Vacuum Casting Vs Injection Molding

Vacuum casting and injection moulding are two prevalent techniques. Vacuum casting entails a silicon mold and liquid resins. The cast is made over a master model, and it captures all the details. Then, liquid resin is injected under vacuum, and the air is sucked out of the mold. It is most suitable when you need low volume manufacturing, functional prototypes, or uniform surface parts without wasting money on metal tooling.

On the other side, injection molding uses steel and aluminum molds. These are hardened, and the molten plastic is injected under pressure. It is quick and repetitive, and it can cut thousands of identical components. The initial price of the tooling is more expensive; however, this gets repaid when you require large quantities with strict tolerances and repeat performance.

What is Vacuum Casting?

Vacuum Casting

Vacuum casting process is ideal for producing small-scale, precise rubber parts. It comes in handy when you need a smooth finish but doesn’t want to fork out the money to buy expensive metal moulds.

It starts with creating a master model. These molds are typically made through CNC machining or 3D printing. The master mold is placed in a box(mold frame), and liquid silicone is poured around it. As soon as the silicone becomes hard, it is sliced open to expose the mould.

As a result, the air bubbles are sucked out with a vacuum so that the resin fills all details. Once it dries, the piece is taken away and cleaned. The process is easy to set up and materials-flexible. It uses resins like polyurethane(PU) resin, epoxy resin, silicon resin, and polyester resin. Silicone molds can produce 20 to 25 samples before wearing out. So, it is helpful for prototypes and small batches. (See Also: vacuum forming)

Lead Time for Vacuum Casting in Production

A vacuum cast presently takes one to two weeks to produce. A master pattern and silicone mold are created first. It usually takes three to seven days to execute this step.

When the mould is prepared, we commence casting. When each part is completely cured, we take it off. The time of this curing will depend on the part’s shape and the resin. The process cannot be rushed or abridged.

One mold makes about one or ten parts per day. Output varies with the type of material, wall thickness, and geometry. In complex parts, the cure time between cycles can be longer. (See more: types of casting)

How Many Parts Can Vacuum Casting Produce in a Single Run?

Vacuum Casted Products

Vacuum casting in China is a short-run production. Silicone mold typically makes 20 to 25 castings before it wears out. The exact number depends upon the part size, the material, and the design complexity.

The cast is one pour at a time, and each pour must be cured. An average mold can provide one to ten parts a day. The efficiency can be increased by better-curing resins and simple shapes. Complex parts can minimise this rate since they will take longer cycle times.

The process is most compelling in low to moderate run volumes where speed, price, and part detail must be considered. It is excellent when 20 to 200 pieces of door parts are wanted, and the quality of these units is stable and highly controlled.

Cost of Tools and Parts in Vacuum Casting

Vacuum Casting Master Mold

Compared to metal molds, vacuum casting costs less and much more economical. Silicone moulds take less time to make and do not need high-pressure tooling. It’s cheap for an initial investment and installs quickly.

The larger part of the cost is in the master pattern. It is usually fabricated via SLA 3D printing or CNC. The techniques are sensitive but may be costly. This is why pattern-making is being outsourced by several manufacturers to save cost and lead time.

Curating agents and resin are also cheap. You may get various grades, including transparent, flexible, or flame-retardant. Vacuum casting is still one of the most affordable methods of producing small quantities of plastic components compared to injection molding.

Try Prolean Now!

What Is the Tolerance of Vacuum Casting?

A typical tolerance of vacuum casting plastic is about 0.3 millimeters. This varies according to the type of plastic, the part size, and shape. Simpler parts and smaller ones are more accurate. There may be a slight variation in bigger or complex shapes.

The silicone mold reads details, and minor changes may occur as the mold matures. To maintain quality in every batch, we check each batch. If you require closer tolerances, we can discuss the optimum choices before commencing.

Is Vacuum Casting Expensive?

No, vacuum casting is affordable for small runs and prototypes. The molds cost less and take less time to make than metal ones. This helps keep your overall costs down.

It is a good option when you need a few dozen to a couple of hundred parts without a significant upfront cost. It works well if you want quick delivery and reliable quality.

What Is Injection Moulding and How Does It Work?

Industrial Injection Molding Machine

Injection molding is an effective method of rapidly producing plastic components in a precise manner. Hot plastic is pressed into a mold using pressure, which aids in accurately filling all the details. It is ideal when you produce many parts, all of which must be identical.

We deploy the latest equipment, such as CNC and EDM machines, to make the molds. These tools are exact and cut the mold to high standards. So, we guarantee that the end products will be according to your design.

Since the process employs heat and pressure, molds have to be strong. They are constructed from hardened steel or aluminum. This maintains strength and durability throughout numerous production runs.

How Injection Moulding Handles Production Volume

Injection Molded Parts

The injection molding service applies to high volume manufacturing runs. After a mould is prepared, it can mass-produce thousands of the same part. This only makes it cheaper when you require a lot of pieces.

The parts made are dependent upon size and design. The smaller and simpler parts can be produced within a shorter time. Parts with complexity will consume more time and could decrease production.

Injection moulding provides uniform quality regardless of the volume. It is effective in medium and large batches.

Tools and Parts Cost for Injection Moulding

Injection Molding Mold(Tool)

The tools need to be of high quality. Hence, the initial cost is relatively high. The molds are constructed of hardened steel or aluminium. They require specific machining to suit your particular design.

A mould has numerous components, and ejection pins or springs are some of them. These parts collaborate to form and launch every piece properly.

Due to the size and the materials, the injection molding cost could reach many thousands of euros, and in other instances, it could soar even higher.

What Is the Tolerance in Injection Moulding?

Aerospace Injection Molded Product

In injection molding process, the parts must fit together and work as planned. Industry standards like DIN 16742:2013 give guidelines on acceptable tolerances for different part sizes.

Using these standards helps keep parts consistent across production. Designing with these tolerances in mind reduces errors and saves time later on.

Try Prolean Now!

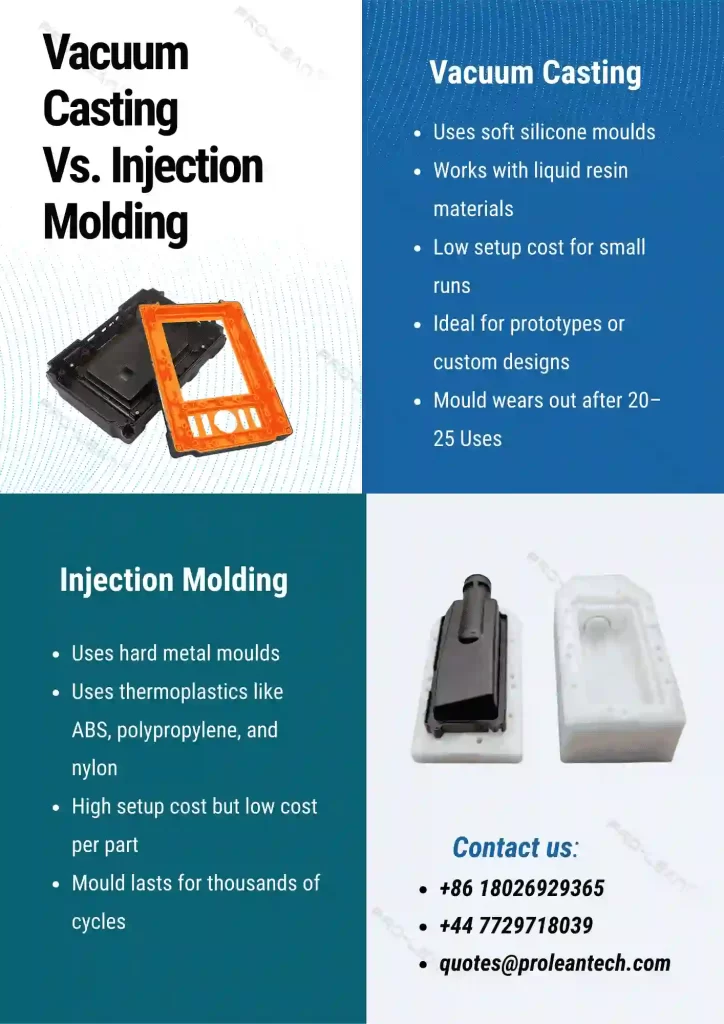

Difference Between Vacuum Casting Vs Injection Molding

Infographic: Vacuum Casting Vs Injection Molding

In vacuum casting, soft silicone molds and liquid resin are utilised. It takes little time to install, is low-cost when making a small run, and is suited to prototypes. Mold life is around 20 – 25 parts.

On the other hand, injection moulding involves complex metal molds and a liquefied plastic. It requires more time and money to be established, but it can produce thousands of replica parts within a specific time. The mold is permanent and takes years to wear out if carefully handled.

In a nutshell, vacuum casting is applicable in small batches at reduced initial cost. Injection has been applied to large-volume productions. It has the benefit of lower cost per part in the long-term view.

Types of Moulds and Materials Types

In vacuum casting, moulds are cast using a master molds. These molds are fast and easy to construct, but cannot last long. The injection moulding technique involves strong metal molds filled with molten plastic. They are lasting and would not be worn out within several years.

Time and Cost of Set Up

Vacuum casting is fast to install, and it is cheaper initially. This is why it is a reasonable option when parts are needed quickly and you want to save money. In contrast, the molds are heavy and costly to produce. Hence, it takes longer to prepare and has higher setup costs since injection moulding is time-consuming.

Optimal Application

Vacuum Casting suits prototypes, custom designs, and small runs best. When many thousands of the same piece are needed, and quickness and efficiency matter, injection molding is preferable.

Production Speed and Part Size

Vacuum casting is slower. Because each silicone mould has a limited number of parts it can make until it becomes worn out, injection moulding is far quicker. It can manufacture large quantities within a short period.

Mold Life

With vacuum casting, it is typical to expect the silicone mold to last 20+ parts. In injection molding, a good metal mold may last several years. It can produce thousands or even millions of parts. (Read more: Die Casting VS Injection Molding)

Choosing the Right Manufacturing Process: Vacuum Casting Vs Injection Molding

When choosing between vacuum casting vs injection moulding, there are a few key points to consider.

First, reflect on how many parts of volume you need. Vacuum casting works well for small runs, usually making 1 to 10 parts daily. While injection moulding suits bigger jobs and can produce hundreds or even thousands daily.

Next, consider tooling costs. Silicone molds for vacuum casting cost a few hundred to a few thousand pounds. Meanwhile, steel or aluminium molds for injection molding can cost £10,000 or more.

Part cost depends on volume. Vacuum cast parts are more expensive per piece due to low volumes and extra labour. Therefore, injection moulding becomes cheaper once you need 1,000 parts or more.

Also, consider material options. Vacuum casting works with resins like ABS, PP, PC, and elastomers. Injection moulding supports a wide range of thermoplastics and thermosets for different needs.

Finally, silicone moulds last for about 20 to 50 parts when it comes to mold lifespan. Steel or aluminium moulds for injection moulding can last for hundreds of thousands of parts.

Summary

This article explained vacuum casting vs injection moulding. It outlines how each process works and when to choose them.

ProLean Tech offers a full range of manufacturing services, including vacuum casting service, injection molding, die casting, compression molding, and more. We support your projects from prototype to production with quality and precision.

FAQ’s

Q1: How much tolerance can be achieved with vacuum casting?

Vacuum casting may reach a tolerance of about ±0.3 mm. The tolerance depends on part size, geometry, and the type of plastic used.

Q2: How many parts can a single silicone mold produce?

A silicone mold may yield 20 to 50 parts before it becomes worn out. The exact figure will depend upon the design, size, and type of resin used.

Q3: What materials are suitable for injection moulding?

Injection moulding can process thermoplastics like ABS, polypropylene, nylon, and thermosetting plastics.

Q4: How long does tooling take for injection moulding?

Injection molding tooling can take from 4 to 12 weeks. This time can vary and depends on the mold complexity, the number of cavities, and finishing requirements.

0 Comments