Vehicle design

Before its launch, a car would have undergone numerous stages from design to manufacture. The vehicle design step is easily the most intricate and involving one. It has to be flawless because getting it wrong at this stage can have very costly ramifications.

Vehicle design entails the formation of the functional and aesthetics elements of the vehicle. It is a core part of the overall vehicle development process. Ideation, sketching, 3D modeling, and prototyping are all part of the automobile designing process.

Bringing all together can be chaotic and unyielding without compliance to design principles ranging from surface curvature to wheel function, and curved shape to packaging.

And when the time for rapid prototyping, mold-making, and custom manufacturing comes, there is no better solution than CNC machining services by ProleanTech. The flexibility, speed, and precision of our services is unmatched and valuable for your next vehicle design project.

Let us unpack what vehicle design is all about.

What Is The Meaning Of Vehicle Design?

Vehicle design is a multidisciplinary process encompassing accoustics, aesthetics, durability, safety, sustainability, aerodynamics, and other elements. It is a complex undertaking that can involve even many engineers spread across several world regions.

Many people tend to confuse vehicle design and vehicle manufacture, which are totally different concepts. Design precedes manufacturing, providing the guiding elements to be followed for an optimized product.

Vehicle design approval is a strenuous exercise that has to pass through many stages. Revisions are inevitable to ensure the interior and exterior designs reflect the needs of the potential buyer. They must also compete with other brands by incorporating trendy features and technological solutions.

This speaks of the many core objects of every vehicle design. Some of the other factors it must address are performance and energy efficiency.

It doesnt then surprise that this process involves many disciplines like mechanical engineering, industrial design, and electronic engineering.

Given this process is complicated and involves many parties, tools come in handy to streamline things and save costs. CFD for simulations and CAD for design are just examples of tools of trade for vehicle designers.

Try Prolean Now!

The Main Principles of Vehicle Design

Every vehicle design should comply with several rules or principles to ensure optimum safety, efficiency, and functionality of the final product. Here we will address how do you design a car using the principles, which include surface curvature, shoulder, plan view curvature, and packaging.

Prototyping and custom machining related to the car design must be in line with these principles, particularly if these services are for supporting the manufacture of vehicle components.

Here are the most prominent vehicle design principles:

-

Surface Curvature

The appearance of the human body does not lie about the health of the person. The same applies to cars, where curves are an indication of good form. Every part or feature of a car should be curved to support motion.

It wasn’t like that initially. The 80’s were dominated by boxy car designs, but that has changed dramatically since the 90’s.

Car design, 80s vs 90s

The introduction of curves was largely informed by design requirements across the world, mostly for enhanced aerodynamics.

Every modern car on the road has characteristic curvatures. Creating curved designs is much easier. Look closely, even cars that you would think have curved designs, are curvy in a real sense. A good example is the Scion xB shown below.

The 2008 Scion xB

-

The Shoulder

In vehicle design, the term catwalk or shoulder refers to the surface or line immediately below the side windows of the car. The design principle for cars is to have this feature as horizontal as possible, but can run slightly upwards at the rear of the car.

-

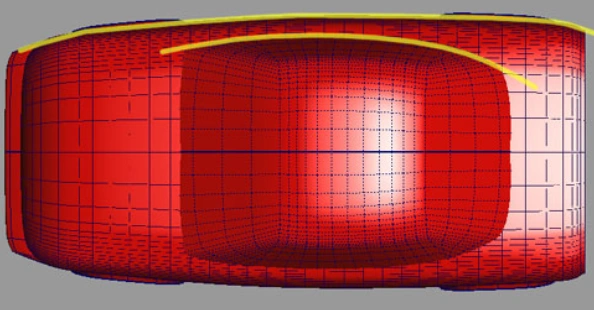

Plan View Curvature

The plan view too has a standard appearance or curvature for all vehicles. While styling plays a big part nowadays, the fundamental function of this is improved aerodynamics.

Plan curvature of a car

The curvature is mostly prominent in the top half of the car, that is, the area covered by the windshield and windows. There will often be a taper of these curves at the rear of the vehicle.

As for the windshield, manufacturers have to comply with the recommended angle to the horizontal (at least 30 degrees).

-

The Wedge And Jellybean

The wedge concept of vehicle design suggests that a car’s cross section should be knife blade-shaped. This design standard had one major motivation – to improve aerodynamics that reduce wind resistance.

The wedge concept was extremely popular in the 1980s, but it seemed to fade away towards the end of that decade.

The wedge design

In came the jelly bean vehicle design, which simply means the vehicle’s cross section looks like a jelly bean.

Jelly bean design

Modern designs are mostly an adaptation of the two, as can be seen in the Kia EV6 and BMW i4.

-

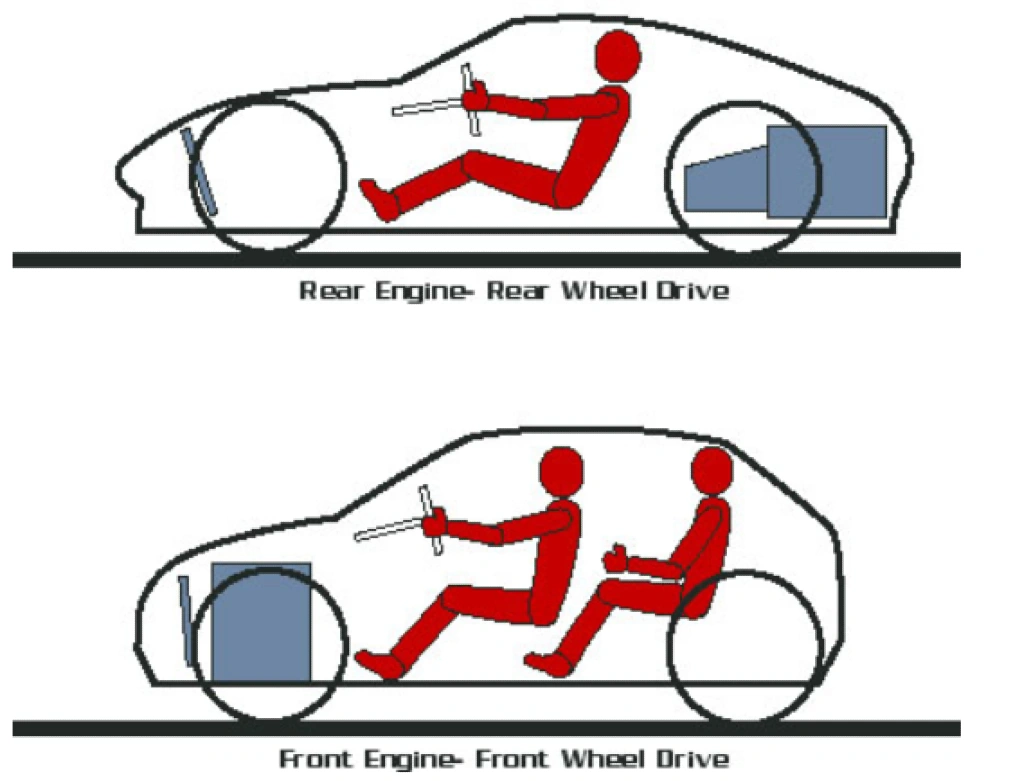

Packaging – Components Within Specified Dimensions

Packaging as a car design restriction means that all components must fit within defined dimensions. The designer must carefully consider all critical components, starting with the occupants and engine.

Packaging principles

The integration of these components is dictated by many things, safety being one of them. This makes vehicles some of the most complicated products to package, and monumental tasks for most manufacturers, especially when seeking to introduce a new model.

-

Wheels

Wheels are also major considerations on how to design a vehicle because of their undisputed effect on safety, comfort, and functionality. Apart from their size, their unsprung weight is crucial for any designer.

Try Prolean Now!

How Do You Design A vehicle?The Steps Followed

As there are vehicle design principles, there are standard design steps to follow. The design process starts with a sketch or drawing of the vehicle. Other considerations that follow are packaging, 3D modelling, clay modeling, material selection, and so on.

It is important to note that this process normally undergoes a lot of feedback mechanisms, so the steps can be repeated multiple times.

Here are the basic vehicle design steps in more detail:

Market Research

Before putting pen to paper to generate the initial sketches or drawings of the car, the manufacturer does a lot of expensive marketing for the new car. At this stage, numerous questions arise and should be answered.

Will people find this product new and exciting? What is the selling point? Such questions must be answered before the next step.

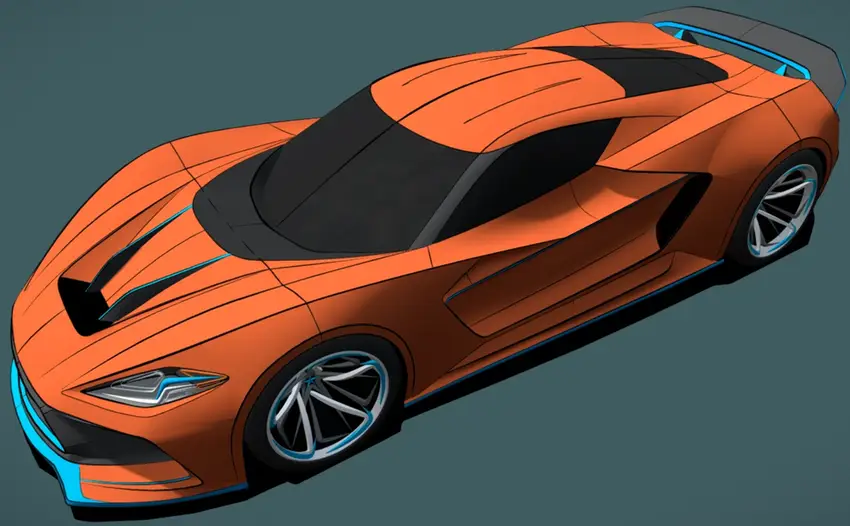

Sketches And Drawings

Artists come up with all sorts of ideas and put them to paper. The ideas can be in their hundreds. In the end, this crosspollination of ideas can generate something really captivating and unique, which paves way for the next step.

A vehicle sketch

The Modelling Step

The modelling stage today entails both conventional handcrafting and modern digital methods. As much as technology has found its way into car design modelling, it cannot beat the intent and emotion that comes with a human touch. So, most companies will seek to blend the two.

A 3D model of a car

Engineering Refinement And Prototyping

With the digital model ready, the vehicle design process proceeds to engineering output and then prototyping. Engineers have to ensure the feasibility or practicality of the envisaged vehicle.

They thoroughly check the aerodynamics, safety, ergonomics, and many other aspects of the car. The vehicle’s prototype may also be generated at this stage.

Tests

Every new vehicle undergoes many tests at the prototype stage. Popular tests are performed to ensure complete compliance – braking tests, crash tests, climbing tests, and so forth.

Car crash testing

Manufacturing

After these design processes are approved, the manufacturer can go to full-scale manufacturing of the vehicle. Different parts suppliers are engaged to contribute to the process. This includes Auto Parts Manufacturing: Solutions for Early Cars, if the concept car design has an older era touch.

The process often starts with small batch manufacturing of vehicles to ensure everything is working fine. The manufacturing then continues, and the finished vehicles are delivered to the respective clients, locally or overseas.

A car factory

Tips For Quality and Cost-effective Vehicle Design Results

As already seen in the text, conceptual car design is a demanding process that can be lengthy and expensive. The goal of every manufacturer is to cut costs, so having an idea of how to optimize the process is necessary.

Automating the process, enhancing inspections, proper identification of the customer, and frequent design tests are some approaches that always work for manufacturers. Here are more details about these secrets to successful automobile designing.

Automating The Conceptual Car Design Process

Automation is an excellent way to minimize human errors in the process and speed up everything. It ensures precision of CNC machining and product assembly, thereby providing reliable results.

There are different types of CNC machines applicable for this process.

Proper Material Selection

This is another critical point because materials can affect the cost of the entire process. Explore the materials that offer the best balance of aesthetics, functionality, costs, and durability.

Identifying The Customer

Knowing the target customers and what they are saying can help make the best vehicle design. Always keep the users in mind when designing for the best car design ideas.

Enhanced Process Inspections

Design flaws are expected at different stages, but they can be minimized with enhanced inspections at every stage of the auto concept design. This is easier and less costlier than product recalls that occur when a lot has already been done.

Vehicle inspection

Cost-effective Prototyping

Prototyping costs can be prohibitive, but this is an area where a manufacturer can reduce costs. For instance, there is no need of producing physical prototypes if you have a high-quality computer-aided design (CAD) tool.

Even when physical prototypes must be used, there are ways to minimize costs. For instance, 3-D printing is one cost-effective method to use.

There are many more tools for quality and cost-effective product design in automotive industry. Consult the able team at ProleanTech for more ideas.

Another interesting read: Optimize Your Car’s Fuel System with Expert-Engineered Parts

Top Vehicle Design Prototypes And Parts By ProleanTech

CNC machining for automotive design must consider the principles highlighted in this article. This applies for prototyping, parts, and even full-scale production. The parts and components of a vehicle must align with the design principles, especially curvature, packaging, and wedge.

For instance, the CNC manufacturing service must ensure that parts for the engine, suspension system, car interiors, and transmission system comply with the packaging requirements.

Find more about car systems covered in these articles:

Optimize Your Car’s Fuel System with Expert-Engineered Parts,

Explore How a Flywheel Powers Your Car Smoothly

https://proleantech.com/automotive-steering-system/

ProleanTech is careful to adhere to the specific requirements when designing and CNC machining parts for parts where any of these principles applies. Our team is not only highly experienced in CNC machining services but also thoroughly understands vehicle design processes.

By ensuring that our prototypes and parts always align to vehicle design standards, we ensure safety on the road and overall integrity of vehicles, which gives value for money.

You can reach us any time for a prompt custom pricing estimate for CNC machined prototypes and parts. Read also our CNC Machining Complete Guide for more about our offerings.

In Summary

Designing a vehicle is a multifaceted process combining consumer car design ideas, engineering requirements, and prevailing technological advances. The car manufacturing steps must not only capture the emotions of the user but also be visually appealing and functional.

The best car parts and prototypes manufacturers know this and adhere to vehicle design principles from start to finish.

ProleanTech continually delivers market and user centric prototypes and CNC machining solutions at competitive prices. Get in contact with our experts for more details!

FAQs

How long is the design process for a car?

It can take a long time, even a couple of years, to design a car.

What are the important factors in car design?

The important factors in car design are safety, ergonomics, fuel efficiency, and market requirements. The aesthetics and feasibility of the car are also critical factors.

What does CCC mean in automobiles?

CCC in automobiles is a quality mark that means “China Compulsory Certification” in full. It is required for all items sold in the country.

How many people does it take to design a car?

Designing a car involves multiple disciplines, from mechanical engineering to design, so the number of people involved can be significant. However, the exact number depends on the scale of the design project.

0 Comments