Tail light lens material

Did you know that about 80% of car tail light lenses are made from polycarbonate for high performance? With the ongoing advancement of car manufacturing technologies and the increasing demand for optimal performance of all systems, the choice of the tail light lens material is crucial.

Using the right material for tail light components ensures superior aesthetics, performance, and durability.

Apart from polycarbonate, there are quality tail light lens material options, including Poly Methyl Methacrylate (PMMA), Polypropylene(PP), Acrylonitrile Butadiene Styrene(ABS), and composites.

The choice of the best tail light lens material depends on the lens design, user preference, and the component’s technical requirements. The aesthetics, chemical resistance, thermal resistance, and manufacturability of the material are significant factors.

This article covers polycarbonate and the other lens materials and outlines the key considerations for selecting any of the materials.

What’s A Taillight?

A tail light is one of the different types of car lights found at the car’s rear. Usually, this light works in tandem with the headlight, turning on concurrently. Its main function is to enhance the visibility of the car.

That means the principles of the top headlight manufacturing process with CNC machining can also apply to the tail light.

What Is A Tail Lamp?

A tail lamp is the entire light unit at the back of the car, which encompasses the tail light, brake light, reverse light, and turn signals. However, the terms “tail light” and “tail lamp” tend to be used interchangeably in the auto market.

Overview Of The Car Tail Light Lens

Car tail light lenses are primarily made of plastic and glass, each material having its unique properties. Glass is the conventional material, known for its impeccable resistance to scratches and excellent clarity.

Despite its perfect transparency and other irresistible properties, glass has serious limitations. Apart from shattering easily, the material is relatively heavy. This presents durability challenges, which can reflect on the overall cost of this lens material.

Modern lenses are made from different materials, particularly polycarbonate and other plastics. The lower weight, high impact resistance, and more durability are some attractive properties of plastic lens material.

Tail Light Lens Assembly

Tail light lens assembly

The car rear light cover is a unit comprising all the rear lights – brakes, hazard lights, reverse lights, and so on. This assembly is built and bought as a whole, with all the components assembled.

Main Considerations for Tail Light Lens Material

When selecting tail light lens material, consider elements like electrical properties, thermal properties, structural integrity, aesthetics, and chemical resistance. The cost of the product can also determine if it’s a fit for the project. These are the main demands of a tail light lens.

-

Electrical And Thermal Properties

Tail lights, particularly the halogen and incandescent bulbs, can be extremely hot. Even the laser and other relatively modern lights can generate some heat. With the possibility of the area around the tail light being as hot as 100°C, it is better to be careful about the electrical and thermal performance of the lens material.

Heat deflection and the capability to maintain performance despite the heat are crucial properties for tail light lens material.

-

Structural Integrity

The tail light lens must overcome the everyday roughness of the car, particularly vibrations, without cracking. Even when the car moves on rough terrain, the component should retain its integrity.

-

Aesthetics

The finish and feel of the lens are essential for suiting the aesthetic requirements of the car. Can the material be manufactured once and it meets this requirement, or does it require further processing? Such a question can determine if the tail light lens material is the best.

-

Chemical Resistance

Car tail light lenses often come in contact with a range of chemicals during use and cleaning. Oils from the car will sometimes fall on the component. The lens material must be capable of withstanding the effects of these chemicals.

Tail light lens materials like Polypropylene (PP), Acrylic (PMMA), and Polycarbonate (PC) have exceptional chemical resistances that make them perfect for this purpose.

-

Cost

Many factors can affect the cost of tail light lens material, from supply chain intricacies to manufacturing complexity. Apart from process-linked factors, the type of material is central to the overall cost of the product.

For instance, with all factors held constant, polycarbonate is more expensive than acrylic. The reason for this relatively high price is the premium this material presents. We’ll look more into the benefits of this and other materials shortly.

Try Prolean Now!

Best Materials For Tail Light Lens

Considering the factors highlighted above, the best materials for the tail light lens are plastics, specifically, polymers and composites. Manufacturers will choose any of these based on certain project goals since each material has its benefits and shortcomings.

You can get your quote now, plus all the details about applicable tail light materials.

What Plastic Material Is Used To Make Tail Light Lenses For Cars?

Plastics (polymers) are widely used for tail light lenses for cars in the form of Polycarbonate, Polymethyl Methacrylate (PMMA), Polypropylene(PP), and Acrylonitrile Butadiene Styrene(ABS). Below is an overview of each of these interesting tail light lens materials.

-

Polycarbonate

Polycarbonate tail light lens

Polycarbonate is a sturdy, impact-resistant material that is commonly used in headlight and tail light lens production. Transparent and highly capable of withstanding impacts, polycarbonate is easily the most popular for car tail light lenses.

Its light transmission capability is almost as flawless as that of glass, a property that combines perfectly with the high durability. Other notable advantages of this lens material are ease of use, low weight, and versatility for customization.

A limitation of the material would be the proneness to oxidation over time, which shows in the tail light lens slowly turning yellowish.

-

Poly Methyl Methacrylate (PMMA)

Also called acrylic, PMMA is a highly durable polymer, one of the reasons it is sometimes used as a tail light lens material. This 92% transparent material largely contains methacrylic acid and methanol.

PMMA tail light lens

When used for tail light lenses, the material offers several advantages, including low weight, affordability, ease of manufacture, and durability. It is also safe to use compared to glass.

-

Polypropylene(PP)

Polypropylene (PP) can be modified and used as a tail light lens material, providing advantages such as durability, heat-resistance, and impact-resistance. Special additives to PP make it stronger and more heat-resistant. Glass fibers, for instance, can be added for higher stiffness.

Polypropylene tail light lens

The impact resistance and clarity of PP are a perfect blend for car tail light lenses. Since the material is lightweight, it is likely to last long if well-maintained.

-

Acrylonitrile Butadiene Styrene(ABS)

ABS is another impact-resistant and tough thermoplastic with many industrial applications. These properties, added to transparency, make an effective tail light lens material. Strength and heat resistance crown it all, as these are equally crucial characteristics for tail light components.

ABS tail light lens

Composites For Tail Light Lens

As you can guess, composite tail light lenses are very rare, but not absent. Composites are renowned for structural strength, which can come in handy in extreme cases where serious deformation and temperature damage are expected. They are used where the above polymers can’t work due to their obvious limitations.

If optical excellence is not as prioritized as heat resistance, impact strength, and durability, composite tail light lenses are picked. That would be the case in military cars and other specialized performance cars.

But note that composites are still related to lens design because they can be found in brackets and housings.

Carbon fiber tail light lens surround

Try Prolean Now!

What Material Is The Most Common For Making Car Tail Light Lenses?

The most popular material for car tail light lenses overall is still polycarbonate. Plastics dominate this area, and polycarbonate is the clear favorite for manufacturers, and advantages such as high impact resistance, heat resistance, availability, and low weight.

Tail Light Lens Material Comparison

Each of the above tail light lens materials is beneficial in its own right, but the user dictates the properties that are most suitable for the situation. That’s why the comparison chart below can be helpful when sourcing the type of lens to order.

| Tail light lens material | Chemical resistance | Heat resistance | Strength | Surface quality | Cost |

| ABS | Average | Average | Good | Average | Low to medium |

| Composites | Perfect | High | Perfect | Variable | Medium to high |

| Polycarbonate | Good | Perfect | Perfect | Perfect | Medium to high |

| Polypropylene | Perfect | Average | Average | Average | Low |

| PMMA | Good | Average | Poor – brittle | Excellent | Medium |

Can You Replace The Plastic Cover On A Tail light?

Yes, it is possible to replace the car tail light cover, but this process demands skill and the right set of tools. Important tools for this task are gloves, electrical tape, a ratchet set, and the replacement tail light assembly.

Most tail lights are accessible via the open trunk of the car or a panel around the same area. Once you locate the fasteners, use the ratchet or screwdriver to remove them.

After disconnecting the electrical connections, the assembly is now free to move. Replace it and fasten as before.

Tail light lens replacement

The Manufacturing Processes For Tail Light Lenses

For effective auto parts replacement, the process must be done right, from the manufacturing process to the workmanship on the right material for automotive parts. Regarding tail light lens manufacture, it all starts with tail light lens material selection, followed by manufacturing technologies such as CNC machining, injection molding, 3D printing, vacuum casting, and surface treatment.

CNC Machining

Computer Numerical Control (CNC) machining machines acrylic and other tail light lens materials with the surgical accuracy of advanced cutting tools. CNC machining technologies are perfect for complex tail light lens designs.

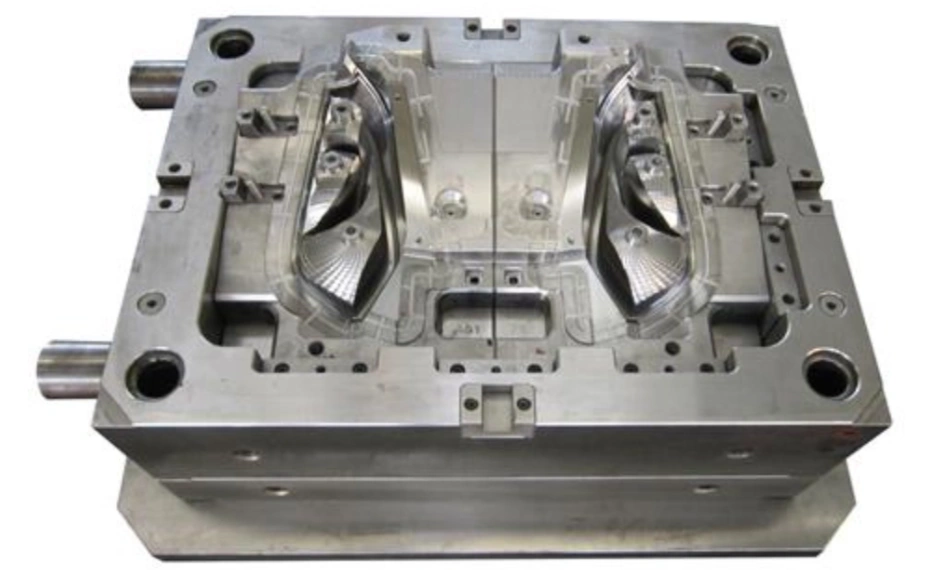

A CNC-machined car light mold

CNC machining is also useful in producing metal molds for injection molding, another production process for tail light lenses.

Injection Molding

Injection-molded tail light lens

Injection molding, the technique of pouring molten plastic into molds, is also useful in tail light lens production. This method applies to custom tail light fabrication and standard orders alike.

3D Printing

This method entails building tail light lenses from digital models by layering the material. It is mostly recognized for its rapid prototyping suitability, which is an important step before mass manufacturing.

3D printed tail light lens

Related: Guide to High-End 3D Printed Motorcycle Parts

Vacuum Casting

Vacuum casting entails using vacuum molds to create complex tail light lenses. The method is often used in the custom manufacturing of lenses, where attention to detail is critical.

Surface Finishing

When the fundamental manufacturing process is complete, the lens requires surface finishing for enhanced appearance and durability. Some effective and popular technologies to consider are chrome plating and vacuum metalizing.

Suggested reading:

In Conclusion

The tail light lens material is one of the major considerations when installing or replacing an automotive lighting system. A quality tail light not only increases a car’s visibility for enhanced safety and withstands weather and driving conditions variability, but also enhances aesthetics and promotes legal compliance.

Consider getting tail light lens replacement parts from professional custom tail light manufacturers adept at processing different materials. Professionals at ProleanTech are committed to producing the highest quality of tail light lenses for the best driving experience.

Contact us now for more on the material selection and manufacturing processes.

0 Comments