Porosity in casting is one of the most prevalent and challenging issues in the metal casting process. Porosity influences the performance and quality of cast components. These issues must be resolved for the long-lasting and reliable parts produced using different casting techniques. Cast components attain the required reliability and lifespan in various industries through effective porosity control.

Die cast components waste less raw material, retain consistent features and tolerances, and provide superb surface finishes.

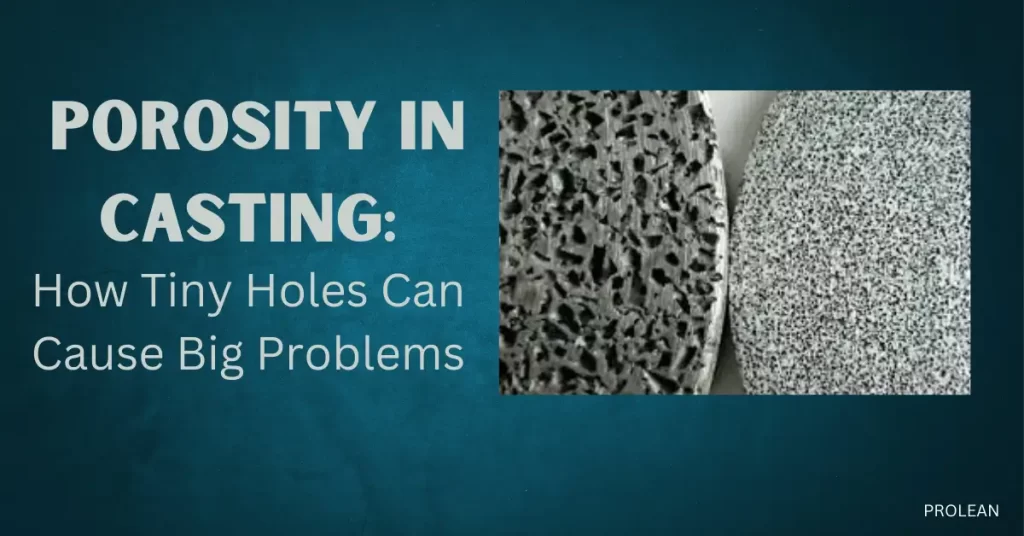

Porosity in Casting

Casting porosity occurs when the smooth formation is interfered with by gas, shrinkage, or solidification. Numerous elements, including mold design, cooling rates, and even what controls a material’s porosity, influence the final outcome. Manufacturers frequently struggle to achieve zero porosity casting.

This article explores kinds, detection techniques, and preventive tactics of porosity, demonstrating how a proper casting process may distinguish between a defective component and a product free of flaws.

What Exactly is Porosity in Casting?

Porosity in casting is known as the formation of pores, holes, or cavities on the surface or within a metal casting. This conditioning reduces a die cast’s structural integrity and results in corrosion or leaking in some areas. It is essential to mitigate porosity to maintain casting performance.

It is essential to address porosity to maintain casting performance.

Die Casting Defects

In other words, the casting produces tiny holes, weakens the component, and shortens its lifespan. This may result in metal casting defects, including leaks, cracks, or diminished strength.

One of the most frequent problems in the casting process is porosity, which must be controlled to achieve zero porosity casting and create metal components of superior quality.

Meet the Culprits: The Different Types of Porosity in Die Casting

Porosity in casting never looks the same. It may take on many forms and show up inside the metal in a variety of shapes. Porosity can be better understood by classifying it in two ways:

- By Cause → why it occurs (solidification problems, shrinkage, or gas trapping).

- By Geometry/Distribution → How the holes form and connect inside the casting.

- By Cause:

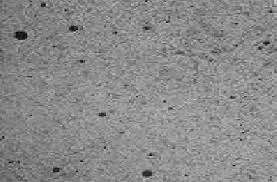

- Bubbly Trouble: Gas Porosity

- Gas porosity is one of the common forms of porosity in metal casting. Trapped gas forms pores such as surface blisters, which show up on the casting as bubble-like swellings. These pores are created when gases become trapped in the die or molten material during solidification. Errors in lubrication, venting, gating, or long-term storage of the die part can all result in trapped gases in the die.

Gas Porosity

- Hollow Pockets: Shrinkage Porosity

Shrinkage in metal casting creates pores when the casting shrinks from thick to thin parts. This shrinkage in casting may form a void in the middle of the part. This happens when the die’s wall thickness and the characteristics of the metal cause the molten metal to decrease at an uneven shrink rate during the solidification phase.

- The Hidden Enemy: Micro-porosity

Micro porosity is made up of tiny, sometimes microscopic voids in the cast material. Microporosity may impact the surface finish of the casting and mechanical characteristics. Such types of metal casting defects lead to decreased functionality and visual appeal.

- By Geometry:

Let’s look at them by geometry:

Types of Porosity

- Hidden Pits: Blind Porosity

The pore begins at a feature’s surface and terminates somewhere in the metal’s body. These kinds may encourage corrosion but often have little effect on mechanical strength.

- Leaky Tunnels: Through Porosity

The pore forms a channel that starts at the surface and extends through the feature and out the opposite wall. This porosity in metal results in a leakage that requires both sides to be sealed.

- Trapped Bubbles: Enclosed Porosity

These pores are contained within the metal’s body and are not visible to the outside. Unless they are subsequently pierced during post-machining. The presence of such pores is often undetectable unless the part is broken open for diagnostic purposes or undergoes a computed tomography (CT) scan after casting.

The table below helps to understand a clear comparison of types of porosity with examples and impact:

| Type of Porosity | Classification | Description | Example in Casting | Impact on Casting |

| Gas Porosity | By Cause | Bubbles or pinholes from trapped gas during solidification | Air pockets in the aluminum casting are due to poor degassing | Weakens surface finish, creates leaks. |

| Shrinkage Porosity | By Cause | Cavities form when metal contracts during cooling and lacks feed metal. | Irregular voids in thicker iron casting sections | Reduces strength, can cause cracks |

| Micro-porosity | By Cause | Tiny voids between metal grains from uneven cooling or alloy issues | Fine pores in steel turbine blades | Lowers fatigue resistance, hidden weakness |

| Blind Porosity | By Geometry (Open defect) | A cavity that opens to the surface but doesn’t go through | Pit-like depression on the cast surface | Surface flaws, traps contaminants |

| Through Porosity | By Geometry (Open defect) | Void forming a complete channel through the casting wall | Hole running across a pump housing wall | Causes leakage, pressure loss |

| Enclosed Porosity | By Geometry (Closed defect) | Void is completely trapped inside the metal with no surface connection | Internal bubble in a die-cast automotive component | Hard to detect, may weaken the structure |

Try Prolean Now!

Why Porosity Happens (and Why It’s So Common)

Porosity in casting is still one of the most difficult flaws to prevent, even with the advanced technologies. Numerous elements in the casting process can produce circumstances that form pores. That’s why it is so common. Let’s dissect the primary offenders:

- Gas Entrapment

When molten metal is poured into a mold, it has a propensity to dissolve gases such as nitrogen, oxygen, or hydrogen. The metal’s capacity to retain gas diminishes as it cools. The gases become trapped within and create pores if they cannot escape in time. Imagine it as the bubbles in a bottle of soda when you open it; the pressure drops and the gas escapes. This manifests as interior cavities or surface pinholes in castings.

Casting Process

- Shrinkage During Solidification

All metals contract when they cool. Cavities form if there isn’t any additional molten metal to “feed” the shrinking areas. This is called shrinking porosity. It often occurs at intersections with uneven cooling or in dense sections. Without proper risers or feeding systems, these hollow pockets are inevitable.

- Turbulence in the Casting Process

It depends a lot on how the molten metal is poured. It traps air and oxides within the mold if it splashes or flows too erratically. Later, these trapped gases develop into pores. Although turbulence is difficult to prevent in real-world foundries, particularly with intricate mold designs, smooth, controlled filling is essential.

- Moisture and Contaminants

Mold or core moisture might cause quite a problem. Water quickly changes to steam when it comes into contact with molten metal. This steam creates pressure pockets inside the casting because it has nowhere to go. Large porosity clusters can be formed by even very small amounts of moisture. That’s why foundries are so stringent with preheating and sand mold preparation.

- Material Properties

Metals react differently from one another. Certain alloys are more likely to develop micro-porosity, dissolve gas, and shrink when cooled. On the other hand, a material’s chemistry, melting point, and solidification properties determine how porous it is. For instance, cast iron is more susceptible to shrinkage porosity, but aluminum alloys frequently experience hydrogen porosity.

- Uneven Cooling

Defect development is significantly impacted by cooling rates. Micro-porosity can result from tensions building up and voids forming between grains. Gases cannot escape if they move too quickly. If you move too slowly, shrinking cavities will worsen. In casting engineering, finding the ideal cooling balance is a never-ending task.

How Porosity Hurts Your Casting Quality

Porosity weakens the part. These hidden pores can decrease the quality and create leak paths. Because of this, porosity plays a vital role in the aerospace and automotive industry, where failure is not an option. Unlike the machining parts, casting has the risk of porosity if the procedure is not properly controlled. Due to this, the tradeoff between machining and casting comes into play. Casting provides cost and shape flexibility, whereas machining ensures reliability.

Here are a few reasons why your casting quality hurts:

- Mechanical Characteristics: Porosity in casting can weaken parts by reducing the tensile strength, fatigue resistance, and ductility of cast components.

- Effects of Surface Finish: Porosity alters the casting’s surface appearance, giving it a rough, uneven appearance.

- Influence on Corrosion Resistance: Porosity can provide corrosive elements with routes, which lowers the material’s resistance to corrosion.

- Diminished Power: Voids impair the casting’s overall structure and lower its ability to support loads.

- Reduced Durability: Porosity increases the casting’s susceptibility to fatigue and failure, especially in high-stress applications.

- Surface Defects: The casting may not be appropriate for applications requiring visibility or aesthetic appeal due to surface porosity.

Try Prolean Now!

How to Spot Porosity Before It’s Too Late

Porosity in metal castings can be spotted using a variety of inspection methods. The kind of metal being cast, the nature of the flaw, and the necessary degree of inspection precision are taken into consideration when choosing a procedure, each of which has benefits.

Inspection Techniques

Seeing is Believing: Visual Checks

The first line of defense for identifying cracks is frequent visual examination. It entails careful inspection of the surface of the porosity casting defects, such as cracks and pinholes. Despite being simple and affordable, this approach is frequently restricted to surface-level problems and might not be able to accurately identify internal porosity or subsurface fissures.

Sounding It Out: Ultrasonic Testing

One of the best non-destructive testing (NDT) techniques for finding interior flaws like fractures and porosity is ultrasonic testing (UT). High-frequency sound waves are used in this method to pierce the metal casting. Sound waves bounce back and are captured by sensors when they come into contact with a porosity casting defect, such as a vacuum or crack. The position, extent, and kind of the flaw are then ascertained by analyzing the data.

NDT Testing of GAs Porosity

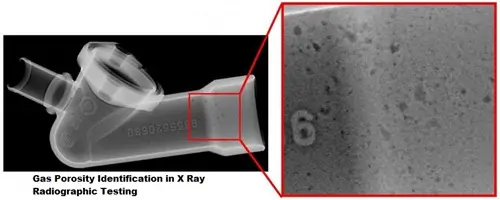

Going Deeper: X-ray and Radiography

Another effective technique for finding interior porosity in metal castings is X-ray examination. In this method, X-rays go through the substance and are picked up by a detector on the other side, just as in a medical X-ray. Cracks or porosity change how the X-ray is transmitted, producing a picture that may be examined for flaws.

This technique is perfect for examining complicated castings where flaws could be concealed inside elaborate geometries. However, it might be more expensive than other approaches and calls for certain tools and knowledge.

Seeing Clearly: Dye Penetrant Testing (DPT)

One popular technique for finding surface porosity in metal castings is dye penetrant testing. It entails putting a liquid dye on the casting’s surface, which permeates any pores or fissures. Following a waiting period, extra dye is scraped off, and a developer is used to extract the dye from the cracks and reveal them.

It’s an economical way to find defects, even though dye penetrant testing can only discover surface-breaking porosity, particularly for cast metal parts that are challenging to examine with other methods.

Feeling the Flaws: Magnetic Particle Inspection (MPI)

Magnetic particle inspection is used for finding surface and near-surface cracks in ferromagnetic materials. This technique involves applying a magnetic field to the casting and sprinkling the surface with magnetic particles. The magnetic field will deform, and the particles will collect around the flaw if there is a fracture or porosity, allowing the inspector to see it.

MPI works well to detect cracks in ferrous castings, such as steel or iron components. The substance must be magnetic for this procedure to work, yet it is dependable and fast.

| Method | What It Detects | Pros | Cons |

| Visual Checks | Surface blisters, pits, and visible pores | Fast, low-cost, no equipment needed | Only detects surface porosity, misses internal defects |

| X-ray & Radiography | Internal voids, shrinkage cavities, hidden casting porosity | Very accurate, shows defects inside the casting | Expensive, requires safety precautions, and slower |

| Ultrasonic Testing | Internal pores and cracks | Portable, safe, and effective for deeper flaws | Needs skilled operators, may miss very tiny pores |

| Dye Penetrant |

Testing (DPT) Surface cracks, fine surface porosity |

Simple, highlights small surface defects, inexpensive | Only works on non-porous metals; surface prep needed |

| Magnetic Particle |

Inspection (MPI) Surface and near-surface cracks, porosity in ferromagnetic metals |

Can detect tiny cracks near the surface, quick for batches | Only works on ferromagnetic metals, limited to shallow defects |

In order to detect hidden porosity, automotive and aerospace components frequently utilize X-ray or ultrasonic testing. DPT, or MPI, simpler components could use optical inspections for surface-level flaws. Selecting the appropriate approach guarantees early fault detection, which reduces time, expense, and rework.

Fighting Back: Proven Ways to Prevent Die Casting Porosity

A combination of appropriate methods and careful attention to detail throughout the casting process is needed to prevent zero porosity casting:

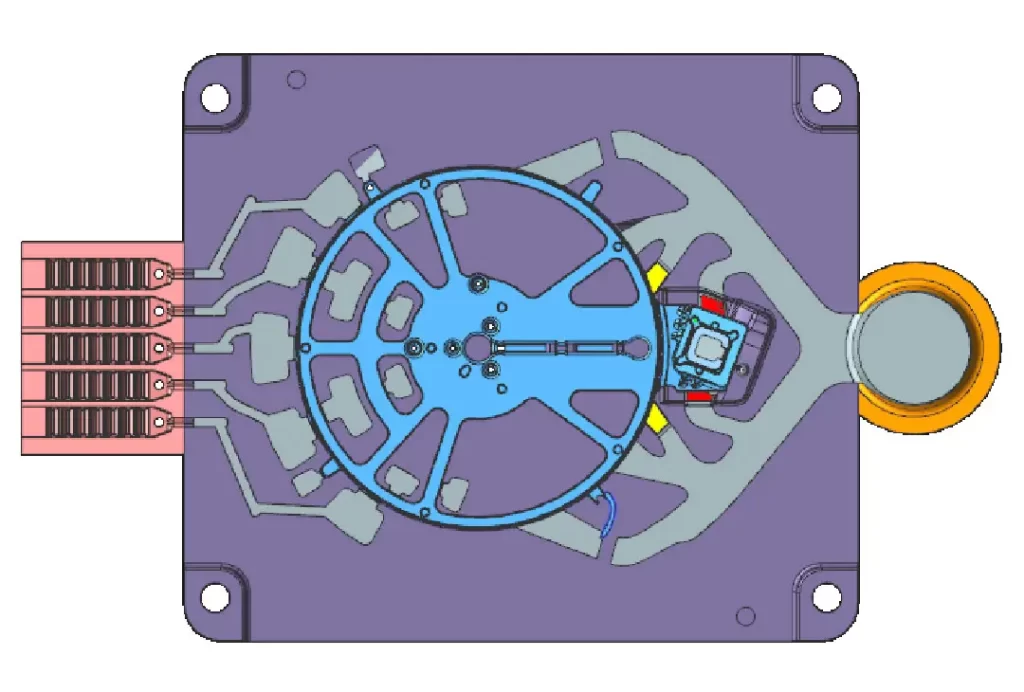

- Optimize Mold Design: Make sure there is enough venting to let gases out. Reduce the possibility of shrinkage porosity and shrinkage cavities in castings by designing the mold to encourage uniform cooling and solidification. To manage the solidification process, strategically use risers or chillers. Low-pressure die casting is used by some industries to fill molds with less turbulence, which lowers the possibility of trapped gas and surface porosity.

Massive Venting Technique

- Control Pouring Temperature: To guarantee a smooth flow and appropriate mold filling, keep the molten metal at the ideal temperature. Steer clear of overheating, which raises the possibility of gas absorption. However, extremely accurate cooling is necessary for processes like high pressure die casting in order to prevent shrinkage porosity and guarantee constant part strength.

- Use High-Quality Materials: To reduce the amount of impurities that might cause gas production, use high-purity metals and alloys. Keep mold-related things clean and dry.

- Degassing: Before the casting process, degassing methods to extract dissolved gases from the molten metal, such as vacuum degassing or the use of degassing tablets, must be utilized.

- Adequate Mold Coatings: Use mold coatings that enhance the casting’s surface polish and lessen the possibility of gas development.

- Frequent Testing and Inspection: To identify and resolve porosity problems early, do routine testing on molds, materials, and completed castings. To find interior porosity without causing damage to the casting, use non-destructive testing (NDT) techniques like X-ray or ultrasonic testing.

Real-World Example: When Porosity Costs Big

Porosity seems like a minor flaw, but in fact, it can result in catastrophic failures and enormous losses. One notable example from the automotive sector is the development of shrinkage porosity in engine blocks made by high pressure die casting. Coolant began to seep into oil passageways during use. These gaps were invisible initially. Resultantly, costly recalls, warranty claims, and reputational harm amount to millions of dollars.

Porosity leads to serious consequences in aerospace. For instance, gas porosity in turbine blades is a problem for aircraft manufacturers. Low pressure die casting was used to manage filling and minimize turbulence in these parts. Hence, irregular degassing resulted in micro-porosity. Whole batches have to be destroyed since even small holes might impair high-performance jet engines.

These incidents demonstrate that porosity is a business risk rather than merely a “casting defect”. Because of this, a lot of manufacturers now examine options like die casting vs injection molding based on the needs of the item or even machining vs casting for important applications. The success of a product depends on selecting the appropriate procedure and making sure that robust porosity prevention measures are in place.

Final Thoughts: Casting Without the Holes

Porosity in die casting is a major problem because of its impact on component quality. The main causes of porosity in die castings are asymmetrical shrinkage or trapped gases creating pores.

Regardless of the alloy, such as steel, aluminum, or another, managing porosity is crucial to creating reliable, long-lasting castings. Strict process control is necessary for high-quality parts in order to reduce faults and guarantee a long service life.

In order to reduce errors and provide dependable outcomes, many businesses turn to reputable suppliers like casting services, which combine technical expertise with state-of-the-art procedures. After all, the ultimate objective is to create cast parts that are robust, free of flaws, and long-lasting.

Visit to learn more about casting methods and to view our selection of die casting services! Contact ProleanTech today.

FAQs

Q1. What is porosity in casting?

Porosity in casting is known as the formation of pores, holes, or cavities on the surface or within a metal casting due to gas trapped or shrinkage.

Q2. Why is porosity a problem in metal casting?

Porosity can cause fractures, leaks, or even total failure by weakening cast components and decreasing reliability.

Q3. What causes porosity in metal?

Trapped gases, shrinkage during solidification, insufficient degassing, and improper mold design are the common causes of porosity.

Q4. How can porosity in casting be detected?

Porosity of the parts can be detected by using methods such as ultrasonic testing, X-ray, and radiology before use.

Q5. How do you prevent porosity in casting?

Vacuum degassing, appropriate mold coatings, ideal cooling management, and cutting-edge processes likelow-pressuree die casting are examples of prevention strategies.

0 Comments