“Alodine coating treatment is a highly preferred solution for industrial applications that demand durable, lightweight, and electrically conductive aluminum finishes.”

Secondary coating or plating in manufactured aluminum parts has been a popular method of finishing and customization of surface characteristics. Alodine aluminum refers to adding a permanent layer of chromium and other metal salts in minor amounts to create a corrosion resistant surface. Specifically, Alodine® is a commercial brand name for for a type of chemical conversion coating, commonly known as chromate conversion or chem film. This process, also referred to as alodine surface treatment, is highly valued for its ability to protect aluminum parts.

The alodine coating can be different ways, but the end purpose is enhancing corrosion resistance and durability. The alodine surface treatment acts as the barrier from exterior environmental conditions and protects the underlying aluminum substrate and acts as a primer for painting.

Let’s discuss the process, methods, and use of alodine coating

What is Aluminum Alodine Coating?

Alodine aluminum coating, , also known as conversion coating aluminum involves the passivation of metal surfaces by developing a protective oxide layer( Al2O3⋅Cr2O3) that prevents corrosion, wear, material degradation, etc. Typically, processes are carried out with the alodine solution or sprays.

This coating also maintains the dimensional stability of parts, the negligible thickness of the coating ( 0.00001-0.00004”) does not affect the accuracy. The process typically involves applying an alodine solution through immersion or spraying techniques, adhering to standards such as MIL-DTL-81706 Alodine or AMS 2473 Alodine for consistent quality.

Consumer items apply the alodine coating to enhance performance and durability. Notably, products like Alodine Bonderite and Alodine Touch-N-Prep offer convenient solutions for achieving these coatings with precision.

Can I Coat Alodine in Other Metals Besides Aluminum?

Yes! Although alodine conversion coating is mostly popular for aluminum alloy parts, it can be used for other various metals and alloys. For instance, zinc, brass, copper, titanium, steel, etc. It can also provide corrosion resistance and adhesion for these types of metals. However, they might require additional treatments or layers to achieve comparable levels of protection. For instance, Iridite finish aluminum—a related chemical conversion coating—is sometimes used for similar purposes on various metals.

Try Prolean Now!

Types of Aluminum Alodine Coating

Alodine aluminum coatings are categorized based on the composition of the alodine solution and specific finishing standards, such as MIL-DTL-81706 Alodine or AMS 2473 Alodine. The most widely recognized standard is MIL-DTL-5541, which includes two primary variations: Type I and Type II.

Type I Alodine Coating

It is a MIL-DTL-5541 standard finish that gives a clear or golden brown aesthetic to aluminum parts. Chemically, Type I alodine or chromate conversion coating is characterized by the presence of hexavalent chrome.

However, it is considered a relatively hazardous coating than type II. So, alodine Type I coatings may be restricted in sensitive industries, prompting the use of alternatives like Alocrom treatment, a similar chromate conversion process.

Type II Alodine Coating

Type II does not contain hexavalent chromium. Instead, it relies on trivalent chrome. This type of chemical conversion coating aluminum also complies with the MIL-DTL-5541. It provides enhanced resistance to corrosion compared to a type I alodine finish. Other benefits include less– time-consuming, electrical conductivity, and a low-temperature process.

Type II is more common across industrial applications, it is used for protection and aesthetic. Moreover, it does not impose any risk of hazardous chemicals like type I.

What are the Steps of the Aluminum Alodine Coating Process?

The alodine aluminum treatment process involves immersion or spraying the substrate aluminum components with a chromate-based solution. It triggers the reaction of chromate with aluminum, producing a thin chemical conversion coating layer.

Alodine coating setup

Here are the steps in brief;

Step 1: Substrate Cleaning

First, thoroughly clean the aluminum substrate to remove debris, oils, grease, or any potential contamination. It is essential to ensure that the surface is free from any contaminations for stronger adhesion of alodine surface treatment.

Step 2: Surface Etching

The chemical etching process makes the cleaned aluminum surface uniform and facilitates better coating. You can use chemicals like ferric chloride to etch the surface. Next, deoxidizing is also important to neutralize the inert oxygen or metal oxides present on the surface.

Step 3: Submerging in Alodine Solution

Dry the etched surface and submerge the aluminum parts into the alodine solution. The etched and dried aluminum parts are submerged in or sprayed with the alodine solution (e.g, Alodine Bonderite or Alodine Touch-N-Prep). The immersion time and chrome ion concentration determine the coating thickness and type. Besides submerging in solution, spraying with automatic nozzles or manually can also coat the alodine.

Step 4: Final Washing of Parts

Once the coating is complete, eject the parts from the solution and wash them with warm water. TheCompliant with MIL-DTL-81706 Alodine, alodine aluminumn, dry and inspect the parts for quality control before packaging.

Why Use Alodine Conversion Coating on Aluminum Parts?

Alodine can be applied on machined, fabricated, extruded, and casted aluminum parts and products to enhance corrosion resistance and serve as primer for painting.

The following are the benefits of applying alodine coating;

Corrosion Resistance

The developed chromium layer not only protects from external environmental factors but also eliminates microscopic irregularities like pores, cracks, etc. The protective film acts as a barrier when exposed to harsh conditions. As a result, the aluminum parts become highly corrosion-resistant.

Room Temperature Process

The type II chemical conversion coating is carried out at room temperature, which makes it simple to operate. Also, it makes it easy to control the processing parameters like temperature fluctuation and immersion time.

Primer for Painting

The alodine aluminum acts as a good adhesion for painting. It strongly bonds the applied paints due to its uniformity and smoothness. Therefore, many applications use it as a primer for aesthetic painting such as aircraft alodine body painting.

Electrical Conductivity

Type II, class 3 alodine slightly improves the electrical properties of aluminum substrates. The negligible thickness of alodine does not cover the original electrical conductivity. Instead, it provides a smooth and uniform contact surface for electrical connectors.

Applications of Aluminum Alodine Finish

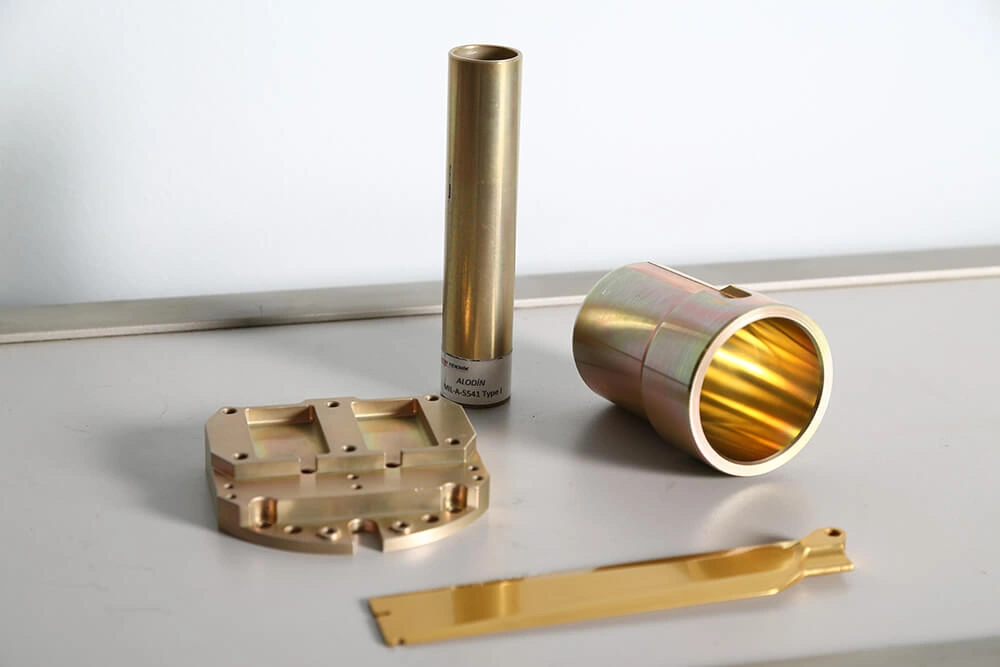

Alodine-coated aluminum parts

Aerospace

Aircraft alodine coatings protect lightweight components like landing gear, wing surfaces, UAV frames, and avionics enclosures from extreme conditions. In many cases, the aerospace parts are subjected to an alodine finish before applying the painting.

- Exterior body parts

- Landing gear

- Tail and wing surfaces

- UAV frames

- Avionics enclosures, etc.

Defense and Military

MIL-DTL-5541 standard also complies with the manufacturing of military-grade aluminum components. Compliant with MIL-DTL-81706 Alodine, alodine aluminum. Diverse military and defense items use it for finishing or foundation for paints and further plating.

- Armor panels

- Armed vehicles

- Gun barrel

- Radar system housings

- Drone frames

Electrical Components

The coating enhances corrosion resistance and improves electrical conductivity for metal housings, heat sinks, connecting wires, circuit board shields, and mounting brackets.

- Metal housings of electrical electronics products

- Aluminum heat sinks

- Connecting wires

- Circuit board shields

- Mounting brackets

Automotive Industry

The alodine finish is applied to various vehicle components to avoid degradation due to corrosion and to apply strong and appealing aesthetic paints.

- Engine hoods

- Chassis components

- Radiator brackets

- Body panel

- Wheels

- Suspension parts and casing

Other Applications

Other industries also use the alodine finish on aluminum parts. For example, architectural, decorative, renewable energy, and marine components.

- Solar panel frame

- Wind turbine blade supports

- Power converter casings

- Building architectural exteriors

- Industrial & chemical processing equipment

- Ships and offshore platform items

Alocrom treatment and Iridite finish aluminum are also employed in these contexts.

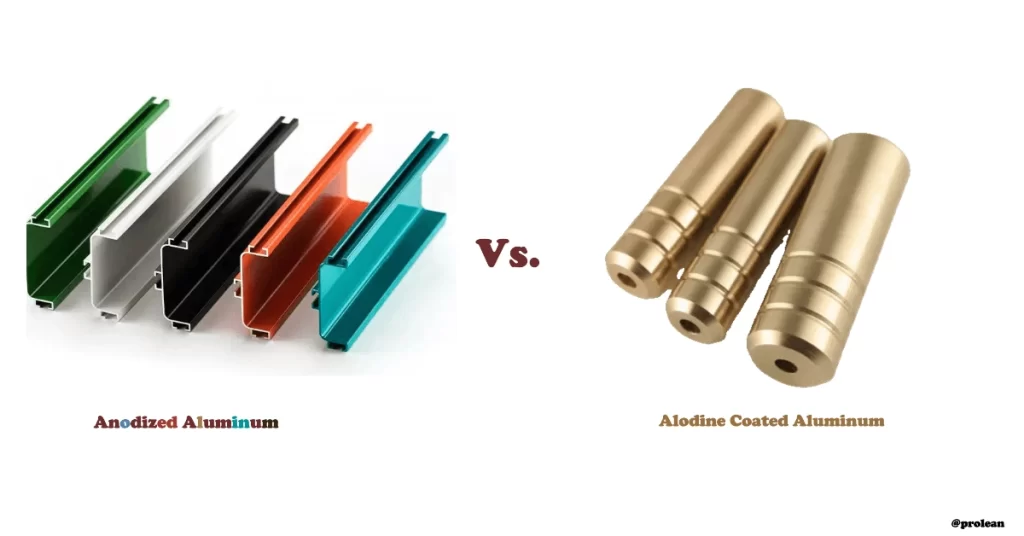

Alodine Coating vs. Anodizing

Unlike alodine, anodizing is an electrochemical process that develops a protective layer of aluminum oxide (Al₂O₃) on the surface, which acts as a natural barrier. However, they both enhance the corrosion resistance. Additionally, anodized aluminum can be dyed into numerous color options and also improves the lubrication properties.

Anodizing vs alodine coating

The anodized surface contains microscopic pores on the surface, applying dyes and sealing helps to absorb the dyes into pores and results in a durable aesthetic.

The table below shows the differences between alodine vs anodize aluminum parts;

| Criteria | Alodine Coating | Anodizing |

| Process | Chemical conversion process without electricity | An electrochemical process that uses an electric current in an acid bath |

| Cost | Economical for small-scale production | It is suitable for medium to large-scale production |

| Corrosion Resistance | Moderate to high corrosion resistance | High corrosion resistance, especially in harsh environments |

| Electrical Conductivity | It retains electrical conductivity | Reduces electrical conductivity due to the oxide layer |

| Coloring Options | Limited to clear or brown shades and gold alodine coating | Wide range of colors available, best for aesthetics |

| Thickness | Thin coating, minimal effect on part dimensions | A thicker oxide layer might affect the tolerances |

| Applications | Aircraft alodine, electrical grounding, marine parts, etc. | Aerospace, medical devices, consumer goods, automotive, etc. |

Try Prolean Now!

Get Alodine Coated Aluminum Parts from ProleanTech

Do you need aluminum parts with alodine chromate conversion finishes? Our factory has been working on finishing CNC machined, sheet metal, casting, and extrusion aluminum parts for more than a decade. We have advanced equipment for immersion and controlling the alodine coating variables.

We protect your aluminum parts with an alodine layer of less than 1 μm. Our engineers closely work with the clients to understand the requirements and deliver the expected results. So, if you need an alodine coating service, contact us today!

Conclusion

Alodine aluminum coating is a popular metal finishing for aluminum parts across industries. Applying its layer enhances corrosion protection in harsh environments. By providing corrosion resistance, serving as a primer for painting, and maintaining electrical conductivity, alodine surface treatment ensures durability and functionality.

Standards like MIL-DTL-81706 Alodine and AMS 2473 Alodine ensure consistent quality, while solutions like Alodine Bonderite enhance application efficiency. Whether for aircraft alodine, Alocrom treatment, or Iridite finish aluminum, this coating delivers long-term protection and aesthetic versatility.

FAQs

Is chromate conversion coating the same as Alodine coating?

Yes, chromate conversion and alodine aluminum refer to the same chemical conversion coating process. Alodine is a brand name for a widely used alodine solution.

What is the functionality of an aluminum Alodine finish?

Alodine aluminum provides corrosion resistance, enhances paint adhesion, and maintains dimensional stability with a thin protective layer.

Are Alodine coated parts durable?

Alodine-coated parts offer moderate durability, especially in terms of corrosion resistance. However, they are not as wear-resistant as anodized finishes.

How thick is the Alodine layer?

The alodine aluminum layer ranges from 0.00001 to 0.00004 inches (0.25 to 1 micron), preserving part dimensions and electrical conductivity.

0 Comments