High volume production machining is about producing large quantities of parts quickly and accurately. It’s used when you need repeatable results at scale. You’ll find it in the automotive, aerospace, and consumer electronics industries.

Moreover, the process relies on automation, tight tolerances, and consistent setups. Once programming is done, machines run the same part 1000 times with minimal to no variation. It allows you to:

- Save Time,

- Cut Costs Per Unit and

- Keep Your Production on Schedule

This guide will walk you through all the intricacies of high volume CNC machining.

High Volume CNC Machining Process

CNC Machined Flanges

In precision manufacturing, an optimized process starts with DFM. It keeps everything on track when running a large volume CNC turning project. The planning, checking, and final checks aim to improve speed, correctness, and production consistency.

Here is how the process works to create parts you desire, right and on time.

1. Know Your Project Needs

Our team starts production by thoroughly reviewing your project. You provide your specifications, and we explain everything. This initial communication prevents you from being surprised later. Besides, it ensures that your parts will be produced to the design specifications.

2. Turning Designs Into Machine Code

G-code execution

Our programmers use state-of-the-art CAM software. It translates your CAD files to CNC instructions. This code instructs the machine to cut and shape every piece. Appropriate programming implies that each piece fits your design.

3. Choosing the Right Tools

It is also essential to choose the right cutting tools for high volume precision turned parts. We select drills, mills, and cutters based on your material and geometry. Having the right tools means no time is wasted, and the machine keeps running smoothly.

4. Setting Up the Machines

Once we have tooled, we set the CNC milling machines into production. Our experienced technicians prepare equipment and test pieces. This is done to ascertain that the process is right before the full production commences.

5. Production Running

The machines are automatic once the setup has been completed. They make components in continuous production, and lead times are kept low. Our technicians keep an eye on the operation to identify the problems early.

6. Inspecting for Quality

Quality Inspection Room

We inspect parts regularly. Checks are made to see that each piece is within your tolerances and operates correctly. In case of a problem, we rectify it on the spot to sustain quality.

Practical Benefits of CNC Precision Machining

High volume CNC machining comes with unique advantages to count on. It helps you produce more, waste less, and keep costs under control.

Faster Production Keeps You on Schedule

Automated CNC machines operate 24/7. This implies that you receive parts quicker and can always meet your deadlines, with no manual time wastage or sluggish configurations.

Consistent Production

When the program is established, the machine does the job verbatim. These machines minimize errors and result in fewer rejected parts, so you can save time and be cost-effective.

Scaleable for Large Runs

Although it is not easy to set up, the price per part declines rapidly as the volume increases. It means fewer working hands and fewer materials waste translate to more budget value.

Ability to Make Complex Parts

CNC Machined Complex Parts

CNC machines work on precision shapes and tight tolerances. You will be able to make parts that other processes cannot. This will enable you to come up with more innovative and better products.

Less Waste Means More Savings

Accurate cutting reduces the material scrap. Efficient use of raw materials minimizes the costs and promotes environmentally friendly production.

No Order Size Limit

After the process has been validated, scaling production becomes more efficient and predictable. CNC machining expands as you need no compromise of quality and speed.

Try Prolean Now!

Industries that Rely on High-Volume CNC Machining

The application of high volume CNC milling is broad, and it is used in various industries requiring accuracy and quantity. Here are the common industries that are dependent on this technology.

Automotive Industry

CNC Automotive Machined Parts

In the automotive industry, CNC parts are found in engines, transmissions, and brakes. It also defines elaborate interior and exterior features. The process assists automakers in maintaining quality at a mass scale.

Aerospace Industry

CNC Machined Aerospace Parts

CNC machining is used in aerospace on vital components. These are the engine parts, landing gears, and frames. Moreover, it works with rigid materials that require strength and safety.

Electronics Industry

The electronics industry requires small and accurate components in large quantities. Connectors, heat sinks, and housings are precision-made using CNC machines. Even minor mistakes may lead to significant issues.

Medical Industry

5 Axis CNC Machined Medical Parts

Medical equipment demands high precision and stringent quality. Surgical tools, implants, and dental parts are made by CNC machining. It allows all medical parts to be safe and regulatory.

Industrial Applications

Industrial manufacturers employ CNC machining to create machinery parts and automation components. It deals with hydraulic and pneumatic systems, metals, and plastics. This flexibility augurs well with high production requirements.

Consumer Electronics

Consumer phones and laptops require complicated, intricate components. CNC machining provides precise detail, high-quality looks, and reliable function.

Power and Energy Generation

CNC machines are used in power plants and renewable energy sectors to make turbines, generators, and compressors. These components should be steady and stable in severe environments.

Alternatives to High-Volume CNC Machining Services

If you require additional options for high-volume CNC machining, various production processes can suit your project. These techniques bring advantages, based on your parts and volume.

Injection Molding

Injection Molded Y-Connectors

Injection molding is well-suited for the large production of plastic parts. It is ideal for complicated shapes as well as small tolerances. It is commonly applied to the automobile, electronics, and medical sectors.

3D Printing

3D printing constructs the parts in layers using digital CAD files. Although it is typically applied to CNC prototype or small quantity production, it can now accommodate small to high-volume production with design flexibility. It is an optimal method when you need custom parts or quick design changes.

Stamping

Metal Stamped Parts

Sheet metal is stamped with presses and dies. It fabricates uniform components quickly and at a low price. It is an appropriate technique for automotive panels, metal brackets, and electronic enclosures.

Casting

Metal Cast products

Casting entails pouring molten metal or plastic into molds. It is good at producing complicated metal components in bulk. Typical examples are:

- Die casting

- Investment casting, and

- Sand casting

Usually, these techniques are applied in the automotive and industrial industries.

Challenges In High Volume CNC Machining

The transition between small-run and large-scale CNC manufacturing is not easy. You must overcome these challenges by developing intelligent solutions to maintain production efficiency.

Challenge 1: Balancing Cost with Volume

People do not perceive CNC as economical in mass production. The price reduces as the volume increases, but only when you streamline each step. Reducing cycle time and part design that is easier to machine saves you money as you scale.

Challenge 2: Keeping Up with Production Speed

In big runs, speed is crucial. The CNC machines are step-by-step; thus, a process can be delayed. Using multiple-axis machines and running them together helps make more parts without losing accuracy.

Challenge 3: Consistent Quality at Scale

Production of 1000s of identical parts does not allow you to make quality slip-ups. It requires constant observation and checks during the run. This will allow you to identify defects early enough and ensure the same quality throughout the end.

Challenge 4: Selecting Suitable Materials

All materials work differently. Some metals or plastics require a longer time, or wear out tools quickly. So, it’s important to know the properties of the material you are going to work with before production. It will avoid delays and additional expenses. In case of doubt, refer to machining professionals for the most suitable one.

Challenge 5: Seamless Integration with Supply Chains

CNC machining must be synchronized with ordering, inventory, and shipping. Effective communication and software integration avoid mistakes and keep your project on schedule.

Challenge 6: Minimizing Setup Time and Machine Downtime

More time is needed for long setup times. The minute delays accumulate in high-volume jobs. Rapid changeover fixtures and robotically controlled setups can keep the machines running longer and accelerate the process.

Try Prolean Now!

Materials and Technologies in High-Volume CNC Machining

High volume CNC Machining accommodates many materials from metals to plastics. Metals like aluminum, stainless steel, brass, copper, and titanium are common. They provide high strength and durability for long-term use.

Besides, plastics like ABS, nylon, PEEK, and polycarbonate are also widely used. These materials are lightweight and handle heat and chemicals well.

To keep production fast and accurate, we employ automation and multi-axis machines.

- Automation helps reduce mistakes and speeds up your machining work.

- Multi-axis Machines can shape complex parts in fewer steps. It saves your time and delivers high precision.

Using the right materials with advanced tools gives reliable parts, even when making large quantities.

Finishing Options for High-Volume CNC Production

It is not always only about the looks. It ensures that parts have longer life, better performance, and fit without issues. The appropriate finish selection may save you time and money when you produce large quantities.

Anodizing

Anodized Pedical Screws

Anodizing is applied to aluminum to make it more rigid and corrosion-free. Its thin yet hard coating safeguards the part against wear and tear. It offers vibrant and consistent color options, which are essential when you require all the pieces to be the same.

Powder Coating

Powder Coating Part

The part is coated with powder, providing a thick, strong coating resistant to scratches and rust. It does not drip or run like paint. It applies through a paint gun, and your parts come out smooth and consistent. So, it’s a good choice where the parts are subjected to rough treatment or conditions.

Polishing

Polishing Turned Parts

Polishing takes away sharp edges and rough surfaces. It makes the parts fit better and minimizes friction between parts that move against each other. Moreover, a smooth surface will reduce the chances of trapping dirt or rust in the parts.

Deburring

Manual deburring metal piece

Parts produced may contain small burrs or sharp pieces of metal, which can cut or make parts an inadequate fit. Those are cleaned up by deburring, which makes the parts simpler to handle and assemble. Automated deburring maintains this process uniform and quick regarding large runs.

Plating

Colorful aluminum alloy plating

Plating involves a thin layer of metal, such as nickel or chrome, added to improve corrosion resistance and, in some cases, wear performance. It is also able to enhance electrical conductivity when it is required. This finish is effective on the parts subjected to heavy use or application of a particular look.

Passivation

Passivation clears up the remaining iron particles of stainless steel parts. This helps the metal to be rust- and corrosion-resistant. It is a basic chemical reaction, but it is needed where the parts are subjected to extreme conditions (clean or harsh), such as in medical equipment or food processing.

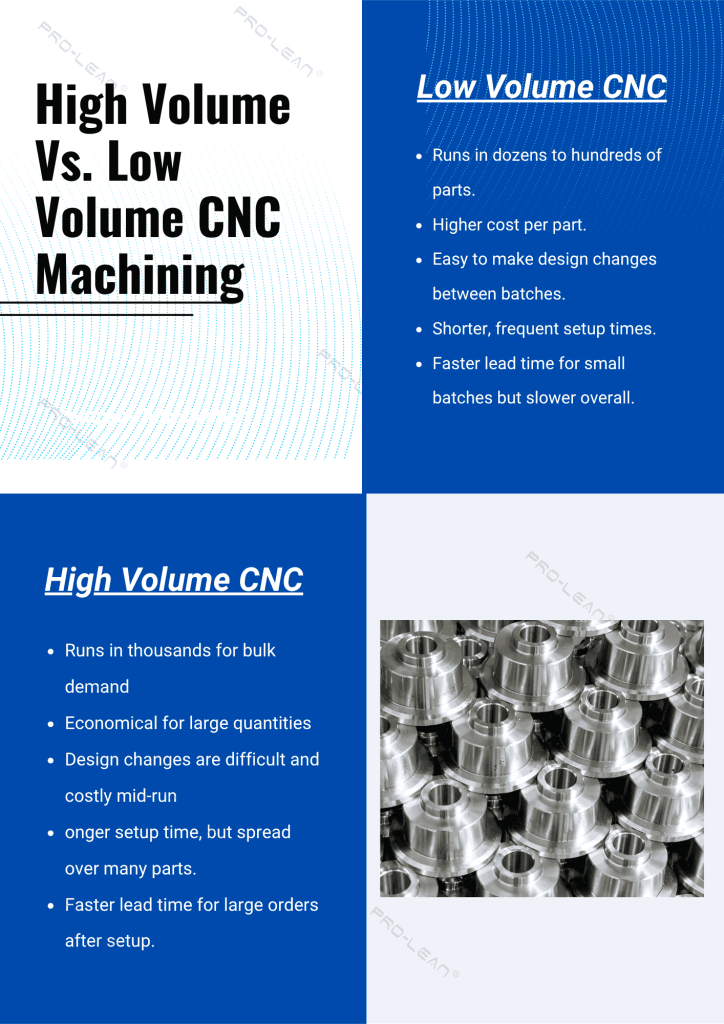

Differences Between High-Volume and Low-Volume CNC Machining

High Volume Vs. Low Volume CNC Machining

Here are the key differences between high-volume and low-volume CNC machining:

| Factors | High-Volume CNC Machining | Low-Volume CNC Machining |

| Production Scale | Runs in the 1000s to meet bulk demand | Runs of a few dozen to a few 100 parts |

| Cost per Part | Economical for many units | Higher cost due to frequent setups and small runs |

| Design Changes | Difficult and costly to implement mid-run | Easy to make design tweaks between batches |

| Tooling Investment | Requires specialized tools and fixtures | Uses standard tools, with less upfront cost |

| Quality Assurance | Automated inspection systems for uniform quality | Manual checks, more hands-on attention |

Final Highlights

This article has covered:

- High volume CNC machining and its process

- Manufacturing industries that benefit from it

- Detailed standard finishing options and when to use each

- Covered significant production challenges and practical solutions

- Shared alternative manufacturing methods

- A detailed comparison between high vs. low-volume machining

Our Advice: If you plan a high-volume CNC project, focus on design, material choice, and finish requirements early. These decisions save you time, reduce costs, and improve results at scale.

Need Precision Machined Parts at Scale?

Prolean Tech provides cheap CNC machining service with:

- Tight tolerances

- Short lead times

- End-to-end support

Whether you’re scaling up or starting fresh, we’ll keep quality uniform from part one to part 10000. Get in touch today and let’s build something that performs better and ships faster.

FAQ’s

Q1. How do you handle tool wear during long production runs?

We use automated tool monitoring systems during the run. It allows us to avoid part variation and maintain surface quality the same across every unit.

Q2. Can I submit multiple part numbers under one high-volume order?

Yes, if the parts share similar features and require the same material and setups, we can integrate them into a single production plan. It helps you optimize cost and lead time.

Q3. What data do you provide for quality assurance in large orders?

- Upon project completion, we provide complete inspection reports, dimensional records, and material certifications.

- Upon request, we provide first article inspection (FAI) for critical parts.

0 Comments