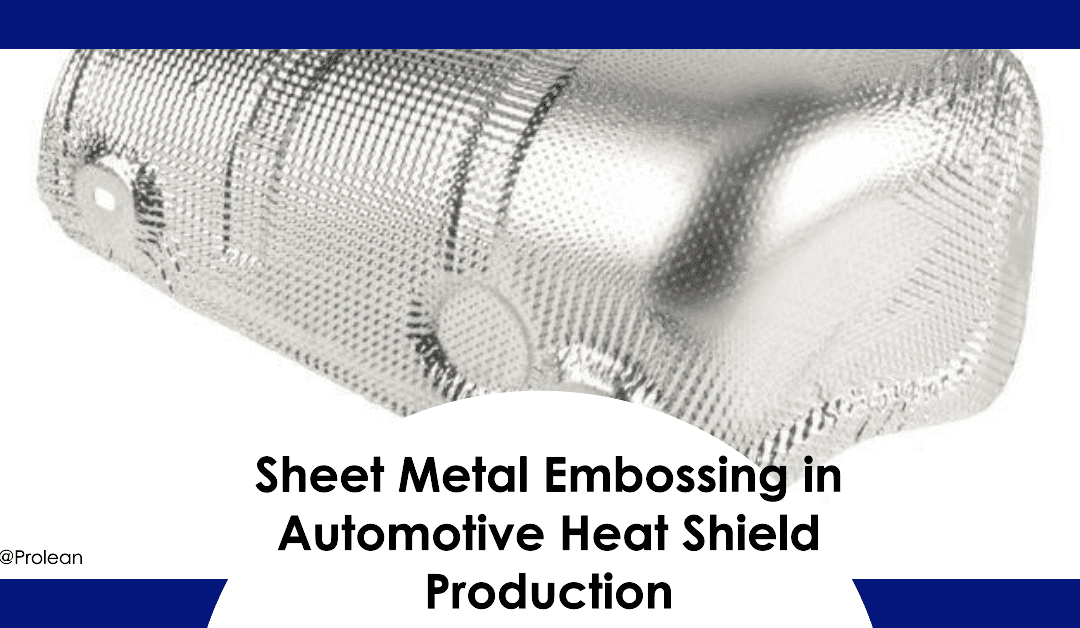

Jun 15, 2023 | Case Study, Industry Application, Sheet Metal Fabrication

Sheet metal embossing, an essential technique in the manufacturing industry, plays an instrumental role in automotive manufacturing, especially in the production of automotive heat shields. The process of embossing enhances the structural integrity and thermal...

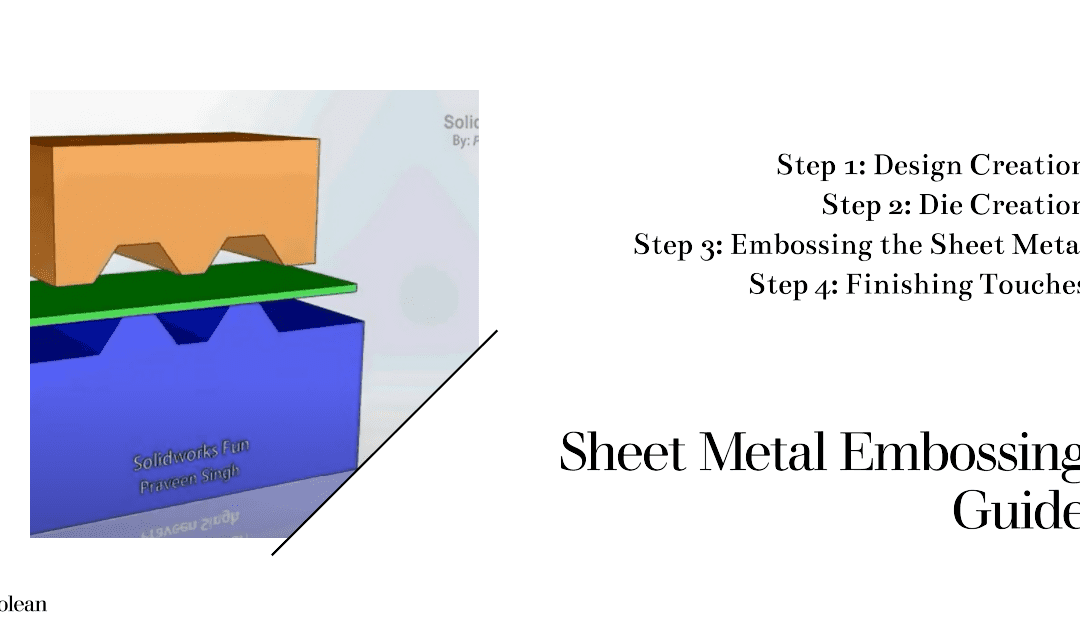

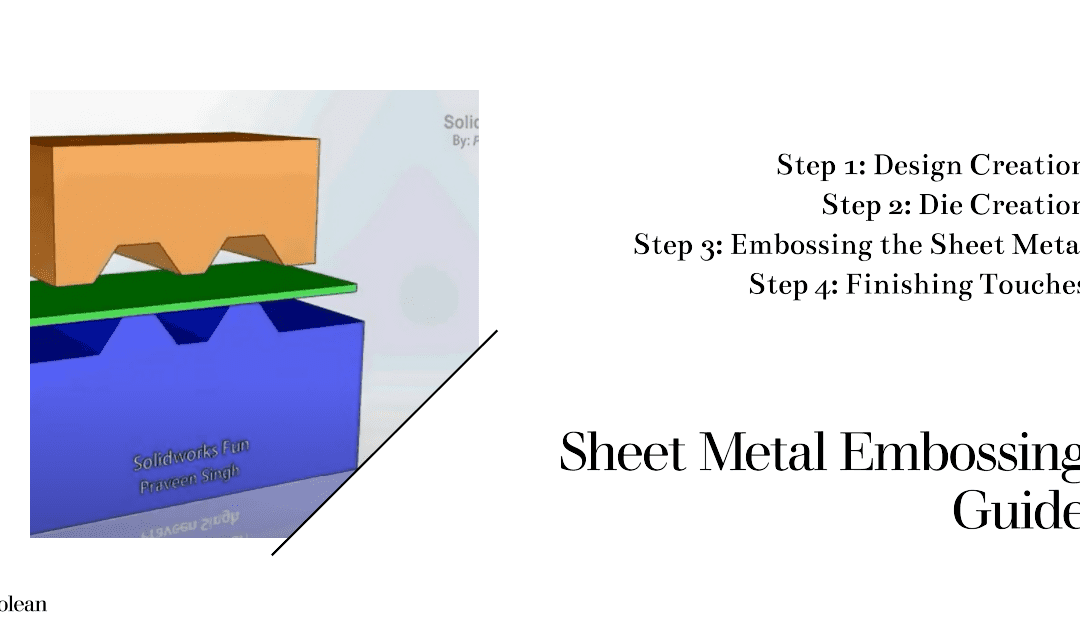

Jun 15, 2023 | Sheet Metal Fabrication

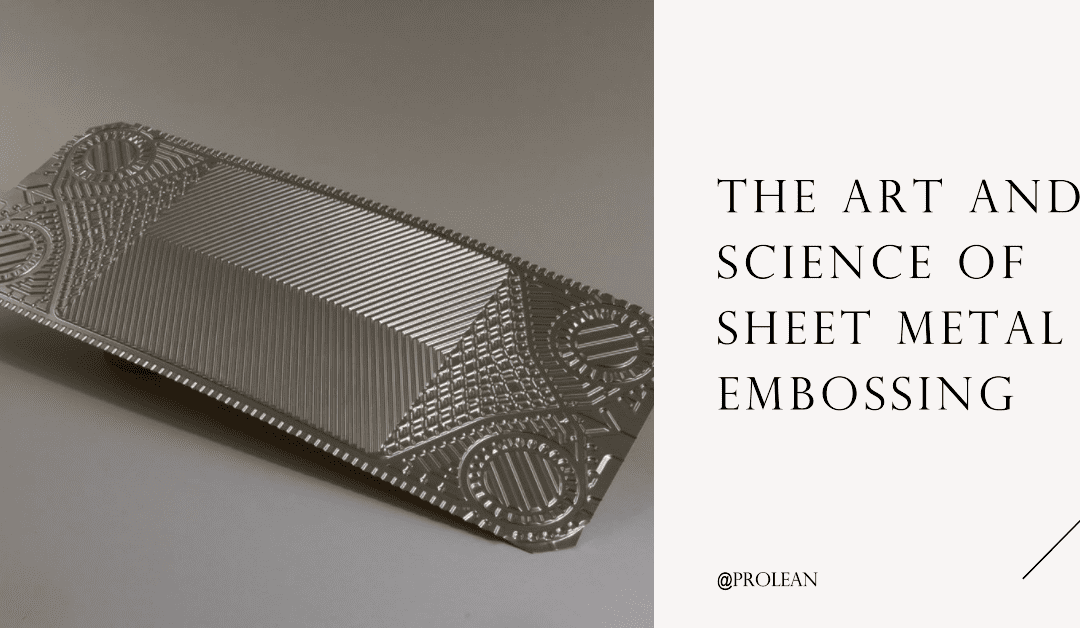

Embossing is an art form that has long been appreciated for the dimension and texture it brings to metalwork. In the context of sheet metal fabrication, embossing is a technique used to create raised or sunken designs or reliefs in metal. The process is versatile,...

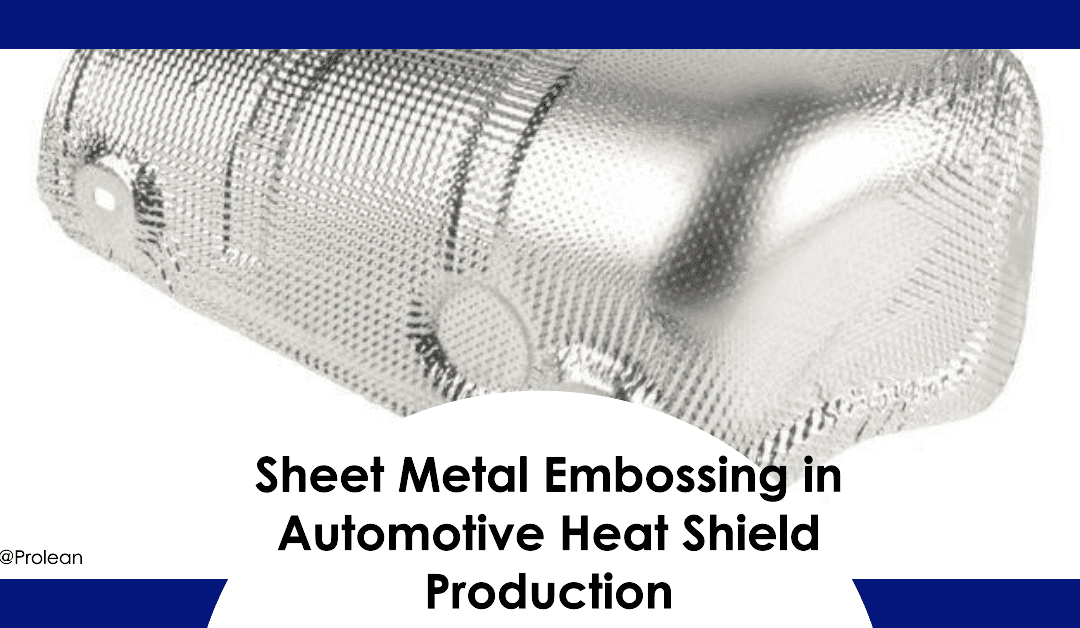

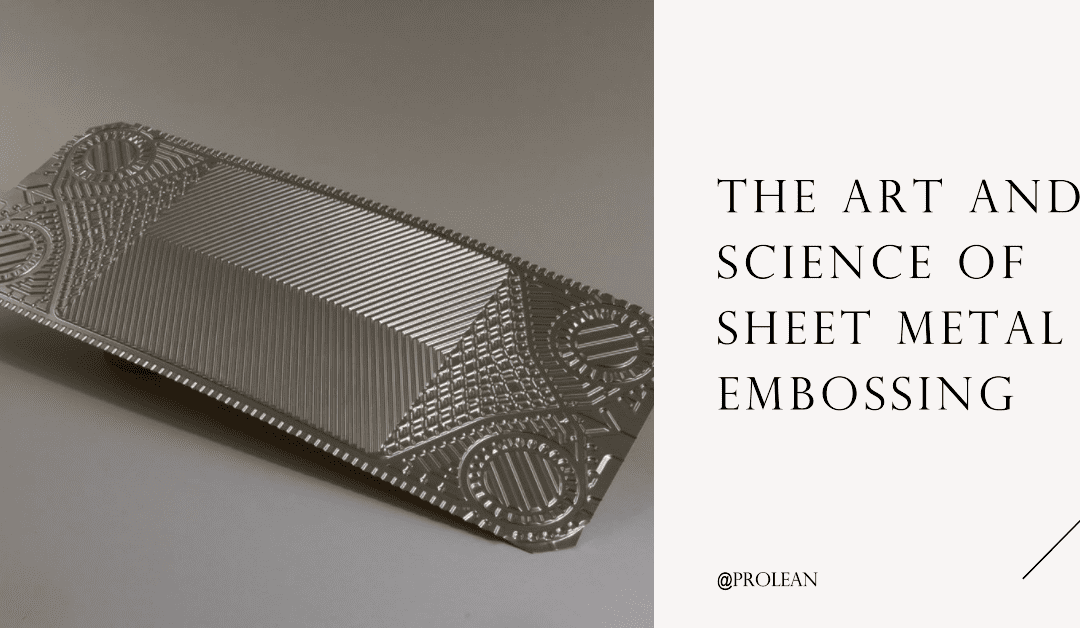

Jun 15, 2023 | Sheet Metal Fabrication

The embossing process is a fascinating interplay of science and art. It brings a unique aesthetic quality to sheet metal, enhancing not only its visual appeal but also its structural rigidity and functionality. With origins tracing back to ancient civilizations,...

Jun 14, 2023 | Case Study, Sheet Metal Fabrication

The field of medical manufacturing is characterized by precision, stringency, and innovation. Surgical instruments are at the heart of this field, and their manufacturing demands not just accuracy but also a high degree of complexity. Among the various processes...

Jun 14, 2023 | Sheet Metal Fabrication

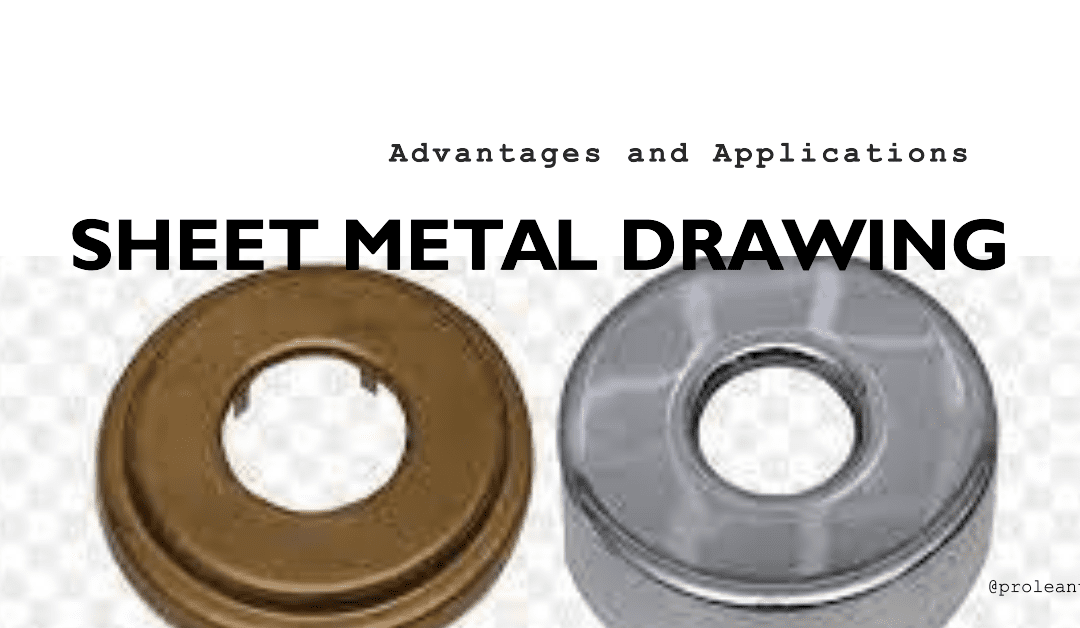

The sheet metal drawing process, a key aspect of metalworking, is an art of transformation that has been perfected over centuries. It breathes life into mundane metal sheets, sculpting them into a myriad of shapes and forms to meet a plethora of requirements. From...