6 to 10 mm |

| Alloy/finish | 6063-T5 / 6063-T6 /Anodized | 6063 (T5/T6)/ anodized or powder-coated |

| Strength | Good(Tensile ≈ 241 MPa, Yield ≈ 214 MPa ) suitable for light loads | Larger surface and weight enhance the joint strength |

| Structural stability | Good for light frames, small motion axes, and robotics | Highly stable even under high loads |

Try Prolean Now!

Factors to Consider While Choosing Between 2020, 2040, 4040, and 8020 Aluminum Extrusion

Applications of 2040 and 4040 aluminum extrusion

Once you understand the key offering and limitations of different series of extruded profiles, you need to consider some factors and analyze the options to choose the right one.

The common factors to consider include load strength, rigidity, wall thickness, and cost.

-

Identify Required Load Strength & Rigidity

First, you need to identify how much load your structure must withstand to operate without failure. For this, you can run computer simulations under real conditions on your design. The reason for doing this is to find out the limit and ensure that the final assembly exceeds that limit.

-

Wall Thickness & Strength-to-weight Ratio

Thickness directly impacts the load-bearing capacity of the extruded profile. So, analyze thickness & weight, and ensure that it is sufficient to withstand the load strength limit you identified earlier. During the design phase, you can aim to achieve the optimal strength while keeping minimal weight.

-

Compatibility With Brackets and Accessories

Along with T nuts, check whether you can use corner brackets, custom connectors, and other required accessories while joining the structure. Brackets help to improve lateral restraint, whereas joining plates help in orientation.

-

Cost Factor

Cost is a key factor in any manufacturing project. So, check which profile is the most cost-effective without compromising the desired performance qualities. For example, 2040 might give the best value for money if the structure is not large and does not involve any heavy-duty operations.

Read More:

Conclusion

Overall, deciding between 2020, 2040, 4040, or 8020 aluminum depends on the size and needs of your project. 2020 can withstand a lighter load and provides compactness, whereas 8020 might be the best choice for larger and stable frames. As we have discussed, the pros, cons, and features of each type in this article, you can identify your requirements and analyze which one fits your needs.

If you are still in doubt, our professional team can help you choose the best extruded aluminum profile. We provide aluminum extrusion services for different industries with high standards and strict quality control, assisting in everything from design optimization to assembly. So, drop your design today, and we will get back to you with a quote shortly.

FAQs

What is the difference between 8020 and 2020 extrusion?

Primarily, the difference is in their cross-section; 8020 is broader and stronger. 8020 means an aluminum extrusion with a cross section of 80 x 20 mm, whereas 2020 refers to a cross section of 20 x 20 mm.

What is the difference between 2020 and 4040 aluminum extrusion?

The 20x20mm extrusion profile is for light applications, whereas the 40 x 40mm is for heavy-duty and provides higher load bearing, greater stiffness, and stability.

What is 2040 aluminum extrusion?

2040 aluminum extrusion refers to the making of an extruded profile with a cross-section of 20 x 40mm. It is also a standard extrusion series.

How strong is 2020 aluminum extrusion?

Due to its compact cross-section, they are not fit for high loads, but strong enough for lighter applications. The tensile strength ranges from 230 to 300MPa, depending on the tempering.

What is 2020 series aluminum extrusion?

This is a 20-series T-slot profile made from aluminum extrusion with a cross-section of 20 x 20mm. One of the common types in industry, and is highly compatible for diverse frame assembly projects.

0 Comments