SLA vs FDM

As a business in manufacturing, medical devices, construction, or any other area requiring rapid prototyping solutions, a possible dilemma is what type of 3D technology to use.

To cut the chase, Fused Deposition Modeling (FDM) and Stereolithography (SLA) are some of the most sought-after 3D printing solutions. Your business needs to properly determine the suitability of FDM vs SLA 3d printing for successful projects.

The SLA printer uses a liquid photopolymer resin as the model material. A UV laser beam cures this material to generate the required geometry or part. The beam repeatedly illuminates the resin until the final product is produced. Printouts from SLA are extremely accurate, and the process works with many materials.

FDM manufacturing, sometimes called Fused Filament Fabrication (FFF), is an additive manufacturing method with a rich history. It is characterized by deposition of layer after layer, each time letting the previous layer cool first.

Many people consider FDM the opposite of CNC machining. Instead of using g-codes to help remove material from a workpiece, this technology uses the approach to add material. Short lead times and affordability are some of the leading advantages of FDM.

ProleanTech-Your custom parts manufacturing partner – handles 3D printing projects with utmost professionalism and engages clients throughout the process. Our machines are the most advanced, and our team the most experienced.

For more on these two processes that rival even the latest 3d printer technology options, we prepared the following analysis of comparing 3d printers using SLA vs FDM technologies.

What is Stereolithography (SLA) In 3D Printing?

SLA 3D printing is a vat photopolymerization-type process that uses light to produce hardened parts from resin. This method is as old as the 1970s, when Dr Hideo Kodama from Japan introduced the layering manufacturing idea.

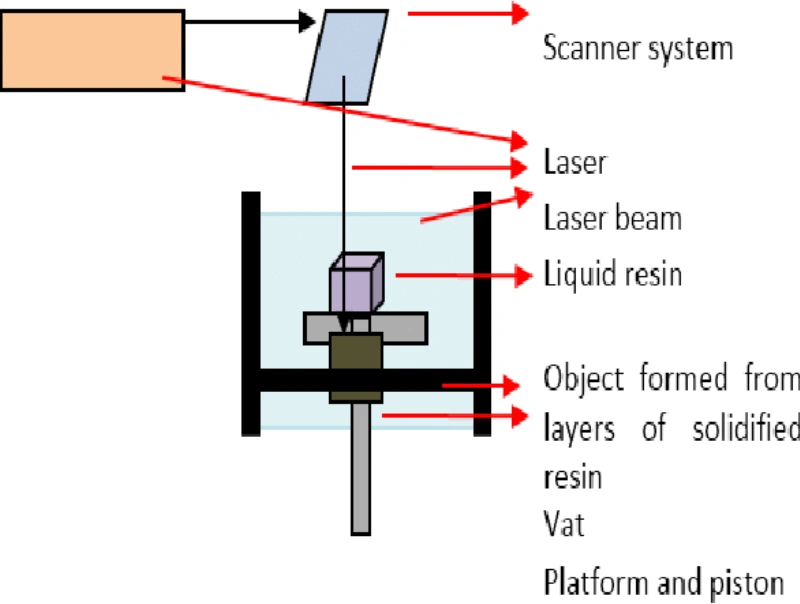

The SLA printing method

As years passed and the process became modernized, the culmination was the emergence of 3D printers in the 2000s. SLA and other additive manufacturing processes became more accessible.

The high-dimensional accuracies, tight tolerances, and smooth surfaces of SLA-produced parts make the technology very popular. The machines are suitable for both prototypes and end-use product manufacturing.

How Does SLA Printing Work? Understanding the SLA Printing Process

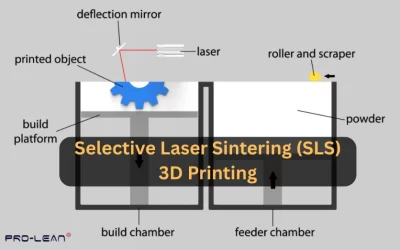

A typical SLA printer comprises a build platform, a resin tank, a powerful UV laser, and a computer–controlled unit for light generation. At the standard of every project, ProleanTech follows the best preparation practice to ensure strict compliance with customer requirements.

We know that even the slightest measurement and surface finish deviations can mean the success or failure of a project.

So, here are the steps of a successful SLA printing process:

First Step: Prepare

Armed with the 3D model of the part, we require a compatible file for it. Common file formats include 3MF and STL. It is important to have the right software because it offers a platform for making any necessary adjustments to the design.

There are many possible adjustments at this stage of the STL 3D printing process – support structure, mesh, alignment, etc.

Second Step: The Printing Stage

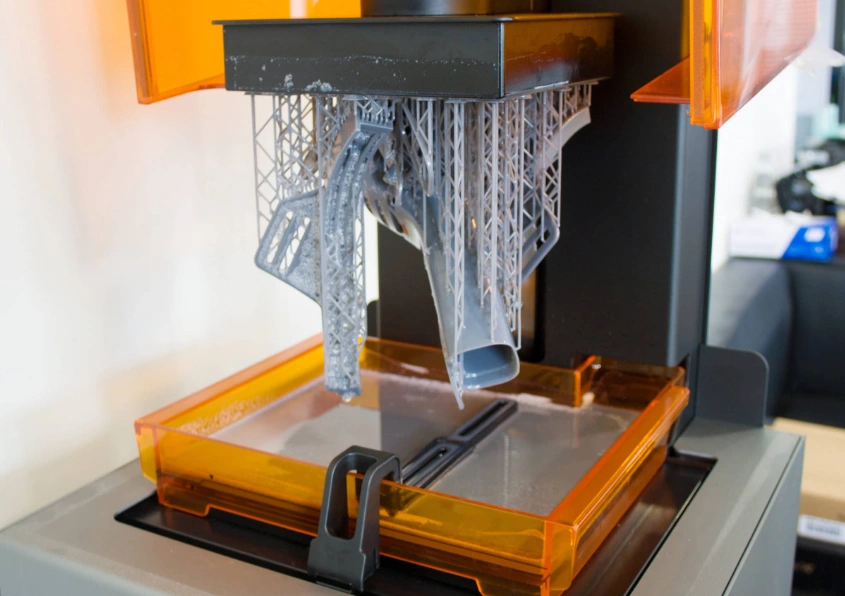

An SLA machine

When everything is set, the SLA printing process can start. Here is an overview of what happens during the printing:

- The lighting system produces uniform illumination

- The illumination attains the recommended intensity of around and iis directed to the curing plane

- The lifting of the build platform is precisely controlled

- A print speed of up to 50mm per hour is maintained, depending on the material and other factors

Third Step: Post-processing

The SLA 3D printed part requires the post-processing and curing steps before it is ready for use. First, the remnant resin is removed by dipping the part in a special bath of ether or isopropyl alcohol (IPA).

Most of the parts will also require curing, whose main function is to enhance the mechanical properties. There are many curing dynamics because specific materials’ desired properties and requirements differ.

As this Guide to 3D Printing with Plastic Materials shows, there are many options, so the manufacturing requirements can differ significantly.

SLA part post-processing

When the support structures are finally removed, the surface of the part is finalized; that’s mostly it. At ProleanTech, we are keen on all these processes, including the final outlook of the 3D printed part.

Try Prolean Now!

Pros And Cons Of SLA To Consider For Parts

Below in a table are the advantages of resin 3d printing technology in relation to SLA vs FDM.

| Pros | Cons |

| Smooth part surfaces | Relatively pricey |

| Print quality and resolution are excellent | The printed parts are relatively weaker |

| Produces intricate parts | Relatively slower printing method |

Applications Of SLA That May Suit Your Requirements

The applications of SLA printers span across many industries, each drawing from the technology’s many pros. Popular applications of the method are healthcare, research & development, and consumer products.

Consult ProleanTech for SLA printing solutions that deliver highly accurate parts for the following areas and more. You can bank on our years of experience of tested quality and professionalism.

Consumer Products

The consumer products industry is wide, so its SLA-based products are bound to be as diverse as you can imagine. They could be electronics, kitchenware, or even miniature toys – the list is endless.

Miniature items

Quality 3D printing solutions from a dependable partner such as ProleanTech mean the services are timely and low-cost, whether for rapid prototyping or market-ready consumer goods.

Like for CNC machining materials, the material variety for consumer products in SLA technology is wide. Some specially designed resins to consider are Somos® WaterClear Ultra 10122, Somos® WaterShed AF, Somos® PerFORM, and Somos ProtoGen 18420.

Healthcare Industry

This industry is equally diverse and a popular user of the SLA 3D printing technology. Some are niche applications while others are common and widespread.

An intriguing and still developing application area is the manufacture of patient models. In a bid to offer the most customized treatments, surgeons are now generating patient-specific models that help in preoperative planning for surgeries.

Other applications in the industry are implants, prosthetics, and dental restorations. Get in contact with our experts team for details on all the possibilities of 3D printing in this vast industry.

Dental application for SLA 3D printing

Research And Development

Research and development firms globally have also widely embraced SLA 3D printing. As technology advances rapidly, the need for research & development testing in manufacturing and other areas cannot be overstated.

An area where SLA is transforming magically is prototype production. Unlike conventional methods, this technique is simple and fast. By shortening and simplifying the production cycle, this 3D printing method makes manufacturing cost-effective.

What is Fused Deposition Modeling (FDM)?

The FDM technique is also relevant and very common in discussions on how 3D printing works and what it’s used for. Its features and how it compares to alternatives such as SLA vs FDM, is important for users looking for 3D printed parts for their operations.

This method is based on the extrusion concept, and uses pellets or filaments of thermoplastics. The nozzle of the setup is heated, so the feedstock melts as it is forced through.

An FDM 3D printer

There is a reason why the FDM method is one of the most popular 3D printing technologies in the market. It is very simple and accessible to many users. You can tell from the numerous FDM printing materials available, including the best PLA materials for 3D printing.

It may surprise many people that FDM came after SLA. Indeed, the patent for FDM came after that of SLA, in the late 1980s. Non-commercial interaction with the technology started after the alternative name, Fused Filament Fabrication (FFF), emerged.

Try Prolean Now!

Details Of The FDM Printing Process

As mentioned, the FDM printing process is characterized by extrusion of the stock material, a perfect distinction from SLA vs FDM. As the thermoplastic material is extruded and layered, it progressively creates a 3-D component.

The method is based on two functions – extrusion/deposition and printhead movement.

The Extrusion And Deposition System Of FDM

This is the system that feeds and deposits the filament. The filament spool is directed to the 3D printer. The filament is heated to enable its extrusion through the nozzle.

The Printhead Motion

The effectiveness of the FDM 3D systems is based not only on the extrusion but also on the movements as the material is deposited. Important components that enable the printer to move include lead screws, stepper motors, and guides.

An FDM 3D printed part

Consider These Pros And Cons Of The FDM Printing Process

Like 3D technology in general as captured in the article “3D Printing vs CNC: Which Should You Choose?”, the FDM method offers several pros and cons. Here are the pros and cons of this popular 3D printing technique:

| Pros | Cons |

| Prototypes are cost effective | Part resolution is lower |

| End-use parts are durable | Layer lines are visible |

| Offers a large selection of colors |

Applications of FDM Printing Relevant For Part Sellers And Users

Like SLA, FDM printing is used in many industries. Experts in diverse fields are now using FDM printing, from 3D Printing In Automotive Parts Manufacturing Industry to applications in the education fraternity. Some of the reasons this technique is easy to adopt are fast prototyping, scalability, cost-effectiveness, and fast turnaround in FDM rapid prototyping.

You can expect ProleanTech to leverage these and many other advantages of the technology for the solutions you are looking for. Ask for a fast & free quote to start the process with the best prototyping and production company.

Common applications of FDM 3D systems are;

-

FDM Rapid Prototyping

This is an expected application considering that the original motivation of 3D printing innovation was the production of manufacturing prototypes. Rapid prototyping is still one of the leading applications of 3D printing.

3D printed prototypes from ProleanTech are ideal for functionality and performance testing. You dont need tooling or design hassles; simply upload your design and collaborate for the other steps to get the best custom printed prototypes.

-

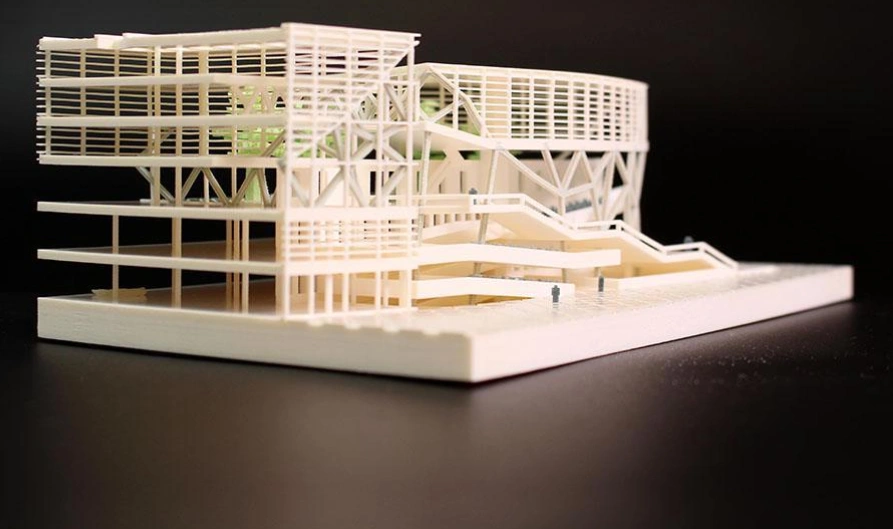

Architecture

The times of using different materials to create architectural models are gone. Using 3D printing in this area is now the norm. Building these models using the technique is cost-effective, fast, and accurate, unlike the older methods.

An architectural model

-

Household Goods

The use of FDM 3D systems extends to household items such as keyholders, mobile phone covers, and shower heads.

A mobile phone case

Which Is Better, SLA Or FDM? The Comparison To Guide For Your Parts

SLA and FDM are both instrumental in many industries, but the beauty is that choosing either for the perfect application helps in optimizing results. For instance, while SLA is renowned for higher resolutions, FDM is ideal for higher volume production.

ProleanTech can help you choose the best method depending on your project requirements. Here are some of the comparisons we consider when choosing between these 3D printing techniques.

How SLA vs FDM Technologies Compare

The two technologies are fundamentally different. The FDM is based on a straightforward extrusion technique. However, SLA is more complex, with its setup consisting of several specialized components.

Nevertheless, each has its place in the industry. Contact our team for the best fdm 3d printer and SLA system services.

Material Versatility

The material range for the SLA method is relatively limited. Taking a material from one machine to another may not work. The color options in this technique are also minimal. The FDM manufacturing technology offers more versatility in colors and filler types.

FDM filament spools

Conclusion

There you have it! Choosing between SLA and FDM 3D printing technologies depends on precision, cost, and production volume. It is a balance that every parts dealer or user needs to consider to get the most from either of these methods.

With ProleanTech as your manufacturing partner, you can be sure all the considerations for SLA printer vs FDM have been addressed. The technology selected is also top-notch, and you will be engaged throughout the manufacturing process.

Talk to us anytime for more on these technologies and our 3D Printing Services in general.

FAQs

What Is An FDM Printer?

An FDM printer is a machine type that generates 3D printed parts by layering from a special filament.

What is SLA printing?

SLA printing is a 3D printing method entailing curing of a special resin using a laser.

What is SLA in 3D printing?

SLA printing is a 3D printing method entailing curing of a special resin using a laser.

Is resin printing stronger than FDM?

No, resin printing is generally more about accuracy than strength, as compared to FDM.

Is FDM stronger than SLS?

No, SLS printing is generally stronger than FDM printing.

Is SLA 3D printing expensive?

Yes, SLA 3D printing is relatively expensive, mostly due to post-processing and the high cost of resin.

Is SLA print strength better than FDM?

No, the FDM print strength is better than SLA

What is a common disadvantage of FDM printing?

A common disadvantage of FDM printing is poor surface finish.

Does SLA use filament?

No. Instead, the technology uses resin, which is cured by a laser.

What is the most accurate 3D printing method?

The most accurate 3D printing method is SLA.

What material is not used in 3D printing?

Examples of materials not commonly used in 3D printing are fabrics and paper.

What is the cheapest FDM material?

PLA (polylactic acid) is an affordable material popular in FDM applications.

0 Comments