Metal Surface with CNC Engraved Letters

Text milling allows you to cut/engrave letters, logos, and part numbers on metal and plastic parts. The machine uses spinning milling cutters and carefully peels away material to leave sharp and readable markings. For traceability, branding, safety guidelines, and assembly steps, engraved text is best.

However, text engraving isn’t without its issues. Small fonts, tight tolerances, curved surfaces, and deep cuts can blur letters and slow production. So, every engraving project requires careful planning and tips. Using the right machine, the appropriate cutter, and the optimized milling speeds and feeds determines the best results.

At ProleanTech, our 3, 4, and 5-axis CNC milling centres overcome these challenges. Expert operators programme machines to lock in text position, smooth the cut, and control depth precisely. We can customize jobs to specific materials, required depths, and surface treatments based on your project needs.

In this article, you will explore:

- What is text milling or CNC text engraving?

- Common challenges faced in text milling

- Layout and text placement

- Fonts and engraving options

- CNC Parameters and Settings

- Best practices

What is Text Milling? How does it engrave letters/Logos on Machined parts?

Code Engraving on Gun Head

Text milling, also known as CNC engraving, is a precision CNC machining process where letters, numbers, logos, or other design patterns are engraved or etched onto the surface of a part. A G-code program, created for CNC machining, translates the desired text into movements for the milling cutter. This computerized control ensures the engraving looks exactly how the material should look and feel after machining. It results in clean, easy-to-read, and uniformly rounded text.

Manufacturing Companies often use text milling for engraving part numbers, serial numbers, assembly notes, or for the brand identity/logo. Since the milling cutter can work with various materials, including metals, plastics, and composites, the method is widely used everywhere, from factory floor parts to prototyping in a small workshop.

Adjusting the text size, font, and position in the CNC program is quick and easy. Engineers can set the text exactly where needed and choose the right font. Each mark is permanently etched, with lasting quality and no shadow, even with heavy use.

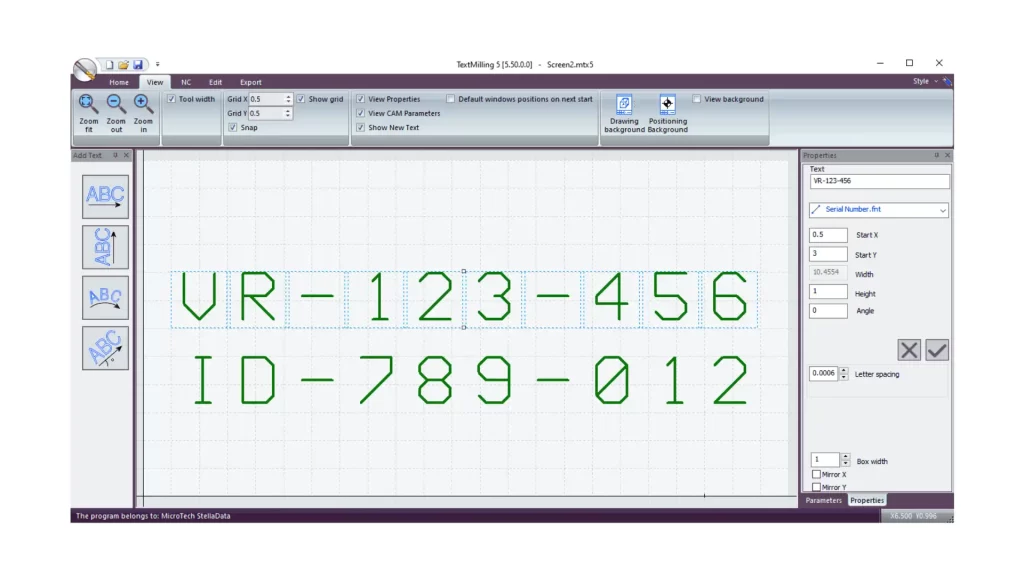

CAM Workflow for Text Milling: How Text is Turned into G-Code

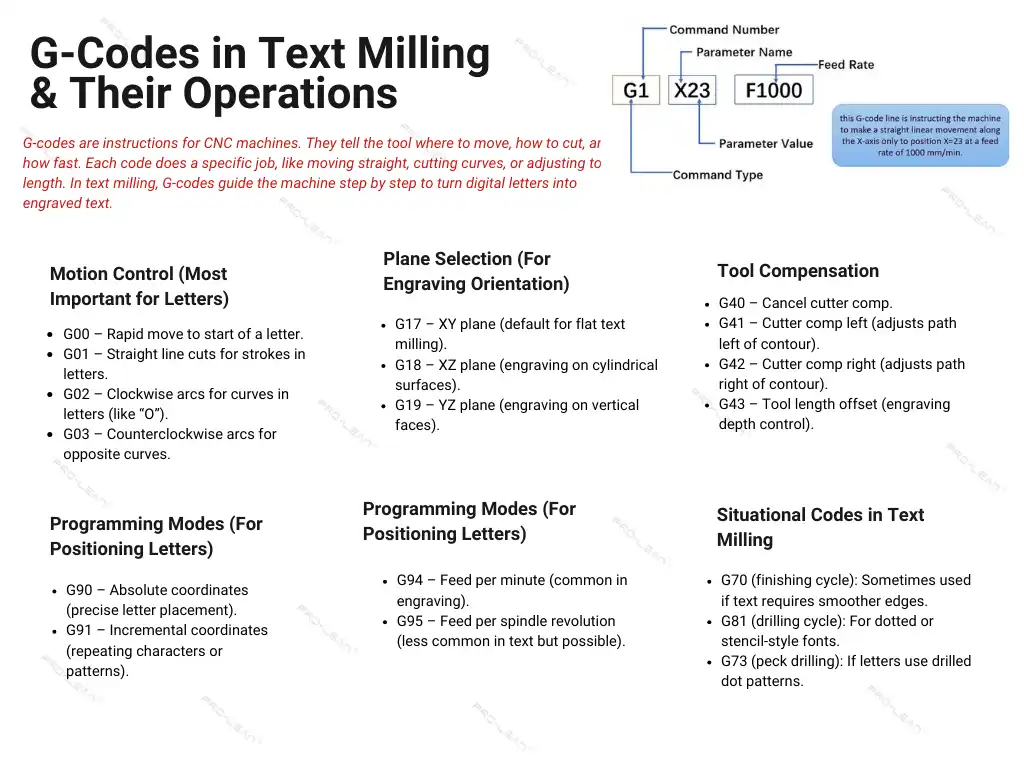

Text Milling G Codes

Let’s see a step-by-step workflow for converting a text design into a CNC-ready G-code for engraving.

First of all, the text is created using CAD software. You must choose a good font style and size, and verify spacing. So, the text fits well and is readable in the design.

Then, CAM software is used to convert the text into toolpaths. These directions lead the CNC machine to cut the text precisely and uniformly.

The cutting style is dependent on the design and the material. Shallow letters are engraved using a light cut. Pocketing is used for deeper or more detailed text.

The machine is configured with the correct feed rate, spindle speed, and cutting depth. These settings are crucial for minimizing tool wear and material issues, ensuring accurate engraving.

The software simulates the toolpaths before cutting starts. This verifies no collisions and errors, so the machine operates effectively and correctly.

Lastly, the toolpaths are converted to G-code. This code guides the CNC machine and is engraved in the part, creating sharp, clean, and permanent marks.

Try Prolean Now!

Which Font Should You Choose for Text Milling?

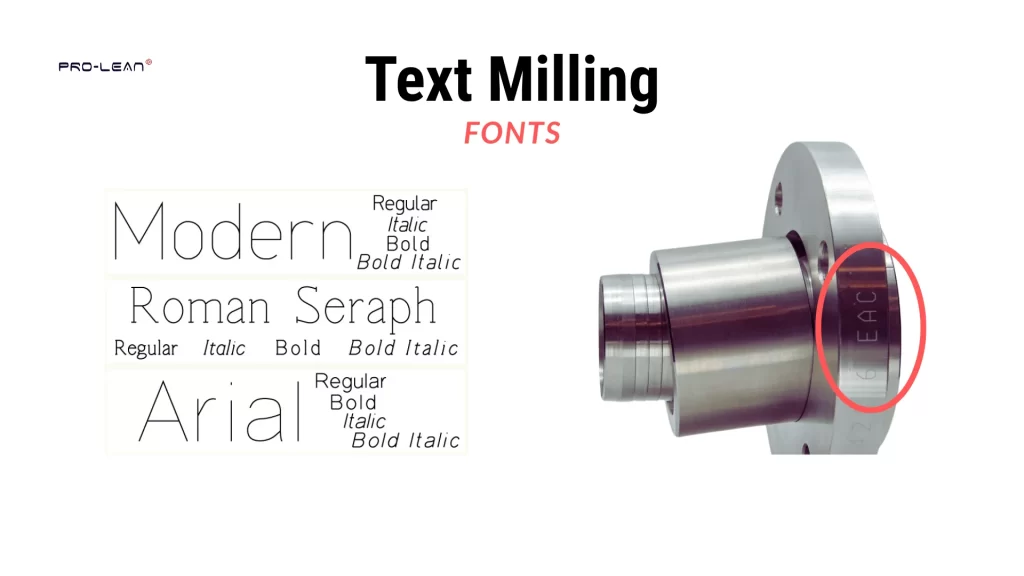

Text Milling Fonts

The most effective fonts for text milling are bold, simple, and easy-to-machine styles such as Arial, Helvetica, Verdana, and Futura.

Most 3D CAD software packages allow you to pick Windows milling fonts, but that doesn’t mean you can throw any text selection into your drawings. Particularly, avoid using serif fonts. These styles feature decorative lines on the ends of characters, and those little curls get lost during the milling process.

When attempting to cut the tiny serifs, the toolpath can result in fuzzy or incomplete letters, making them difficult to read. Go with sans-serif fonts instead. Sans fonts have clean lines with consistent stroke widths. So, cutting them accurately on the mill is way convenient.

Take SolidWorks, for example; the default font, Century Gothic Bold, is spot-on for shop drawings. If you need more options, look for familiar sans-serif faces like Arial, Helvetica, and Verdana. They are simple, neat, and easy to read on a milled surface.

If you want your text to pop more, Century Gothic Bold and Impact fonts can add some heft and keep the cuts readable.

Text Milling: What is the Recommended Font Size?

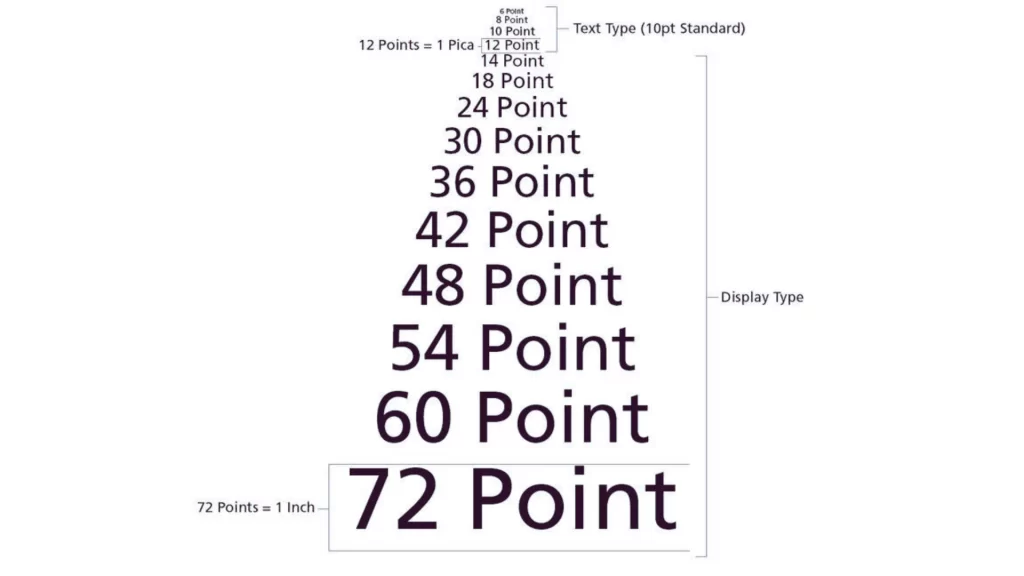

Font Sizes In Text Milling

In engraving text on a part, the font size of the letters is essential for readability. A height of approximately 0.02 inches (0.5 mm) is considered optimum. However, you must ensure the text is readable but not too big.

It is also better to use fonts with at least 20 points. The bold fonts, such as Century Gothic Bold and Impact, provide additional clarity in milling texts on items.

In case of tiny text, seeking help from a professional is preferable. At Prolean Tech, we are good at dealing with smaller fonts, and please let us know in your quote request so that we can ensure we bring the best results for you.

Use slightly larger fonts when placing text on raised and uneven areas, like tall ribs. This helps you keep the text clear and readable despite surface variations. (See more: CNC metal cutting)

How to Achieve Clear and Readable Text Milling

Clear Font Selection for Engraving

You must follow simple guidelines when adding text to a part for the best possible outcomes. For example:

Choosing the Right Font

Use non-serif fonts like Arial, Helvetica, Verdana, or Century Gothic Bold. They are not complex and easily measurable. Do not use serif fonts because the tiny ornamental lines can render blurred or partial texts. Large fonts are advised to have more visibility.

Recommended Font Size

The text must be at least 0.02 inches (20 points) high. This makes it clear and readable. The text becomes more prominent with bold fonts. Smaller text may be milled, though this is not to be done without first checking by professionals.

Using Embossed Text

Embossed text stands out in 3D designs. It is most suitable for logos, serial numbers, and part numbers, particularly on surfaces subject to frequent wear and cleaning.

Placement Tips

The text should not be put on high or uneven surfaces, like ribs. Plain or slightly curved surfaces most effectively guarantee clean and uniform milling.

CNC Settings

Select tool type, depth, and feed rate according to the material complexity and text. The right CNC parameters allow keeping the text sharp, precise, and readable, even with small or complex designs.

Try Prolean Now!

Which Materials are Suitable for Text Milling

Text milling works on many materials for different projects. Here are the standard options: metals, plastics, wood, composites, and others.

| Material Type | Examples |

| Metals | Aluminum, Steel, Titanium, Copper, Brass |

| Plastics | Acrylic, ABS, Polycarbonate |

| Wood | Oak, Maple, Cherry, MDF |

| Composites | Carbon Fiber, Fiberglass, Kevlar |

| Others | Ceramics, Glass |

Milling, Laser, and Stamping for Part Marking: Which Is Better?

The choice of marking technique usually depends on the material you are working with, the permanence of the mark you will require, and the detailing level you will need. All these approaches are applicable in particular circumstances.

Text Milling

Text Engraving on Wood

Text milling involves a cutting tool that cuts the text or design into the material. It leaves permanent and deep marks, perfect in metal, plastic, and composite parts. The text is readable even in the case of heavy utilization, and depth, width, and style could be adjusted.

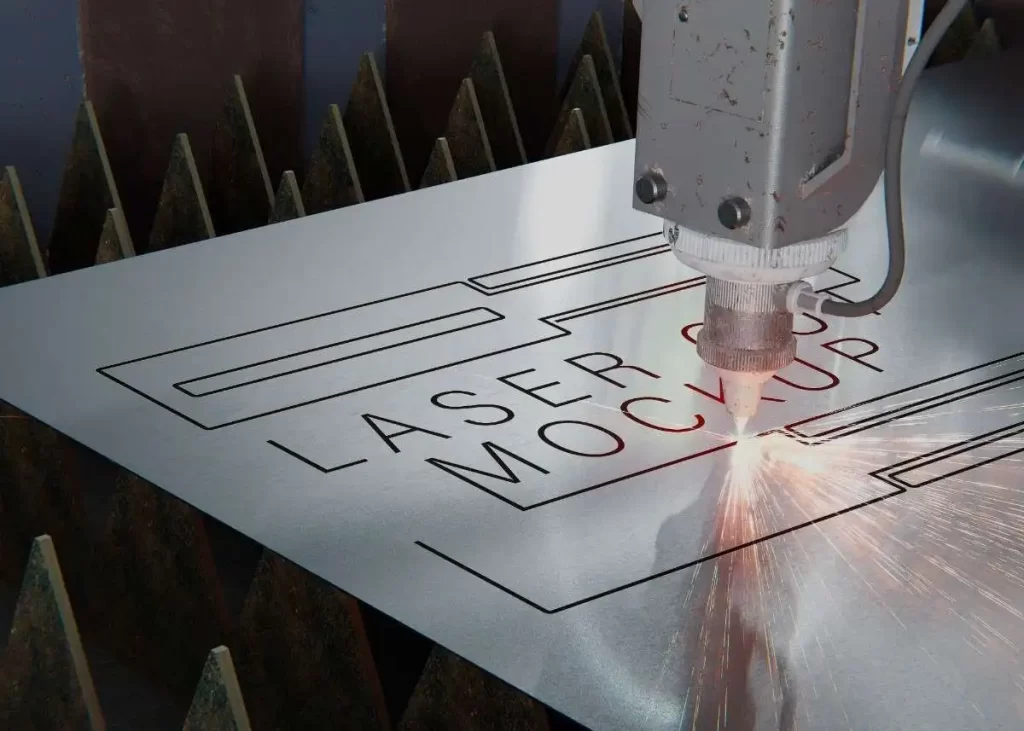

Laser Engraving

Laser Engraving

Laser engraving is a non-contact process. It normally etches and changes the material’s color. It is a go-to option when you need finer details and shallow marks.

Manual Stamping

Manual stamping uses a pressing machine to make patterns on parts. It is a comparatively fast and cheap option. However, it is not as accurate as laser and milling options. It depends on manual intervention and is desirable when making non-critical and straightforward markings.

Comparison Table: Part Marking Methods

| Factors | Text Milling | Laser Marking | Manual Stamping |

| Suitable Materials | Metals, plastics, composites | Metals, plastics, composites | Soft metals, plastics |

| Mark Depth | Deep and permanent | Shallow | Medium, varies |

| Precision & Detail | High | High | Low to medium |

| Production Speed | Moderate | Fast | Fast but inconsistent |

| Best Use for | Serial numbers, logos, part IDs | Decorative marks, lightweight parts | Simple IDs, low-cost parts |

Text Milling in Metal Vs Plastic Parts

Milling text on metals and plastics requires different approaches. For instance, the text cutter should move slowly using metals like aluminum, stainless steel, or titanium. The high speed of the spindle allows it to cut through the hard surface, but the depth of the cut has to be regulated to avoid tool breakdown or the part being ruined. Coolant helps improves the text sharpness, and makes it long-lasting.

Plastic materials such as ABS, PVC, or polycarbonate can melt when overheated. So, the movement of the cutter must be slow, and the depth of the cut shall be shallow. Optimal clamping prevents the part from cracking or deforming. Selecting an appropriate feed rate and a sharp tool is essential to have the text readable with no jaggy edges. (Also read: CNC plastic parts machining)

Let ProleanTech Add Engraved Text to Your Machined Parts

ProleanTech provides custom milling services for your machined components. Our facility follows ISO standards and employs state-of-the-art CNC machines. We guarantee our customers effective engraving of letters, numbers, logos, or serial numbers on metals, plastic, or other materials.

Upload your design to receive professional help and quickly request a free instant online quote. Start adding precise text to your parts with ProleanTech now.

Conclusion

Text milling provides a fast way to add clear text, logos, or serial numbers onto your parts. Through CNC engraving, you can make precise, repeatable outcomes every time, which is ideal for production runs where every detail matters.

If the batch is small and the budget is tight, simpler manual engraving or even handheld machines can still offer good quality. Choosing the right method allows you to obtain a professional look for your parts and makes them easy to track, label, or warranty.

0 Comments