The manufacturing industry has come a long way over the past few decades. With rapid advancements in technology, it is no surprise that new methods and innovations are being introduced to enhance the way products are designed and produced. From 3D printing to robotics, these advancements have revolutionized the manufacturing process, leading to increased efficiency, reduced costs, and improved product quality.

One of the most significant innovations in manufacturing technology has been the introduction of laser engraving machines. These high-tech devices have transformed the way businesses create and customize their products, allowing for precise and intricate designs that were once impossible to achieve. This comprehensive guide will explore the world of laser engraving machines, providing an in-depth look at their capabilities, benefits, and the factors to consider when choosing the right machine for your needs.

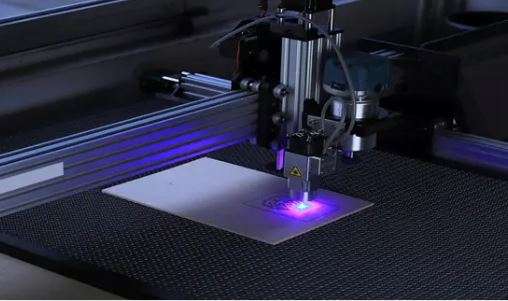

The Rise of Laser Engraving Machines

Laser-engraving on an aluminum plate

Laser engraving machines have risen in popularity in recent years, thanks to their versatility and ability to create detailed designs on a wide range of materials. From wood and metal to glass and plastic, these machines have become an essential tool for businesses seeking to create unique and high-quality products. The demand for personalized and custom items has never been higher, and laser engraving machines have emerged as a top choice for meeting this demand.

The rise of laser engraving machines can be attributed to several factors. Firstly, the technology has become more affordable, allowing small businesses and hobbyists to invest in these machines. Secondly, the software used to control the machines has become increasingly user-friendly, enabling more people to quickly learn and master the process. Finally, the growing awareness of the benefits of laser engraving, such as increased precision and reduced waste, has encouraged more businesses to adopt this technology.

Understanding Laser Engraving Technology

Laser engraving is a non-contact process that uses a focused beam of light to create a design on a material’s surface. The laser heats the material, causing it to vaporize or change color, leaving a permanent mark. Laser engraving machines use computer software to control the movement of the laser beam, allowing for intricate and precise designs to be created.

There are three main types of lasers used in engraving machines: CO2, fiber, and diode lasers. CO2 lasers are the most common and are suitable for engraving a wide range of materials, including wood, acrylic, and glass. Fiber lasers are ideal for engraving metals and plastics, while diode lasers are best suited for engraving materials with low melting points, such as plastics and rubber.

Laser engraving machines come in various sizes and configurations, from small desktop models to large industrial machines. The choice of machine will depend on factors such as the materials being engraved, the size of the projects, and the level of detail required in the engraving.

Types of Laser Engraving Machines

a. CO2 Laser Cutter

CO2 laser cutters are the most popular type of laser engraving machine, thanks to their versatility and ability to engrave a wide range of materials. These machines use a CO2 gas mixture as the active laser medium, which allows them to produce a high-power, continuous laser beam. CO2 laser cutters are ideal for engraving materials such as wood, acrylic, glass, leather, and fabric.

One of the key benefits of CO2 laser cutters is their ability to produce intricate designs with smooth edges and fine details, making them a popular choice for industries such as woodworking, signage, and textile manufacturing.

b. Fiber Laser Engraver

Fiber laser engravers use a solid-state laser source, which generates a high-energy beam of light that is focused onto the material’s surface. These machines are specifically designed for engraving metals and certain types of plastics. Fiber laser engravers are ideal for applications such as jewelry design, aerospace, and automotive manufacturing, where precision and durability are essential.

Fiber laser engravers offer several advantages over CO2 laser cutters, including faster engraving speeds, lower maintenance requirements, and a longer lifespan. However, they are generally more expensive than CO2 laser cutters, which may be a consideration for some businesses.

c. Laser Etching Machine

Laser etching machines are similar to laser engraving machines, but they use a different process to create designs on the material’s surface. Instead of vaporizing the material, laser etching machines use the heat generated by the laser beam to cause a chemical reaction that changes the material’s color. This process is ideal for creating high-contrast, permanent marks on materials such as metals, ceramics, and glass.

Laser etching machines are often used in industries such as electronics, medical devices, and automotive manufacturing, where the durability and legibility of markings are critical.

Key Features of Industrial Laser Cutters

Industrial laser cutters are designed for high-volume production and offer a range of features that set them apart from smaller, desktop models. These features include:

| Key Features of Industrial Laser Cutters | Description |

|---|---|

| Larger work area | Industrial laser cutters typically have a larger work area, allowing them to handle bigger projects and process multiple parts simultaneously. |

| Higher power output | Industrial machines have more powerful laser sources, enabling them to cut and engrave thicker materials and work at faster speeds. |

| Advanced control software | Industrial laser cutters come with sophisticated software that allows for greater control over the engraving process, including the ability to import complex designs and adjust settings for optimal results. |

| Automated material handling | Some industrial laser cutters are equipped with automated material handling systems, which can load and unload materials, reducing manual labor and increasing productivity. |

Benefits of Using a Laser Cutting Machine

Laser-cutting machines offer a range of benefits for businesses and individuals alike. Some of the key advantages include:

- Precision and accuracy: Laser engraving machines can create incredibly detailed designs with high precision, allowing for intricate patterns and logos to be engraved on virtually any material.

- Speed: Laser cutting machines can work at high speeds, reducing production time and increasing efficiency.

- Reduced waste: Because laser cutting is a non-contact process, it produces less waste and fewer material deformations, leading to lower costs and a more eco-friendly production process.

- Versatility: Laser engraving machines can work with a wide range of materials, making them suitable for various applications and industries.

- Low maintenance: Laser cutting machines require minimal maintenance compared to traditional cutting methods, reducing downtime and associated costs.

Factors to Consider When Choosing a Laser Engraving Machine

Before investing in a laser engraving machine, there are several factors to consider:

| Factors to Consider | Description |

|---|---|

| Materials | Consider the type of materials you will be working with and choose a machine that is compatible with those materials. |

| Size and power | Determine the size of the projects you will be working on and select a machine with a suitable work area and power output. |

| Software compatibility | Ensure the machine’s software is compatible with your existing design software and easy to use. |

| Budget | Consider your budget and select a machine that offers the features you need within your price range. |

| Support and warranty | Look for a reputable manufacturer that offers excellent customer support and a comprehensive warranty on their products. |

ProleanTech: Your Trusted Partner for Laser-Engraving Projects

When it comes to laser engraving, ProleanTech is the trusted partner for businesses and individuals seeking high-quality, reliable machines. With a wide range of CO2 laser cutters, fiber laser engravers, and laser etching machines, ProleanTech offers the perfect laser engraving solution for every application.

Our knowledgeable team of experts is on hand to help guide you through the selection process, ensuring you choose the right machine for your needs.

Our team of experts takes the time to get to know our customers, their needs, and their goals, so we can provide personalized recommendations that are tailored to their unique requirements. Let us help you make the most of your investment and find the perfect solution for your needs today!

Conclusion

Laser engraving machines have revolutionized the manufacturing industry, offering a range of benefits that have made them an essential tool for businesses and individuals alike. Whether you’re looking to create intricate designs on wood, metal, glass, or plastic, there’s a laser engraving machine out there that’s perfect for your needs. By understanding the different types of machines available and the key features to look for, you can make an informed decision about the best machine for your business.

FAQ’s

- What is a laser engraving machine?

- A laser engraving machine is a device that uses a focused beam of light to etch designs onto a material’s surface. The laser heats the material, causing it to vaporize or change color, leaving a permanent mark.

2. What materials can be engraved with a laser engraving machine?

Laser engraving machines can work with a wide range of materials, including wood, metal, glass, plastic, leather, and fabric.

3. What types of laser engraving machines are available?

There are three main types of laser engraving machines: CO2 laser cutters, fiber laser engravers, and laser etching machines.

4. What are the benefits of using a laser cutting machine?

Laser cutting machines offer a range of benefits, including precision and accuracy, speed, reduced waste, versatility, and low maintenance requirements.

5. What factors should be considered when choosing a laser engraving machine?

Factors to consider when choosing a laser engraving machine include the materials being engraved, the size and power of the machine, software compatibility, budget, and support and warranty offered by the manufacturer.

0 Comments