Fabrication Vs Machining

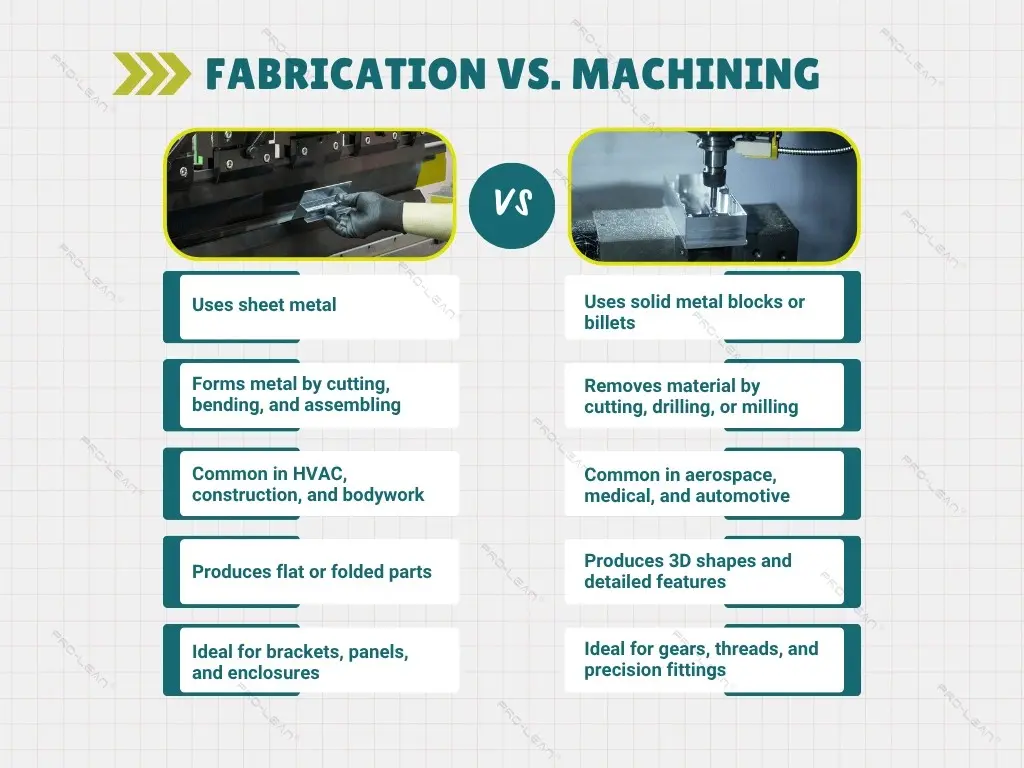

You’ve probably heard the terms “metal fabrication” and “metal machining”. These sound the same and are used interchangeably. But they’re not. Yes, both involve shaping metal. But how they do it, and why, makes all the difference. These processes serve unique objectives, tools, and results.

If you’re managing procurement or planning a custom part, you must understand the distinction between fabrication and machining. Making the wrong choice could lead to wasted budget, poor fit, or production delays. Understanding how each method works will help you choose the right one. It’s the kind of decision that can directly impact your bottom line.

What Is Metal Machining?

CNC Metal Machining

Metal CNC machining means transforming solid metal blocks into precise and working parts. Unlike shaping metal by bending or hammering it, it involves removing different parts by cutting or grinding, like a sculptor would work on a statue. As a result, you end up with a precise and tidy component according to your design.

What makes machining different is its focus on precision. You can produce parts with slight differences in size and fit that optimally together. Whether for Rapid Prototyping or making many components, machining ensures you handle every part of the process. Therefore, aerospace, automotive, and medical manufacturing industries depend on it because there is no place for mistakes.

Machining can be performed without blades. Usually, high-speed tools are used in machining to accurately grind, shear, or drill different types of metal. You can’t get these precise edges, holes, or features from forming or casting, so machining is the best option.

Turning, Milling, and Drilling: The Core Methods

CNC Drilling

Turning is carried out frequently in machining and is done with a lathe. When using the process, a metal part rotates as a sharp tool is applied against it. Through turning, you can make objects with symmetry such as cylinders, screw threads, or round grooves. It makes your job faster and easier when you need to use the same shape many times or depend on exact curves.

Milling is done differently. Here, the tool makes a rotating motion, not the metal piece. The tool (or workpiece) moves along multiple axes (e.g., X, Y, Z) to cut away material. Milling can handle different tasks and is usually selected when complicated parts need careful control. Most of the time, this is the main way to make advanced designs in machining.

The process of drilling is straightforward. A drill bit helps you create a straight hole through metal, usually as an early step for fixing screws or bolts in place. With the help of its sharp edges, the fast-moving drill bit cuts through whatever material it is drilling. Though it does not seem complicated, precise drilling means your parts come together correctly, fasten properly, and are reliable.

Try Prolean Now!

What Is Custom Metal Fabrication?

Bending metal plates

Custom sheet metal fabrication is meant to shape metal according to your needs. As opposed to machining, fabrication uses sheet metal instead of solid blocks. Using flat materials, you change them into parts, products, or structures. It’s like working with paper; instead, you are dealing with steel, aluminum, or copper.

Many HVAC, automotive, and construction industries frequently use fabrication techniques. If you are working on panels, frames, or enclosures, fabrication ensures you get the versatility you need while keeping objects strong. It is possible to move from an idea to the product often without requiring dedicated molds or casting.

In addition, this process makes use of different techniques. Punching holes, bending angles, or stamping forms are ways to make your design. This process leads to making exact and reliable components according to your requirements.

Punching, Bending, and Stamping: The Core Fabrication Processes

Sheet Metal Punching Machine In Operation

Punching is used to make contours/holes. The tool enters the metal by force rather than being sliced by cutting machines. The shape of the tool goes together with how big your hole is. It works best when repeating patterns like vents, grids, or bolt holes.

Bending means folding the sheet. You use the metal in a straight line to draw angles. It’s possible to create corners, round arcs, or shapes that look like a U. You need it when your part has to be supported with structure or framing.

Stamping is different because it makes fully three-dimensional shapes. Putting the sheet in a press allows a tool to shape it. You can create detailed and raised patterns using this tool. It applies to branded panels and products used in cars.

Fabrication Vs Machining: What are the Similarities?

Fabrication and machining share many common ground points when working with metal parts. Awareness of these similarities can guide you to make the right project decisions.

Assembly Is Common in Both Processes

A significant part of fabrication and machining is joining different parts together. When welding, heat melts two metal pieces so they stay bonded permanently. It forms a solid and long-lasting bond. Another convenient way is to use bolts, screws, or rivets to fasten various parts. Disassembling something becomes easy if you use fasteners.

Both Use the Same Metals

Mostly, the materials used in fabrication and machining are similar. Due to their rugged and long-lasting nature, manufacturers pick sheet metal materials like steel, aluminum, and stainless steel for many uses. Since they can withstand heat and pressure, these metals are perfect for several industrial applications. The resulting parts are typically rigid and resistant to corrosion.

Flexibility in Metal Shaping

You can change and work on metal parts in many ways, including machining and fabrication. You can cut, bend, drill, weld, or fasten metal based on what you need to make. Because the process is flexible, you can try several techniques to get what you want. Because of this, many industries that require exact and solid products depend on them.

Try Prolean Now!

Differences Between Machining and Fabrication

Comparing Fabrication Vs Machining

Both sheet metal fabrication and machining shape metal differ in how they start and what they can create.

Different Starting Materials

Usually, machining starts with a metal block or billet. As a result, your shapes will be carefully formed and strong. But, in the fabrication process, metal sheets or coils are used. They are shaped, folded, or trimmed to become flat things such as boxes, panels, and frames. The fact that they use unique methods allows them to work on various projects.

Precision and Accuracy

Machines can produce precision outcomes. It removes the extra material by using cutting tools and makes the piece look polished with tight dimensions. It is best to choose when the items require precise, small details, like threaded bolts or valves.

By bending and shearing, fabrication may stretch or slightly modify the metal. That’s why fabricated parts usually aren’t as precise and have smoother edges than machined parts.

Speed and Cost Considerations

The process of fabrication works well when many items are made at once. Using stamping or punching, many parts can be made quickly and affordably. Machining operates more slowly and is more costly since it entails precise cutting and polishing steps. If you want simple shapes and large volumes, fabrication usually gives you better results. If you wish for strict geometry or exact specifications, machining is better.

See Also: Sheet Metal vs Machined Parts

Which Service Do You Need? Contact Prolean Tech

The metalworking method you choose should fit your project’s specific needs. A few businesses provide only parts and help you design your components immediately. Some companies create a prototype before mass-producing their products.

A leading manufacturing company, Prolean Tech offers comprehensive custom machining service. We ensure that everything in your project and supply chain is managed to deliver your parts on time. If you look for exact and high-quality parts, Prolean Tech is the smartest choice. They have gained knowledge over many years and have plenty of pre-made industrial hardware parts.

If you can’t find the part you need, Prolean Tech’s team can custom-make it for you. Our team will help you from the planning phase to testing with a prototype and mass production.

We use various approaches and techniques to address multiple requirements. Contact them now, and our specialists are available to assist you with getting the best parts for your project.

FAQ’s

Q1: Is fabrication the same as machining?

No, fabrication and machining are different processes. Fabrication usually involves cutting, bending, and assembling sheet metal to make parts or structures. Machining, on the other hand, removes material from a solid block of metal to create precise shapes and details. So, while both are made of metal, they do it differently.

Q2: What is the difference between fabrication and manufacturing?

Manufacturing is a broad term that covers all ways of making products. Fabrication is a specific part of manufacturing that focuses on shaping and joining metal pieces, especially sheet metal. So, fabrication is one step inside the bigger world of manufacturing.

Q3: What is the difference between manufactured and fabricated?

Manufactured parts are made using any process, such as moulding, casting, or machining. Fabricated parts are made explicitly by cutting, bending, and assembling metal pieces. So, all fabricated parts are manufactured, but not all manufactured parts are fabricated.

0 Comments