Air bending sheet metal is considered to be the most popular bending process in sheet metal shops today. In this process, the die and punch tip only contact the workpiece at the edge. The punch goes over the die top edge into the V-opening without coming into contact with the bottom. The die’s V-opening is made deeper than the required workpiece angle to overbend the material and counteract spring-back.

Moreover, it’s common to use acute angle tooling when performing full air bending. For partial air bending, 90° or 88° tooling is typically used. Recently, 75° tooling was introduced, allowing full air bending without being limited by sharp punches. The new tooling is different from the conventional acute punches where knife-like dies are applied.

In this article, we will primarily focus on air bending sheet metal, its benefits, and comparative techniques.

What is Air Bending Sheet Metal?

Air Bending

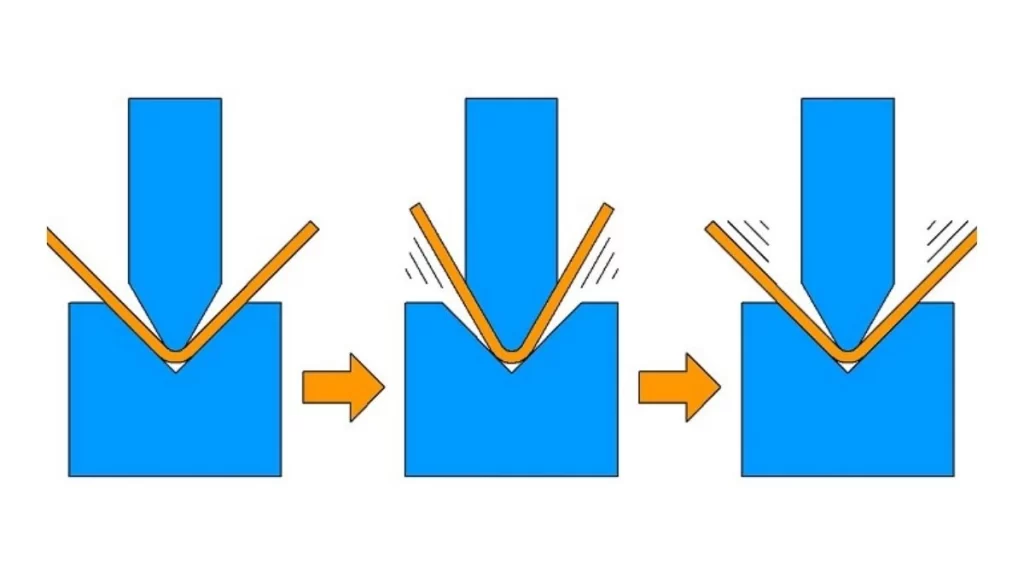

Air bending is an effective forming technique for metals. The process involves three points of contact: the punch tip and the outer edges of the die. The upper die forces the sheet metal into the V-groove of the lower die without contact with the die base. The bending angle, therefore, depends on the penetration depth into the V-opening.

Air bending sheet metal enables manufacturers to utilize the same die on different materials, radii, and angles. The adjustments can vary with the punch design and the extent of its penetration. Air bending is popular because it offers flexibility and can achieve high accuracy, even with CNC-controlled press brakes. The technology reduces such factors as material spring back which makes it a preferred technological process in modern sheet metal workshops.

For all the above reasons, air bending sheet metal is a fast way of forming multiple angles in the current metal fabrication industries since tool changeover is done after several cycles.

Try Prolean Now!

The Function of Air Bending Sheet Metal?

Air bending helps in making the specific angles required during the operations of the press brake. It is used to bend metal sheets into right angles and specific shapes needed for their purpose. But such success significantly relies on modern equipment. With the old press brakes, the error margins are higher.

In air bending, there is a significant importance for adjusting the depth of the plunger. To get accurate results, operators tend to make the spring back of the material and the punch depth. CNC machines can automatically set the bending radius and rebound controls. The process typically provides more control over bending force and final dimensions; therefore, perfect for achieving uniformity.

Key Components In Air Bending Sheet Metal

The components involved in air bending work together to shape metal sheets with precision.

Punch and Die

Die & Punch For Bending

The punch and die form the basis of air bending. The punch puts downward force which is used in bending and the die has a V-shaped cavity for bending. For instance, in the automobile industry, it is employed in giving chassis parts particular angles and measurements.

Air Gap

Air Gap In Bending

The air bending is a distance from the metal sheet to the top of the die. This air gap makes the material slightly not conform to the die shape hence giving more flexibility. For instance, in manufacturing metal girts, a company can create brackets of different angles in a single die setup, hence increasing efficiency and decreasing tooling expenses.

When to Use Air Bending Sheet Metal?

Air Bending With Multiple Bend Angles

- When your design requires several bending angles.

- When you need to work on different angles without using different tools.

- When it’s necessary to control the bend radius.

- When applying CNC controllers to minimize springback compensation.

- When joining several parts with different construction types.

- When lower bending force is utmost.

- You can use air bending when the overall goal is to minimize tooling costs and frequent maintenance problems.

How Does the Air Bending Process Work?

Air Bending Process

Air sheet metal bending uses force in a controlled manner to form metal sheets. The process of aligning the drilling systems depends on fine-tuning to get the right angle. Here is how sheet metal air bending is done in a step-by-step process.

- Die Preparation

The process starts with choosing the correct die. It is typically narrow at the top punch while the bottom die has a V-shaped or U-shaped groove. The die selected depends on the material type, thickness, sheet angle, and bending types, that need to be formed.

- Placing the Metal Sheet

Then the metal sheet is laid correctly on the bottom die. It stays in the groove which is located below the top punch for precise bending of the workpiece.

- Applying Pressure

The top punch goes down to force the sheet into the groove. In the die’s cross-sectional view, it doesn’t touch the die’s bottom. It is spaced a certain distance from the die base and is made of metal.

- Forming the Bend

It forms an arc by the pressure, applied by a punch on the sheet metal. The bending angle is a function of punch depth, the bottom die shape, and the sheet thickness. The pressure of the upper die acts on the material without direct contact while the press forming.

- Releasing the Material

After reaching the desired bending angle, the punch reverts again or moves back. The bent metal is now extracted for assessment and further utilization.

- Evaluate and Adjust

The operator examines the formed angle as the work is in progress. If for some reason the punch pressure or the depth of descent is not sufficient, it is changed to get the required result.

How Is the Inside Radius of Air Bending Controlled?

Air Formed Inside Radius

In air bending sheet metal, however, the punch tip does not make an indentation on the workpiece. Rather, the inside radius of the bend depends on the size of the V-opening made in the bottom die. The greater the size of the V-opening, the maximum is the radius. But by changing the bottom die, operators can control the bend radius regardless of the material and its thickness.

The process flexibility offers two advantages:

- Error Correction: Small layout errors are easily corrected by making corresponding adjustments on the die.

- Design Variety: Different creative designs can have varying radii, depending on the operator.

The inside radius of the finished product is not the same as the punch tip size. To achieve a radius equal to the punch tip, the tip has to be forced into the material – referred to as Bottom Bending. Air bending is characterized by three points of contact: the punch tip and the peripheral die edges.

Try Prolean Now!

What is Bottom Bending?

Bottom Bending

Die bending, also known as bottom bending. It’s one of the oldest processes used in shaping metal sheets into required designs. The action is similar to that of stamping but a punch pushes the material (get more insights about bending aluminum) into a die from above applying force on the workpiece, while the die applies force from below. Punch and die essentially cooperate in the process of cutting the metal into its desired form or shape with close precision.

Unlike air bending, bottom bending relies on the die profile to form the bend. The process yields good results since the angles and die surface are mirrored on the metal. The method results in less springback than other conventional means. The bottom-bending sheet metal is ideal for applications where uniformity is desired, and so is commonly used in high-precision industries.

When to Use Bottom Bending?

Mark Free Bottom Bending

Bottom bending or bottoming is an accurate press brake operation. It involves pressing the material near the bottom of the die, making contact with the die sides. While in coining the metal is deformed, bottom bending only bends the metal without deforming it. The technique is also comparatively more accurate than air bending and offers a better spring back. But the rate of tool exchange for different angles.

High-Quantity Production

As a result, bottom bending is optimum for large production jobs. It outperforms when dealing with a single type of part that needs only one bending operation. This method guarantees quick results, especially with fast-cycling mechanical press brakes.

Older and Less Accurate Press Brakes

Bottom bending is ideal on earlier models of press brakes that are less precise. Such machines can be challenging for repeatable positioning of the punch. Bottom bending compensates by making the material conform to the punch and die angle of the material. This helps maintain consistent results, even with the available equipment.

The bottoming technique is perfect when accuracy and repeatability are of paramount importance in the sheet metal fabrication processes.

Air Bending Vs Bottom Bending Sheet Metal: Key Differences

Air Bending Vs. Bottom Bending

Air bending and bottom bending are two general methods of bending sheet metal using punch and die though the principles involved are somewhat different. In air bending, the material is not fully formed to the die but instead, the bottom part of the die is left open. Bottom bending, however, forces the material into the die/cavity bottom with high precision. Thus, it eliminates the high springback effect.

Air bending is conversely faster and less demanding in terms of tooling hence preferred where accuracy is not your major concern. On the other hand, Bottom bending is applicable in situations where high precision is required since the method delivers uniformity in the shape. Still, bottom bending requires specific tools for each angle while putting more pressure on equipment and may lead to higher wear and maintenance.

However, both methods can be done with a standard, mechanical press brake, or a CNC press brake. Air bending requires close tolerance for angles, while bottom bending takes into account the imperfections of the equipment since the shape of the die is determined by the bend.

Table Comparing Air Bending Sheet Metal and Bottom Bending

| Feature | Air Bending | Bottom Bending |

| Tooling Requirement | Single die for multiple angles | Unique die required for each angle |

| Accuracy | ± 45′ | ± 15-30′ |

| Material Contact | Partial contact with the die | Full contact with the die |

| Speed | Faster, suitable for high flexibility | Slower |

| Cost | No tooling investment, higher part price | Tooling investment, lower part price |

| Maintenance | Less pressure on equipment, less maintenance | Higher pressure, increased equipment wear |

| Best Use Case | Parts with flexible angles and less accuracy | Parts requiring strict accuracy |

Air Bending vs. Coining Sheet Metal: A Quick Comparison

Press Brake Coining

In sheet metal forming, two basic techniques namely air bending sign and coining, and each of them has its merits and demerits. Prolean Tech employs various bending techniques but chooses between them depending on the material properties, the expected application, and the required results.

Advantages of Air Bending Sheet Metal

- Air bending can be optimally used on several materials and thicknesses.

- Less force is needed to bend as compared to other techniques.

- The process usually leads to less tooling wear and tear.

- Air bending sheet metal allows some angle adjustment after bending.

Disadvantages of Air Bending Sheet Metal

- The material may regain(spring back) its shape before it bent.

- Air bending is preferred for applications such as enclosures and brackets where 90-degree bends are typical. There is always springback, but engineers must know how to work it out to get the right measurements.

Coining Sheet Metal Bending

Sheet Metal Coining

Coining is a bending process that applies more pressure than air bending to the sheet metal and dies. The method renders high accuracy with a very slight spring back.

Advantages of Coining

- It produces accurate bends with minimal spring back.

- Suitable for accurate and precise, close tolerance applications

Disadvantages of Coining

- Demands more stress on the cutting tools.

- Needs more volume and pressure, and hence, adds more stress on the machinery.

Materials Used in Press Brake Air Bending

- Steel (Mild, Stainless, and High-Strength Alloy Steels): The bending stainless steel produces automotive components, structural beams, and brackets.

- Aluminum: Used to create products like Aircraft parts, heat exchangers, and enclosures.

- Brass and Copper: Products: Electrical connectors, decorative fixtures, radiators.

- Titanium and Nickel Alloys: Products: Aerospace parts, medical implants, chemical reactors.

Try Prolean Now!

Sheet Metal Bending Services at ProLean Tech

Our engineers and technicians at ProLeanTech have accumulated decades of experience in sheet metal fabrication. We appreciate the opportunity to work with you to assess and intensify your product design, as well as to select the best fabrication process. No matter if you need air bending, bottom bending, or any other operations such as laser cutting or stamping, we will help you get the best outcome for your product. So, reach out to us, and get to know more about our sheet metal bending service.

0 Comments