7075 billet aluminum vs 4140 steel

7075 billet aluminum and 4140 steel are different materials with distinct properties, capabilities, and applications. While 7075 billet aluminum is strong, lightweight, and fatigue-resistant, 4140 steel is tough but heavier.

Due to these and other differences, the materials are used differently. 7075 billet aluminum is renowned for its perfect performance in automotive, aerospace, and other areas where high strength and superior weight savings are necessary.

On its part 4140 steel is preferred in heavier-duty applications such as shafts and gears where wear resistance and hardness are more preferred.

While both metals can be CNC-machined, less tool wear and faster machining is witnessed with 7075 material. Machinists require adjustments such as tougher tooling and slower cutting speeds to achieve good machining results with 4140 steel.

Despite these disparities, choosing which one to use between 7075 billet aluminum vs 4140 steel can still be confusing because they both have their strengths. Don’t worry, the CNC Machining Services at ProleanTech can guide and produce quality parts from both metals.

In this guide, we present an indepth comparison that informs our CNC machining services where the two metals are involved. Read on for insights as you choose the better of the two for your project.

What is 7075 Billet Aluminum?

7075 billet aluminum is a popular alloy containing primarily zinc as the alloying element. It is a very strong metal that finds use where strength is a major requirement. The high strength aluminum alloy is also notable for its high strength-to-weight ratio.

The “billet” in the name refers to the shape or form of the material, which is typically a cylindrical or rectangular block. This block is unfinished and ready for further processing.

Aluminum billets

7075 billet aluminum is extensively used for gears, shafts, and structures. It is a common material in automotive and aerospace applications.

The Mechanical Properties Of 7075 Aluminum

This aluminum alloy has suitable mechanical properties for the applications mentioned above. A most important one is tensile strength that can reach up to 572 MPa. Its yield strength is between 455 and 465 MPa, with the exact figure dependent on the exact temper.

Below is a table of the main mechanical and physical properties of 7075 aluminum:

| Material property/characteristic | 7075 aluminum |

| Density | 2.81 g/cm3 |

| Tensile strength | 572 MPa |

| Yield strength | 465 MPa |

| Electrical Resistivity | 5.15e-006 ohm-cm |

| Modulus of Elasticity | 72 GPa |

| Thermal Conductivity | 130 W/m-K |

| Thermal Expansion | 173 W/m-K |

| Machinability | Fair |

| Weldability | Poor |

The Chemical Properties Of 7075 Aluminum

The chemical properties of 7075 aluminum are the epitome of the strength and resilience associated with the material. The main alloying element, zinc, is between 5.10% and 6.10% of the metal’s weight. Other elements of the alloy include magnesium, chromium, and copper, as captured in the table below.

| Element | Percentage weight in 7075 aluminum |

| Silicon | – |

| Iron | – |

| Copper | 1.2 – 2% |

| Manganese | – |

| Chromium | 0.18 – 0.28% |

| Magnesium | 2.1 – 2.9% |

| Zinc | 5.1 – 6.1% |

| Tin | 0.2% |

| Aluminum | Balance |

What Are The Advantages Of 7075 Aluminum?

A renowned performer where strength is key, 7075 aluminum has several key advantages including strength-to-weight ratio, good machinability, and wear resistance.

Here are some advantages of 7075 billet aluminum to consider:

- Excellent strength-to-weight ratio

- Visually appealing when finished expertly – no need for painting

- Easy to machine

- High fatigue strength

7075 billet aluminum visual appeal

What Are The Disadvantages Of 7075 Aluminum?

Despite its high strength-to-weight ratio and other attractive properties, 7075 billet aluminum has some shortcomings as listed below.

- Relatively low corrosion resistance

- Poor weldability

- High cost

Related: 6061 vs. 7075

Try Prolean Now!

What is 4140 Steel?

4140 steel round bars

4140 steel is a strong, tough, wear-resistant, and dynamic low-alloy steel widely used in the manufacture of shafts, gears, and other heavy-duty parts. Its high versatility is evident in the many parts it is used to produce at ProleanTech.

It is common in various critical industrial components such as machinery parts, crankshafts, and heavy-duty screws. Such applications suggest a material that is reliably strong and hard.

4140 steel crankshaft

4140 is easy to machine and treat to suit the different applications. While it may appear a bit costly, the alloying element and the resulting superior performance justify this.

The Chemical Properties Of 4140 Steel

The chemical properties of 4140 steel are central to the characteristics of this metal. As indicated in the table of primary elements of the alloy below, the main alloying element is chromium.

| Element | Percentage (maximum) in 4140 steel |

| Carbon | 0.43 |

| Chromium | 1.10 |

| Molybdenum | 0.25 |

| Manganese | 1.00 |

| Silicon | 0.35 |

| Phosphorus | 0.035 |

| Sulfur | 0.035 |

The Mechanical Properties Of 4140 Steel

The excellent mechanical properties of this steel are the reason you find it in numerous steel CNC machining applications.

Find in the table some important properties and characteristics, which include high tensile strength, superior hardness, good machinability, corrosion resistance, and density of 4140.

| Material property/characteristic | Value or level in 4140 Steel |

|---|---|

| Density | 7.85 g/cm³ |

| Tensile strength | 860 MPa |

| Yield strength | 415 MPa (Annealed) |

| Electrical Resistivity | 0.49 µΩ·m |

| Modulus of Elasticity | 190 to 210 GPa |

| Thermal Conductivity | 42.6 W/m·K |

| Thermal Expansion | 12.3 µm/m·K |

| Machinability | Good |

| Weldability | Good |

| Corrosion resistance | Requires treatment/coating |

What are the advantages of 4140 steel?

4140 steel is a dependable material for applications where durability and wear resistance are essential. Its notable advantages are:

- Good ductility, thus suitable for complex shapes

- Can be toughened through heat treatment

- Excellent wear resistance

A complex 4140 steel part

What Are The Disadvantages Of 4140 Steel?

While 4140 steel is popular for its toughness and strength, it also has some drawbacks, especially when elements such as weight and cost-efficiency are considered. Identifying these trade-offs is critical when alternatives such as the lighter 7075 billet aluminum are in the picture.

Here are the drawbacks of 4140 steel:

- Poor corrosion resistance

- Relatively more expensive, especially compared to carbon steels

4140 steel corrosion problem

Related: 4140 vs 4340, 4130 vs 4140, 1018 vs. 4140

Comparison Of 7075 Billet Aluminum vs 4140 Steel

Choosing between two quality metals like 7075 material and 4140 steel is all about balancing key properties such as strength, wear resistance, machinability, and cost. For each property, one of the options can have a notable advantage over the other one.

The innate differences can show even in the CNC machining. This process has its requirements, as the CNC Machining Complete Guide With Process, Benefits, & Applications shows.

In the following section, we’ll compare the metals considering important properties.

7075 Billet Aluminum vs 4140 Steel: Chemical Properties

The chemical properties or compositions of both metals vary, as their respective tables of components showed. Indeed, this is the main notable difference between them.

7075 Billet Aluminum vs 4140 Steel: Mechanical Properties

Also different are the mechanical properties of 7075 aluminum and 4140 steel. The variations in hardness, strength, weldability, and machinability are the reasons even their applications are different.

- Hardness

- Strength

- Weldability

- Machinability

7075 Billet Aluminum vs 4140 Steel: Physical Properties

Both alloys may be strong, but they have different physical properties. For instance, 4140 steel is approximately three times denser than 7075 billet aluminum. The aluminum alloy also has higher thermal conductivity and electrical conductivity.

However, the steel alloy melts at a much higher temperature.

7075 Billet Aluminum vs 4140 Steel: Industrial Applications

Both 7075 aluminum and 4140 steel are processed and used in various industrial applications. However, the properties we have already discussed determine where exactly the CNC machined metals can be used.

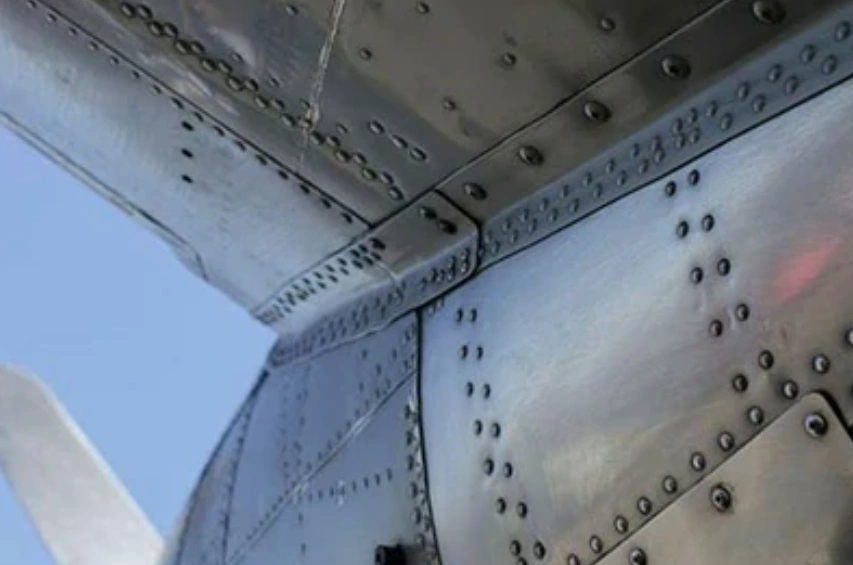

While 7075 billet aluminum is mostly used in aerospace and other industries where weight savings are mostly valued, 4140 steel is popular in structural, machinery, and tooling applications for its fatigue resistance and toughness.

7075 billet aluminum for aircraft

7075 Billet Aluminum vs 4140 Steel : Processing Technologies

4140 steel heat treatment

Considering the different mechanical and physical properties, the metals support precision machinery, but with different approaches. CNC machining services, heat treatment, and forging apply for both.

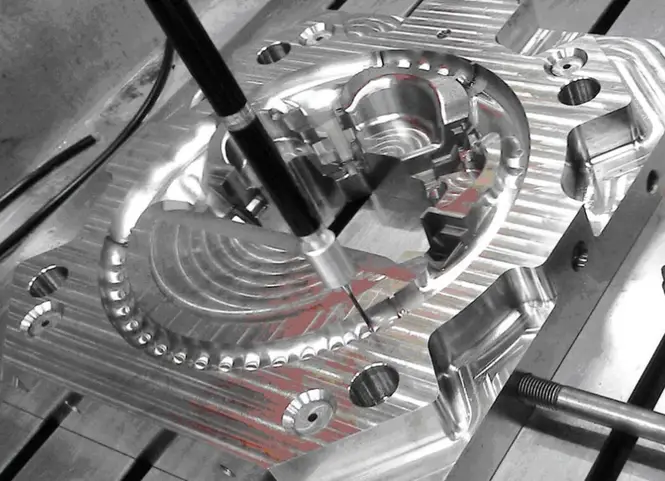

CNC machined 7075 billet aluminum

Industrial players can therefore use parts from the alloys, but should consider the specific manufacturing requirements. For instance, the harder 4140 steel causes more tool wear and may require more post-machining processing for a smooth surface.

7075 Billet Aluminum vs 4140 Steel : Cost

Generally, 4140 steel is more cost-effective to produce because of steel’s more robust supply chain and availability. 7075 billet aluminum is more expensive because of its rarer elements.

However, there are many intricacies surrounding the overall cost considerations in any particular project, which can lean the preference to either metal.

So, we would rather you get in contact with ProleanTech Experts to invest your budget at right place.

Summary Table Of 7075 Billet Aluminum vs 4140 Steel Comparison

Here is a table that summarizes key properties showing the differences between 7075 billet aluminum and 4140 steel:

| Property | 7075 aluminum | 4140 steel |

| Density | 2.81 g/cm3 | 7.85 g/cm³ (higher) |

| Tensile strength | 572 MPa | 655 – 950 MPa |

| Corrosion resistance | Good | Requires a coating |

| Machinability | Fair | Easier |

| Weldability | Poor | Easier |

| Toughness | Lower toughness | Superior toughness |

| Electrical Resistivity | 5.15e-006 ohm-cm | 2.2e-005 ohm-cm |

| Modulus of Elasticity | 72 GPa | 190 to 210 GPa |

| Brinell Hardness | 150 HB | 197 to 237 HBW |

| Initial cost | High | Lower |

Read more: 6061-T6 vs T651

Try Prolean Now!

How To Choose Between 7075 Aluminum And 4140 Steel

Both 7075 material and 4140 steel are tough and strong, but their innate properties differ. Therefore, you must align your project with the most suitable metal for the best performance.

Some expert tips to apply as you consider either of these options are:

- Start with the chemical composition of the metals

- Analyse the mechanical and physical properties

- Consider the machinability of the alloys

- Determine the heat treatment requirements of the metals

- Do a cost comparison of 7075 aluminum vs 4140 steel

Conclusion

7075 billet aluminum and 4140 steel have characteristics suitable for various industries. We have noted how the materials can be CNC-machined to precise parts to meet demanding industrial requirements.

Understanding the specific characteristics and applications, alongside the potential shortcomings helps make an informed decision about using 7075 billet aluminum and 4140 steel.

We are here to offer professional guidance, which is backed by extensive experience processing many alloys. Call us and ask anything about 7075 billet aluminum vs 4140 steel. You can also get your order quotation from ProleanTech for any of these alloys and we will respond promptly.

FAQs

Is 7075 aluminum as strong as steel?

Generally, 7075 aluminum is not as strong as steel. It only approaches the strength of mild steel.

Is billet aluminum stronger than steel?

No, 7075 aluminum is not stronger than steel. It only approaches the strength of mild steel.

What is so special about billet aluminum?

Billet aluminum is highly regarded for its uniform grain structure, excellent strength-to-weight ratio, and good machinability.

What steel is stronger than 4140?

A high-strength alloy steel like 4340 and tool steels like AISI D2 and H13 are stronger than 4140 steel.

Is 4140 steel good for gun barrels?

Yes, the high toughness and strength of 4140 steel is preferred for gun barrels.

0 Comments