Aluminum forging vs extrusion vs casting

Forging, extrusion, and casting are renowned manufacturing methods for aluminum parts. Although they have different approaches, capabilities, and applications, the techniques produce quality products, depending on the project.

Casting, the process of pouring molten aluminum into a mold cavity and allowing it to cool, is highly regarded by manufacturers looking for complex parts in large volumes. Options include investment casting and sand casting.

Extrusion entails forcing aluminum through a die to produce an elongated part of uniform cross-section. With this capability for uniformity and relative efficiency in long runs, extrusion is preferred for piping and frames.

Forging, available as hot, cold, open-die, and closed-die, involves compressive forces placed on aluminum to shape it. The resulting strong aluminum parts are ideal for high-stress applications like automotive parts and aircraft parts.

In this article, ProleanTech highlights the comparison points for aluminum forging vs extrusion vs casting, starting with the definition of each. Read on for more details and insights for successful projects.

What Is Aluminum Forging Process?

Aluminum forging is the process of shaping aluminum metal using hammering, pressing, or any other technique that applies compressive force and heat. Forging alters the grain structure of the metal and enhances strength.

Although forging is mostly related to harder metals like stainless steel and carbon steel, the softer aluminum is also a candidate for this process. It is one of the softer metals that can undergo forging alongside options like copper and brass.

The original aluminum undergoes plastic deformation as it acquires the envisaged shape. Aluminum forging is cost-effective, and the applications of aluminum forging are usually parts with desired mechanical properties.

What Are The Types Of Aluminum Forging?

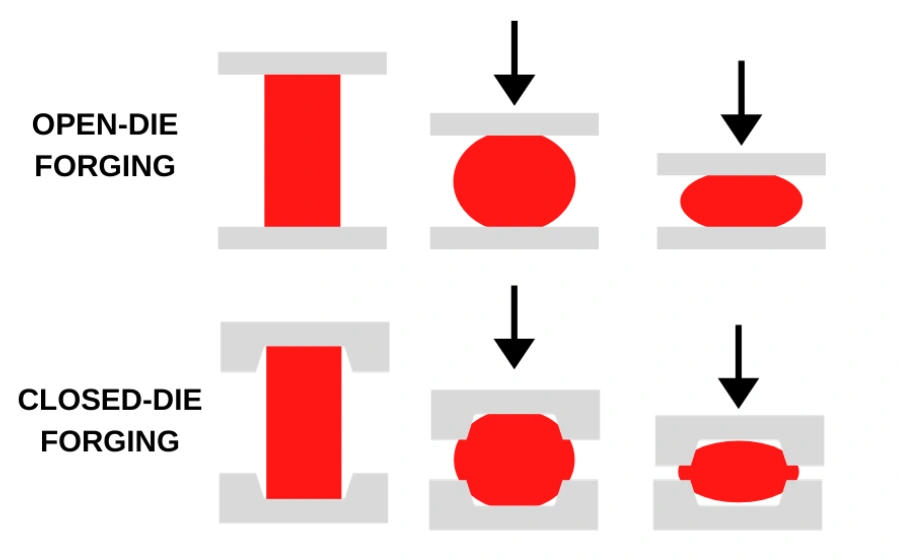

Aluminum forging can be categorized as cold and hot forging, based on the temperature at which the process is performed. From this fundamental categorization, other techniques of forging aluminum, the most recognizable ones being open-die forging and closed-die forging.

Cold And Hot Forging

In cold forging, an unheated billet of aluminum is passed through an open die and forced to acquire the shape of the die. The concept is that the forging process is done below the recrystallization temperature of aluminum.

Cold forging

Hot forging involves heating aluminum to a temperature above its recrystallization point and then striking it into a die. The die is also heated for an even easier movement of the aluminum.

Hot forging

Open-Die Forging

Open die forging entails heating the aluminum metal in a furnace, placing it on an anvil, and then hammering it into the desired shape.

Closed-Die Forging

This process involves two die halves, which come together and compress the billet aluminum. The aluminum material is forced to flow through the die cavities to form the final desired shape.

Open-die forging vs closed-die forging

Try Prolean Now!

What Are The Benefits Of Forged Aluminum? What Are Its Limitations?

Below are the advantages and limitations of aluminum forging.

Benefits Of Forged Aluminum

The benefits of forged aluminum are;

- Enhanced mechanical properties

- Refined and uniform grain structure

- Cost-effective process

- Greater design flexibility

Limitations Of Forged Aluminum

The limitations of forged aluminum include;

- Labor-intensive process

- Mostly suited for low-volume manufacturing

- The dimensional accuracy of parts is low

What Is Aluminum Extrusion?

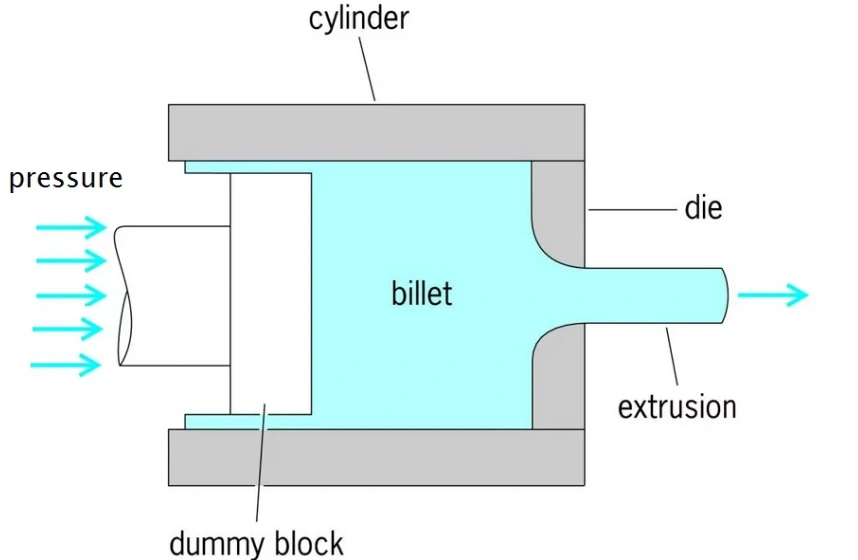

Aluminum extrusion is an aluminum billet processing method whereby the metal is forced through a smaller aluminium extrusion die with a specific cross-section to produce the desired shape. The best applications of aluminum extrusions are elongated parts with a uniform cross-section, especially rods and pipes.

Extrusion process

What Are The Types Of Aluminum Extrusion?

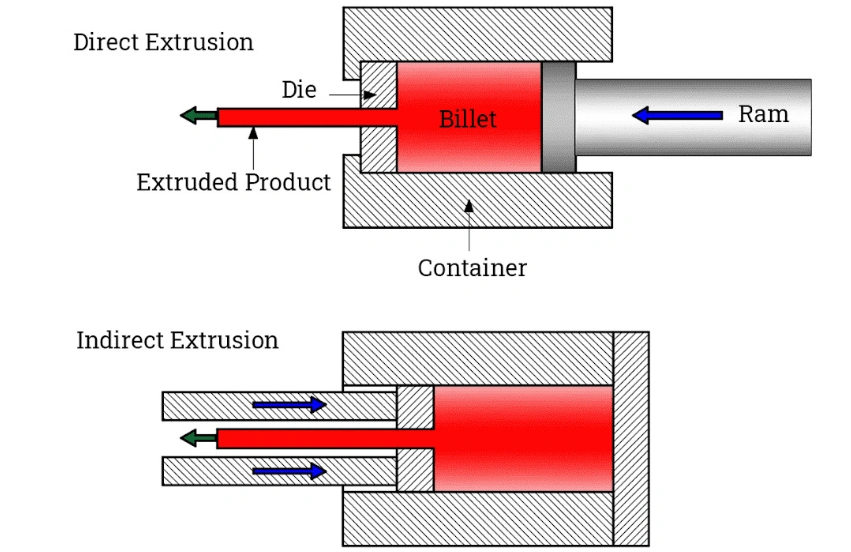

There are two main types of aluminum extrusion: Direct extrusion and indirect extrusion.

Direct Aluminum Extrusion

Direct aluminum extrusion, also called forward extrusion, is where a high-pressure ram forces billet aluminum through a die opening. The material moves in the direction of the ram.

Indirect Aluminum Extrusion

Indirect aluminum extrusion is defined by the secured billet aluminum having a ram with a hollow die pass that forces the material to pass through. In this case, the aluminum and the ram move in opposite directions.

Direct extrusion vs indirect extrusion

What Are The Advantages & Disadvantages/Limitations Of Aluminium Extrusion?

Aluminum extrusion is low-cost and fast, but it also presents a complexity limitation, a factor considered in aluminum extrusion design. Below is a longer outline of the advantages and limitations of aluminum extrusion.

Advantages Of Aluminum Extrusion

Aluminum extrusion offers the following advantages;

- Precise dimensions

- Cost-effective for large volumes of aluminum brackets and other parts

- Flexibility of products – easy to add features

Limitations Of Aluminum Extrusion

Here are the limitations of aluminum extrusion;

- Limited cross-section complexity

- Risk of inconsistent material properties

What Is Cast Aluminum?

Aluminum cast products are manufactured by heating the aluminum billet to a melting state and then either pouring or injecting it into a mold to get the envisaged end product. The part is ready when the molten metal cools and solidifies into shape.

Casting

Since the molten metal can flow to every corner of the mold, this process is ideal for generating complex parts. However, a significant drawback is that the cast product is relatively weak, with the potential of internal porosity rife.

What Are The Types Of Aluminum Casting?

There are several types of aluminum casting, each with its benefits and limitations. The most common ones are die casting, sand casting, and permanent mold casting.

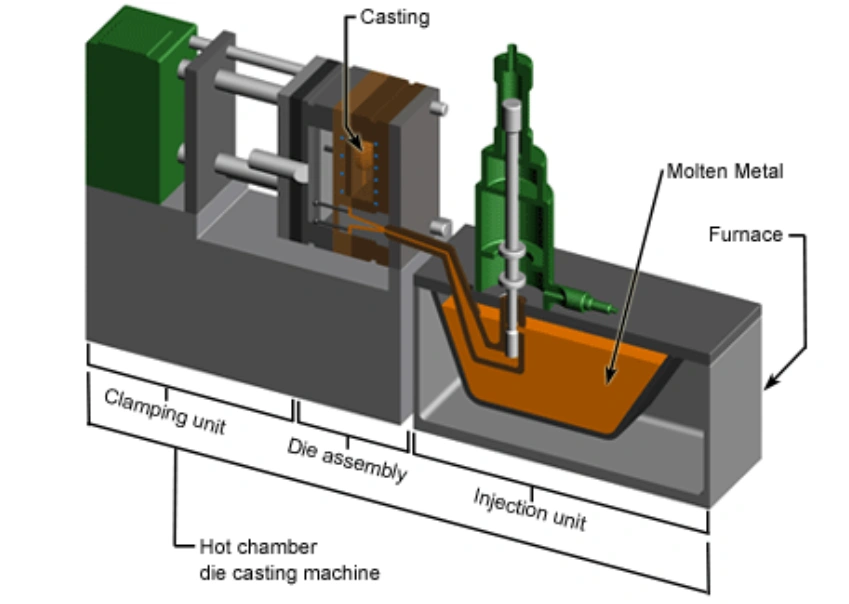

Die Casting

Die casting involves pressurizing molten aluminum into a metal die and allowing the metal to cool and solidify into the predetermined shape.

Die casting (Hot chamber)

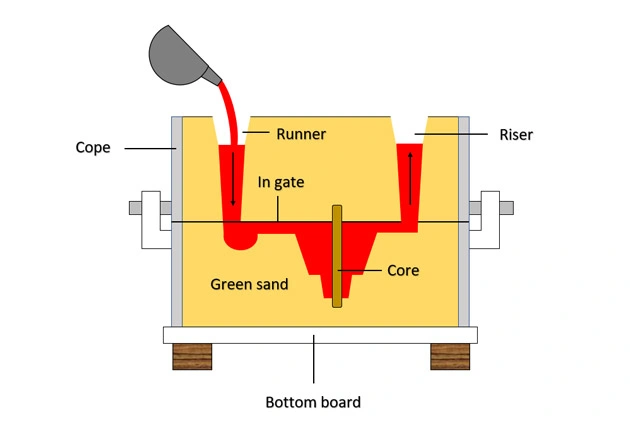

Sand Casting

As the name indicates, sand casting features a sand mold. Sand is packed around a pattern, and the pattern is removed to create a cavity, and then the cavity is filled with molten aluminum.

Permanent Mold Casting

In permanent mold casting of aluminum, the mold is reusable, usually cast iron or steel. When the molten metal has been poured in by gravity and solidified, the mold is opened to release the finished part.

The Advantages And Limitations Of Aluminum Casting

Casting produces the exact shape of the aluminum part and is relatively low-cost, but the part is not as strong as a forged one. Below is an overview of the main advantages and limitations of aluminum casting.

Advantages Of Aluminum Casting

- The part has a high strength-to-weight ratio

- Sustains different types of loads

- High-precision parts

- High electrical and thermal conductivity

- Suitable for high-volume manufacturing

Limitations Of Aluminum Casting

- Poor fatigue resistance

- Poor abrasion resistance

Try Prolean Now!

What Is The Difference Between Extrusion And Forging Aluminum?

Extrusion and forging aluminum differ in several ways, primarily in product strength, part complexity, applications, and cost.

Part Strength

Extruded and forged aluminum parts differ in strength because of their different mechanical properties. Forged aluminum parts are generally stronger than extruded parts. The grain structure of extruded parts is relatively coarse, so the parts have poor mechanical properties compared to the finer forged aluminum parts.

Part Complexity

Compared to aluminum extrusion, the aluminum forging process can produce more complex parts. Its parts have better grain structure, and the process has 3D shaping capabilities.

A complex forged aluminum part

Applications

Aluminum alloy forging is suitable for manufacturing precise, heavy-duty parts for automobiles, aircraft, and such applications. Aluminum alloy extrusion is more preferred for simpler shapes and dimensions, and lighter parts such as aluminum extrusion heat sink. These are for applications like architectural projects.

Process Cost

The combination of manpower, energy, and complex machines required for aluminum forging process makes the process more complex. Largely for its simplicity, the extrusion process is more cost-efficient.

Which Is Better, Casting, Forging, Or Extrusion?

Choosing between aluminum forging vs extrusion vs casting requires careful consideration of the weight of the part, the size of the part, and the design complexity. Other factors are the requirements for CNC machining, surface finishing, fabrication requirements, tooling requirements, and production costs.

The following side-by-side comparison of the three processes can help in the decision-making process as you consider requesting a quote.

| Property | Casting | Forging | Extrusion |

| Assembly and Fabrication |

Complex part assembly Post processing necessary |

Multiple part assembly required Rigid mechanical connections |

Sections joined or welded |

| CNC Machining | Extensive CNC machining necessary | Minimal CNC machining | Moderate CNC machining |

| Design Complexity | Highest part complexity | Complexity is limited | Profile complexity can vary |

| Part Size | Large parts can be produced | Small to medium, compact parts | Unlimited length but limited cross-section parts |

| Tooling Requirements | High initial cost | Very high costs | Moderate costs |

| Weight | Heavy parts | Light parts | Moderate weight |

| Production Costs | Low cost per unit part | High cost per unit part | Moderate cost per unit part |

Related read: CNC machining vs aluminum extrusion

In Conclusion

Forging, extrusion, and casting can make excellent aluminum products for your project. The question is, did you choose the ideal manufacturing process between aluminum forging vs extrusion vs casting?

Extrusion suits high-volume production of uniform cross-section parts, forging focuses on strength and performance, while casting is perfect for lighter and more complex parts.

If you still have a question on the aluminum forging vs extrusion vs casting comparison, don’t hesitate to contact the experts at ProleanTech. We are more than ready to share insights and support with high-quality custom extrusion services and more.

0 Comments