Two Shot Injection Molding Vs Overmolding

If you’re working with plastic parts, custom injection molding is likely on your radar. It’s quick and precise and delivers consistent quality products across industries. However, not all injection molding methods are the same.

Two prominent types of injection molding techniques you’ll encounter are over-molding and two-shot molding. While these may seem similar at first glance, they are different. Choosing the wrong one can significantly affect your product’s quality, expenses, and part performance.

In this guide, you’ll learn how each process works, where they differ, and when to use one over the other. So, keep on reading.

What Is Two-Shot Injection Molding?

Two Shot Injection Molding

Advanced two-shot molding allows molders to produce one part from different plastic materials during one molding cycle. The industrial sector refers to this technique as dual-shot, multi-shot, and double-injection molding, among other terms used for the same process.

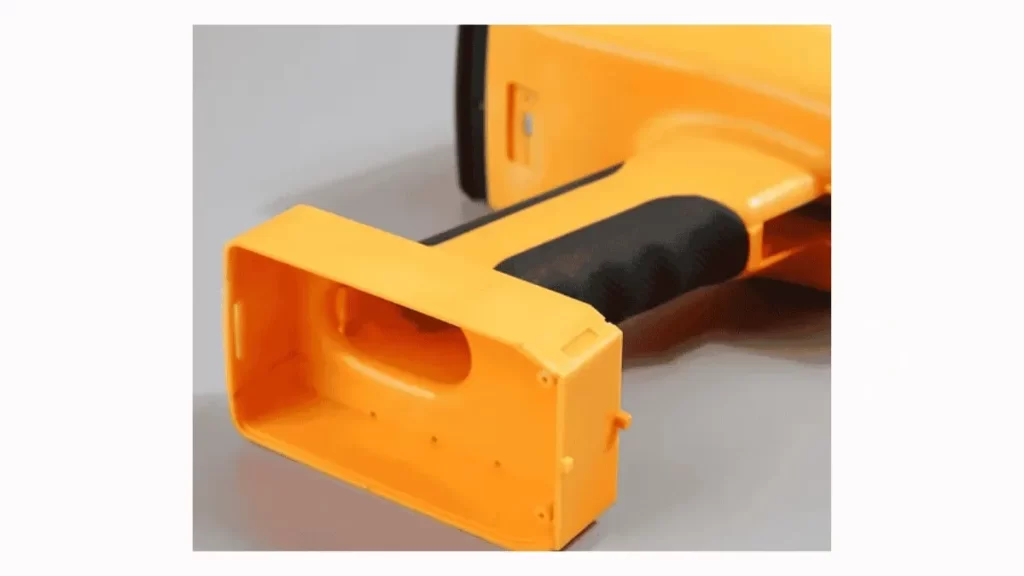

It allows you to manufacture multiple material parts with vibrant colors in a single operational cycle without any additional assembly steps. It is primarily used in producing products that need a soft-touch grip, layered aesthetics, and combined functional capabilities, such as power tool handles, buttons, and medical components.

Two-shot molding is an affordable solution that enhances part strength, reduces labor costs, and improves part finish quality. It also decreases production time and offers precise part consistency during high-volume manufacturing operations.

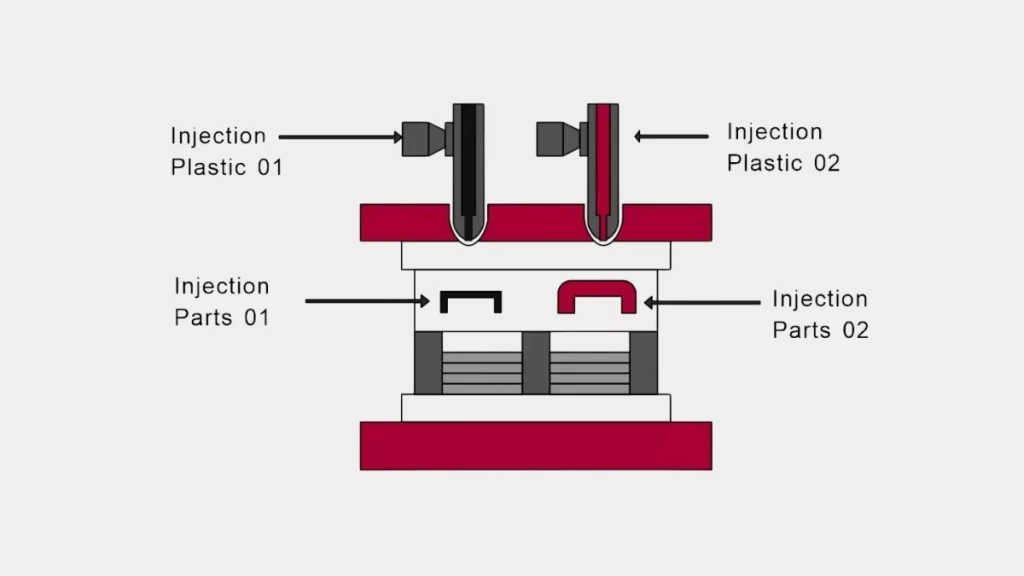

How Two-Shot Injection Molding Works?

Two Shot Injection Molding Process

The first material is injected into the mold, forming the base layer. The base layer is allowed to cool sufficiently before the second material is injected. After setting the mold, the substrate is rotated or moved to an inner cavity of the same machine.

The machine requires a different plastic resin to be injected over or near the current component during this procedure. Chemical methods develop material bonds with the base substrate. As a result, it produces one integrated part from two materials without adhesive processing.

Fastened transfers in high-volume production require the use of rotary platens. Robotic arms and manual part readjustments dominate operations for basic mold layouts and minimal production runs, although they execute procedures at a reduced speed./

Common Applications of Two-Shot Molding

Two Shot Injection Molding In Electronics

Two-shot injection molding is a go-to approach for a single part made from two materials. It is paramount that function and appearance work together. It is specifically beneficial for ergonomic, seamless, and multi-function parts that demand precision.

Here are products where two-shot molding is widely used:

- Smartphone side buttons

- Electric toothbrush handles

- Smartwatch outer casings

- Power tool grips and triggers

- Automotive climate control knobs

- custom game controllers

- Reusable travel mug lids

- Hearing aid enclosures

- VR headset face cushions

- Industrial control panel buttons

- Protective phone case frames

- Waterproof fitness band straps

Try Prolean Now!

Two-Shot Molding: Pros and Cons

The Two-shot molding technique is a wise solution for handling large-scale plastic production operations. It joins two materials during a single cycle, reducing waste, speeding up production, increasing product strength, and eliminating the need for assembly steps.

Two-shot molding works well for power tool grips, sealing gaskets, living hinges, and other components that simultaneously need rigid and flexible properties. Part formation occurs inside a single machine. Therefore, post-processing and extra steps become unnecessary.

Moreover, two-shot molding offers designers increased freedom for their product designs. The same mold allows designers to create intricate part shapes while allowing texture combination and color mixing ability.

The expenses associated with starting two-shot molding are notably high. Because of their complex design, the price surpasses conventional machine equipment. Even so, the initial expense for tooling up mold equipment remains elevated. Despite its initial high equipment costs, the manufacturing process becomes economical for large product runs.

What Is Overmolding?

Overmolding

Overmolding is a versatile approach. However, it requires carefully selecting compatible materials and appropriate designs for successful bonding. This method is not limited to specific materials or designs, making it a dependable choice for various manufacturing needs.

Overmolding provides manufacturers with a cost-saving solution for creating soft-touch grips, layered housings, and multi-material subcomponents. Its affordability for creating product prototypes and quick-run production requirements makes it a secure choice for small-scale manufacturing needs.

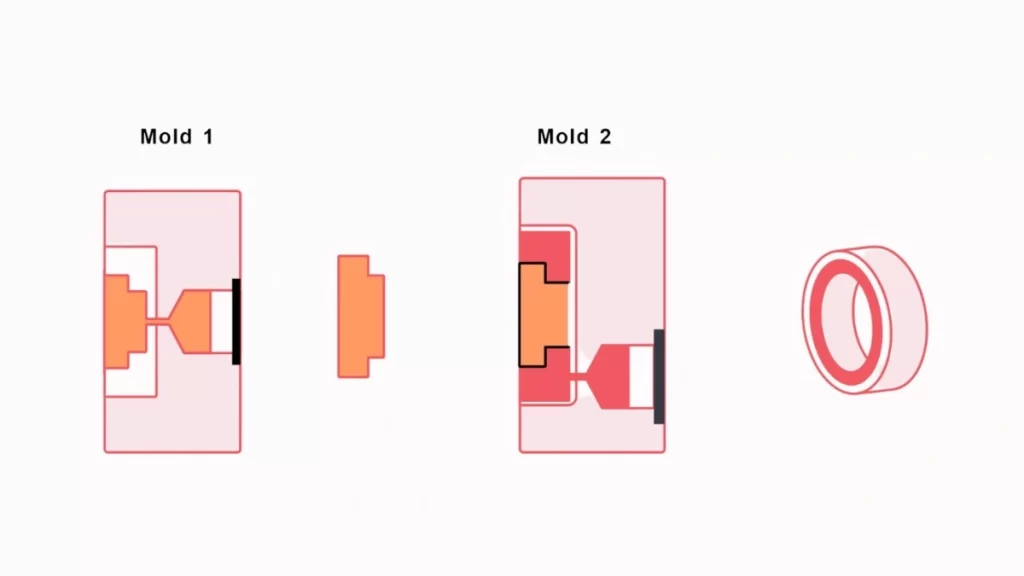

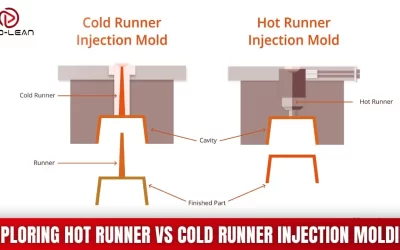

How the Overmolding Process Works?

Overmolding Process

The Overmolding Process starts by creating the substrate from rigid plastic or metal base materials. Once the substrate has cooled, it is moved from its original mold cavity into a separate mold cavity created for the second material.

A molten overmold material is injected to surround the substrate during production. The second material develops a bond to the base substance during the cooling process.

Overmolding creates a single part that contains various material characteristics, including softness, texture, flexibility, and contrasting color.

Most overmolding operations employ two materials, yet specific designs require three or multiple material layers for their implementations. Every participating material needs to have complementary qualities for adequate bonding to occur. Different incompatible resins will lead to bond failures and defects that affect surface quality and may create material distortions.

The process effectively works for unions between different plastics and between plastics and metals. In addition, metal overmolding projects often require surface preparation or mechanical interlocks to ensure strong bonding between plastic and metal.

Common Applications of Overmolding

Overmolding Applications in Automotive Control Systems

- Soft-grip surgical instrument handles

- Rubber-coated hand tools

- Waterproof electronic key fobs

- Shock-resistant phone cases

- Overmolded electrical connectors

- Automotive gear shift knobs

- Sealed industrial control panels

- Fitness tracker wristbands

- Anti-slip kitchen utensil grips

- Medical diagnostic device housings

- Power cable strain reliefs

- Noise-dampening headphone pads

Pros and Cons of Overmolding

Dual Strength Overmolded Product

The process enables the production of high-strength multi-component products through a single production run, eliminating the need for separate part assembly.

It delivers effective solutions for functional and ergonomic elements, mainly during design phases focused on user comfort. The molding process allows you to add soft materials to rigid materials to create a better grip, reduce shock effects, and provide sealing abilities during a single manufacturing step.

This technique is the optimal solution for low to medium production quantities. When you install proper tooling, your standard injection equipment will work for such applications. This method simplifies the overmolding setup yet remains most effective for limited product quantities and runs of various sizes.

Overmolded parts include tool handles, military gear housings, automotive trim, and sealed electronics. They allow product enhancements with better performance and cost less than complex automated systems. Contact us for reliable Overmolding service.

Pros

- It works with standard injection molding machines

- It reduces part count and post-processing steps

- It is ideal for low-volume, multi-material production

- Overmolding adds cushioning, grip, and helps parts perform well in harsh weather

- It is excellent for retrofitting existing components

Cons

- It is less accurate than two-shot molding on tight tolerances

- It takes more time due to the separate mold stages

- Overmolding requires careful resin compatibility matching

- Manual substrate loading increases labor time

- Risk of poor bonding if materials are mismatched

Try Prolean Now!

Similarities Between Two-Shot Injection Molding Vs Overmolding

- The two techniques permit molding multiple materials as one unified part, which benefits operational quality and the aesthetics of the final product.

- Manufacturing techniques improve the final pieces’ grip, flexibility, and durability.

- These simplify the additional assembly work. Different parts get molded into one piece, which undergoes post-production work.

Comparing Two Shot Injection Molding Vs Overmolding

Multiple material manufacturing involves using two-shot molding and overmolding as standard production techniques. These processes have divergent operational methods, although they bring unique advantages to manufacturing. Understanding these distinctions allows you to identify the appropriate molding strategy for your project.

Process and Equipment

As mentioned before, the two-shot injection molding process allows the injection of two substances within the same molding cycle. These are comparatively more expensive. On the other hand, overmolding is simpler. Standard injection molding machines operate this process, making the setup affordable and straightforward.

Bonding Materials

- Materials used in Two-Shot Molding must hold chemical bonding properties. For successful bonding, both materials should match in their properties.

- Overmolding can use mechanical bonding. The process enables a broader range of material selection.

Cost and Production Volume:

Two-shot molding is economical when handling large manufacturing quantities. However, manufacturers should choose over-molding when running production volumes between small and medium levels, such as when producing prototypes.

Material Considerations

Selecting appropriate materials is an essential consideration for both production methods.

The bonding of materials used in two-shot molding should work effectively. They must be chemically compatible and thermally suitable, but not identical.

Overmolding offers more flexibility. The materials can differ. This method works best when combining hard plastic with soft rubber over-molded material.

Production Volumes

Two-shot molding is the optimal mold method for producing high-volume products. It delivers dependable results for creating large numbers of items.

Overmolding works effectively for manufacturing small and medium product quantities. The process becomes more economical for low manufacturing batches.

Choosing Between Two-Shot Injection Molding Vs Overmolding

Two-shot molding is a good choice when you need to produce many parts. However, the initial investment is high because it requires complex equipment and customized tooling. The manufacturing process suits production requirements that involve large quantity output and long-term distribution of start-up costs across multiple components.

Overmolding is the right fit for short production volumes and standard tolerance requirements. It is an excellent solution for users to integrate rubber or other soft materials onto existing components. Standard injection molding machines can perform the process, which helps reduce overall tooling expenses. The method of overmolding should be selected when operating with limited volumes of parts or testing prototypes and refraining from investing in costly equipment.

Get Your Plastic Molded Parts at Prolean Tech

Prolean Tech Injection Molded Service

Understanding the differences between two-shot molding vs overmolding is important, but making the right choice for your project requires expertise. That’s where Prolean Tech comes in.

With years of experience, our team of designers, engineers, and machinists is here to help guide you through every stage of production, from initial concept to final product.

At Prolean Tech, we don’t just help you select the proper molding technique. We collaborate with you from every production stage to ensure the process fits your project’s needs. Whether you’re prototyping or mass-producing parts, our injection molding services are perfect for the automotive and consumer electronics industries.

We deliver fast turnarounds and top-quality products at competitive prices. Upload your CAD files and receive an instant quote to start your next project.

FAQ’s

Q1. What is the difference between two-shot injection molding vs overmolding?

Two-shot molding involves injecting two different materials into the same mold in one cycle. It creates a strong bond between them. Overmolding, on the other hand, uses a base part and adds a second material over it, which may not always require a perfect bond between materials.

Q2. Which molding method is more cost-effective?

Using standard injection molding equipment, overmolding is typically more cost-effective for smaller runs or prototypes. Two-shot molding requires specialized machinery and higher upfront costs, but its speed and efficiency make it more affordable at larger production volumes.

Q3. Can any materials be used in two-shot molding and overmolding?

Not all materials are suitable for these processes. Two-shot molding requires materials that are chemically compatible to develop strong bonding. Overmolding can accommodate more material options, but the materials must adhere well to each other for optimal results.

Q4. Which molding process is better for creating multi-functional parts?

Two-shot molding is ideal for multi-functional parts as it allows for precise control of material combinations and can achieve complex geometries. Overmolding is optimum for adding soft grips and protective coatings. However, it may not offer the same material flexibility and complexity.

Q5. What is the lead time for two-shot injection molding vs overmolding projects?

Due to its complex setup, two-shot molding generally has longer lead times and requires specialized molds. Overmolding usually has faster lead times, especially for smaller projects. It can be done using standard molding machines with simpler tooling.

0 Comments