ABS Plastic

Acrylonitrile Butadiene Styrene (ABS) is a vital engineering plastic comprising acrylonitrile, butadiene, and styrene. These monomers have distinct properties that, when combined, result in a tough, durable, and versatile polymer that’s widely used in Plastic CNC machining.

With remarkable corrosion resistance, impact resistance, thermal resistance, and electrical properties, ABS material finds use in different industrial and domestic applications. It can be processed in different ways, chief among them being CNC machining, injection molding, and 3D printing.

Even with its weatherability and hazards when burnt, ABS continues to stand tall among alternative plastics and materials. Definitely, it is a potentially good option for your part.

This article covers the details of the plastic.

What is ABS Plastic?

ABS is the acronym for Acrylonitrile Butadiene Styrene, a thermoplastic polymer comprising three monomers, namely acrylonitrile, butadiene, and styrene. These distinct components give the plastic its unique properties. Acrylonitrile accounts for ABS plastic heat resistance, butadiene is for impact resistance, and styrene mostly makes the plastic smooth and machinable.

Since its commercialization in the 1950s, ABS plastic has been used in piping, fittings, refrigeration components, and structural materials, to name but a few. Its durability, cost-effectiveness, and manufacturability are some of the highly sought-after material properties in these and other ABS plastic applications.

Chemical Formula of Acrylonitrile Butadiene Styrene

The chemical formula for ABS is (C8H8 · C4H6 · C3H3N)n. It shows that ABS is made up of C₈H₈ (styrene), C₄H₆ (butadiene), and C₃H₃N (acrylonitrile). The ‘n’ outside the brackets refers to the multiple repetitions of the three units. Many of these units create long chains, which are the basis of ABS’s strength and durability.

Structure of Acrylonitrile Butadiene Styrene

ABS plastic features a blend of crystalline and amorphous structures. Therefore, though its molecular arrangement is flexible, it is also ordered. The crystallinity is average, so the material is strong, tough, and dimensionally stable. It is not as defined as in pure polymers.

Properties of ABS Plastic

Here is an overview of the main properties of ABS plastic, covering mechanical, physical, and chemical properties.

Mechanical Properties of ABS plastic

- Tensile Strength of ABS Plastic

The tensile strength of ABS material is approximately 46 MPa (6,600 PSI). However, this can vary based on the source. This material is strong enough to create durable parts for automotive applications, electronics, toys, and other products.

- ABS Yield Strength

ABS yield strength typically falls between 29.6 MPa and 48 MPa. The exact level depends on the processing conditions and formulation. The strength is enough for many industrial and consumer components.

- Impact Resistance

Acrylonitrile butadiene styrene is one of the most impact-resistant plastics alongside polycarbonate plastic and pDCPD (Polydicyclopentadiene) plastic. That’s why it makes excellent tool housings, golf clubs, and car bumpers.

ABS car bumper

Physical Properties of ABS

Density of Acrylonitrile Butadiene Styrene

A density of 1.05 g/cm³ qualifies ABS as a light plastic. It is heavier than polyethylene, though. Note that this density can vary depending on the specific grade. For instance, flame inhibitors make the fire-retardant grade heavier.

Thermal Properties of ABS Plastic

Thermal Stability of ABS

Being an amorphous thermoplastic, ABS exhibits a gradual increase in chain mobility when exposed to heat. As it approaches its glass transition temperature (Tg), the plastic becomes rubbery. Further heating makes the material less viscous and more receptive to extrusion and molding processes.

Melting Point of ABS Material

From the above explanation, we wouldn’t say that ABS has a specific melting point. Instead, it has a softening and flow range. The softening starts at 95–105 °C. This is why engineers usually focus on the material’s softening range and related thermal behaviors instead of a specific melting point.

Chemical Resistance of ABS

ABS shows impressive resistance to diluted alkalis and acids. Its resistance to aliphatic hydrocarbons is poorer. However, the plastic’s poorest resistance is against alcohols and hydrocarbons (both aromatic and halogenated).

ABS Plastic Electrical Properties

The electrical insulation of ABS plastic is one of the most widely applied in the industry. It is popularly used for devices such as computer keyboards, sockets, and power tools.

An electrical socket

Summary Table of the Properties of ABS Plastic

Here is a table of the common properties of ABS plastic:

| Property | Value/level |

| Density | 1.05 g/cm³ |

| Impact Resistance | Very high |

| Tensile Strength | 46 MPa |

| Service Temperature | 80–90 °C continuous |

| Softening Range | 95–105 °C |

| Electrical Insulation | Excellent |

| Chemical Resistance | Good against dilute acids & alkalis, but prone to damage from aromatic & chlorinated hydrocarbons |

| Surface Finish | Smooth, high-quality, easily polished |

Benefits of ABS Plastic in Manufactured Products

There are many benefits of using products made from ABS plastic, including corrosion resistance, durability, cost-effectiveness, impact resistance, and a high-quality surface finish.

- Corrosion Resistance: As a plastic, ABS polymer is not prone to rust like metals. It is engineered to withstand many types of chemicals. This property is critical for parts that are meant to protect or enclose other vulnerable ones.

- Durability: Apart from resisting corrosion, ABS is also built for high impact resistance. It can withstand many industrial hits and knocks. The plastic can make thin and thick parts alike. However, the thicker ones have higher impact resistance.

- Cost-effectiveness: The manufacturing process for acrylonitrile butadiene styrene is relatively straightforward. You can literally produce the plastic in the laboratory next to you. This is why the material is common and affordable.

- High-Quality Surface Finish: ABS plastic parts are of excellent surface finish, at a pocket-friendly price.

Limitations/Disadvantages of ABS Plastic

Here are the main limitations or disadvantages of using ABS material components;

- Degradation under excessive UV exposure

UV exposure damage

- Tends to soften at temperatures beyond 90°C

- Poor performance against aromatic hydrocarbons and chlorinated hydrocarbons

With these limitations, it can be challenging to use ABS plastic parts in outdoor applications without UV stabilization.

How the ABS Polymer is Made

ABS polymer is mostly produced through polymerization, which is the process of producing long chains from monomers. Polymerization is categorized as either continuous mass-suspension or emulsion type.

Continuous Mass-Suspension Type

Polybutadiene rubber is dissolved, then mixed with acrylonitrile and styrene. The resulting ABS plastic variety is transparent and strong.

Emulsion Type

Acrylonitrile, butadiene, and styrene are mixed with emulsifiers and water. This prompts butadiene to form a latex polymer that attaches to acrylonitrile and styrene. Upon washing and drying, the resulting ABS polymer is in the form of powder or pellets.

Manufacturing Processes for ABS Plastic

The following are the main processing methods for ABS material.

- ABS CNC Machining

- ABS 3D Printing

- ABS Injection Molding

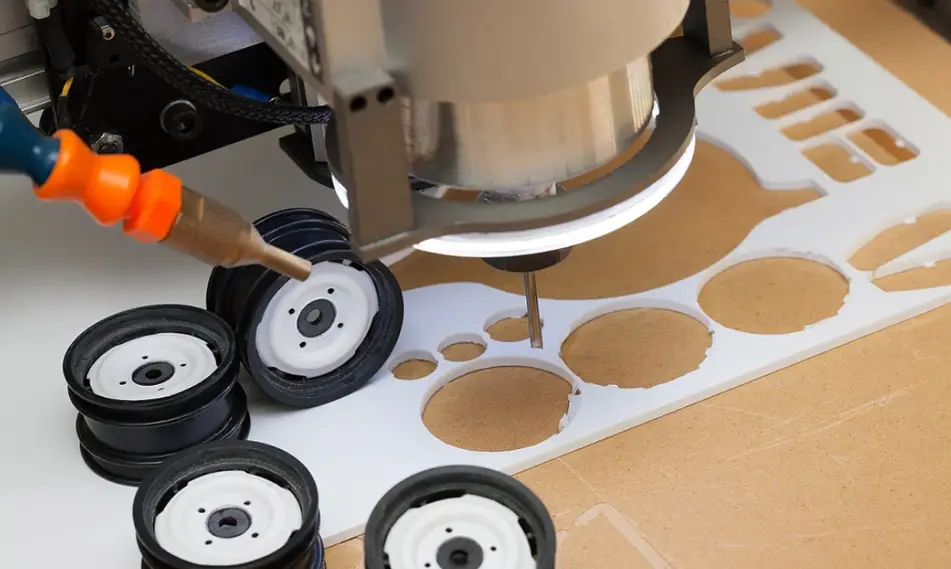

ABS CNC Machining

ABS engineering plastic has suitable mechanical properties for CNC machining. It is also stable enough to allow for precise finishing. That explains the popularity of ABS CNC Machining in finished parts and prototypes.

ABS CNC machining

As for the finished parts, the impact resistance and toughness of ABS enhance durability and performance. However, there are a few issues to handle when machining this plastic. The major one is the material’s low melting point. Therefore, CNC turning, milling, drilling, and other operations must be done with effective heat generation measures.

Here are some best practices that machinists use for ABS Machining.

- Use a moderate spindle speed to prevent melting.

- Use cutting tools that remain sharp for longer, for instance, uncoated 2 or 3-flute carbide.

- Apply quality coolant or compressed air to remove chips and cool the part/tool.

- Maintain a high feed rate – helps remove heat and form thick chips

- Secure the part firmly during machining

Advantages of ABS CNC Machining

- Higher accuracy

- Durable parts

- Fast prototype production

- Superior surface finish

- Suits complex geometries

Limitations of ABS CNC Machining

- Can generate a lot of waste

- High cost of CNC machining equipment

ABS 3D Printing

ABS 3D printing is a popular process with a long history. Indeed, this plastic was used with industrial 3D printers in the past. Manufacturers who use this technique cite smooth surface finish, good wear/impact resistance, and cost-effectiveness as the main motivators towards using the plastic.

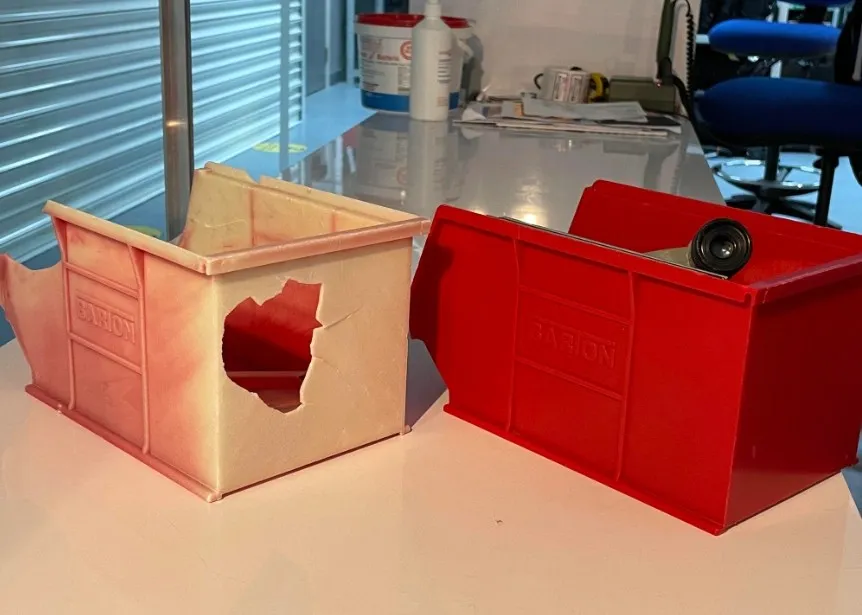

3D printed ABS parts

FDM and FFF printers are commonly used for this process. Filamentous ABS is liquefied by heating and printed out to make parts.

Advantages of ABS 3D Printing

- Smooth surface finish

- Cost-effective

- Simple

Limitations of ABS 3D Printing

- Parts prone to cracking and warping

- The process emits a foul smell

- Requires advanced printing equipment

ABS Injection Molding

ABS injection molding is equally popular in the manufacture of various plastic parts. The process entails melting ABS plastic pellets and then using pressure to inject the melt into a mold. After cooling and curing, the plastic part is ready for use. Injection-molded ABS parts include LED lamp parts, ECG monitor buttons, perfume caps, and calculator housings.

Advantages of ABS Injection Molding

- Low waste production

- Large volume manufacturing

- Durable and mechanically strong parts

- Can be easily automated

Limitations of ABS Injection Molding

- Expensive tooling and equipment

- Materials can ignite

Try Prolean Now!

How Long Will ABS Plastic Last?

Indoor ABS plastic parts last longer than outdoor ones. The indoor ones can survive for up to three decades, while outdoor ABS plastic can degrade within a year, if it lacks UV stabilizers. That said, it is important to note that service life mostly depends on these factors:

- UV exposure

- Chemical exposure

- Temperature dynamics

- Type and amount of load

When choosing ABS polymer, it is important to specify the specific material and, if possible, use it in a controlled environment. This can help make the lightweight material more durable.

How is ABS Plastic Recycled?

ABS plastic recycling follows several steps that start with shredding the material. The fragments are then mixed with water. Metals and other pollutants are filtered out. Further filtration separates ABS plastic from other types of plastic. The retrieved ABS is mixed with fresh ABS to make the final plastic.

ABS plastic is recyclable

What is ABS Material Used For?

The most common applications for ABS plastic are found in automotive, electrical & electronics, medical, home appliances, construction, and toys & games. Here are more details about these uses of ABS polymers.

Automotive Parts

ABS material is widely used in the automotive industry for parts such as dashboards, hubcaps, protective covers, instrument panels, and door panels.

ABS car interior parts

Electrical and Electronics

In this equally vast industry, plastics are used to manufacture computer covers, TV covers, and many other parts.

Medical Industry Parts

The durability, chemical resistance, and sterilization properties of ABS polymer are essential in the manufacture of laboratory equipment, syringes, device housings, and other medical parts.

ABS plastic cover for medical

Home Appliances

The household appliance industry relies on ABS material properties for refrigerators, air conditioners, washing machines, and other machines.

ABS washing machine pulsator

Construction Industry

These plastics are widely used in structural parts such as panels, partitions, doors, and windows.

Toys and Games

ABS molds easily, so using it to make small parts is not a challenge. Different types of toys and games are made from this plastic.

ABS plastic toy

ABS plastic toy

Try Prolean Now!

Comparing ABS Plastic to Alternatives

ABS plastic sheets offer a good blend of cost-effectiveness, durability, and versatility for projects. However, this material can, in some circumstances, be replaced by PVC, Delrin, nylon (PA), and acetal.

Here’s how ABS sheets compare to these alternatives.

Is ABS Plastic Better Than PVC?

In the ABS plastic vs PVC discussion, ABS material is better than PVC in the following ways;

- Higher impact strength

- Better machinability

- Doesn’t become brittle in cold temperatures; PVC does

- Safer than PVC when heated because it doesn’t emit chlorine

Based on these advantages, ABS is preferable for applications where shock absorption is critical. Drainage, Waste, and Venting (DWV) plumbing above-ground installations are good examples where plastic is used.

Brittle PVC pipes

Is ABS Delrin?

No, ABS and Delrin have fundamental differences. Even though both are plastics, ABS is amorphous while Delrin, also called acetal or POM, is semi-crystalline. Specific differences include about 70% higher tensile strength in Delrin, higher wear resistance in Delrin, affordability of ABS, and higher moisture absorption in ABS.

ABS Plastic vs Nylon (PA)

Compared to nylon, ABS has less tensile strength and abrasion resistance. It also performs poorly under high temperatures. The advantages of ABS include higher cost-effectiveness, better electrical insulation, and lower moisture absorption.

ABS Plastic vs Acetal

Both ABS plastic and acetal are food-grade, durable, and strong. However, when it comes to specific jobs, one can perform better than the other. The biggest point is that while acetal thrives in CNC machining projects, ABS plastic is best used in bonding and forming. Therefore, it is important to critically compare the properties of each of these materials with the intended product performance.

Is Acrylonitrile Butadiene Styrene (ABS) More Heat-Resistant than Polyethylene (PE)?

Yes, ABS is more heat-resistant than most PE varieties. It can continuously perform at 80°C. Shorter performance stints are also possible at higher temperatures, as much as 105°C. Parts for relatively hot applications can be made using this thermoplastic. Consider heat-resistant plastics for parts such as hot water plumbing pipes and headlamp covers in cars.

An ABS pipe fitting

Other comparisons are captured in the tables below.

ABS Plastic vs Polycarbonate

The key differences between ABS vs polycarbonate plastic in surface durability, resistance, and applications are:

| Element | ABS Plastic | PC |

| Scratch resistance | More likely to be damaged by a harsh environment | Better scratch resistance |

| Surface durability | Less applicable for high-clarity components | Better for high-clarity applications |

| Common applications | Electronic housings, automotive parts | Car headlights, spectacle lenses |

ABS Plastic vs High-Density Polyethylene (HDPE)

Here are some differences between ABS and HDPE in terms of advantages and tensile strength:

| Element | ABS Plastic | HDPE |

| Tensile strength | Superior structural integrity – 40 to 70 MPa | Lower tensile strength – 20 to 40 MPa |

| Main advantage | High structural integrity under load | Higher chemical resistance, impact resistance, and flexibility |

ABS Plastic vs High Impact Polystyrene (HIPS)

The main differences between ABS vs HIPS in terms of applications and surface finish are:

| Element | ABS Plastic | HIPS |

| Surface finish | Smoother, more polished, appealing | Rougher, less appealing |

| Applications | Consumer electronics, decorative products, housings | Applications with less focus on visual appeal |

ABS Plastic vs Polyethylene Terephthalate (PET)

The differences in dimensional precision and mold shrinkage of ABS plastic and PET are:

| Element | ABS Plastic | PET |

| Mold shrinkage | Lower shrinkage during cooling | Higher shrinkage during cooling |

| Dimensional precision | Suits automotive parts and other applications requiring high-dimensional precision | Requires specialized adjustments for tighter tolerances |

ABS Plastic vs Polybutylene Terephthalate (PBT)

ABS plastic and PBT behave differently in thermal conductivity and thermal management, as:

| Element | ABS Plastic | PBT |

| Thermal conductivity | Lower thermal conductivity | Higher thermal conductivity |

| Thermal management | Not the best for heat management applications | Perfect for thermal management applications, for instance, in electronics and cars |

Conclusion

The chemical resistance, durability, versatility, and aesthetics are some of the unique properties of acrylonitrile butadiene styrene (ABS) plastic. This plastic type often outperforms alternatives, hence its popularity in various industries.

Choose ABS plastic sheets for top performance and customization. Link with a dependable provider for honest analysis to use the sheets correctly. At ProleanTech, experience, expertise, and advanced machinery merge to deliver some of the best ABS machining services in China and across borders.

0 Comments