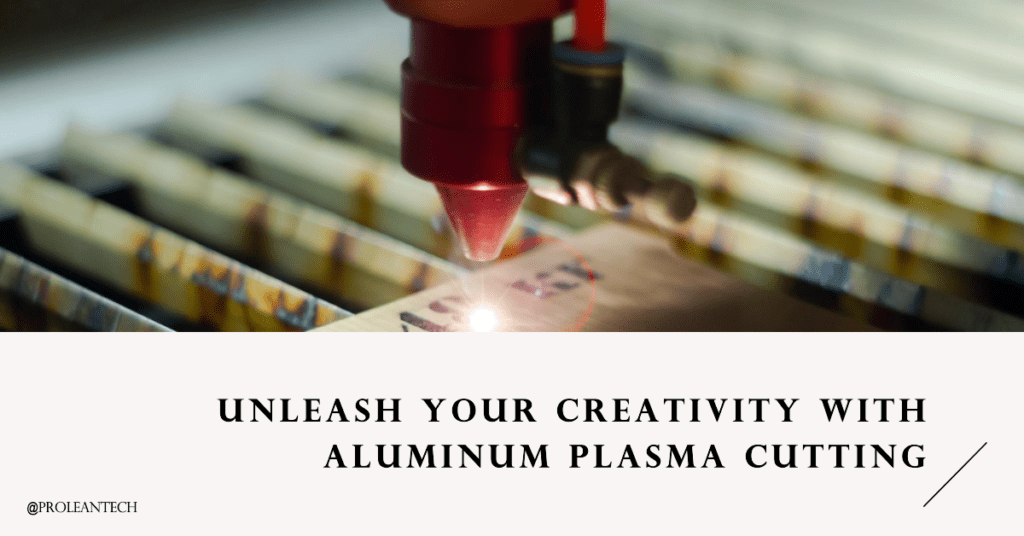

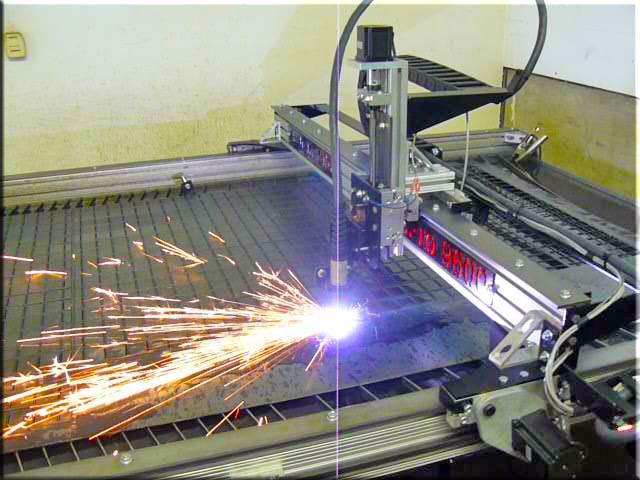

As one of the most abundant elements on Earth, aluminum offers a multitude of benefits that make it a preferred choice for many industries. Its lightweight nature, impressive strength, and superior corrosion resistance are just a few of the attributes that lend aluminum to a vast array of applications. Yet, it’s the incorporation of plasma cutting that truly unlocks aluminum’s full potential, allowing us to shape, design, and manufacture with an unmatched level of precision and efficiency. Through plasma cutting, aluminum morphs into complex and intricate shapes that enable innovation across sectors, from automobiles and aircraft to electronics and architecture.

| Capability | Applications | Alloys | Tolerances | Wall Thickness | Max Size | Strengths |

| CNC Mill CNC Lathe |

Accurate automotive, aerospace, construction, home appliances, defense, electrical, and electronic parts | Aluminum (MIC6) Aluminum (2024) Aluminum (5052) Aluminum (5083) Aluminum (6082) Aluminum (6061-T6) Aluminum (6063) Aluminum (7075-T6) |

Not lower than ±0.125mm (±0.005″) based on the drawing ( ISO 2768) | Minimum 0.80 mm (~0.03”); may vary depending on alloy and wall thickness-to-planar dimension ratios | 200 x 80 x 100 cm | Exceptional strength-to-weight ratio, machinability, thermal & electrical conductivity, and highly resistant to corrosion. |

In this article, we delve into the myriad applications of aluminum plasma cutting, uncovering its transformative influence on industry and innovation.

Embracing Speed and Precision in the Automotive Industry

The automotive industry is at the forefront of adopting advanced manufacturing technologies, and plasma cutting is no exception. With a constant eye on performance and efficiency, this sector values the lightweight yet robust nature of aluminum. But when combined with the rapid and precise cuts offered by plasma cutting, aluminum becomes a cornerstone of automotive manufacturing.

Table 1: Plasma Cutting Applications in the Automotive Industry

| Application | Benefit |

|---|---|

| Body Panels and Frames | Plasma-cut aluminum components are lightweight yet sturdy, contributing to fuel efficiency while maintaining vehicle safety. |

| Engine Components | Plasma cutting allows for the creation of intricate aluminum engine components, optimizing vehicle performance through precision shaping. |

The advantages extend beyond mere weight savings. Aluminum’s excellent thermal conductivity makes it ideal for engine blocks and heat exchangers, where rapid heat dissipation is crucial. The resistance to corrosion also helps in extending the vehicle’s lifespan, lowering maintenance costs in the long run.

The speed and precision of plasma cutting make it a valuable tool in the automotive manufacturing process. Traditional cutting methods are time-consuming and may lead to material wastage. In contrast, plasma-cutting technology offers fast turnaround times, superior accuracy, and minimal material waste, streamlining the production process.

Related to: Applications of Titanium Plasma-Cutting

Soaring High with Aerospace Applications

In the high-stakes world of aerospace, the margin for error is infinitesimal. Every component of an aircraft, whether a commercial airliner or a space-bound rocket, must be meticulously designed and crafted to exacting standards. This is where the marriage of aluminum and plasma cutting comes into play.

Table 2: Plasma Cutting Applications in the Aerospace Industry

| Application | Benefit |

|---|---|

| Structural Elements | Aluminum, being lightweight yet sturdy, is used in critical aircraft structures such as fuselages and wing components. Plasma cutting ensures these parts are cut with extreme precision. |

| Interior Components | Plasma cut aluminum is used extensively in aircraft interiors due to its strength-to-weight ratio and resistance to corrosion. |

The use of plasma-cut aluminum reduces the overall weight of the aircraft, leading to improved fuel efficiency—a key factor in an industry where fuel costs can make or break profitability. Moreover, aluminum’s resistance to corrosion increases the longevity of the aircraft components, reducing maintenance costs over the aircraft’s lifecycle.

From the smallest bracket to large structural elements, plasma-cut aluminum parts form the backbone of many aircraft designs. The advent of plasma-cutting technology has allowed aerospace manufacturers to create complex parts with unparalleled accuracy, speeding up production times and reducing material waste.

Enhancing Consumer Electronics with Aluminum Plasma Cutting

In an era where technology reigns supreme, consumer electronics have become an integral part of our daily lives. Everything from our smartphones and laptops to home appliances and wearable tech incorporates aluminum components. This prevalence can be attributed not only to aluminum’s inherent advantages such as lightweight, high conductivity, and aesthetic appeal but also to the precision and efficiency offered by plasma cutting.

Table 3: Plasma Cutting Applications in the Consumer Electronics Industry

| Application | Benefit |

|---|---|

| Smartphone Chassis | Lightweight and durable plasma-cut aluminum frames are commonplace in premium smartphone designs, providing a robust yet sleek structure. |

| Laptop Casings | Aluminum casings, precisely cut and shaped using plasma, offer a premium look and feel while aiding in heat dissipation. |

| Heat Sinks | Plasma-cut aluminum heat sinks are critical for maintaining optimal operating temperatures in various electronic devices. |

Plasma cutting allows manufacturers to create intricate designs and patterns on aluminum surfaces, enhancing the aesthetic value of the product. It’s also an essential process in producing fine cutouts for ports, cameras, and speakers with a high degree of precision.

Aluminum is renowned for its excellent thermal conductivity, and plasma-cut aluminum heat sinks play a pivotal role in managing heat in electronic devices. By maintaining optimal operating temperatures, these components ensure the longevity and performance of the electronics.

Shaping the Construction Industry with Aluminum Plasma Cutting

Aluminum’s durability, strength, and resistance to environmental corrosion make it a popular choice in the construction industry. From skyscrapers and bridges to residential homes, aluminum finds applications in various structural and architectural elements. With the precision and versatility of plasma cutting, the possibilities are virtually endless.

Table 4: Plasma Cutting Applications in the Construction Industry

| Application | Benefit |

|---|---|

| Building Frameworks | The combination of plasma-cut aluminum’s strength and lightness provides robust and easy-to-install structural elements. |

| Decorative Components | Plasma cutting allows for the creation of complex designs in aluminum, used in balustrades, screens, and other architectural elements. |

| HVAC Systems | Plasma-cut aluminum is often used in the production of heating, ventilation, and air conditioning systems due to its heat transfer properties. |

The ability to create precise cuts and intricate designs using plasma cutting technology greatly simplifies the fabrication process, allowing for easy installation and reduced construction time. Moreover, the use of plasma-cut aluminum leads to lighter building structures, reducing the load on foundations and enabling innovative architectural designs.

From providing functional structural components to enhancing the aesthetics of a construction project, the integration of aluminum and plasma cutting is shaping the future of the construction industry. Whether it’s the creation of a sprawling commercial complex or a humble residential home, plasma-cut aluminum is an invaluable asset to the modern builder.

Powering the Energy Sector with Aluminum Plasma Cutting

The energy sector has seen substantial advancements in recent years, with an increasing focus on renewable sources. Aluminum, being lightweight, strong, and corrosion-resistant, has become a material of choice in various applications, from solar panels to wind turbines. With the precision of plasma cutting, aluminum is shaped into key components that power our sustainable future.

Table 5: Plasma Cutting Applications in the Energy Sector

| Application | Benefit |

|---|---|

| Solar Panels | Aluminum frames, precisely plasma-cut, are used to house solar panels, offering lightweight durability and resistance to environmental elements. |

| Wind Turbines | Plasma-cut aluminum components are integral to wind turbine structure and operation, reducing weight and increasing efficiency. |

| Heat Exchangers | Aluminum’s thermal conductivity coupled with the precision of plasma cutting facilitates the production of efficient heat exchangers in power plants. |

Plasma cutting offers the energy sector the flexibility to work with complex designs and exact specifications, which is paramount in maximizing efficiency in power generation and distribution. From the precise cuts needed for the aluminum frames of solar panels to the precision required for components in wind turbines, plasma cutting is at the forefront of renewable energy technology.

Moreover, in conventional power plants, aluminum heat exchangers, produced with the accuracy of plasma cutting, play a crucial role in energy conservation and efficiency, reducing the environmental impact of these facilities.

Conclusion

From shaping the vehicles we drive and the buildings we live in, to powering the devices that connect us, plasma-cut aluminum has revolutionized numerous industries with its unique blend of strength, lightness, and durability. The precision, efficiency, and flexibility of plasma cutting allow it to meet the exacting demands of various sectors, enhancing the properties of aluminum and unlocking its full potential.

In these endeavors, Prolean’s CNC Plasma Cutting Services stands as a reliable partner. We combine cutting-edge technology, skilled craftsmanship, and a deep understanding of industry-specific needs to deliver unparalleled plasma-cutting services. By choosing Prolean, you choose excellence, precision, and a commitment to your project’s success.

FAQs

Can plasma cutting be used for all construction applications?

While plasma cutting is highly versatile, its suitability depends on the specific requirements of a construction project. Factors such as the type of material, thickness, desired finish, and production speed influence the choice of cutting technique.

How does plasma cutting contribute to sustainable construction practices?

Plasma cutting is an efficient process that results in minimal waste, making it an eco-friendly choice. Additionally, using aluminum, a highly recyclable material, further contributes to sustainable construction practices.

What are the safety considerations while using plasma cutting in construction?

While plasma cutting is generally safe, it involves high temperatures and can generate fumes. Therefore, proper safety measures are necessary, including wearing protective gear and ensuring good ventilation. At Prolean, we prioritize safety and adhere to strict safety protocols in all our processes.

0 Comments